Patents

Literature

51 results about "Polyfunctional aziridine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink-jet recording medium with an opaque or semi-opaque layer coated thereon, method for recording an image, and a recorded medium with at least one layer rendered clear or semi-opaque

InactiveUS20040109958A1Extended drying timeAvoid excessive adhesionLayered productsCoatingsAziridineCross linker

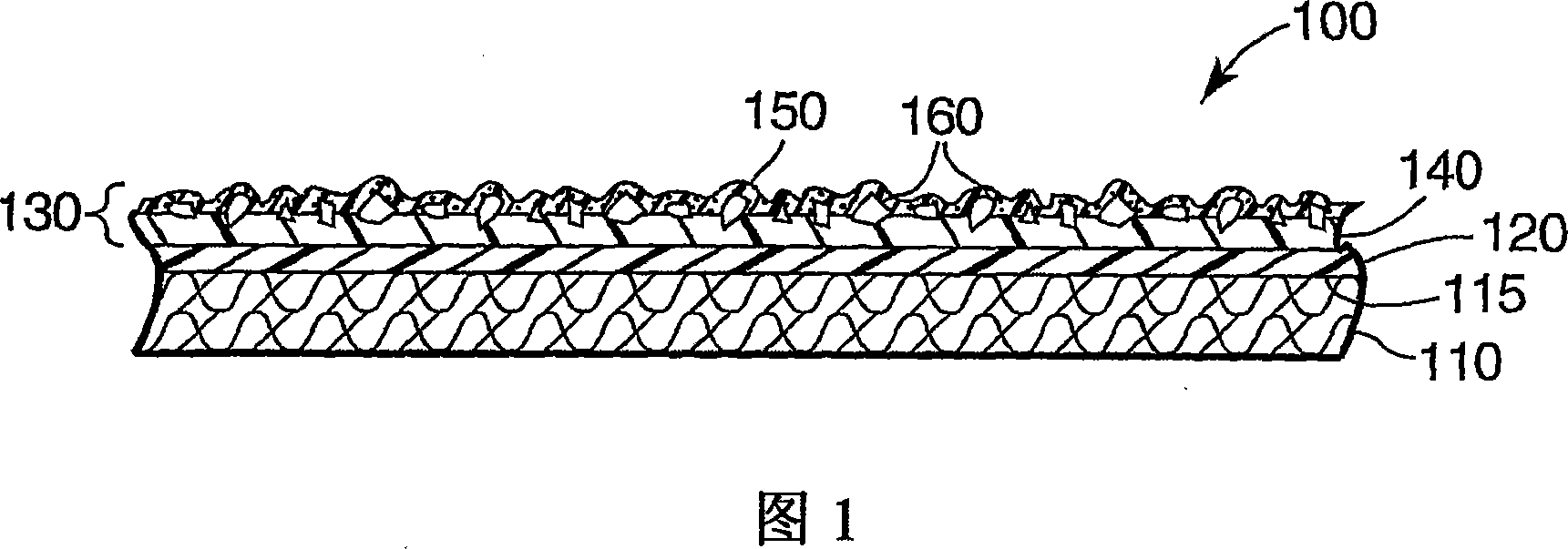

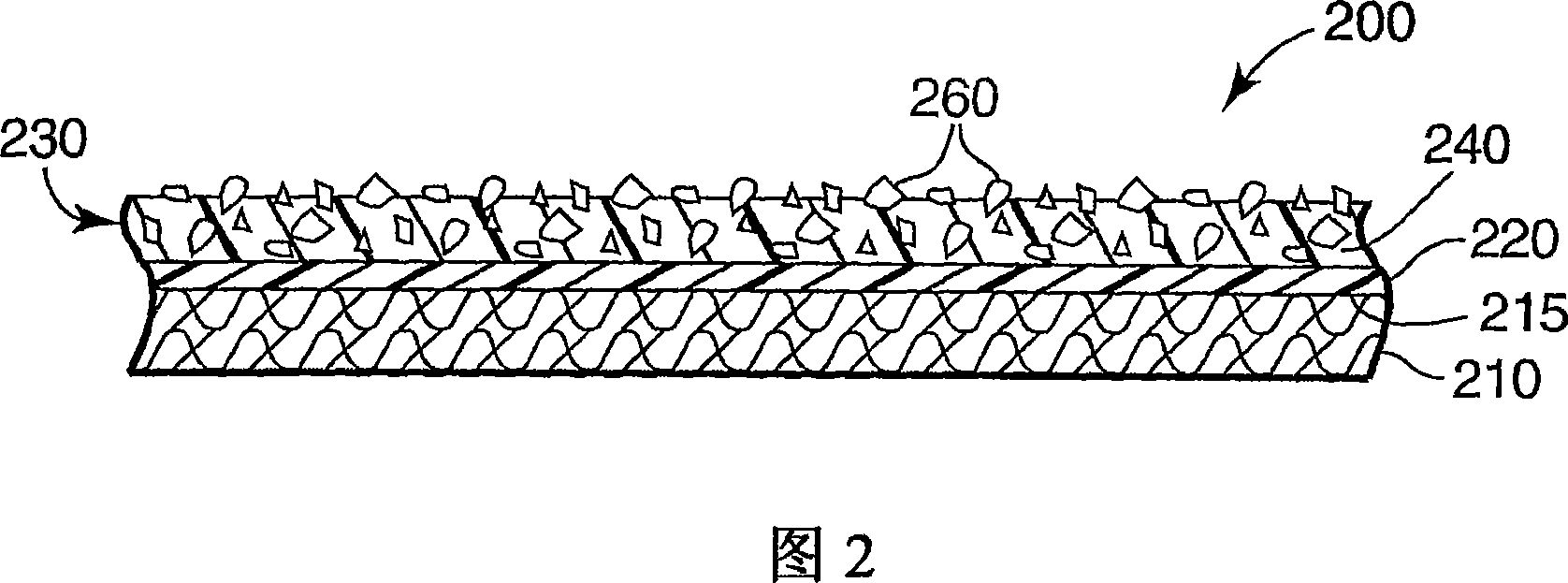

The present invention features a multi-layer ink-jet recording medium, suitable for recording images with dye and pigmented inks and thereby providing light-emitting, reflective, glossy, metallic-looking or holographic images, comprising a substrate coated with at least two layers comprising: (a) a first transparent ink-receptive layer comprising a polymeric binder and a cross-linker and optionally having a plasticizer and pigment particles such as alumina and silica coated over the substrate, wherein the cross-linker comprises and azetidinium polymer or a salt thereof, and / or a polyfunctinal aziridine or a salt thereof or a polyfunctional oxazoline or a salt thereof; and (b) a second ink-receptive layer comprising an opaque or semi-opaque coating composition, wherein the opaque or semi-opaque coating composition is capable of accepting a printed image and thereby becoming semi transparent or clearly transparent from application of ink-jet printing ink or similar inks, while presenting a light-emitting, reflective, glossy, metallic-looking or holographic image of high clarity and quality, wherein said first layer is located between said second layer and the substrate in said recording medium and the first and second layers are chemically coupled.

