Sludge drying apparatus and sludge drying method using the same

A sludge drying and shell technology, which is applied in the sludge drying device and the sludge drying field, can solve the problems of low efficiency of solar drying sludge, high energy consumption and high operating cost of the sludge drying equipment, and achieves the The effect of preventing heat dissipation, small installed power, and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

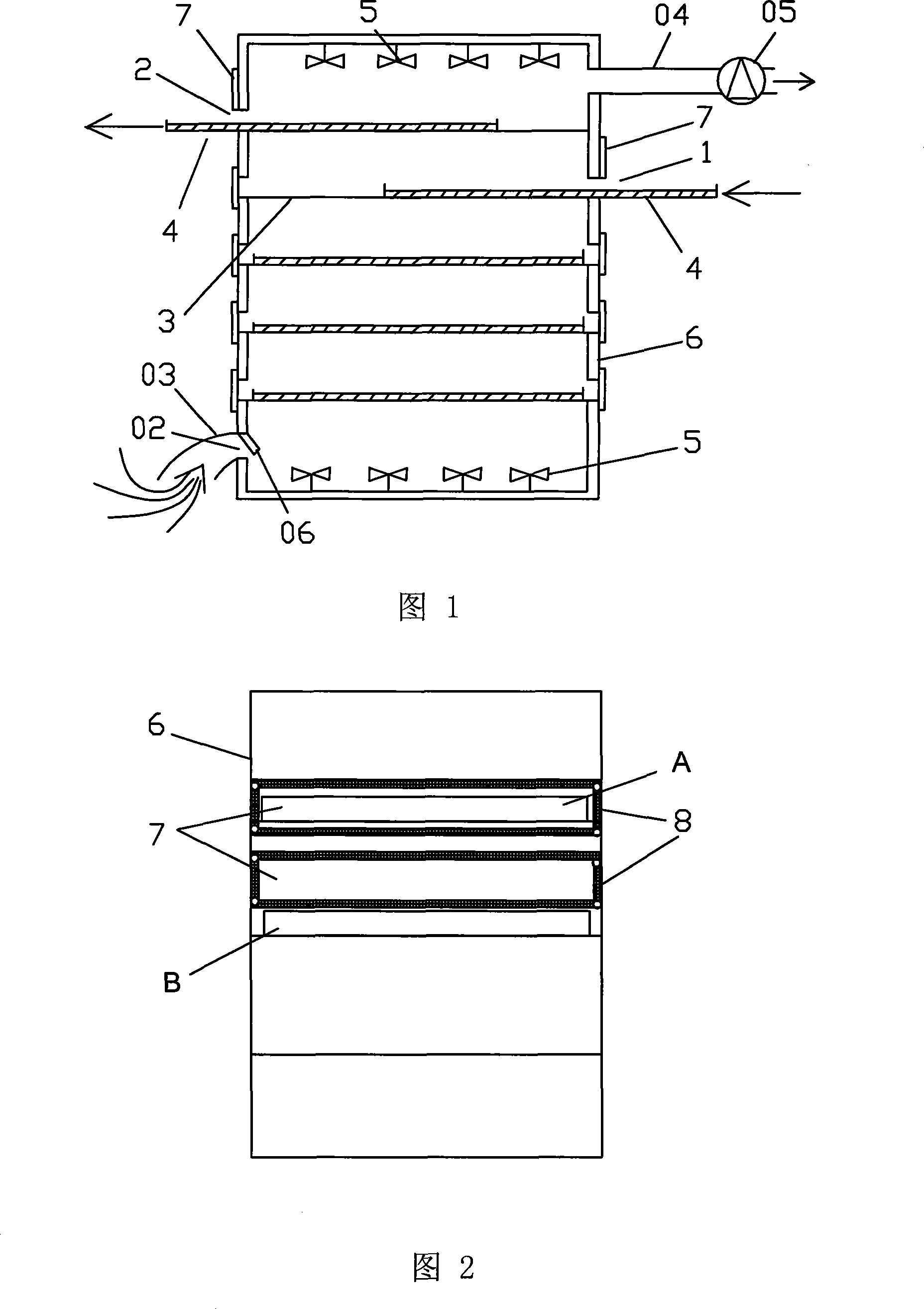

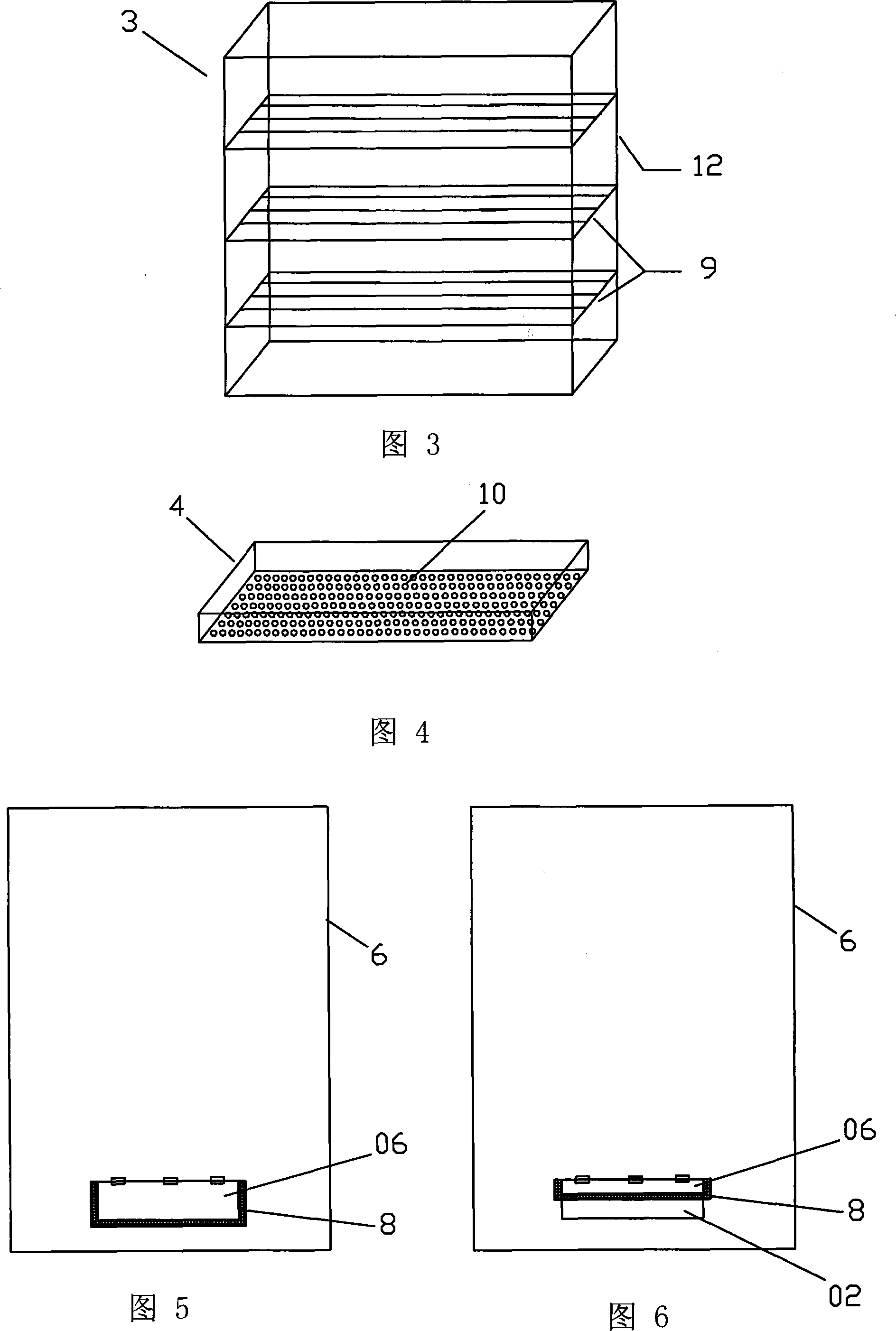

