Through-hole metal foam with gradually varied morphologic characteristics, preparation method of through-hole metal foam, and heat exchange device

A technology of metal foam and shape characteristics, applied in metal processing equipment, manufacturing tools, heat exchange equipment, etc., can solve the problems of low heat exchange efficiency, large amount of consumables, large volume, etc., achieve less metal consumables, increase heat exchange Thermal specific surface area, effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

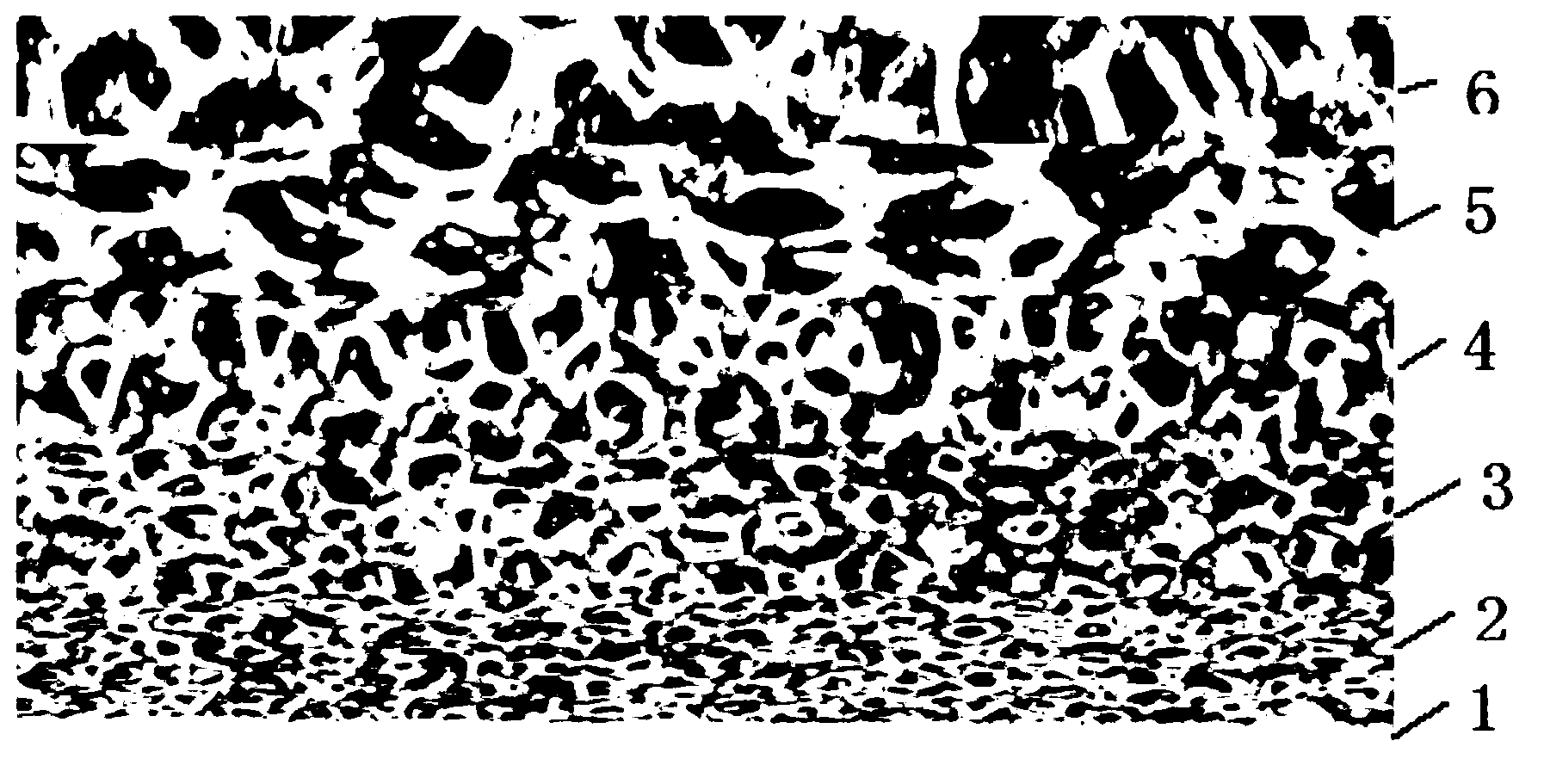

[0026] like figure 1 As shown, this embodiment includes: a copper substrate 1 and a first through-hole copper foam layer 2, a second through-hole copper foam layer 3, a third through-hole copper foam layer 4, and a fourth through-hole copper foam layer sintered on one side of the copper substrate 1. layer 5 and fifth via copper foam layer 6. After the through-hole copper foam layer is prepared by the investment casting method, the copper foam 2 is brazed to the copper substrate 1 .

