Recycling method for pure terephthalic acid industrial wastewater

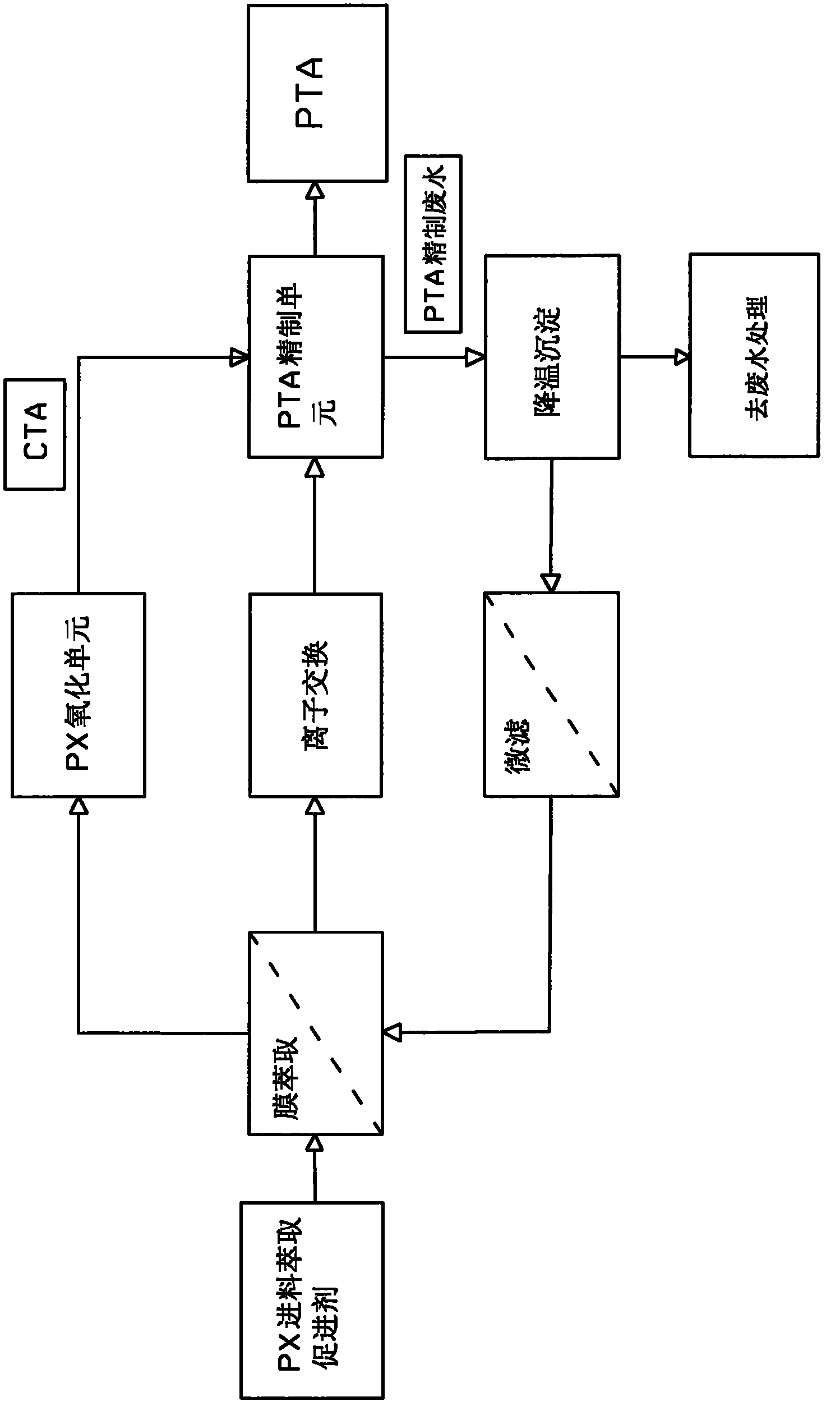

A technology of purified terephthalic acid and terephthalic acid, which is applied in the field of recycling waste water from the production of purified terephthalic acid, can solve the problems of high investment and operation costs, large floor space, waste of water resources, etc., and achieve investment And the effect of low operation and maintenance costs, reduced discharge of waste water, and reduced consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for recycling purified terephthalic acid production wastewater, comprising the following steps:

[0048] Step a: removing the solid organic aromatic carboxylic acid in the purified terephthalic acid production wastewater by microfiltration, and returning the filtered solid aromatic carboxylic acid to the oxidation unit;