Owner:PIXTERRA

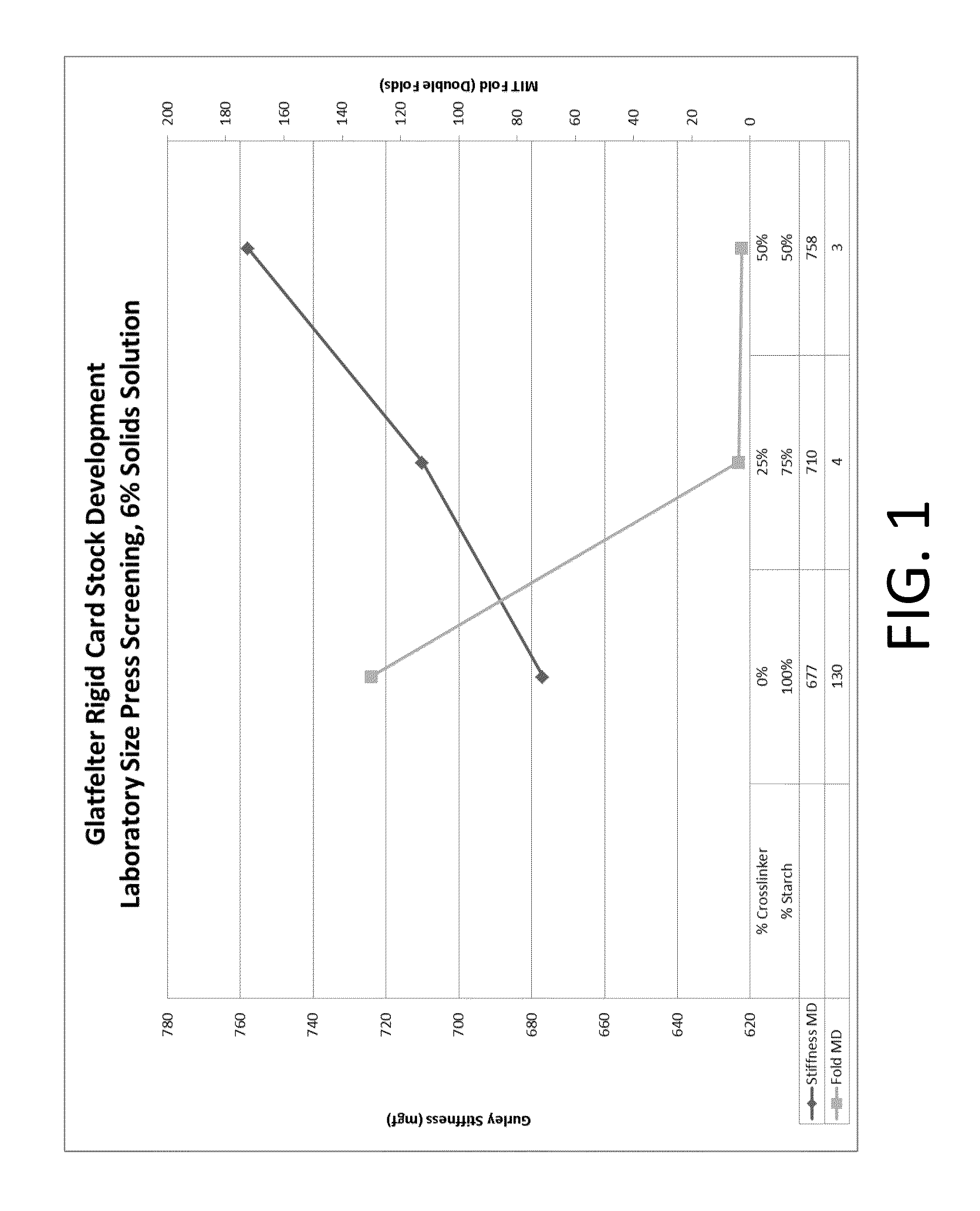

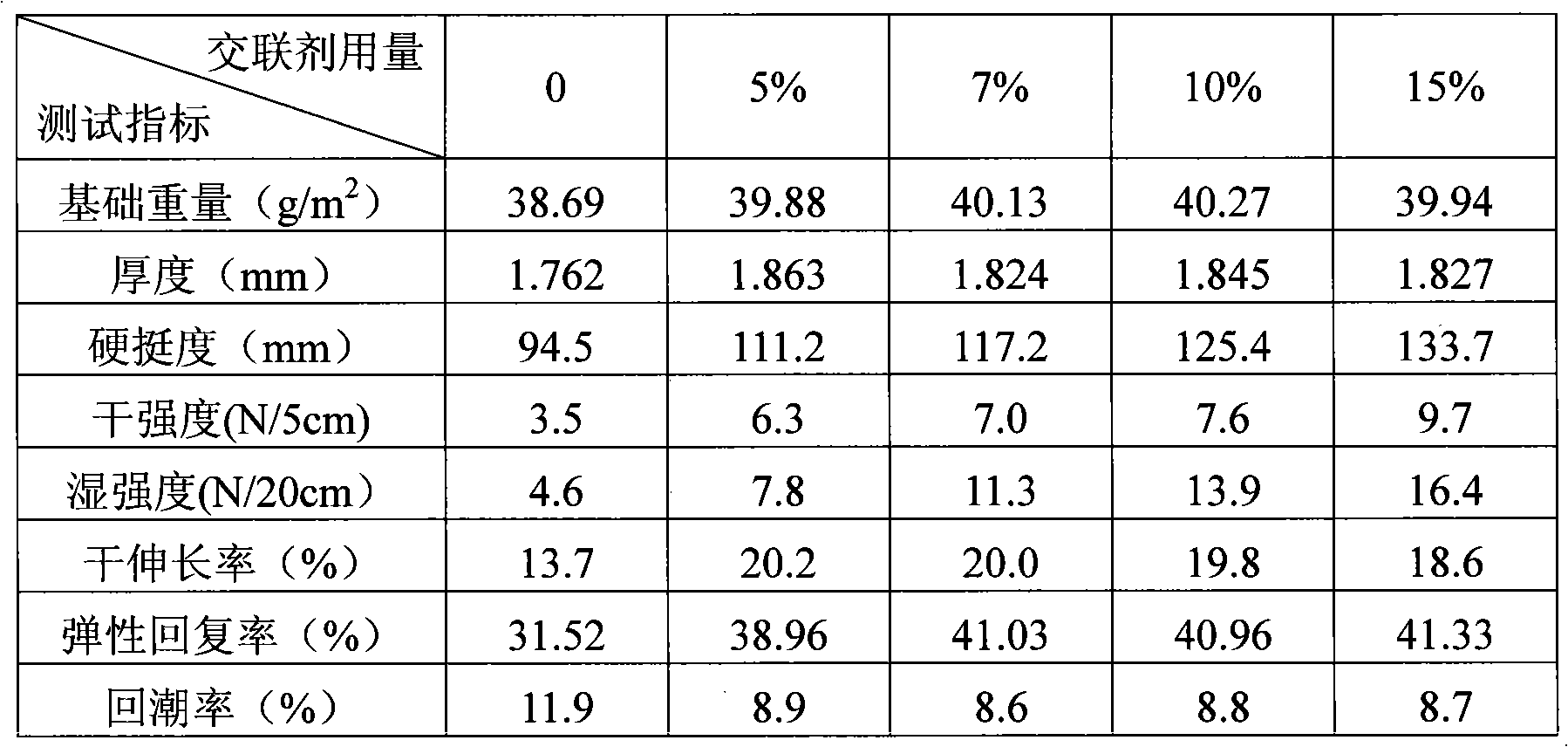

Process for making a stiffened paper

ActiveUS9133583B2Improve mechanical propertiesIncreased stiffness and rigidityNatural cellulose pulp/paperSpecial paperPapermakingSlurry

