Vacuum insulation panel suitable for field of building

A technology in the field of vacuum insulation panels, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of short life, physical and chemical damage, poor fire resistance, etc. Excellent fire performance, excellent heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below according to example the present invention is further described:

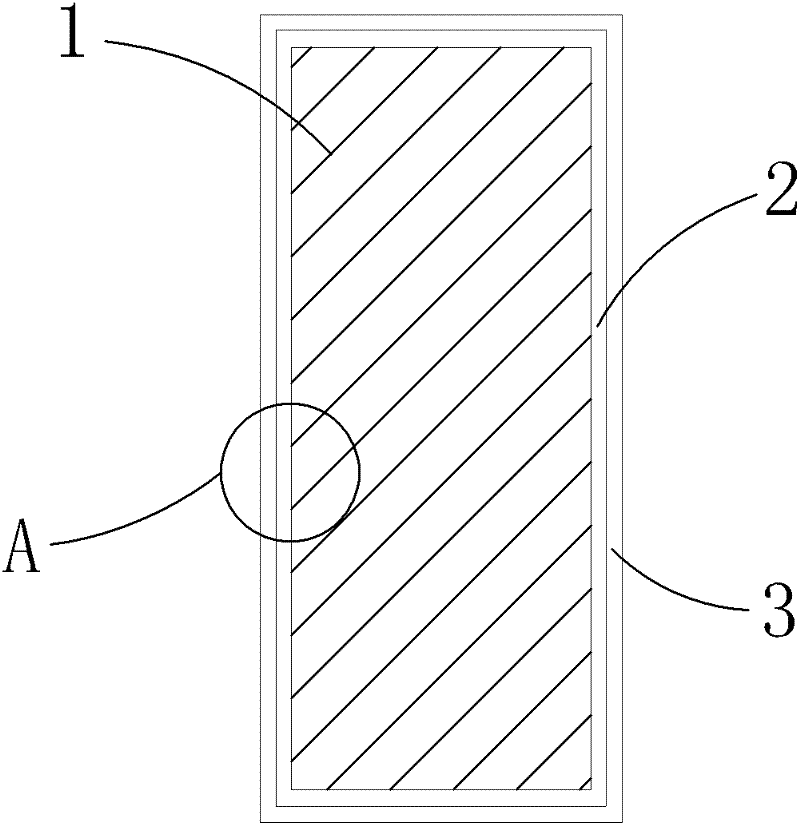

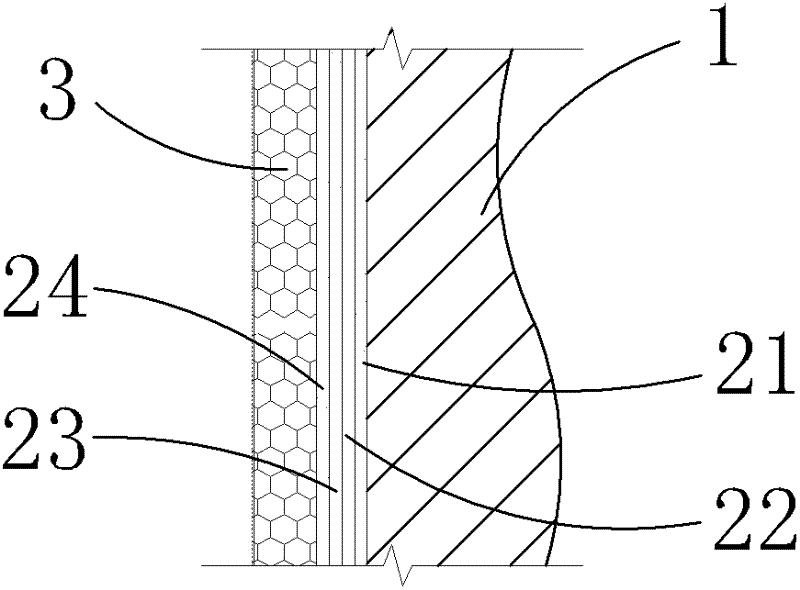

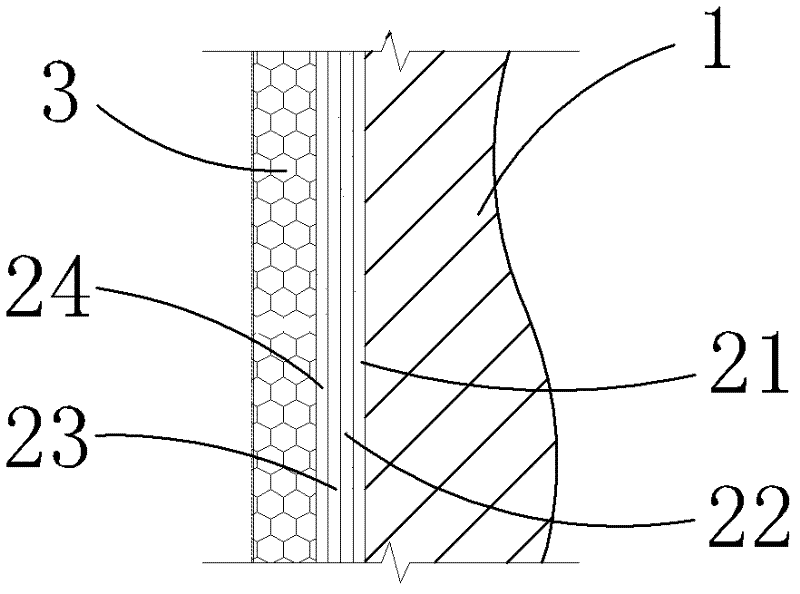

[0020] like figure 1 and figure 2 As shown, a vacuum insulation panel suitable for the construction field includes a core material 1, a high-performance barrier film 2 and an inorganic protective layer 3, the high-performance barrier film 2 is coated on the outer surface of the core material 1, and the inorganic protective layer 3 coated on the outer surface of the high performance barrier film 2.

[0021] The core material 1 can generally adopt perlite, turpentine, obsidian, pearlite, or diatomite with a particle size of 50-2000, and the core material 1 adopts perlite, turpentine, Obsidian, pearlite, diatomaceous earth or wollastonite.

[0022] Its main component is silicon dioxide containing 50-90%, and the rest is inorganic impurities of Al2O3, Fe2O3, CaO, MgO, K2O, Na2O, or P2O5.

[0023] like figure 2 As shown, the high-performance barrier film 2 is successively composed of polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com