A heat dissipation device that adopts pulsating flow and foam metal plate to strengthen

A technology of heat dissipation device and metal plate, which is applied in cooling/ventilation/heating transformation, electrical components, electric solid devices, etc. The effect of small flow resistance loss and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

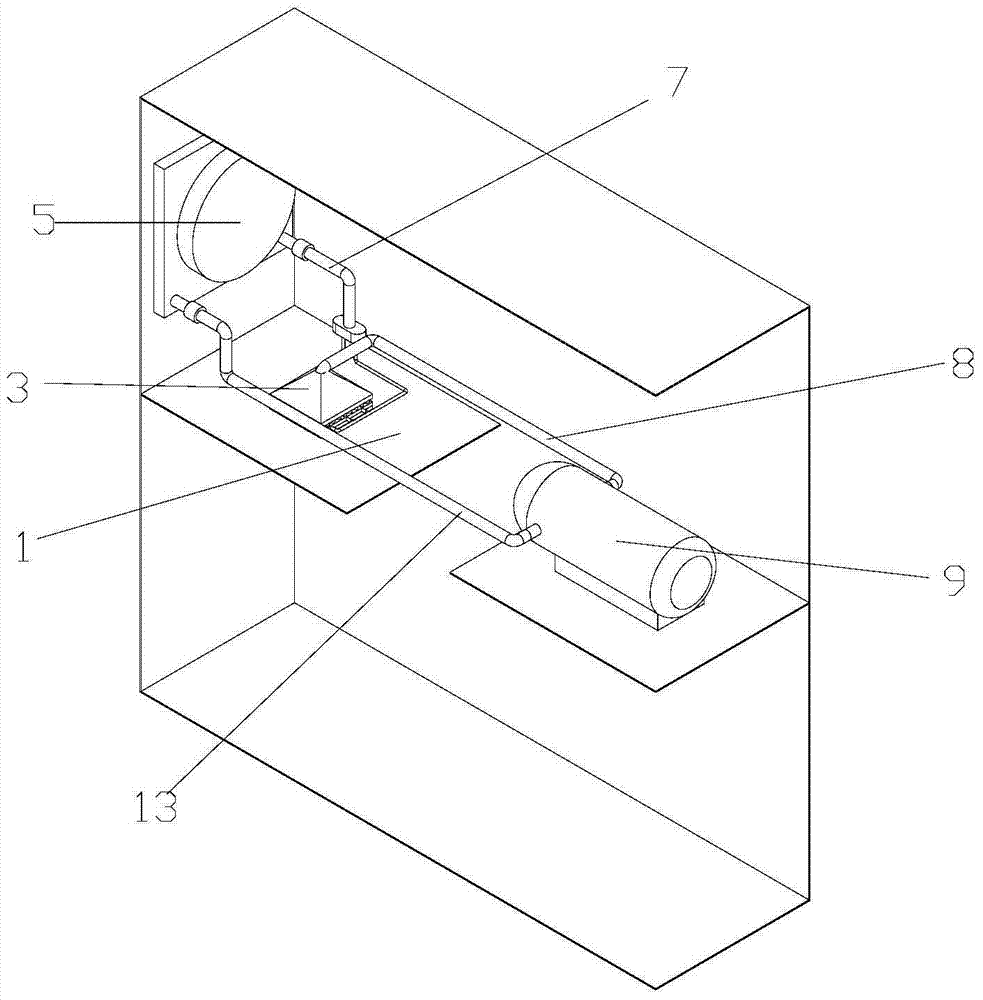

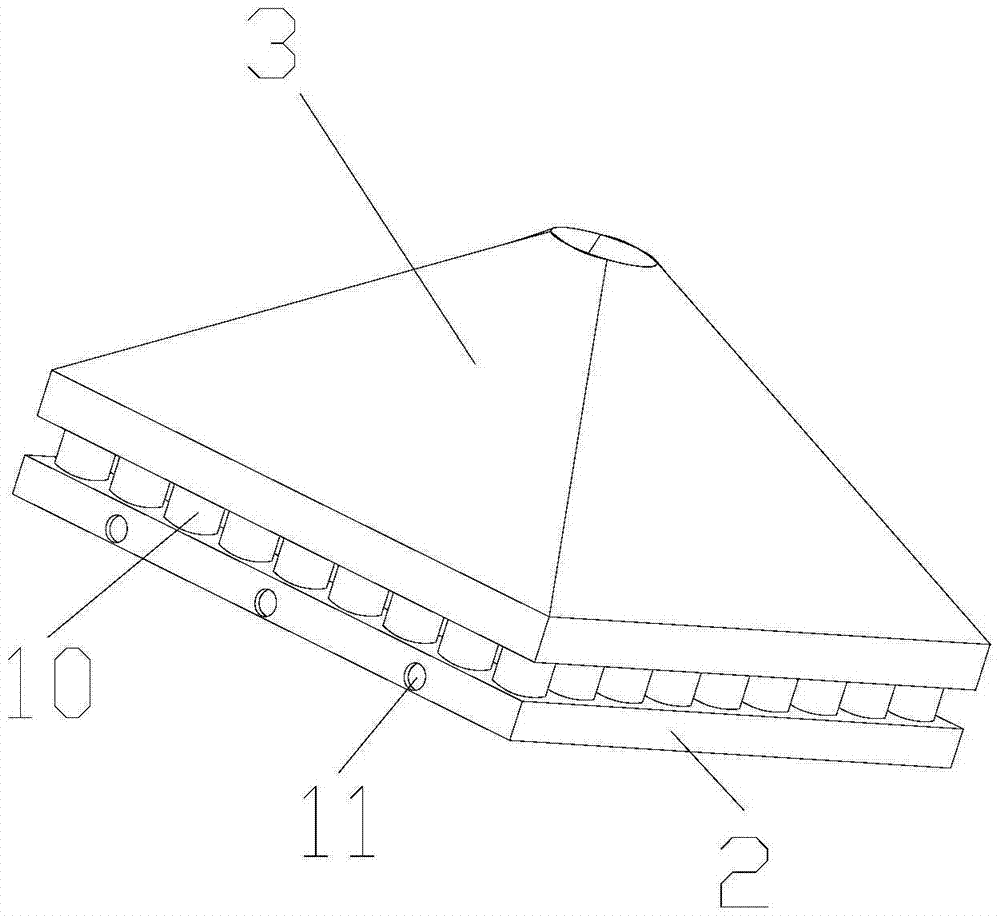

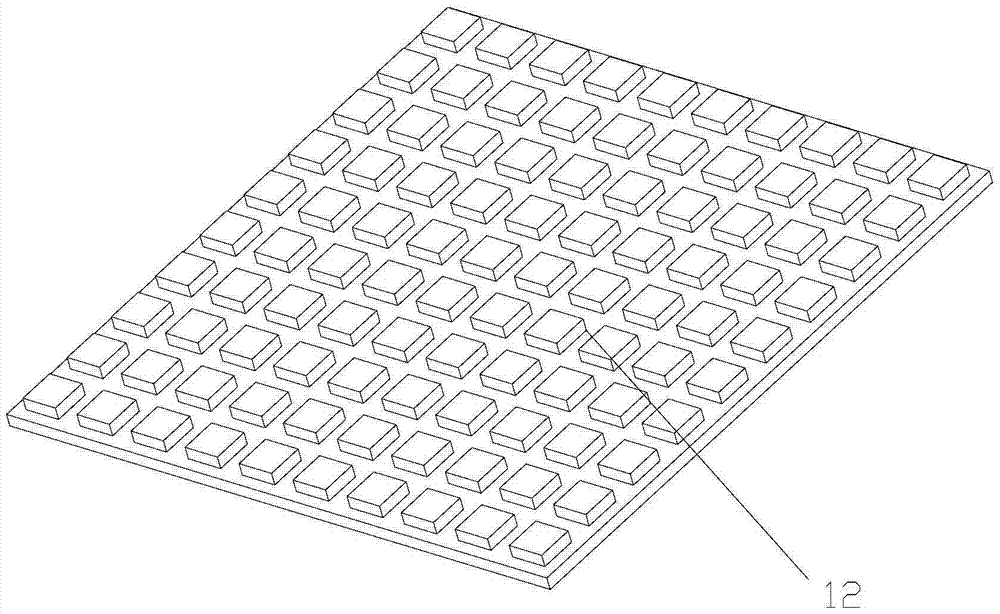

[0018] Such as Figure 1 to Figure 3 Shown, a kind of adopting pulsating flow and metal foam plate of the present invention strengthens heat radiation device, comprises pulsating pump 9, heat sink chamber, the liquid accumulation chamber 3 of trumpet-shaped cavity and cooler 5, and described pulsating pump 9 passes liquid into The pipe 8 sends the cooling liquid into the liquid accumulation chamber 3 and connects it. The liquid accumulation chamber 3 sprays the cooling liquid into the heat sink chamber through the cylindrical liquid separator 10, and the heat sink chamber discharges the heat-exchanged liquid through the liquid discharge pipe 7. Send it into the cooler 5 for cooling, and the pulsating pump 9 sucks the cooled cooling liquid from the cooler 5 through the connecting pipe 13, and the cooler 5 is a circulating water cooler 5. The heat sink chamber includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com