[0027] The density of 2 holes in the first through-hole copper foam layer is 40PPI; the density of 3 holes in the second through-hole copper foam layer is 30PPI; the density of 4 holes in the third through-hole copper foam layer is 20PPI; the density of 5 holes in the fourth through-hole copper foam layer is 10PPI; the density of 6 holes in the fifth through-hole copper foam layer is 5PPI.

[0028] Specific steps of investment casting method:

[0029] The first step is to glue polyurethane spon...

Embodiment 2

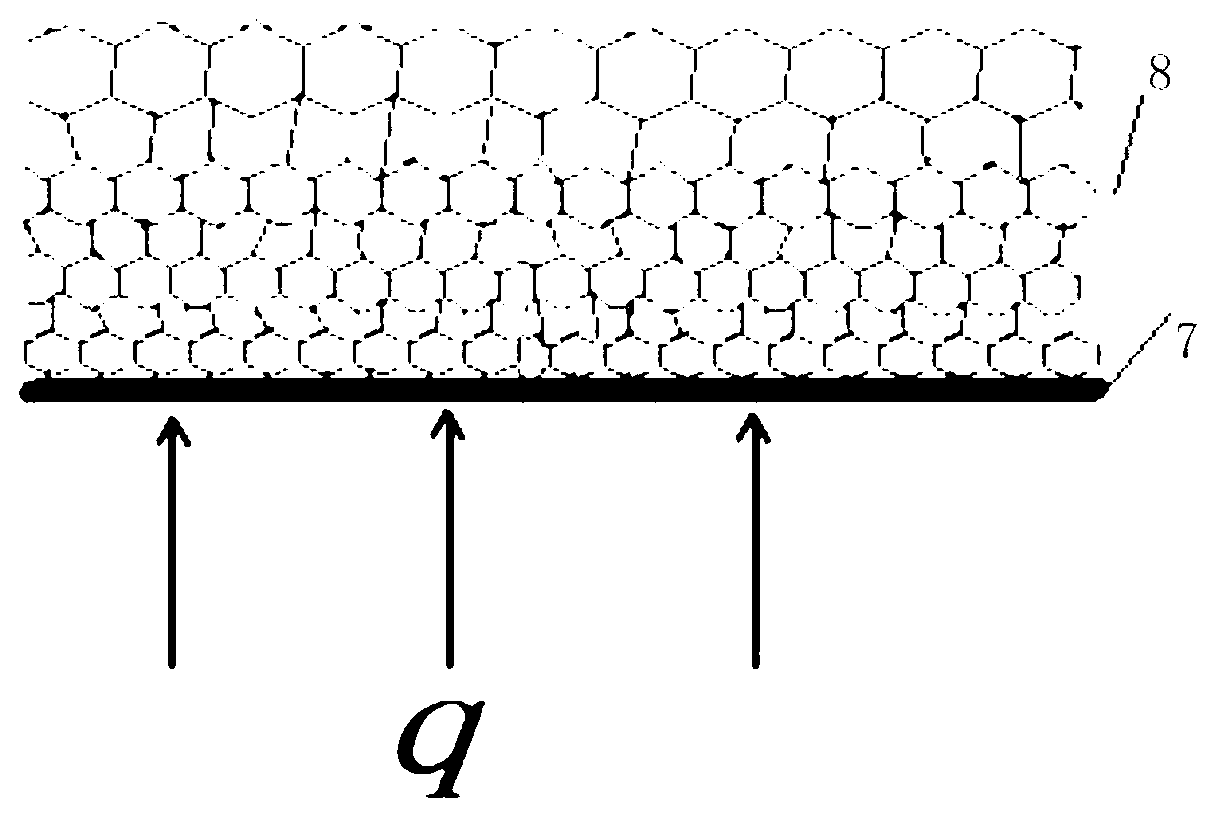

[0034] like figure 2 As shown, this embodiment includes: a heat exchange wall 7 and a through-hole metal foam 8 sintered on one side thereof, wherein the density of the through-hole metal foam 8 gradually decreases along the vertical direction outward of the heat exchange wall 7 .

