Advanced flame-retardant polyurethane spray foam material and preparation method thereof

A technology for spraying foam and polyurethane, applied in the field of polyurethane foam, can solve problems such as unfavorable large-scale production and use of foam, inability to meet the needs of high flame retardant use, foam shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

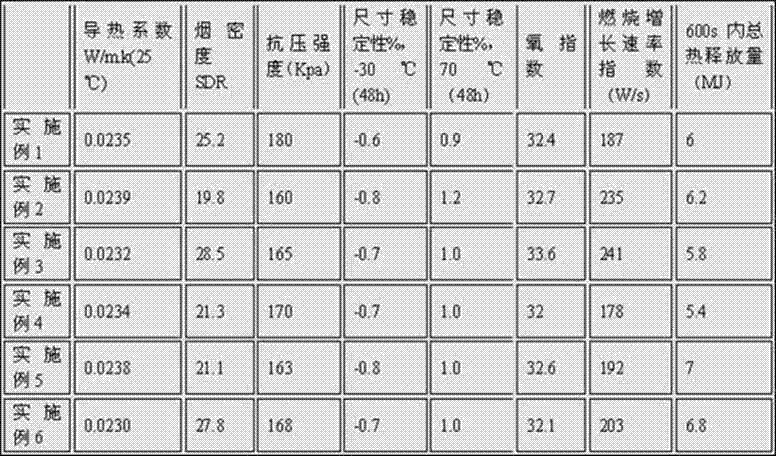

Examples

Embodiment Construction

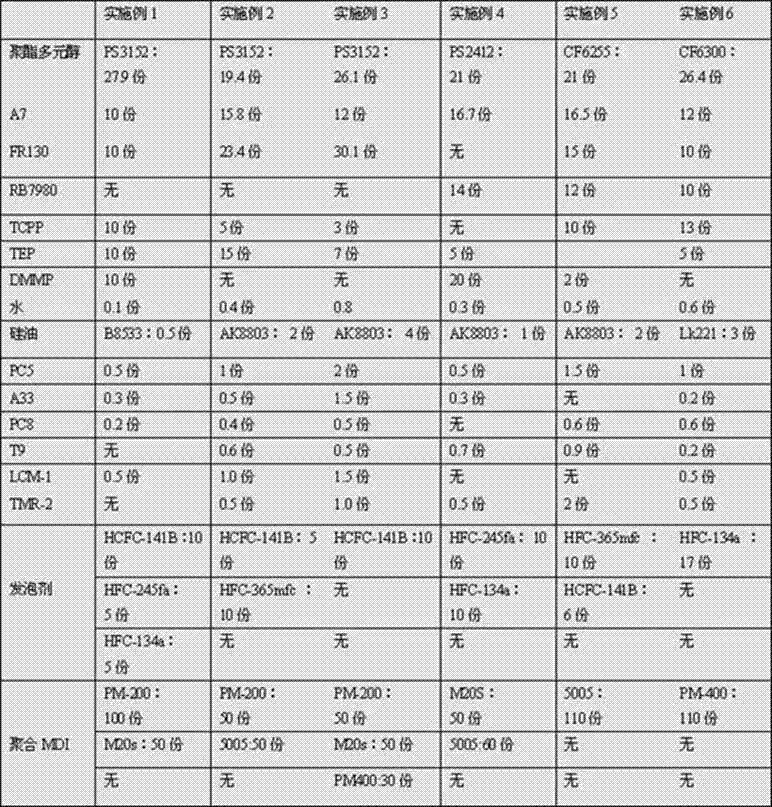

[0044] The following examples will further illustrate the method provided by the present invention, but the present invention is not limited to the listed examples, and should also include any other known changes within the claimed scope of the present invention.

[0045] Embodiment uses raw material:

[0046] Polyester polyols: the grades of polyester polyols of Nanjing Kangsude Chemical Co., Ltd. are CF6300 and CF6255, and the grades of polyester polyols of Stepan Company are PS3152 and PS2412

[0047] Mannicene polyether polyol: brand A7 of Ningbo Wanhua Rongwei Polyurethane Co., Ltd., with a nitrogen content of 4.6%.

[0048] Bromine-phosphorus composite flame-retardant polyether polyol: Wanol FR130 from Ningbo Wanhua Rongwei Polyurethane Co., Ltd., with a bromine content of 30% and a phosphorus content of 6%, RB7980 from Albemarle in the United States, with a bromine content of 36% and a phosphorus content of 1.9%

[0049] Flame retardant: TCPP, TEP, DMMP

[0050] Water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat release | aaaaa | aaaaa |

| heat release | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com