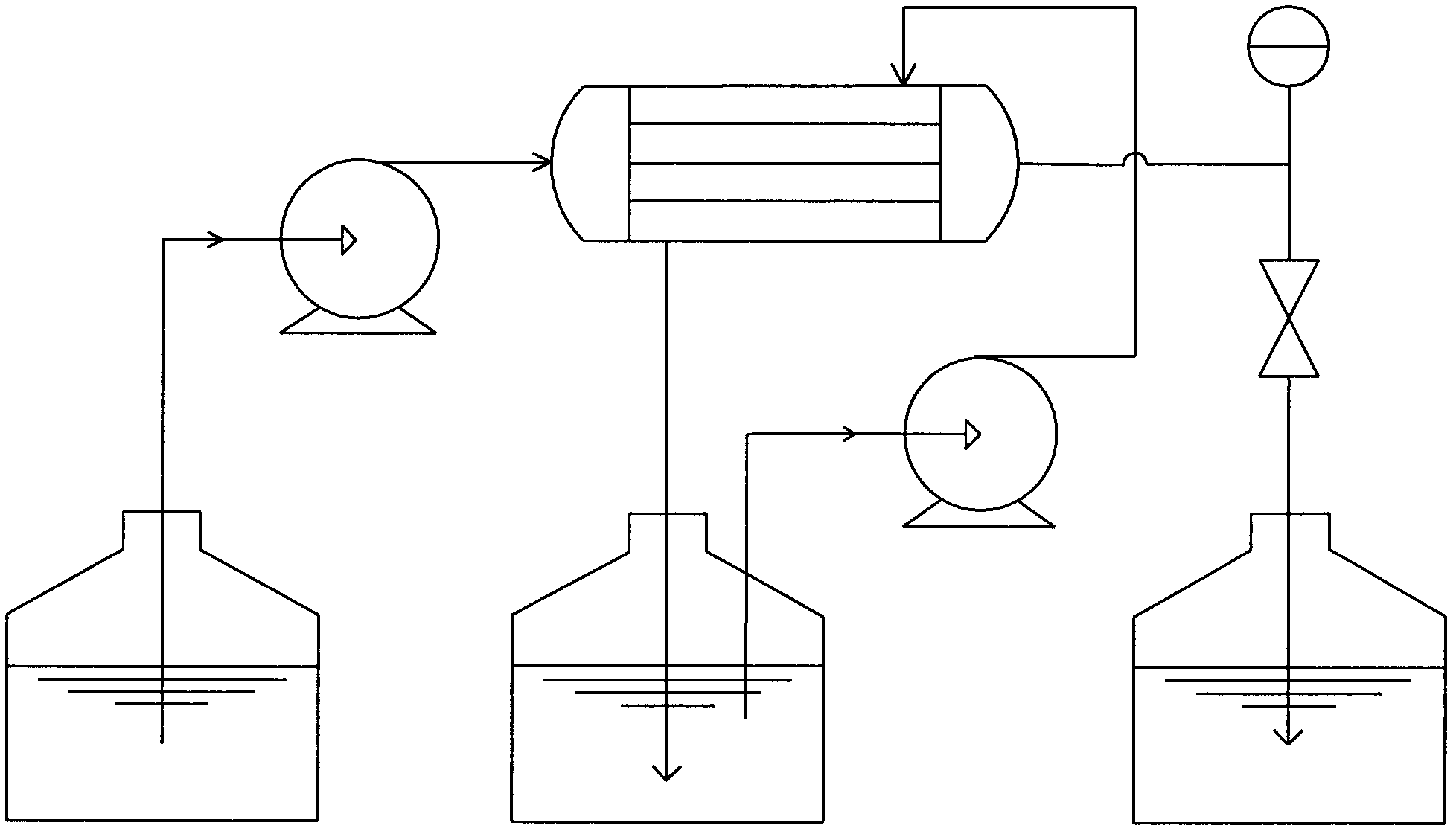

[0049] Step b: PTA production wastewater and p-xylene are pumped to the membrane extraction unit, the water phase and the oil phase pass through the porous organic membrane on both sides of the membrane module respectively, and the pressure of the wastewater phase containing aromatic carboxylic acid is kept slightly higher than For the p-xylene extraction phase, the wastewater and p-xylene phases are contacted and mass-transferred in the membrane module in a countercurrent, co-current or fully mixed flow mode, and most of the aromatic carboxylic acids in the wastewater are extracted and carried out by the p-xylene extractant;

[0050] Step c: tr...