Owner:PIXELLE SPECIALTY SOLUTIONS LLC +1

Process for making a stiffened paper

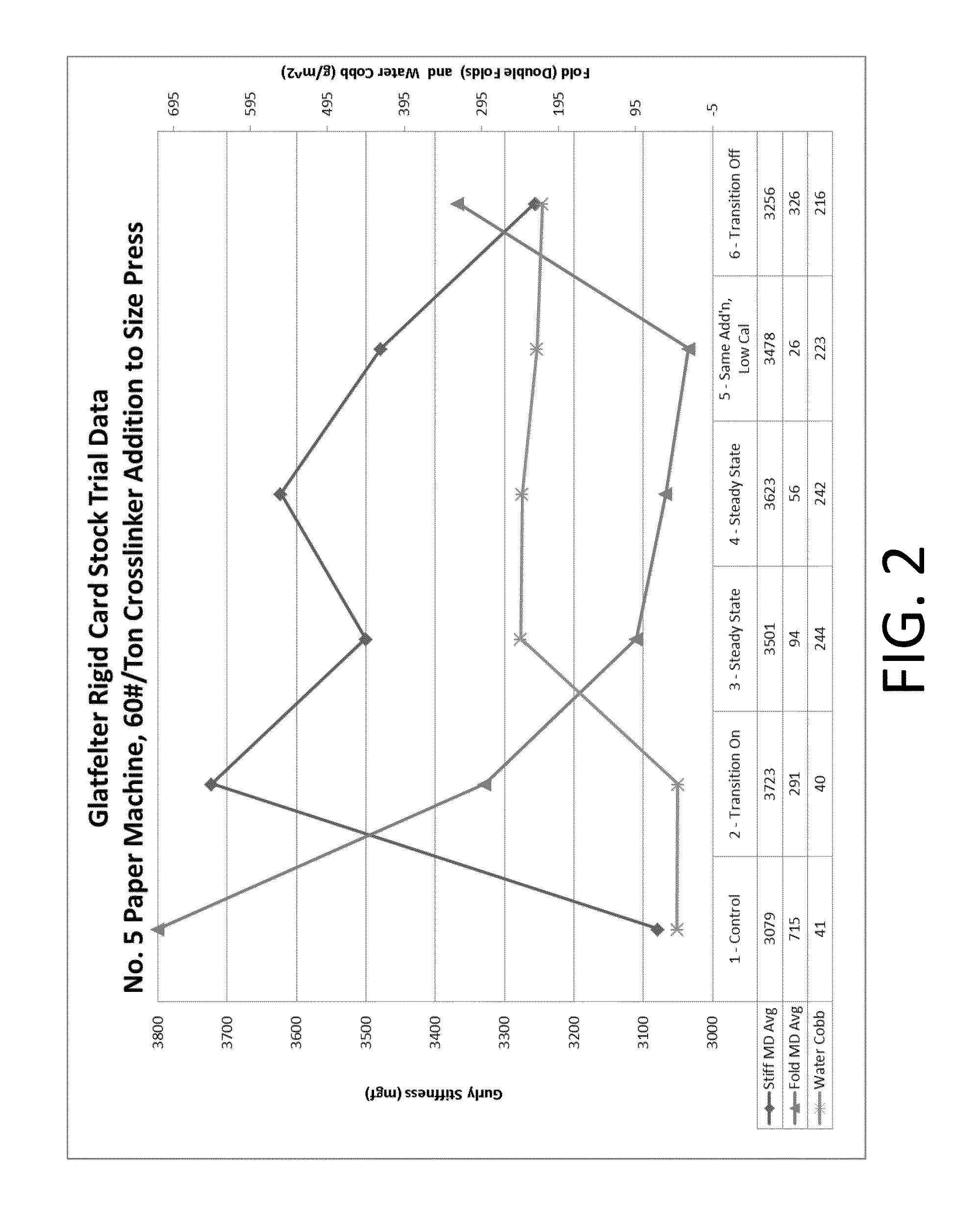

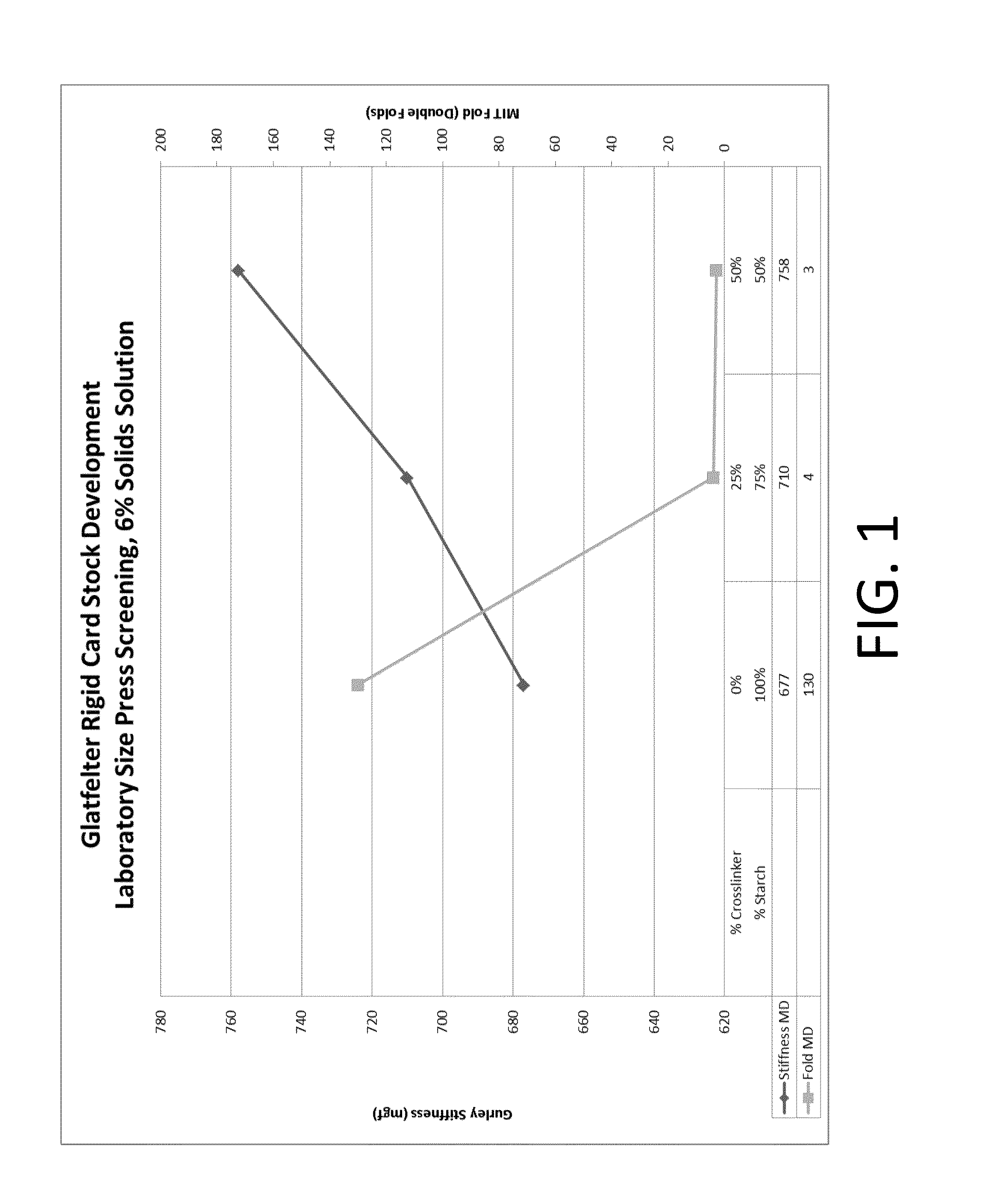

ActiveUS20130284388A1Improve mechanical propertiesIncrease stiffnessNatural cellulose pulp/paperSpecial paperPapermakingSlurry

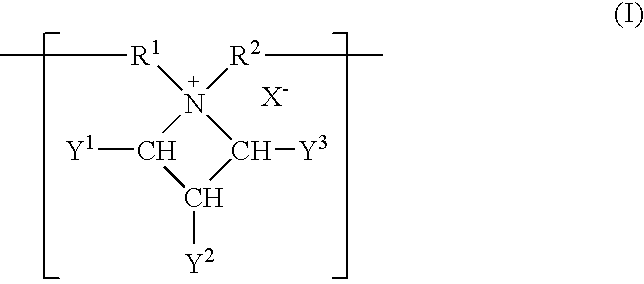

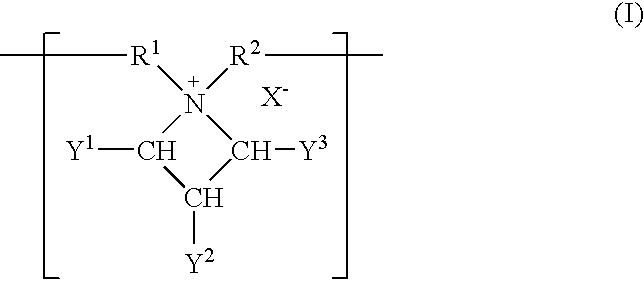

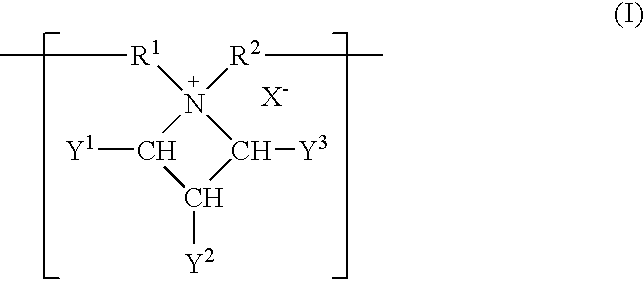

A process for making a stiffened and rigid paper includes preparing a pulp slurry consisting essentially of water, a cellulosic pulp, a crosslinker, and a starch, and optionally a binder; draining the liquid from the pulp slurry to form a web; and drying the web. Alternatively, a process for making a stiffened and rigid paper includes the step of adding at least one crosslinker at one or more locations, such as at the wet-end, dry-end, or at both ends of the papermaking process. Suitable crosslinkers include a glyoxal-containing crosslinker, a gluteraldehyde, a polyfunctional aziridine, a zirconium-containing crosslinker, a titanium-containing crosslinker, and an epichlorohydrin, and mixtures thereof. When a binder is employed, it can be added either in the dry or wet form. Provided is a neutral or alkaline process to produce a paper product having the improved mechanical properties of a laminated product in the Z-direction, without a lamination step.

