Solution regeneration device based on heat accumulating chamber low-temperature flue gas residual heat utilization

A solution regeneration, low temperature flue gas technology, applied in waste heat treatment, climate sustainability, lighting and heating equipment, etc. Ideal and other problems, to achieve the effect of low operation and maintenance cost, good thermal shock resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

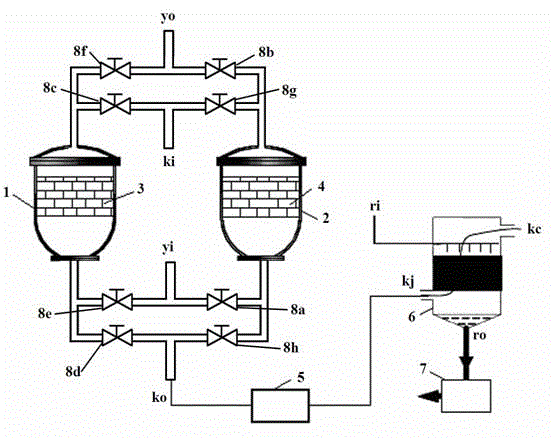

[0012] exist figure 1 Among them, the first regenerator 1 and the second regenerator 2 are installed in pairs; the flue gas inlet y i Divided into two paths, the flue gas inlet y i One of the passages is connected with the first valve 8a, the first valve 8a is connected with the second heat storage chamber 2, the second heat storage chamber 2 is connected with the second valve 8b, and the second valve 8b with flue gas outlet y o communicated, the flue gas inlet y i The other passage of is connected with the fifth valve 8e, the fifth valve 8e is connected with the first heat storage chamber 1, the first heat storage chamber 1 is connected with the sixth valve 8f, and the sixth valve 8f and smoke outlet y o connected.

[0013] air inlet k i Divided into two paths, the air inlet k i One of the passages is connected with the third valve 8c, the third valve 8c is connected with the first regenerator 1, the first regenerator 1 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com