Heat-storage lead-melting furnace

A lead-melting furnace and heat storage technology, applied to furnaces, crucible furnaces, furnace types, etc., can solve the problems of small heat transfer specific surface area, large air pressure and large resistance of blowers and induced draft fans, etc., to achieve increased heat transfer Effect of heat specific surface area, reduction of flue gas circulation space, and reduction of regenerator volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

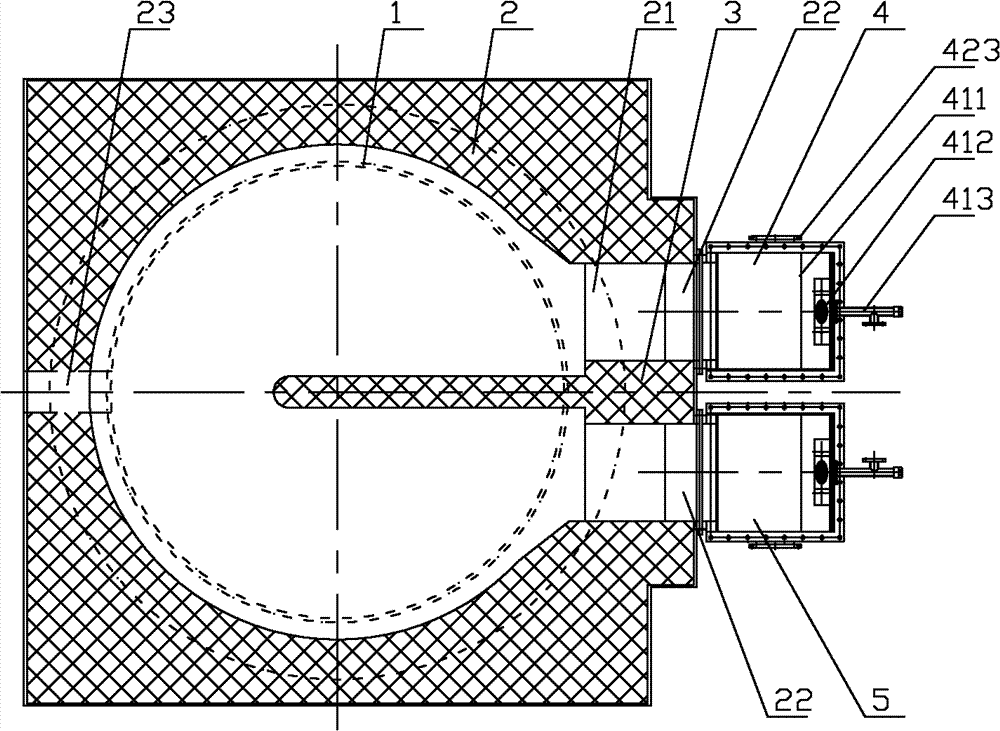

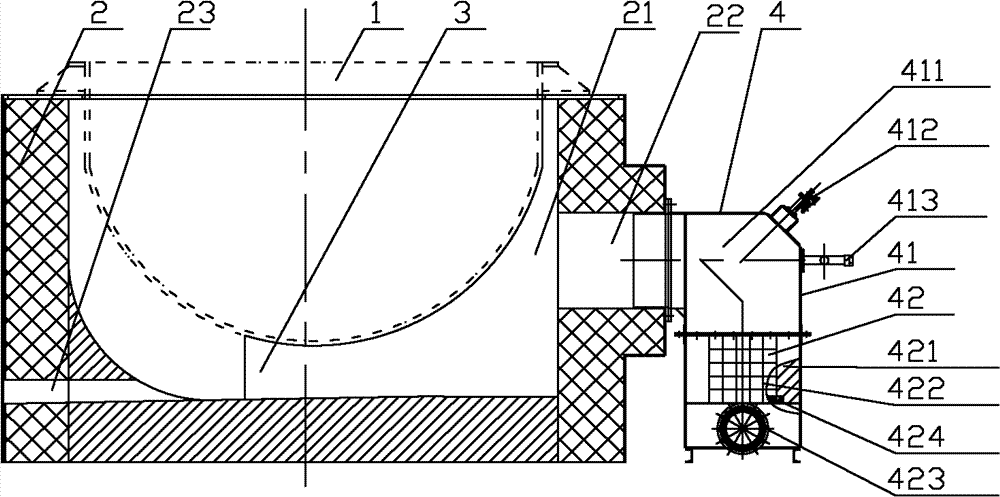

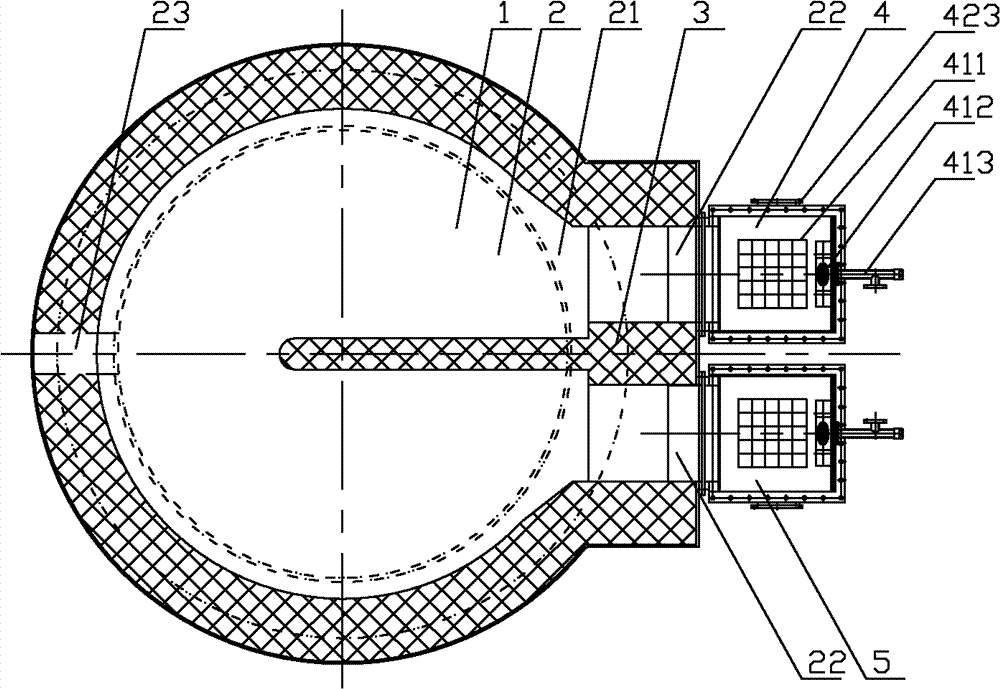

[0030] The heat storage lead-melting furnace of the present invention comprises a pot body 1, a body of furnace 2 and two heat storage combustion assemblies, and the body of furnace 2 can adopt such as figure 1 with figure 2 The rectangle can also be used as image 3 with Figure 4columnar. The pot body 1 is placed on the furnace body 2, and the furnace body 2 only retains the heating area of the pot body 1, and the furnace body 2 is divided into two independent heating chambers 21 by a partition wall 3, which separates the high-temperature flue gas inlet and outlet sections , to ensure that the high-temperature flue gas flows around the pot body 1 as much as possible in the furnace body 2 to enhance heat exchange. Each heating cavity 21 communicates with a regenerative combustion assembly through a flue gas pipe 22 provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com