Owner:PIXELLE SPECIALTY SOLUTIONS LLC +1

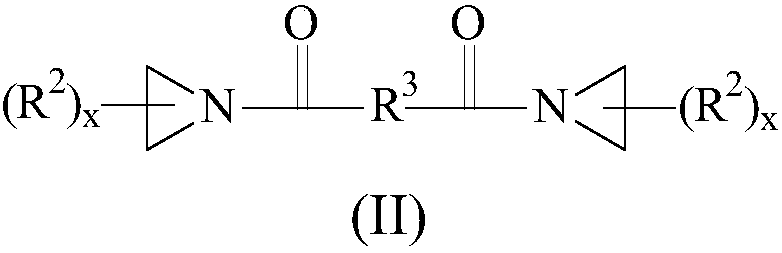

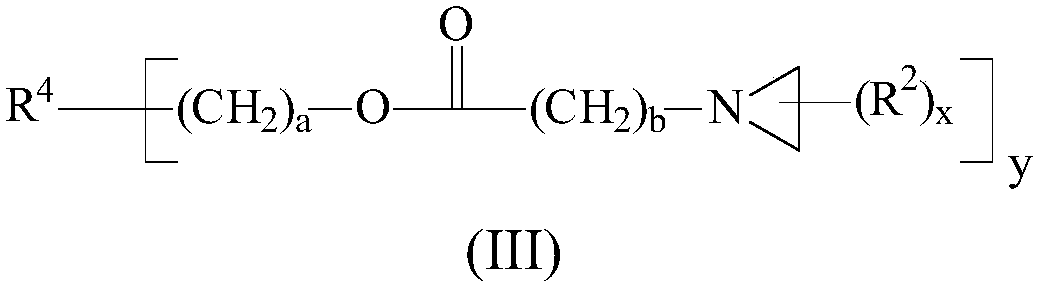

Ambient temperature rapid self-polymerization compositions of high cross-linked or linear type beta-amino-ester alternative co-polymers and their applications

