Novel composite building energy-saving building block and manufacturing method thereof

A technology of building energy saving and production method, which is applied in building materials, ceramic products, other household appliances, etc., can solve the problems of failing to meet energy saving standards, unfavorable fire protection, and burying hidden fire hazards, and achieves good thermal insulation effect and no Keep fire hazard and good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

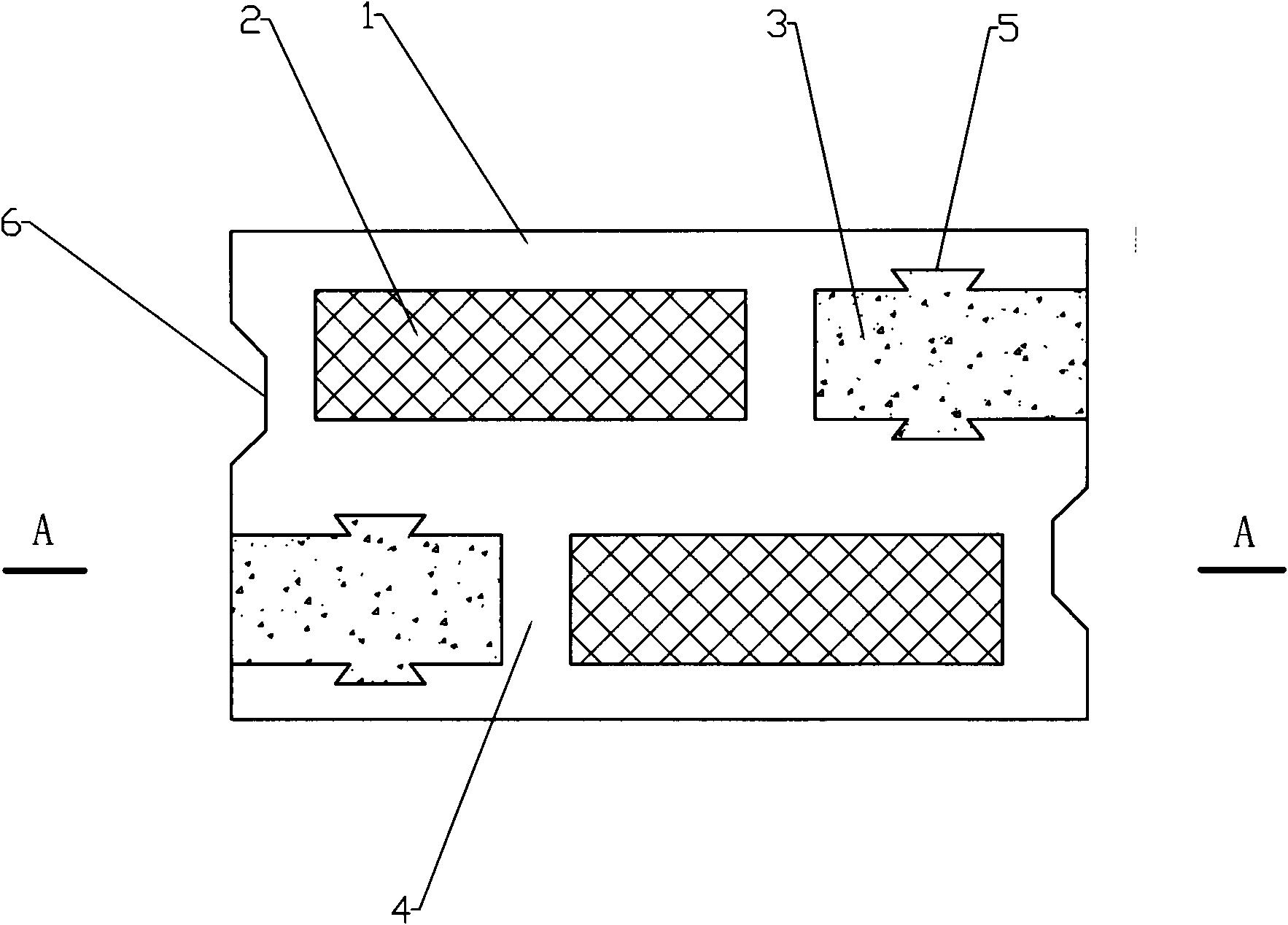

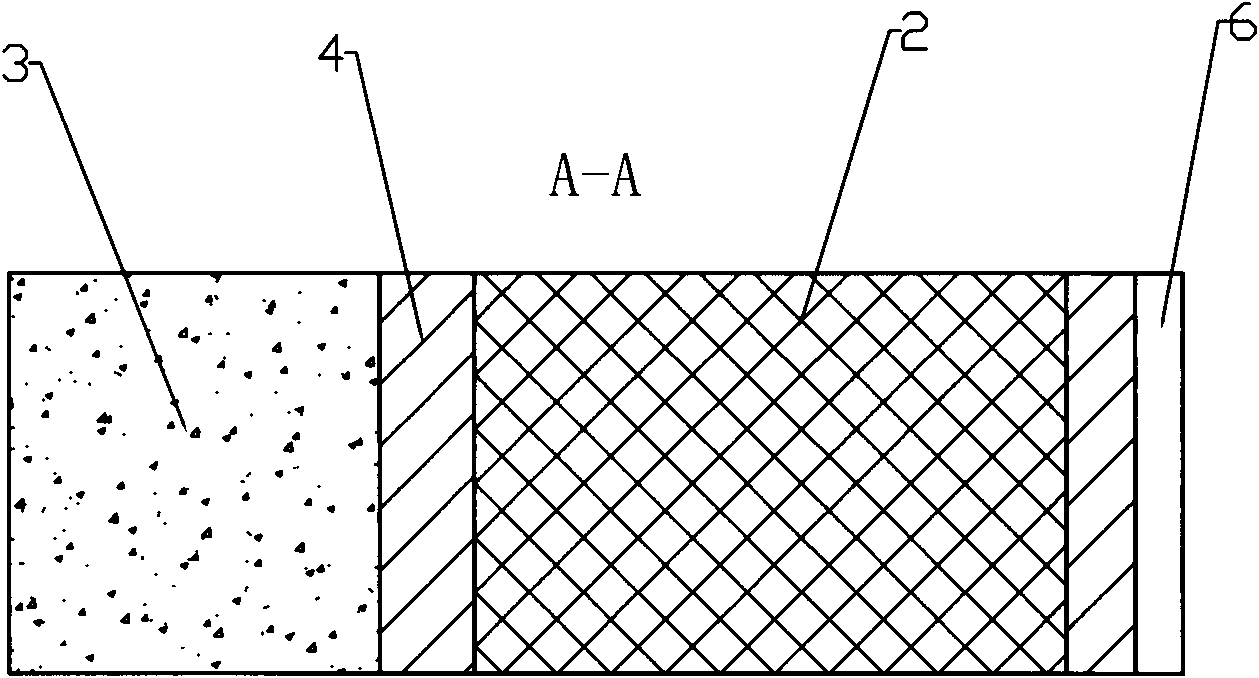

[0022] Such as figure 1 and figure 2 As shown, the present invention is a new energy-saving building block for composite buildings, which includes a microporous lightweight concrete block 1, and two rows of hole slots are vertically staggered on the block body 1, and each row of hole slots is divided into two holes by a rib 4, One is a closed hole, and the other is an open hole. A bolt riveting hole groove 5 is arranged in the open hole, an adiabatic molded polystyrene board 2 is arranged in the closed hole, and a vermiculite board 3 is arranged in the open hole. The joint end is provided with a tenon and groove 6.

[0023] The manufacturing method of the novel composite building energy-saving building block of the present invention: first prepare the vermiculite board for standby, and its manufacturing method is: mix 85% of vermiculite powder, 13% of phenolic resin, 2% of organic silicon emulsion, put into the mold and extrude, select and cut the heat insulation The molded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com