Abrasion proof, vortex street strong mixing equipment in grille of spraying ammonia

An ammonia injection grid and anti-wear technology, applied in mechanical equipment, dispersed particle separation, internal combustion piston engines, etc., can solve problems affecting denitrification efficiency, weak disturbance, long mixing distance, etc., to improve denitrification efficiency and reduce wear rate , enhance the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and example.

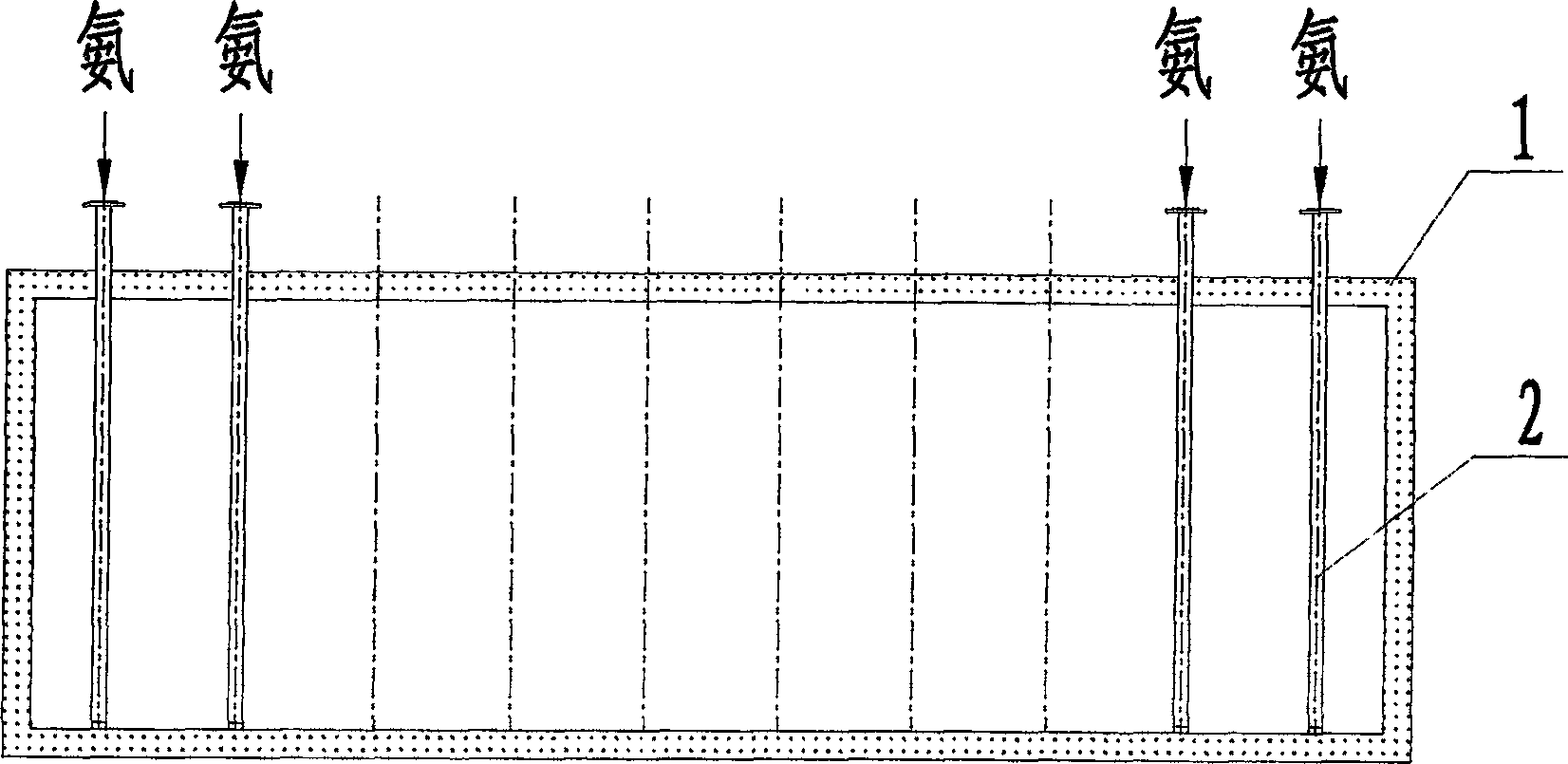