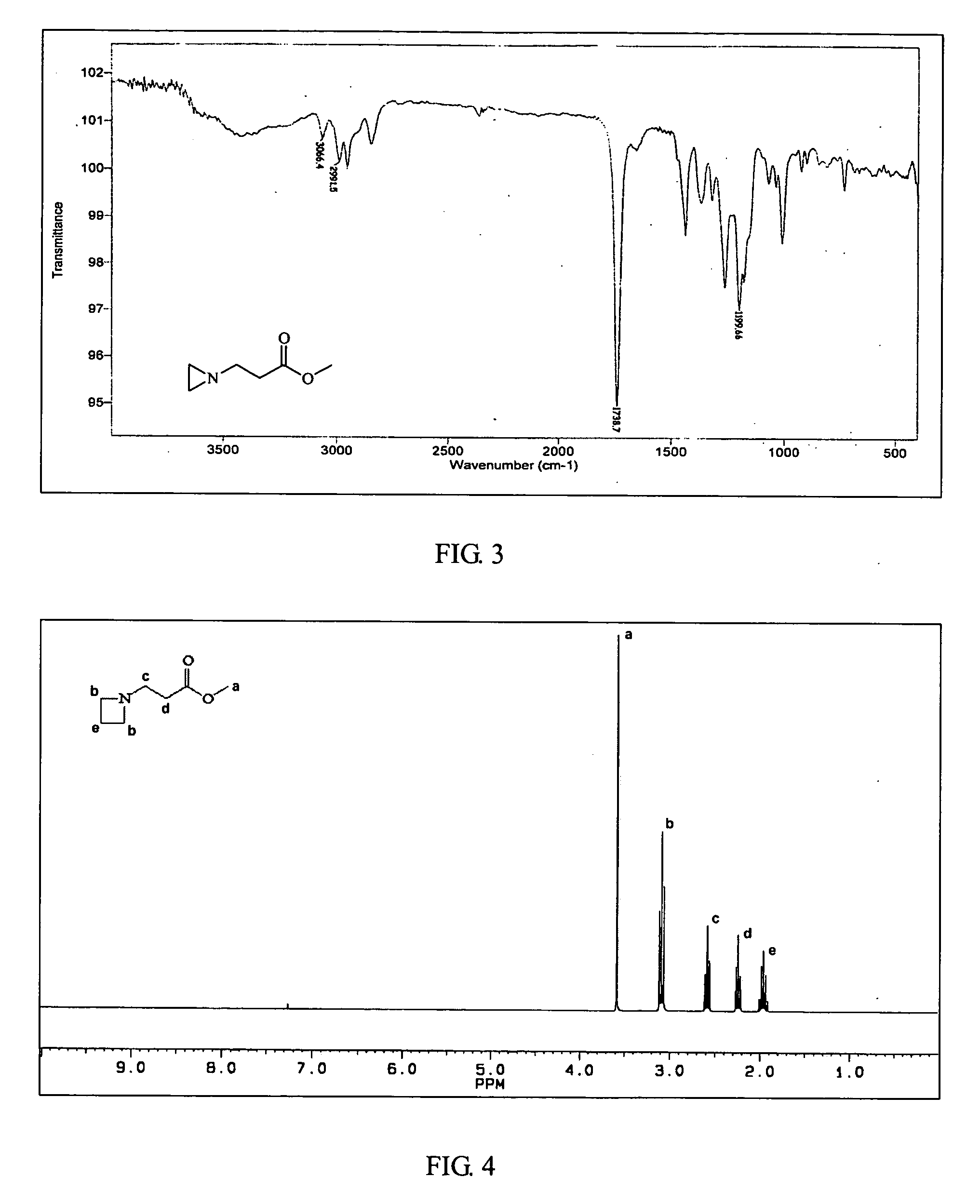

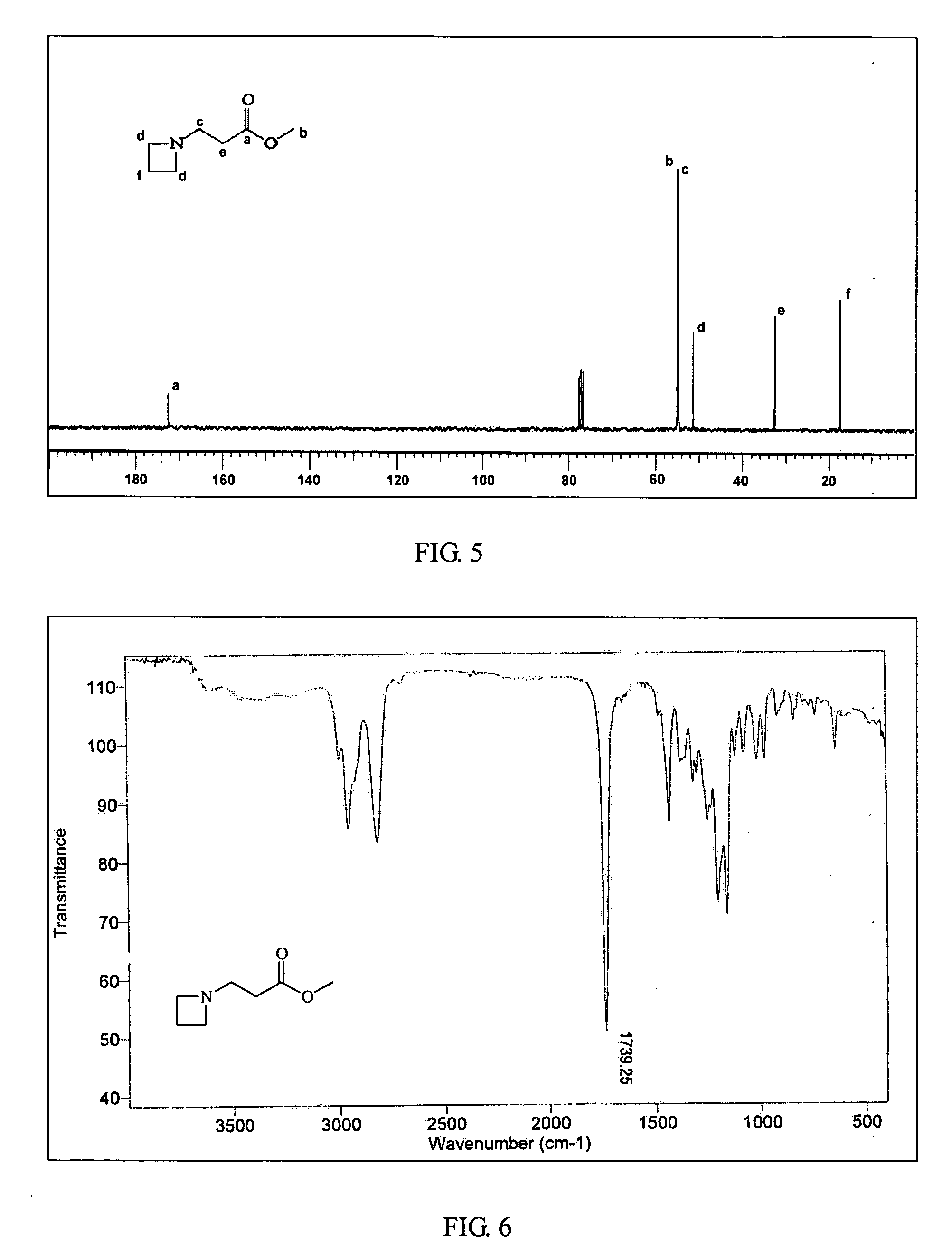

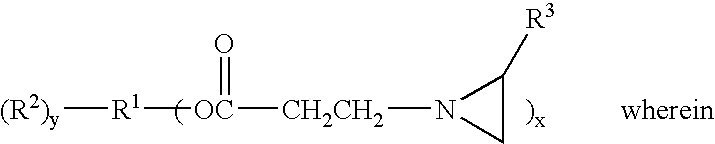

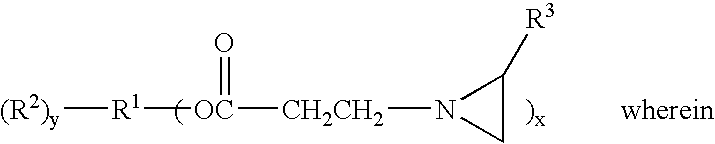

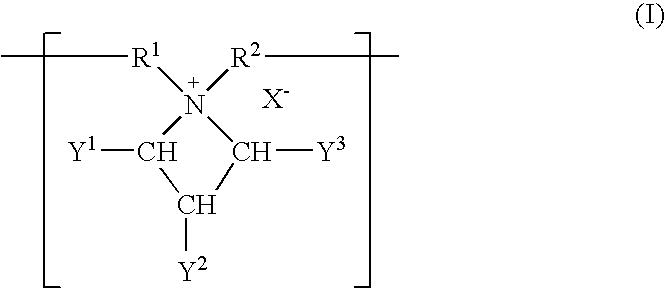

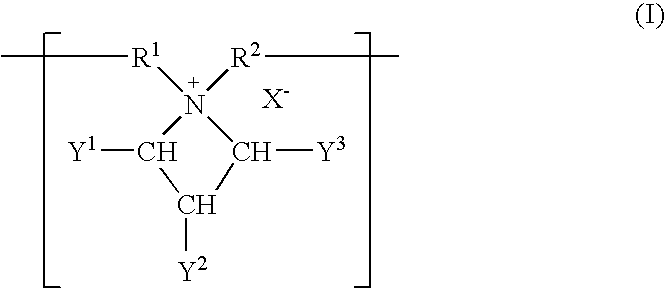

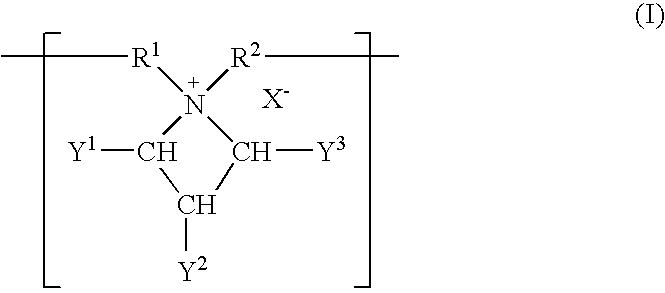

InactiveUS20070299211A1Self-polymerization can be very rapidSelf-polymerization rate can be controlledCross-linkAmino esters

