Internal thread heat-transferring pipe

A heat transfer tube and internal thread technology, applied in the field of heat transfer tubes, can solve problems such as increasing flow resistance, and achieve the effects of strengthening condensation and boiling heat transfer, reducing included angle, and strengthening disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

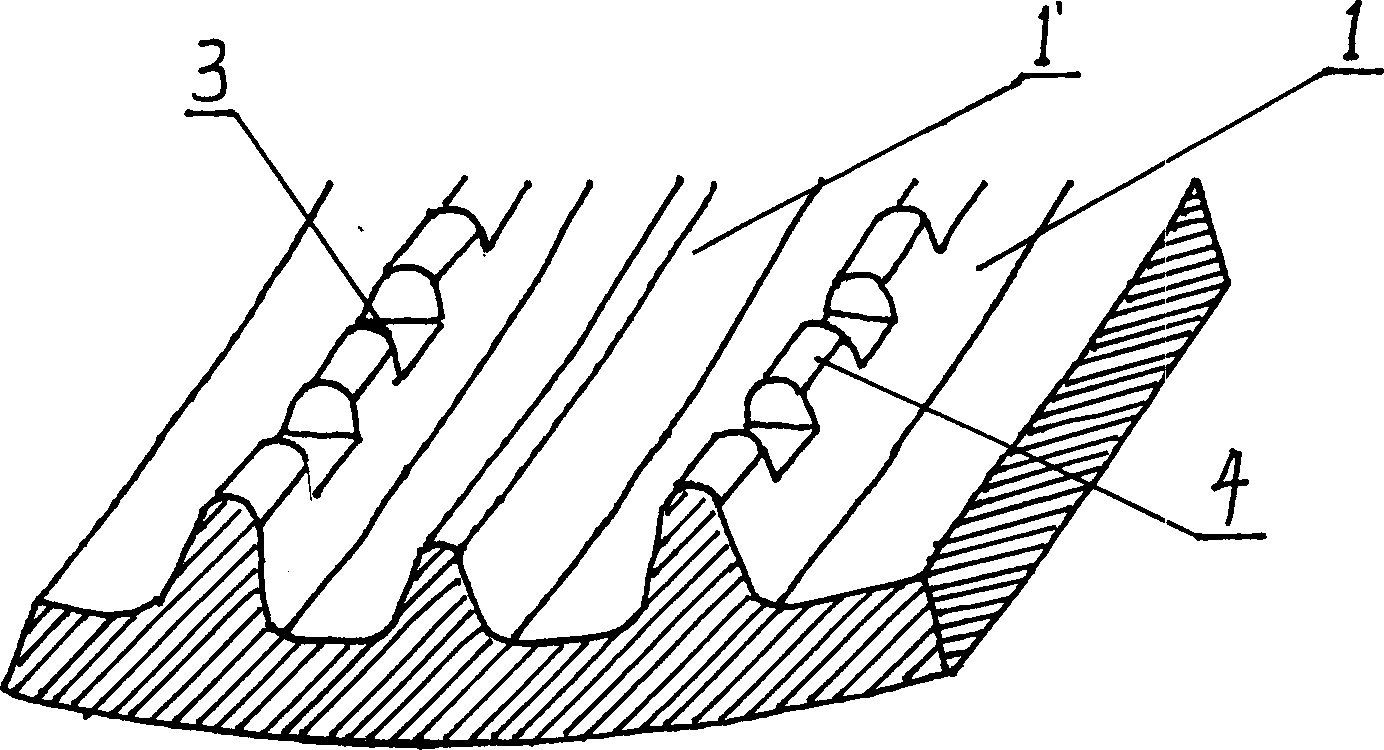

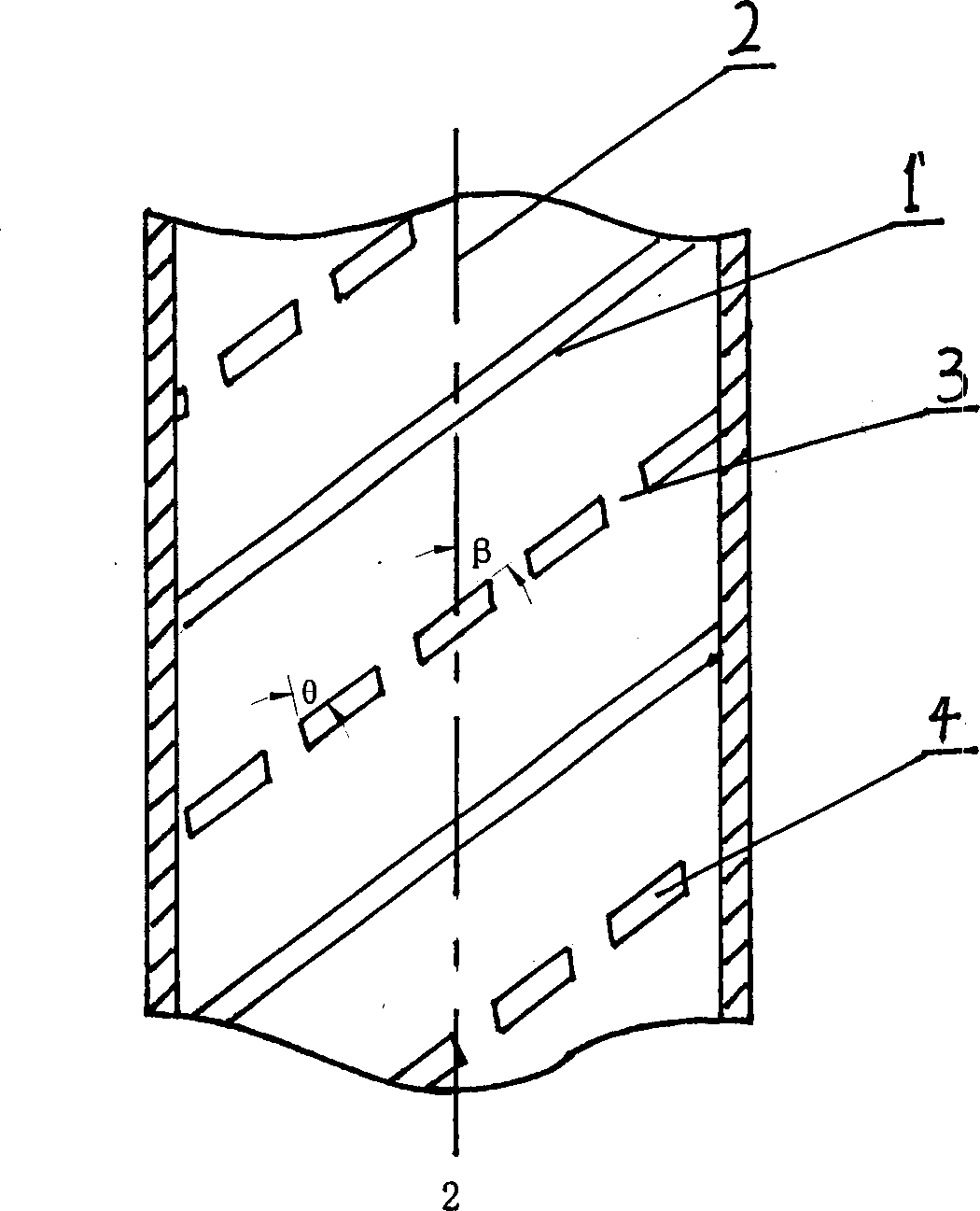

