A continuous entrainment thin material layer microwave evaporation method and device

A technology of an evaporation device and an interlayer, which is applied in the field of continuous entrainment type microwave evaporation methods and devices for thin material layers, and can solve the problems of low area utilization rate, uncontrolled thickness and uniformity of the stacking layer, unfavorable decompression evaporation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

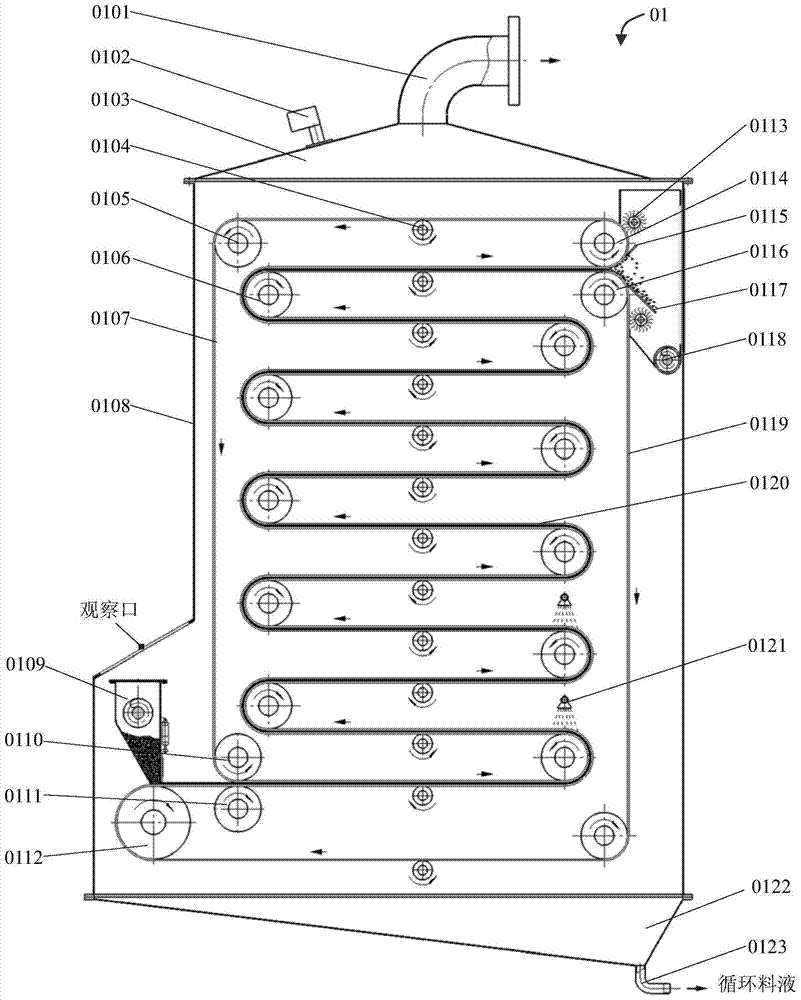

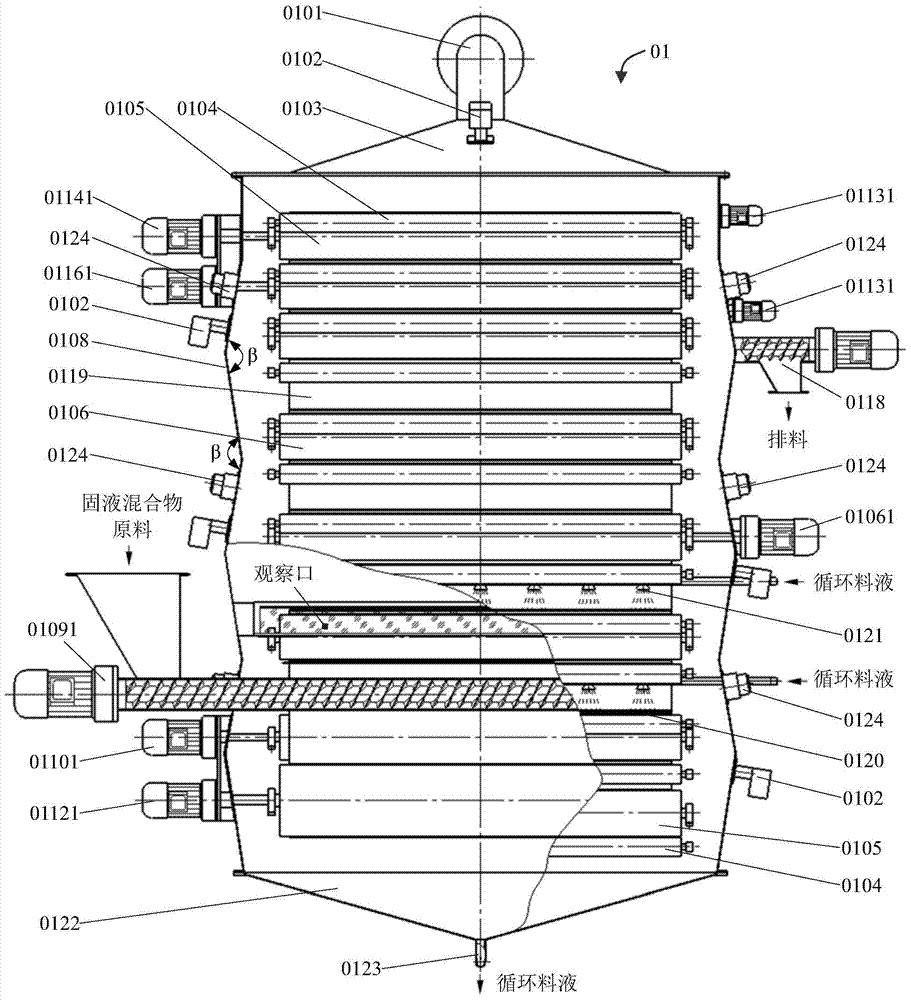

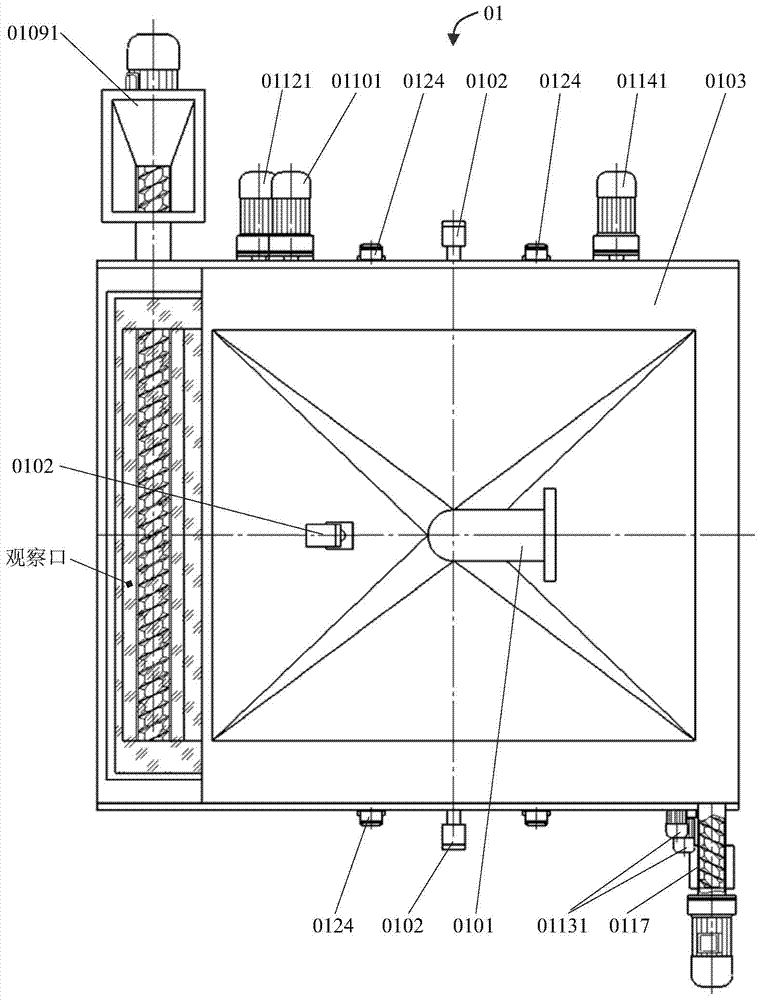

[0082] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0083] The continuous entrainment thin material layer microwave evaporation method of the present invention adopts a pair of rotating upper and lower nip rollers, through two endless filter belts, the solid-liquid mixture is sandwiched between the filter belts to form an upper filter belt , the solid-liquid mixture material layer and the lower filter belt's sandwich layer structure, and the microwave resonant cavity is passed through the microwave resonant cavity in a horizontally reciprocating and layer-by-layer transport mode, so that the solid-liquid mixture material in the double sandwich layer is uniformly thin In the layer state, it absorbs microwave energy and is heated and evaporated.

[0084] The thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com