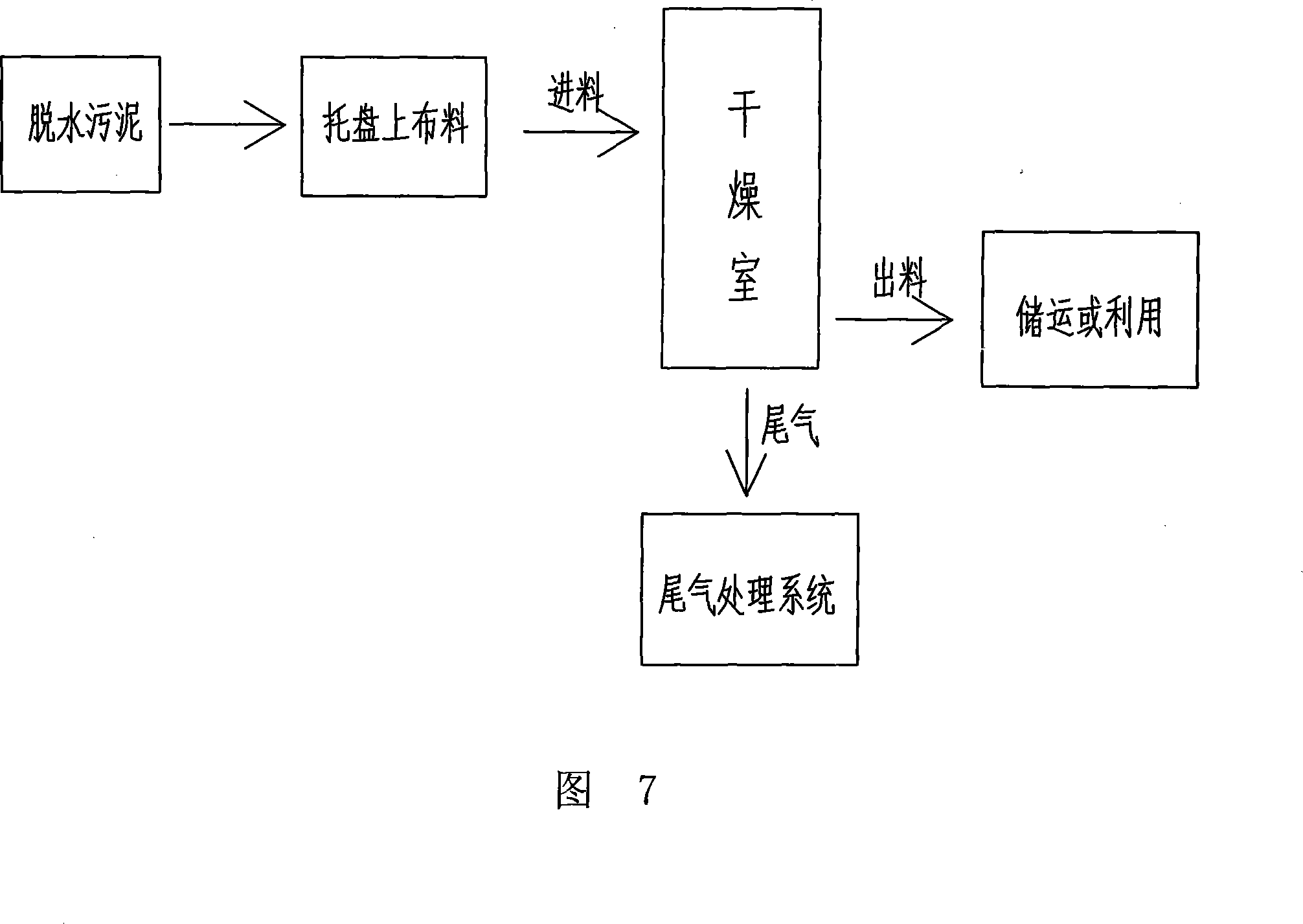

[0037]Fig. 1 has shown the basic structure of the preferred embodiment of the sludge drying device of the present invention, described sludge drying device, it comprises the drying room that is made of a closed shell 6 of transparent glass, divides into layers and arranges horizontally The tray bracket 3 in the housing, the feeding port 1 corresponding to each layer of tray brackets on the lateral right side wall of the housing 6, and the opposite side (left side) of the housing 6 to the feeding port 1 Outlet 2 on the wall. The inlet and outlet ports are respectively connected with sealing plates 7 that can seal the inlet and outlet ports. In this embodiment, the sealing plate 7 is rectangular and made of double-layer hollow transparent glass. The sealing plate can move up and down, and is fixed to the corresponding position on the surface of the housing by bolts. Sealing strips 8 are provided on the four sides (such as Shown in Figure 2, wherein, what A shows is the closed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com