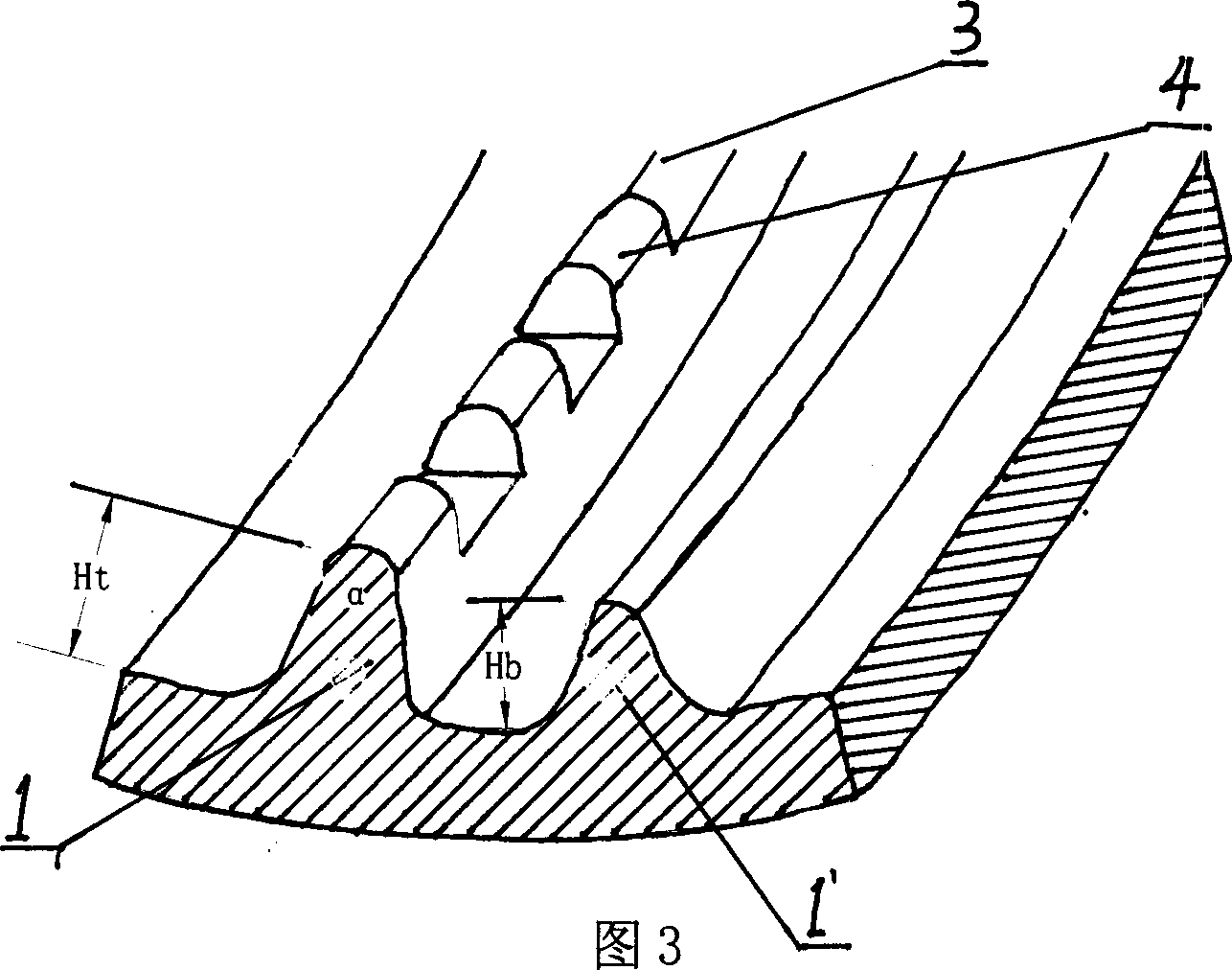

[0011] See figure 1 In the present invention, 40 to 70 spiral main teeth 1 and spiral main teeth 1'of different heights are arranged periodically and uniformly on the inner surface of the heat transfer tube. The rib height Ht of the spiral main tooth 1 is 0.15 to 0.3 mm, and The height ratio Ht / Hb of the spiral main tooth 1 to the spiral main tooth 1'is 1:0.4~0.95. For the 9.52mm heat transfer tube commonly used in room air conditioners, the tooth height is preferably 0.20~0.27mm. The spiral main tooth The number of teeth is preferably 50 to 70. For the 7mm heat transfer tube commonly used in room air conditioners, the tooth height is preferably 0.10 to 0.24 mm, and the number of teeth of the spiral main tooth is preferably 40 to 60. The top end is provided with uniformly arranged grooves 3. The length of the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com