[0035] If the heat flow of the heat exchange wall 7 is very large, the pore density of the metal foam close to the heat exchange wall 7 can be selected as the highest pore density 130PPI that can be prepared at present, the porosity is selected as low as 0.88, and the material is preferably selected with a high thermal conductivity metals, such as pure copper, brass, etc., so the contact area between the metal skeleton close to the heat exchange wall 7 and the heat exchange wall 7 is large, and the thermal conductivity of the metal skeleton is high, which is beneficial to the heat transfer wall 7 through heat conduction way to transfer more heat to the foam. In the case of single convective heat ...

Embodiment 3

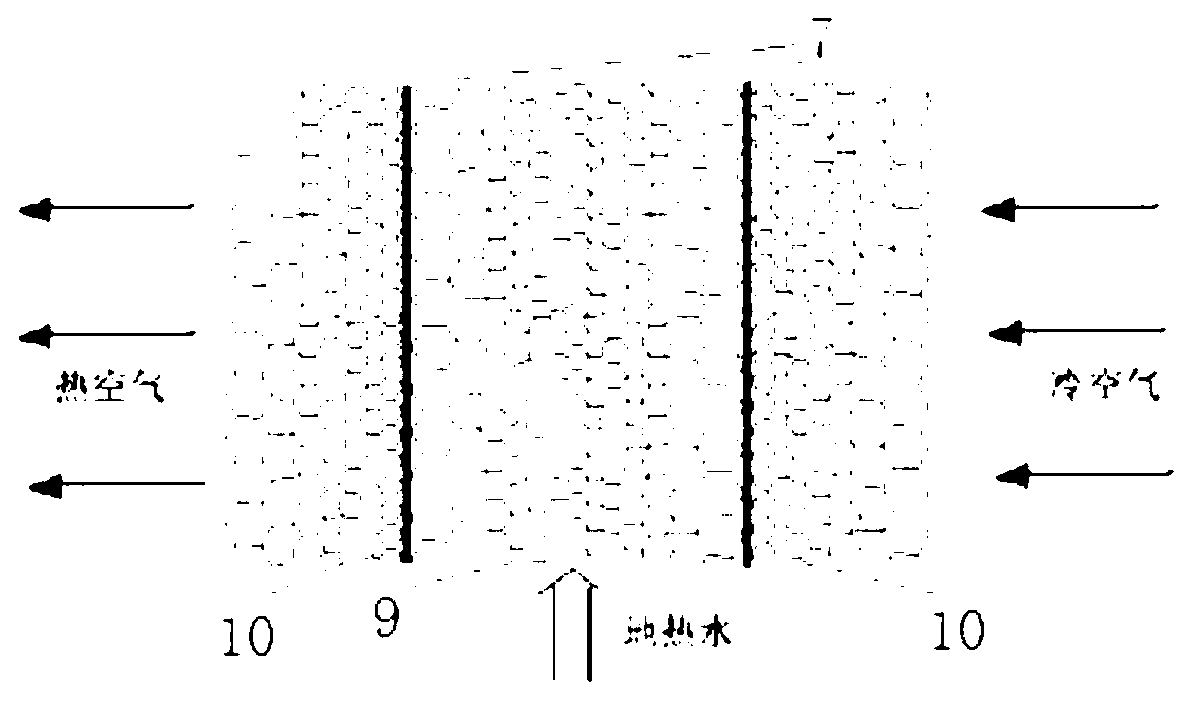

[0038] like image 3 Therefore, this embodiment includes: two heat exchange wall surfaces 7, a first through-hole metal foam 9 and two second through-hole metal foams 10, wherein: the first through-hole metal foam 9 is sintered in the middle of the two heat exchange wall surfaces , the density of the foam is larger in the middle and smaller at the two sides, and the two second through-hole metal foams 10 are respectively sintered on the outer sides of the two heat exchange walls, and the density of the foam gradually decreases along the direction perpendicular to the heat exchange wall. Because the pipe is a single-phase flow heat exchange, the density of the middle part of the first through-hole metal foam 9 depends on the inlet temperature, pressure and flow rate of the geothermal water. If the inlet temperature and pressure are higher, the geothermal water flow rate is larger. The pore density (more than 30PPI) of the metal foam in the middle part of the pipe is larger than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com