Embodiment 2

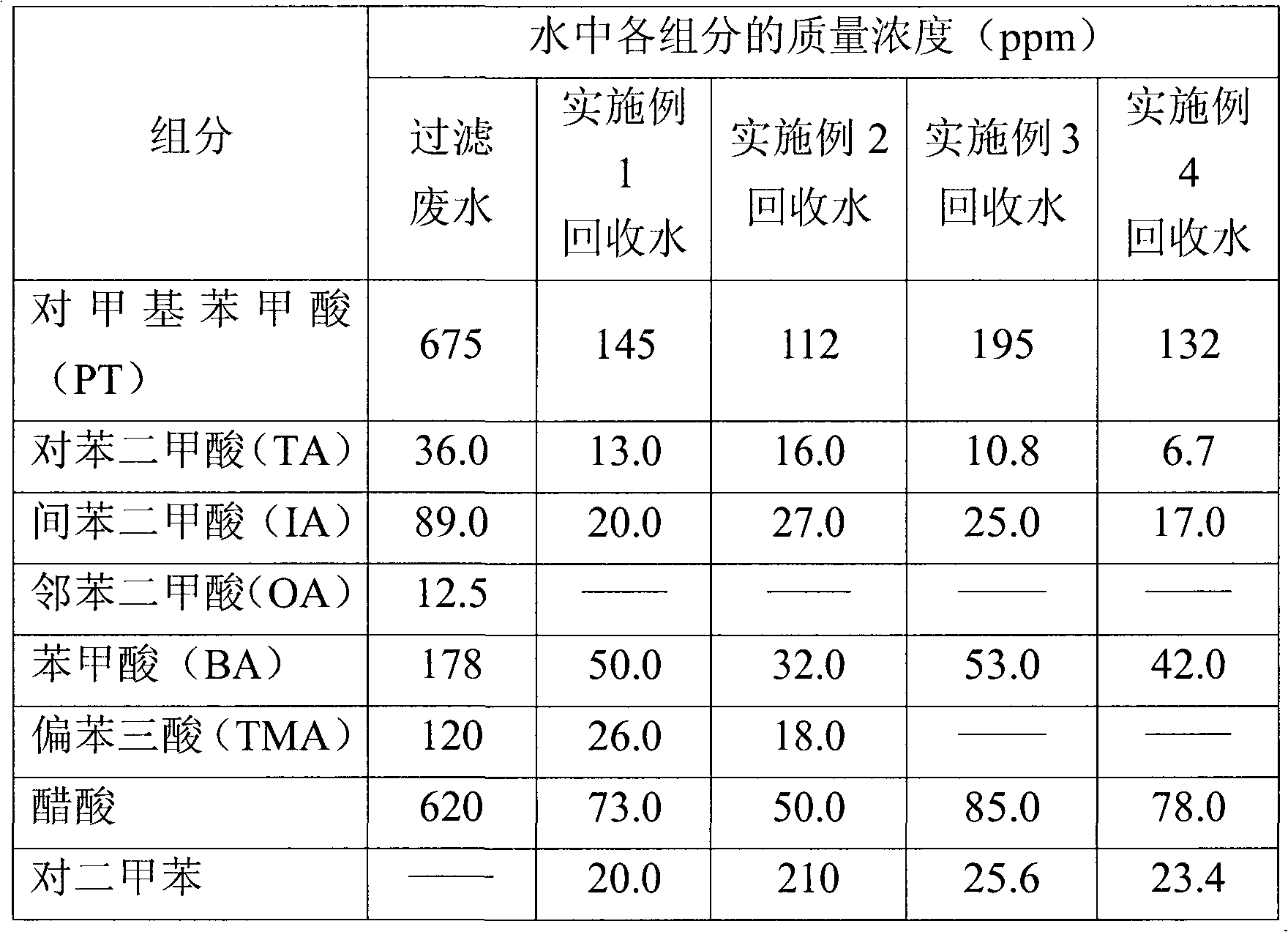

[0062] A method for recycling purified terephthalic acid production wastewater, using the same purified wastewater as in Example 1 to carry out a common liquid-liquid extraction experiment. Take 300ml of waste water and 100ml of p-xylene (PX) in a 500ml separating funnel, vibrate vigorously and mix them, let stand in a constant temperature water bath at 40°C for 24 hours, take the lower layer of water for HPLC and GC analysis, and compare the analysis results shown in Table II.

Embodiment 3

[0064] A method for recycling purified terephthalic acid production wastewater, using the same purified wastewater as in Example 1 to perform a similar membrane extraction experiment. Keep all the operating conditions the same as in Example 1, except that the p-xylene (PX) extraction phase used contains 2000ppm p-toluic acid. After 4 hours of continuous operation, the outlet water of the membrane extraction module was taken for HPLC and GC analysis, and the comparison of the analysis results is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com