Natural volcanic ash autoclaved aerated concrete block and preparation method thereof

A technology of natural volcanic ash and concrete blocks, applied in clay preparation devices, mixing operation control, chemical instruments and methods, etc., can solve problems such as high damage rate, increased cost of using blocks, and affecting the use of new wall materials, etc. Achieve the effect of low density, resource consumption saving and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

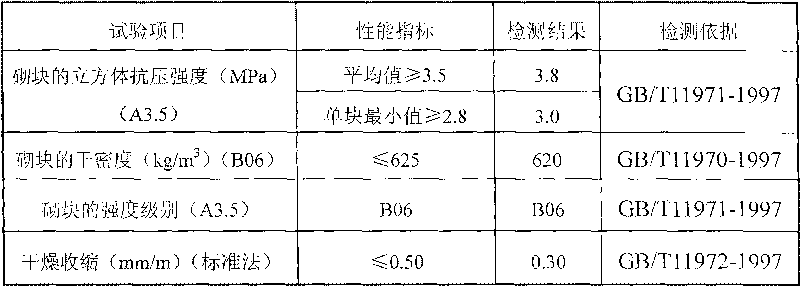

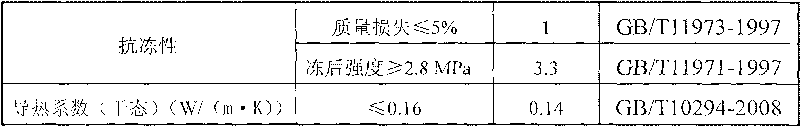

[0025] Example 1 To prepare a natural pozzolan autoclaved aerated concrete block with a total mass of 1000 kg, 500 kg of natural pozzolan, 40 kg of cement, 200 kg of quicklime, 9.6 kg of building gypsum, 0.4 kg of aluminum powder paste and 250 kg of water are required.

[0026] Among them: natural volcanic ash is natural volcanic ash produced in the Dangjin Mountain area of Akesai County, Gansu Province, and its main components are: SiO 2 74-77%: Al 2 o 3 11-15%; the cement is 42.5-grade ordinary Portland cement produced by Yongdeng Qilianshan Cement Co., Ltd., and its performance index meets the requirements of GB175-1999 "Portland Cement, Ordinary Portland Cement"; The performance of quicklime for construction produced in Dangjinshan area of Kesai County meets the requirements of the industry standard "Quicklime for Silicate Products" (JC / T621-1996); the construction gypsum is desulfurized gypsum from Gansu Jingyuan Power Plant, and its performance meets the national st...

Embodiment 2

[0034] Example 2 To prepare natural pozzolan autoclaved aerated concrete blocks with a total mass of 1000 kg, 550 kg of natural pozzolan, 50 kg of cement, 160 kg of quicklime, 19.7 kg of building gypsum, 0.3 kg of aluminum powder paste and 220 kg of water are required.

[0035] Wherein raw material and preparation method are with embodiment 1.

Embodiment 3

[0036] Example 3 To prepare natural pozzolan autoclaved aerated concrete blocks with a total mass of 1000 kg, 600 kg of natural pozzolan, 45 kg of cement, 150 kg of quicklime, 4.7 kg of building gypsum, 0.3 kg of aluminum powder paste and 200 kg of water are required.

[0037] Wherein raw material and preparation method are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com