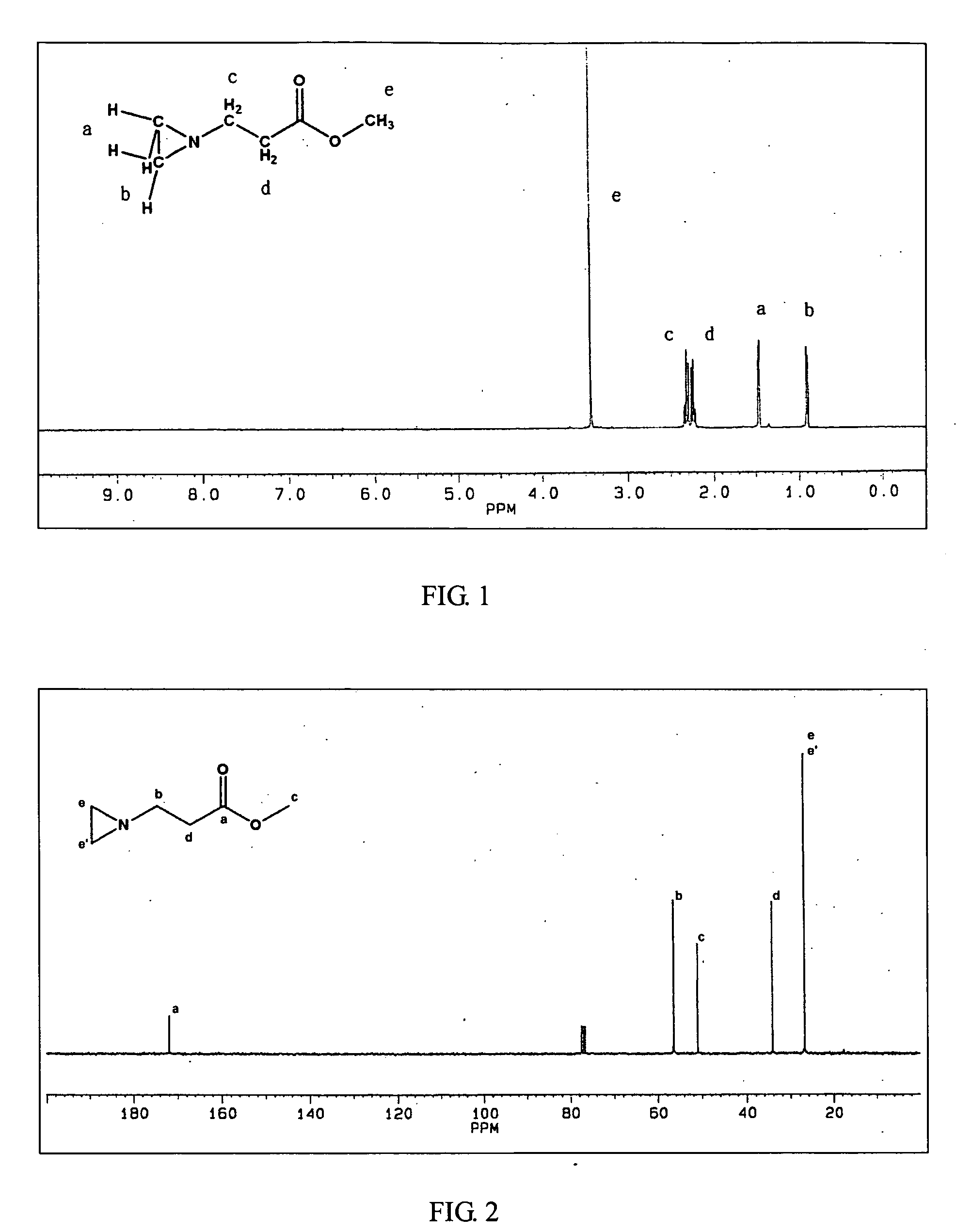

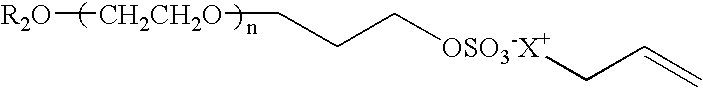

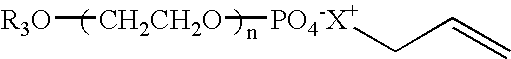

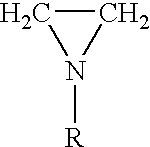

Self-polymerization of mono-aziridine (or azetidine) and multi-aziridine (or azetidine) containing compounds with vinyl group containing organic acid, such as acrylic acid (AA), 2-methylenesuccinic acid, 2,3-dimethylenesuccinic acid and etc, at ambient temperature results in the new type of cross-linked and linear type copolymers, respectively.The polymerization of multi-functional aziridine (or azetidine) containing compounds with vinyl group containing organic acid results in the formation of high cross-linked polymers. The self-polymerization takes place at ambient temperature and the resultants, cross-linked polymeric networked materials, are solvent insoluble and potential for adhesive, composite matrix and other applications. These insoluble materials are hydrolyzed in an acidic or basic condition to form the water soluble β-amino acids.A linear poly(β-aminoester) is obtained from the self-polymerization of vinyl group containing organic acid with mono-aziridine (or azetidine) containing compound at ambient temperature. poly(β-aminoester) is applicable for gene transfer, controlled drug release and other applications. This self-polymerization process offers a convenient route for preparing poly(β-aminoesters).

Owner:TAMKANG UNIVERSITY

Pressure-sensitive adhesive containing acicular silica particles crosslinked with polyfunctional aziridines

InactiveUS20080200587A1Increase in overlap shear property of adhesiveImprove clippingNanostructure manufactureEster polymer adhesivesSilica particleMeth-

Owner:3M INNOVATIVE PROPERTIES CO

Ink-jet recording medium with an opaque or semi-opaque layer coated thereon, method for recording an image, and a recorded medium with at least one layer rendered clear or semi-opaque

InactiveUS6936316B2Avoid excessive adhesionExtended drying timeCoatingsThermographyAziridineCross linker

The present invention features a multi-layer ink-jet recording medium, suitable for recording images with dye and pigmented inks and thereby providing light-emitting, reflective, glossy, metallic-looking or holographic images, comprising a substrate coated with at least two layers comprising:(a) a first transparent ink-receptive layer comprising a polymeric binder and a cross-linker and optionally having a plasticizer and pigment particles such as alumina and silica coated over the substrate, wherein the cross-linker comprises and azetidinium polymer or a salt thereof, and / or a polyfunctinal aziridine or a salt thereof or a polyfunctional oxazoline or a salt thereof; and(b) a second ink-receptive layer comprising an opaque or semi-opaque coating composition, wherein the opaque or semi-opaque coating composition is capable of accepting a printed image and thereby becoming semi transparent or clearly transparent from application of ink-jet printing ink or similar inks, while presenting a light-emitting, reflective, glossy, metallic-looking or holographic image of high clarity and quality,wherein said first layer is located between said second layer and the substrate in said recording medium and the first and second layers are chemically coupled.