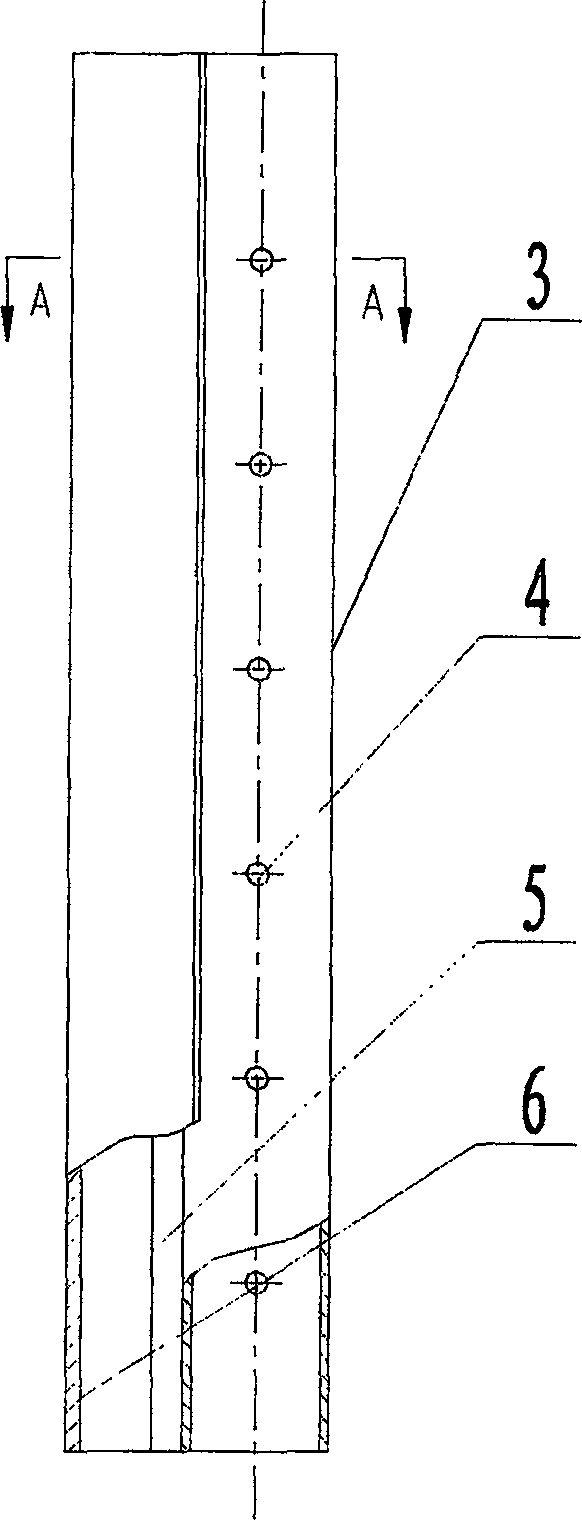

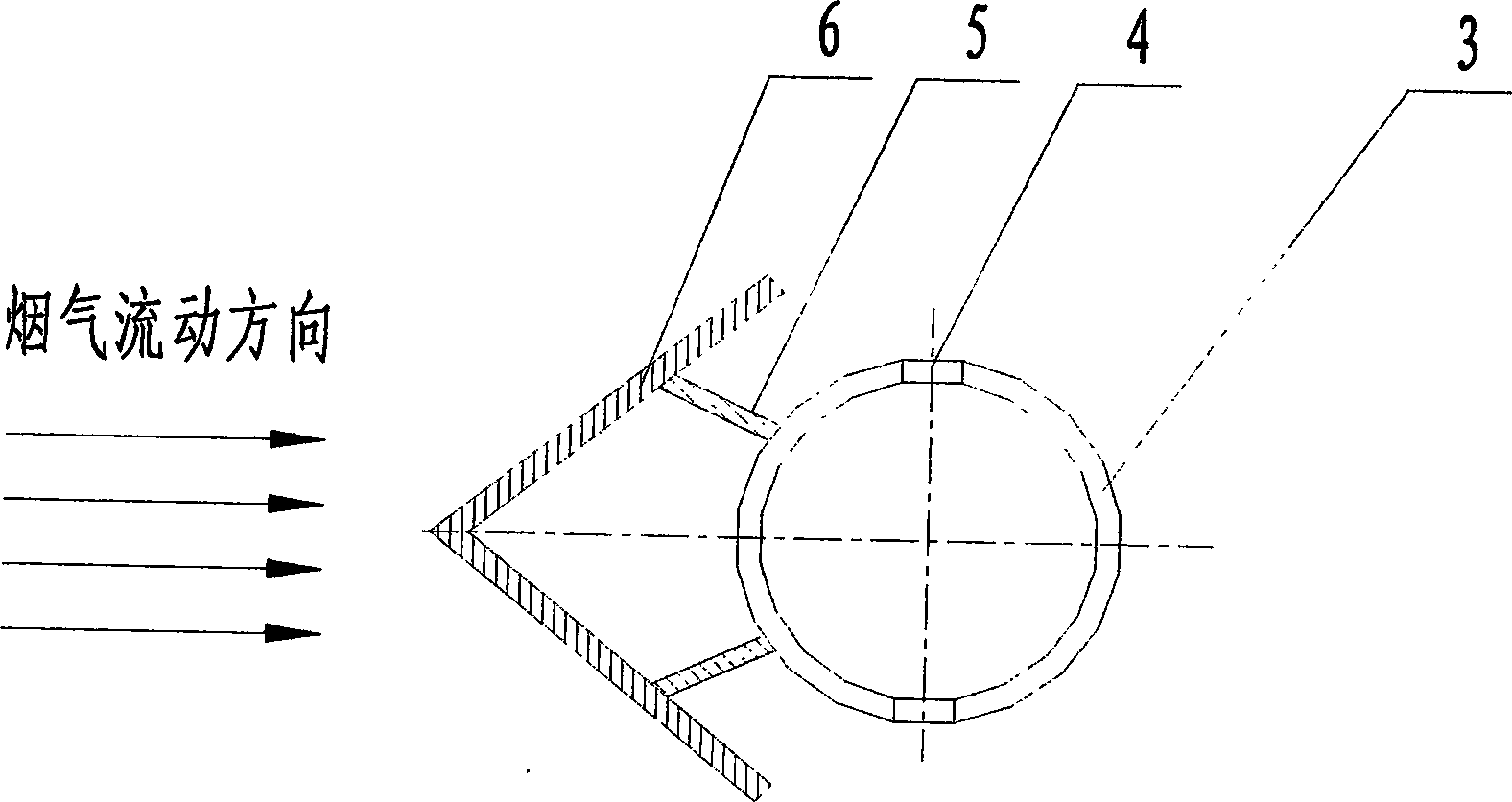

[0013] Examples of the present invention are figure 1 A number of ammonia injection pipes 2 are arranged on the cross section of the flue 1, one end of the ammonia injection pipe 2 is connected to the ammonia-air mixed gas supply main pipe, and the other end is a blind end. Each ammonia injection pipe 2 or several ammonia injection pipes 2 is equipped with a valve, and its flow rate can be adjusted individually. The ammonia injection pipe 2 is made of a metal pipe, and there are several ammonia injection holes 4 with different diameters on the pipe. On the windward side of the metal pipe 3 , an anti-wear spoiler 6 is provided, and the anti-wear spoiler 6 is connected to the metal pipe 3 through a support structure 5 . The anti-wear spoiler element 5 is an angle steel, the angle at the top of the angle steel is 60-120°, and the end is made into a regular sawtoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com