Marine immersed type porous medium condenser

A porous medium and immersion technology, which is applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of complex structure, large size, and extremely high requirements for the utilization of ship power space, and achieve enhanced heat transfer effect and compact structure , The steam spray effect is stable and continuous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

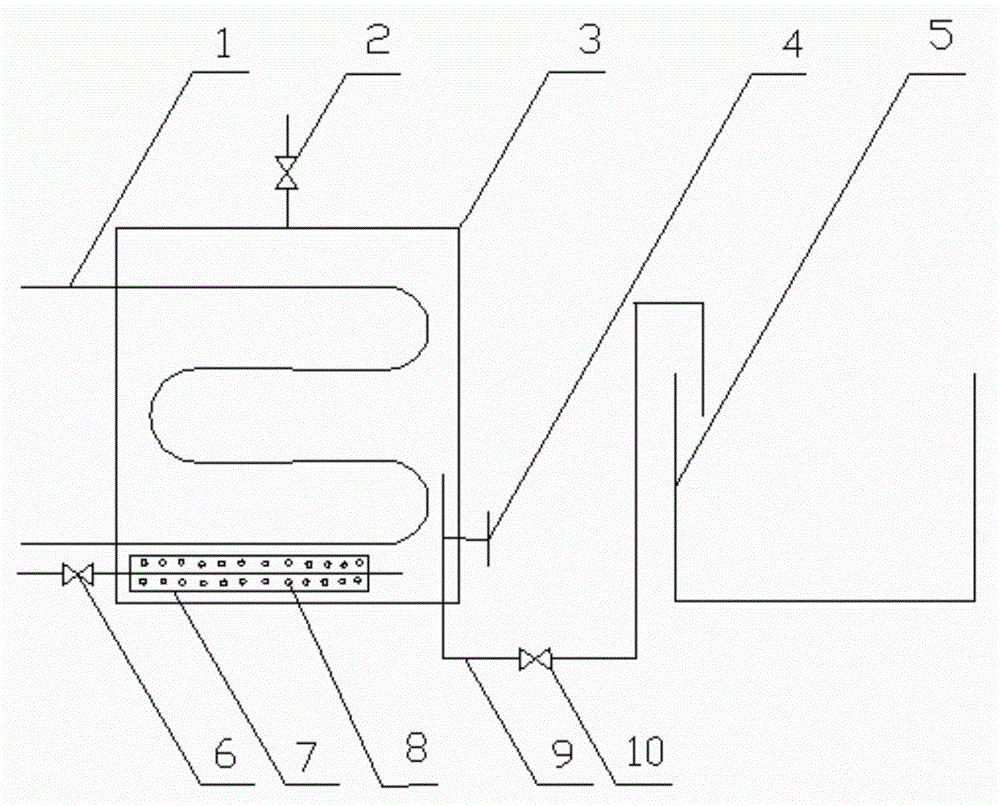

[0012] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0013] combine figure 1 , a submerged porous medium condenser of a chemical regenerative cycle gas turbine device of the present invention, comprising a tank body 3, a steam conduit 8, a porous medium 7, a cooling water conduit 1, a condensed water drain pipe 9, a steam trap 10, and an exhaust valve 2. The liquid level regulating valve 4 and the steam regulating valve 6 are composed of a cooling water conduit 1, a steam conduit 8 and a porous medium 7 etc. inside the tank body 3; the porous medium 7 is evenly distributed on the steam conduit 8; the cooling water conduit 1 A filter is installed at the inlet to remove impurities in the water; the liquid level regulating valve 4 is located at the bottom of the tank to adjust the liquid level of condensed water; the exhaust valve 2 is located at the top of the tank to discharge the non-condensable gas in the tank , A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com