Method and apparatus for preparing solid natural gas

A natural gas and solid technology, applied in the direction of solid fuel, gas fuel, petroleum industry, etc., can solve the problems of complex natural gas hydrate preparation and transportation equipment, slow accumulation of large-volume hydrate, and low efficiency of hydrate preparation process, and achieve Save high-pressure natural gas compressors, reduce energy consumption, and promote rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing. However, it does not limit the scope of rights of the present invention.

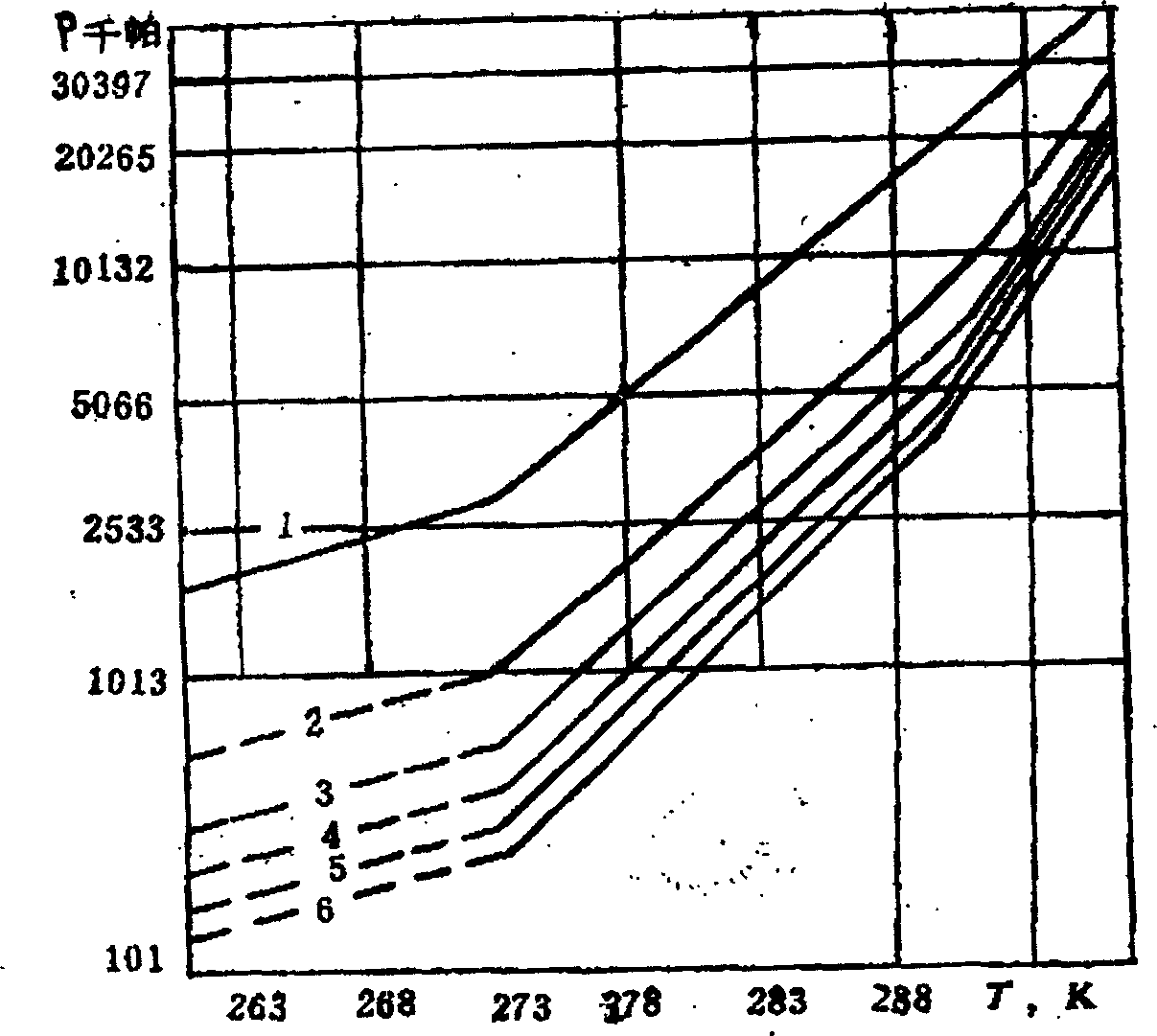

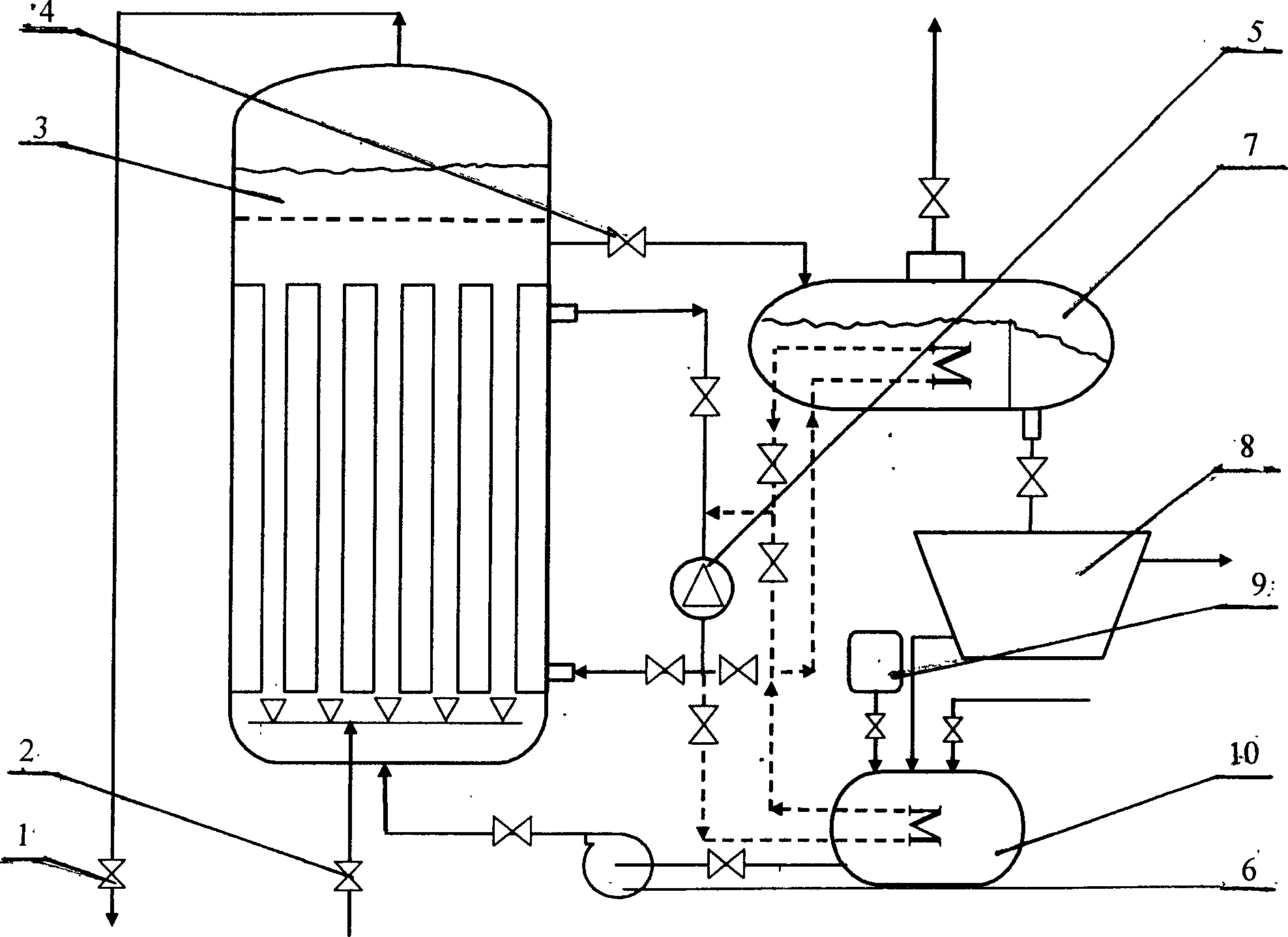

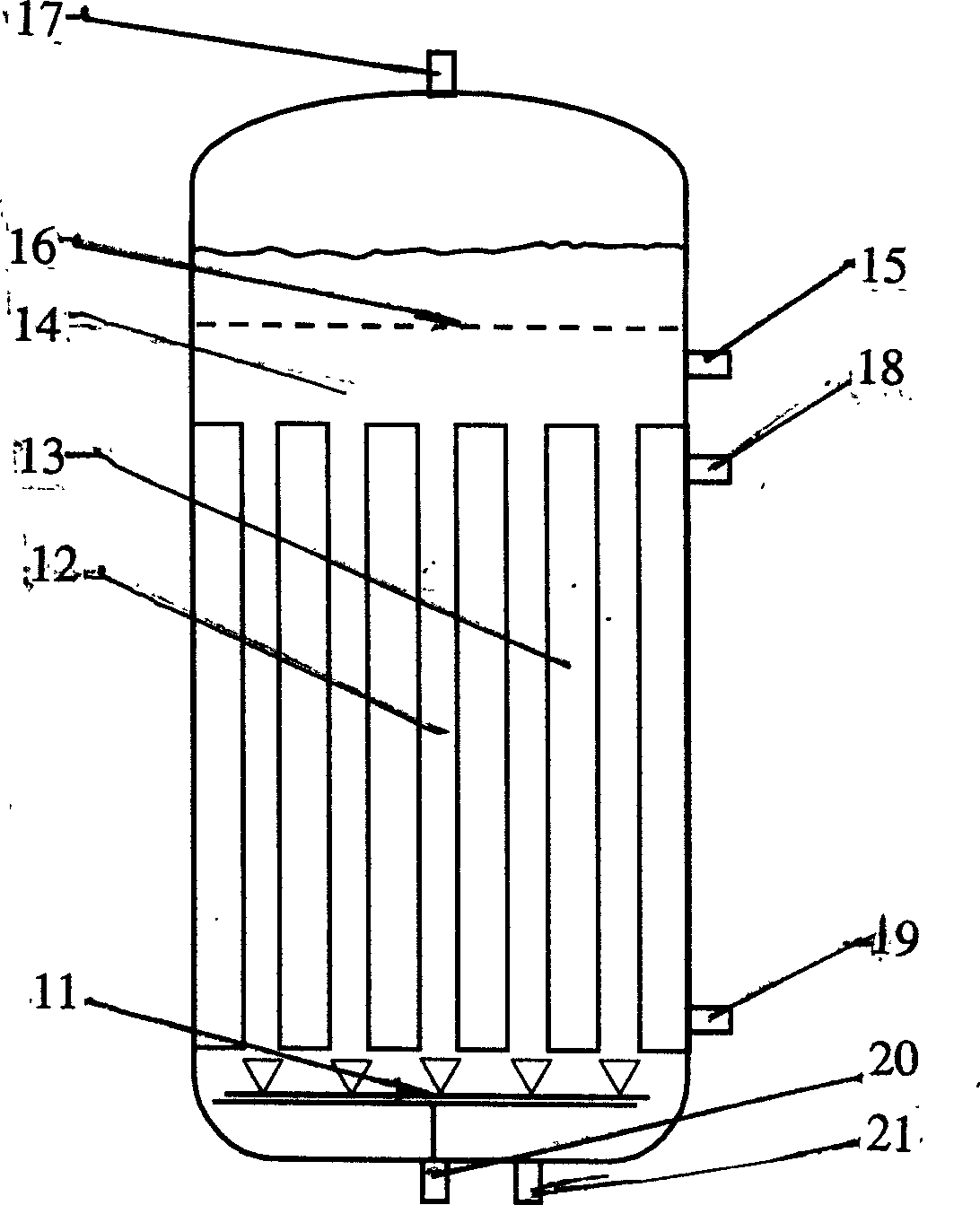

[0046] First start the high-pressure water pump 6, and pump the water added with the additive into the tube side of the reactor 3. When the water level at the top of the tower exceeds the partition plate 16 and reaches the specified level, open the drain valve 4 at the outlet of the bypass pipe, adjust the opening degree of the valve and the displacement of the high-pressure water pump 6, so that the water passes through the drain valve 4 and the flash degassing tank 7. The filter 8 and the water tank 10 form a stable water cycle; then start the refrigeration unit to supply chilled water to the cold row in the water tank 10 and the flash tank 7, and control the water temperature in the entire reactor 3 within the required range . The preferred temperature is about 10°C lower than the equilibrium temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com