Vertical separation connector and vertical separation mechanism thereof

A technology of vertical separation and connector, which is applied in the direction of connection and connection of parts and electrical components of the device, to achieve the effect of simple and compact structure, saving space and avoiding stuck phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

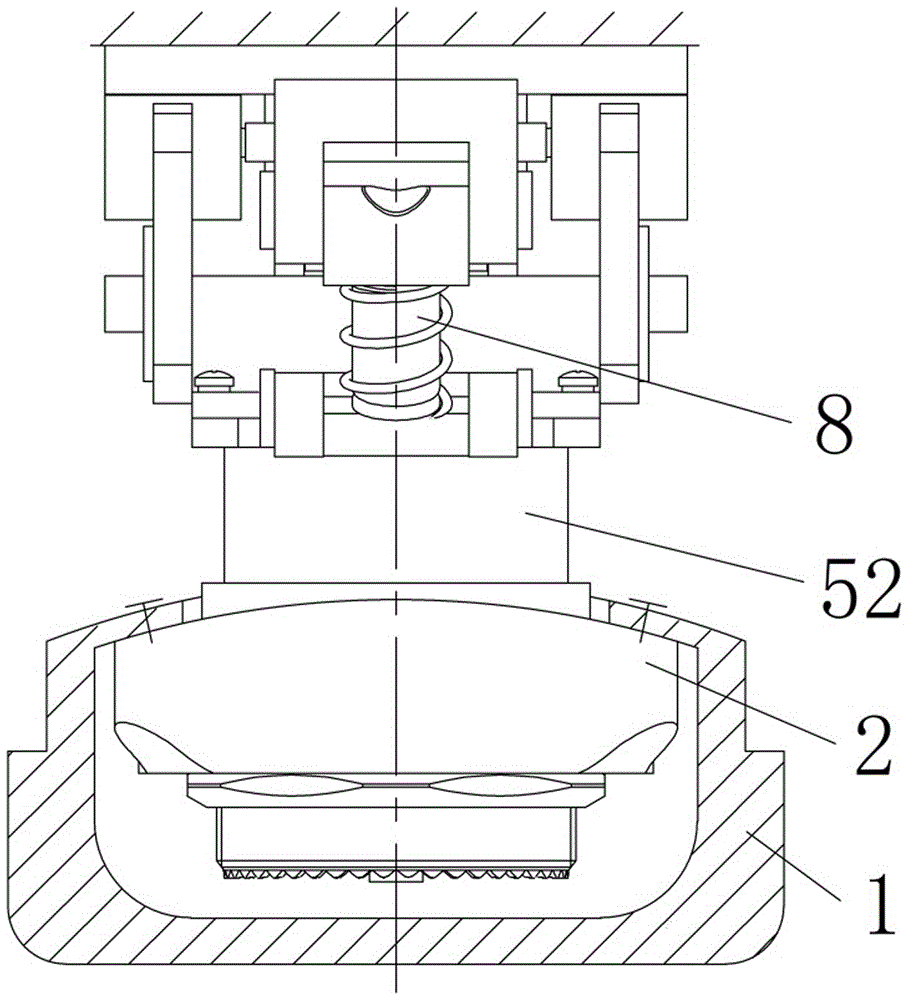

[0086] As another embodiment of the present invention, the linkage mechanism 4 can also be provided with multiple groups of swing rods in the front and rear direction as required, such as three or four groups, as long as these swing rods can be guaranteed to be parallel to each other when moving, The plug located at the lower end of the swing rod only moves in translation and does not rotate during the movement.

[0087] As another embodiment of the present invention, in specific embodiment 1, when the plug and socket are inserted and connected, the setting position of the swing bar can also be set to an inclined state instead of a vertical state, and the plug and socket can also be vertical Separated, but compared with the vertical state at this position, when the swing bar swings at the same angle, the displacement of the plug in the vertical direction is not as large as that of the plug in the specific embodiment 1, which is not conducive to the vertical displacement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com