Devices and methods to provide air circulation space proximate building insulation

a technology of air circulation space and building insulation, which is applied in the direction of building repairs, heating types, applications, etc., can solve the problems of leaking water infiltration through the outer skin of the structure into the building frame and insulation, and the space cannot be maintained without a ventilating device,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

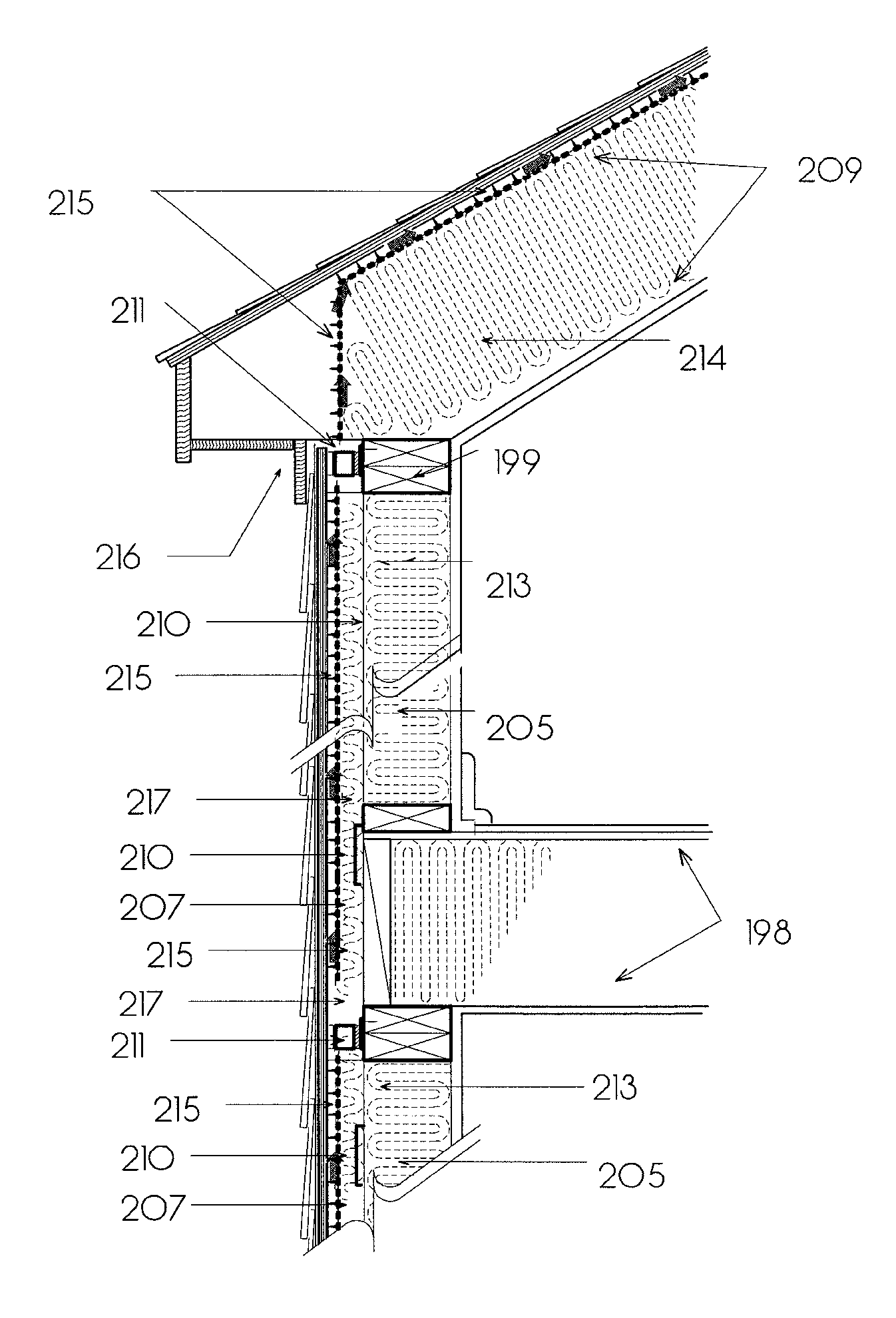

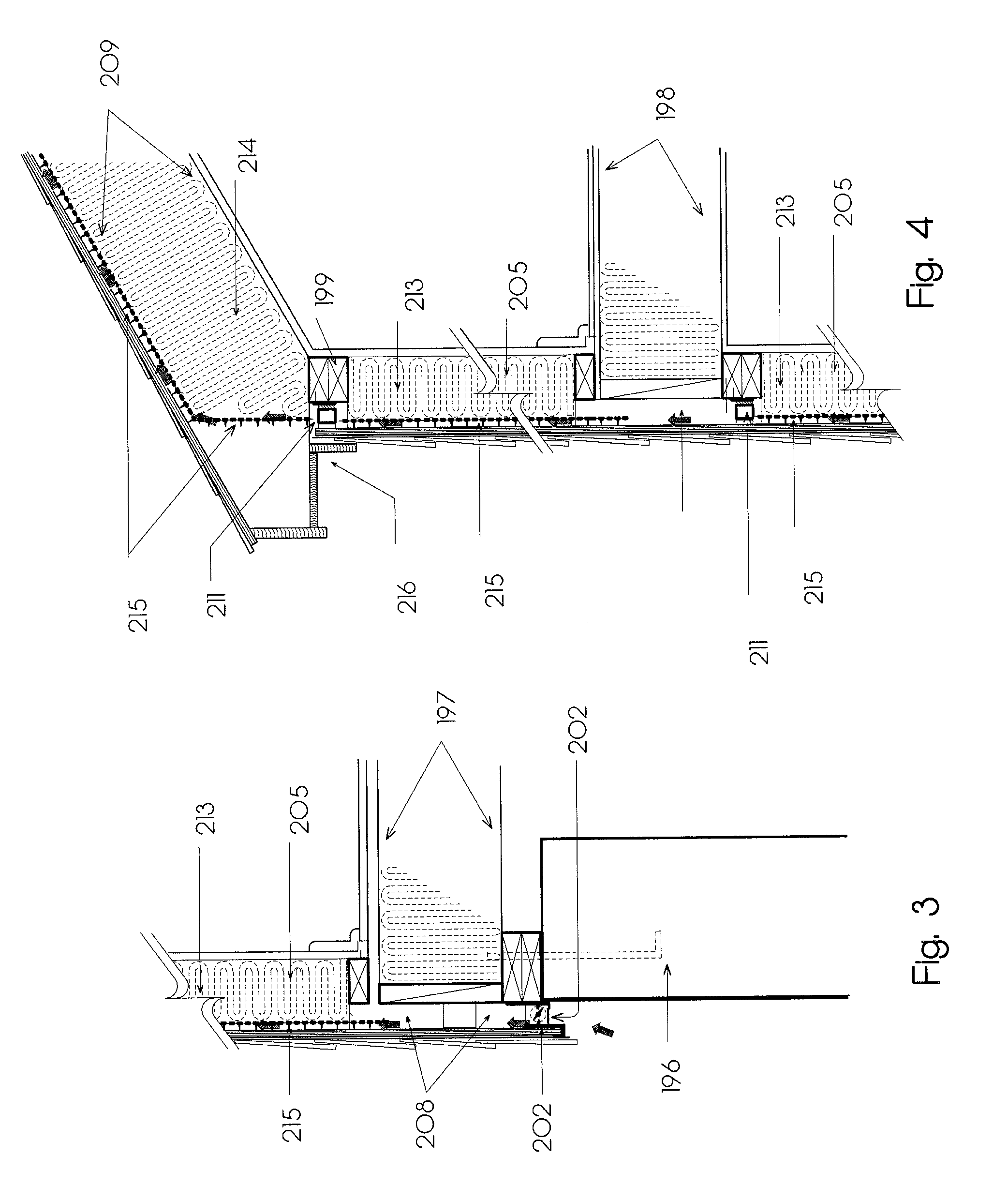

[0043]Reference will now be made in detail to the present preferred embodiments of the disclosure, examples of which are illustrated in the accompanying drawings. The method and corresponding steps of the disclosed embodiments will be described in conjunction with the detailed description of the system.

