Cooling system of ultra-high strength steel hot stamping forming die

A technology of hot stamping and ultra-high strength, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., and can solve the problem of limited production efficiency, difficulty in meeting the above requirements for the cooling system of stamping molds, time-consuming cooling of molds and steel plates, etc. problems, to achieve the effect of ensuring the strength and precision requirements of parts, reducing requirements, and speeding up the stamping cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

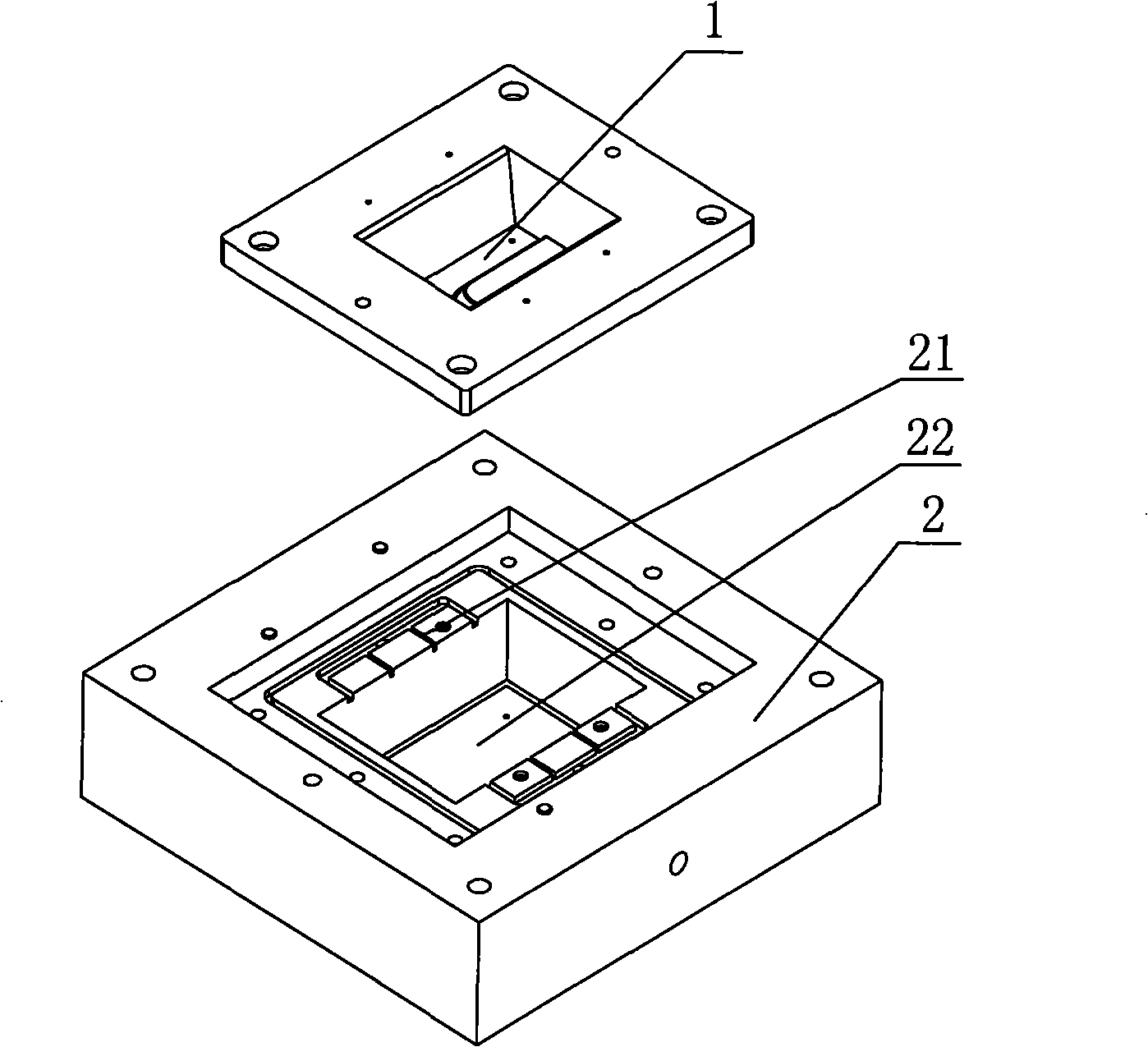

[0018] Such as figure 1 As shown, the cooling system of the ultra-high-strength steel plate hot stamping die of the present invention is provided with a water cavity 22 between the die 1 and the die base 2, and the water cavity 22 is connected to the water inlet and the water outlet through the water guide groove. The water guide groove includes a horizontal water guide groove in the die holder, a vertical water groove and a water channel 21 located at the contact point between the die holder surface and the die for cooling water input and output. Since the speed of cooling water is determined by the minimum cross-sectional area in the whole process, when designing the water channel, 4 water channels are designed at 21 places of the water channel to avoid the bottleneck of water speed resistance. The total cross-sectional area of the finally designed water channel 21 is basically the same as the minimum cross-sectional area in the water cavity.

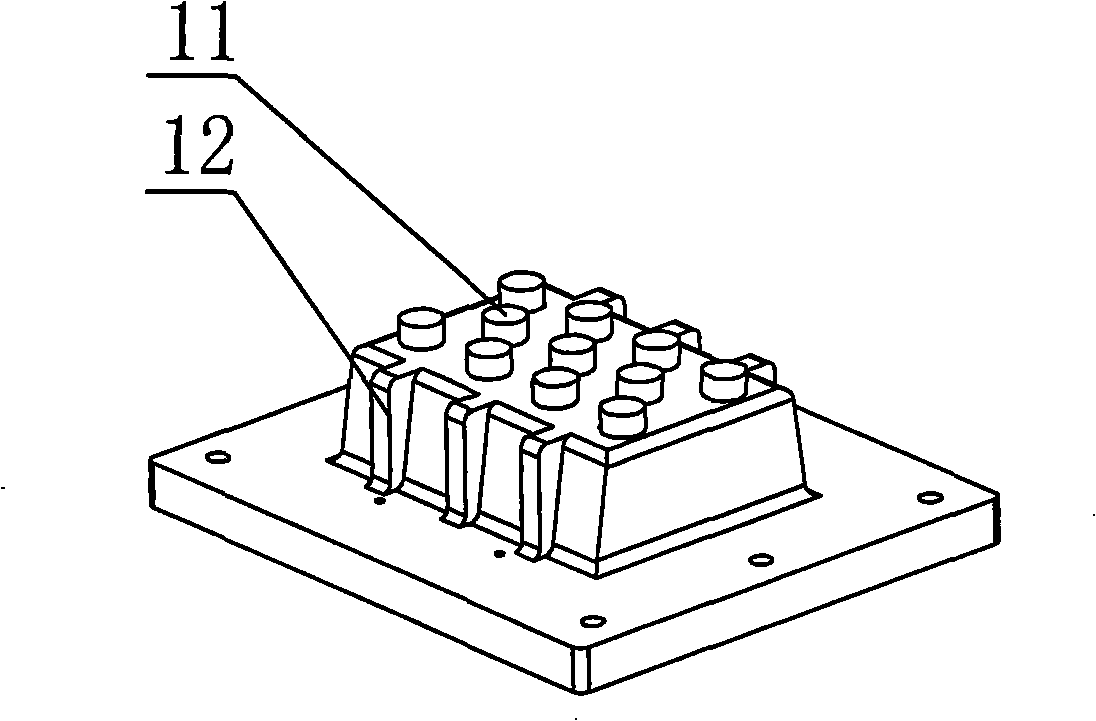

[0019] Such as figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com