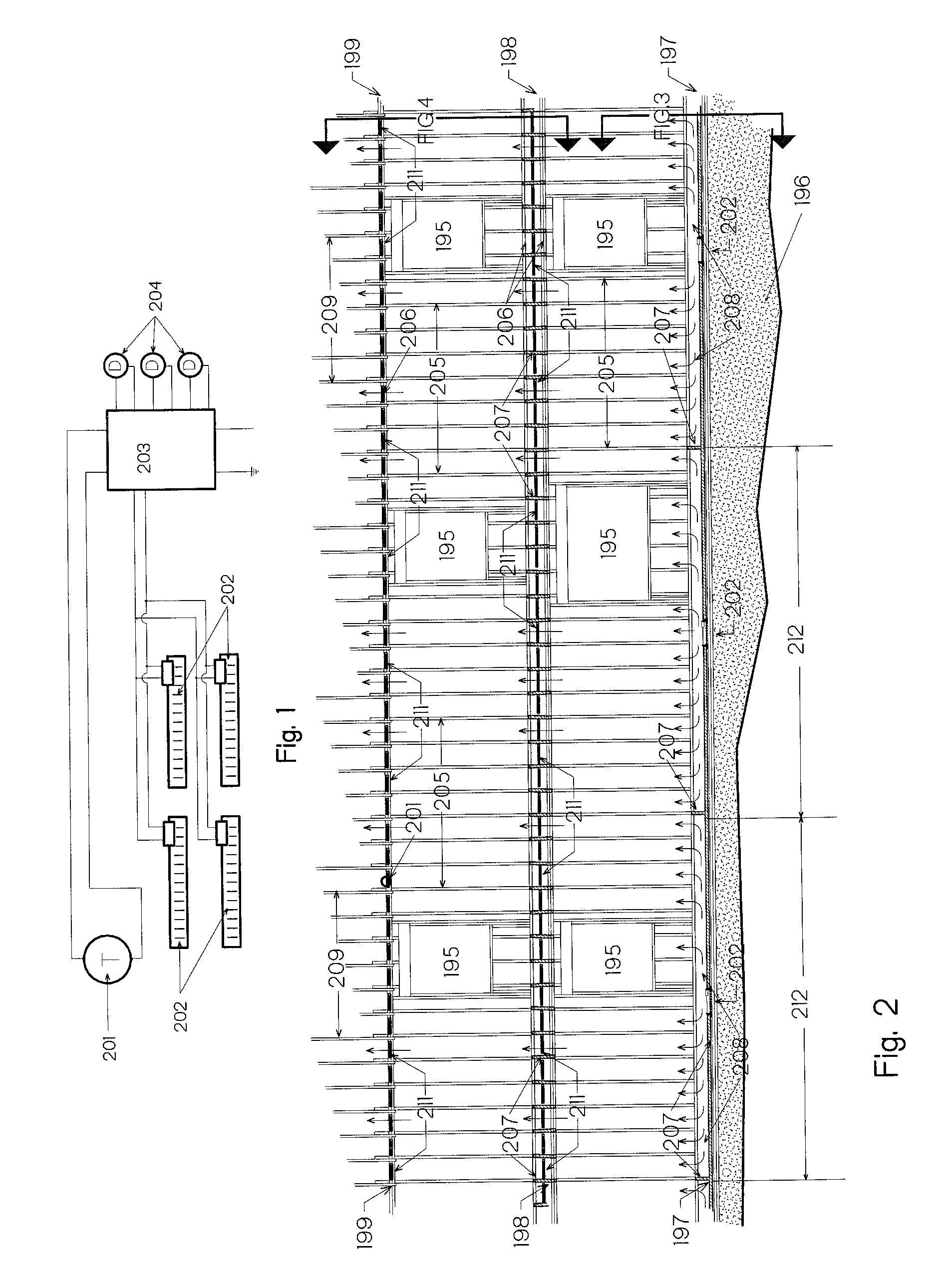

[0044]For purposes of illustration, and not limitation, FIG. 1 is a schematic diagram of an exemplary low voltage control system to control air intake to insulated framing bays. A temperature sensor switch 201 is illustrated which can be located on a roof soffit protected from the elements and direct sunlight. It is preferable to shut-off power to the intake solenoids, 202, when ambient outside temperatures drop below a preset temperature such as 40 degrees F. Closing the cavities to cold air is desirable as cold air is naturally dry, and a static air space would add to the insulating values of the exterior wall assemblies. 203 indicates a central low voltage control unit which ties t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com