Owner:PIXTERRA

Pressure-sensitive adhesive containing acicular silica particles crosslinked with polyfunctional aziridines

Owner:3M INNOVATIVE PROPERTIES CO

Removable, water-whitening resistant pressure sensitive adhesives

Removable, water-whitening resistant pressure sensitive adhesive (PSA) comprising a crosslinked aqueous emulsion polymer comprising (a) at least one hydrophobic monomer; (b) at least about 2 wt. % of at least one hydrophilic monomer; and (c) at least about 5 wt. % of at least one partially hydrophilic monomer; wherein the crosslinked aqueous emulsion polymer is crosslinked with an effective amount of at least one polyfunctional aziridine crosslinker, and the wt. % of monomers (a), (b), and (c) are based on the total weight of monomers (a), (b), and (c).

Owner:CYTEC SURFACE SPECIALTIES INC

Waterborne antistatic coating and preparation method thereof

InactiveCN103305108AImprove antistatic performanceImprove water resistancePolyurea/polyurethane coatingsElectrically-conductive paintsAlcoholConductive polymer

The invention relates to a waterborne antistatic coating and preparation method thereof. The method comprises the following steps: slowly adding the water solution of carboxylated waterborne polyurethane resin in a water solution of a carboxylated waterborne conductive polymer system, uniformly stirring, adding a polyfunctional aziridine compound, stirring to uniformly mix the components to obtain the waterborne antistatic coating, wherein the content of the carboxylated waterborne conductive polymer system in the waterborne antistatic coating is 0.1-2.5wt%, the content of the carboxylated waterborne polyurethane resin is 2-28wt%, the content of the polyfunctional aziridine compound is 0.1-3wt%, and the rest is water. The waterborne antistatic coating is tightly combined with the surfaces of substrates such as plastic, glass, wood, round and the wall to form the antistatic paintcoat with good antistatic effect, good water resistance and alcohol resistance; the antistatic coating can be widely applied to the fields of film negative film package, electron component package, display protective film and electromagnetic shielding.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

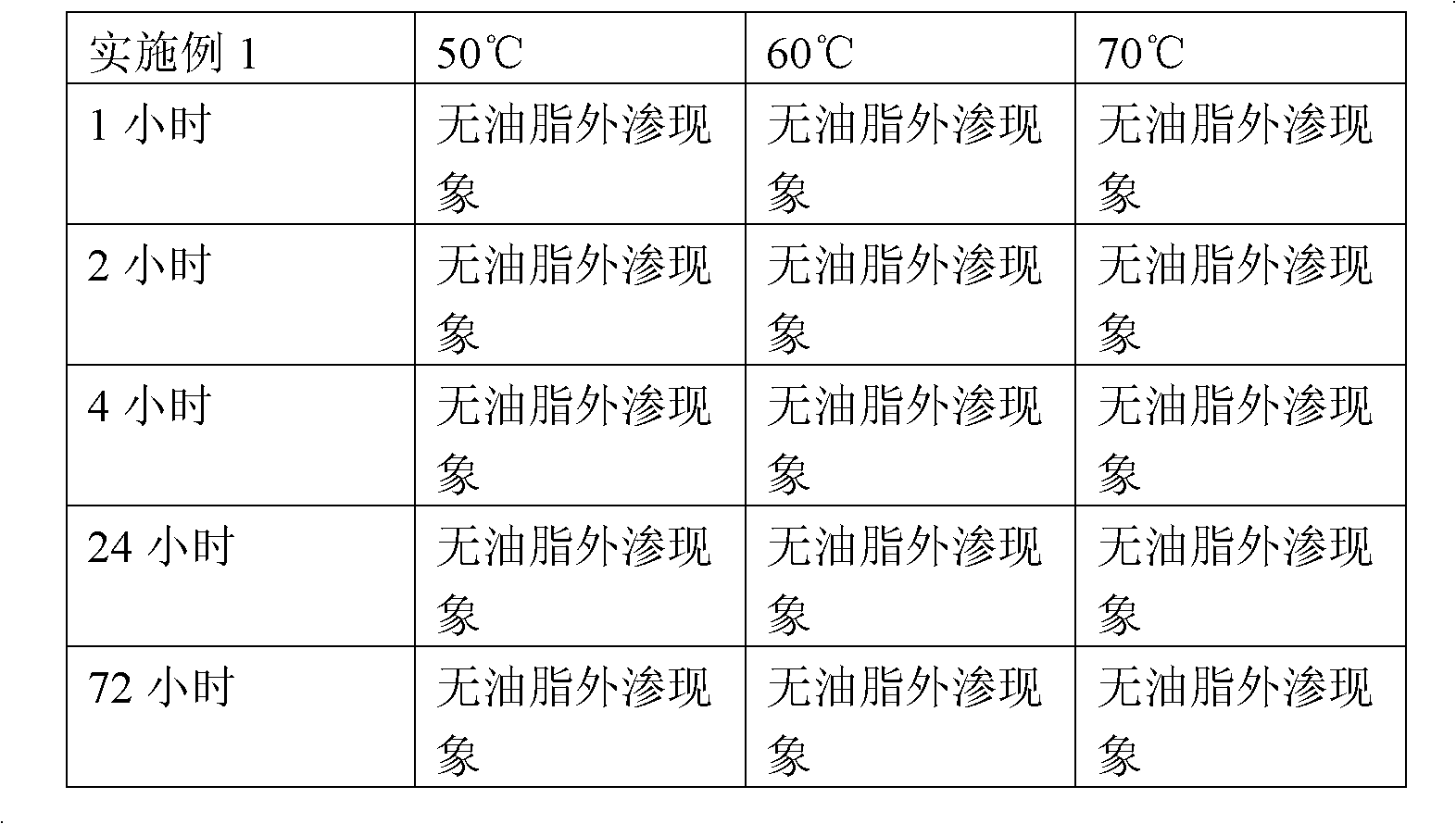

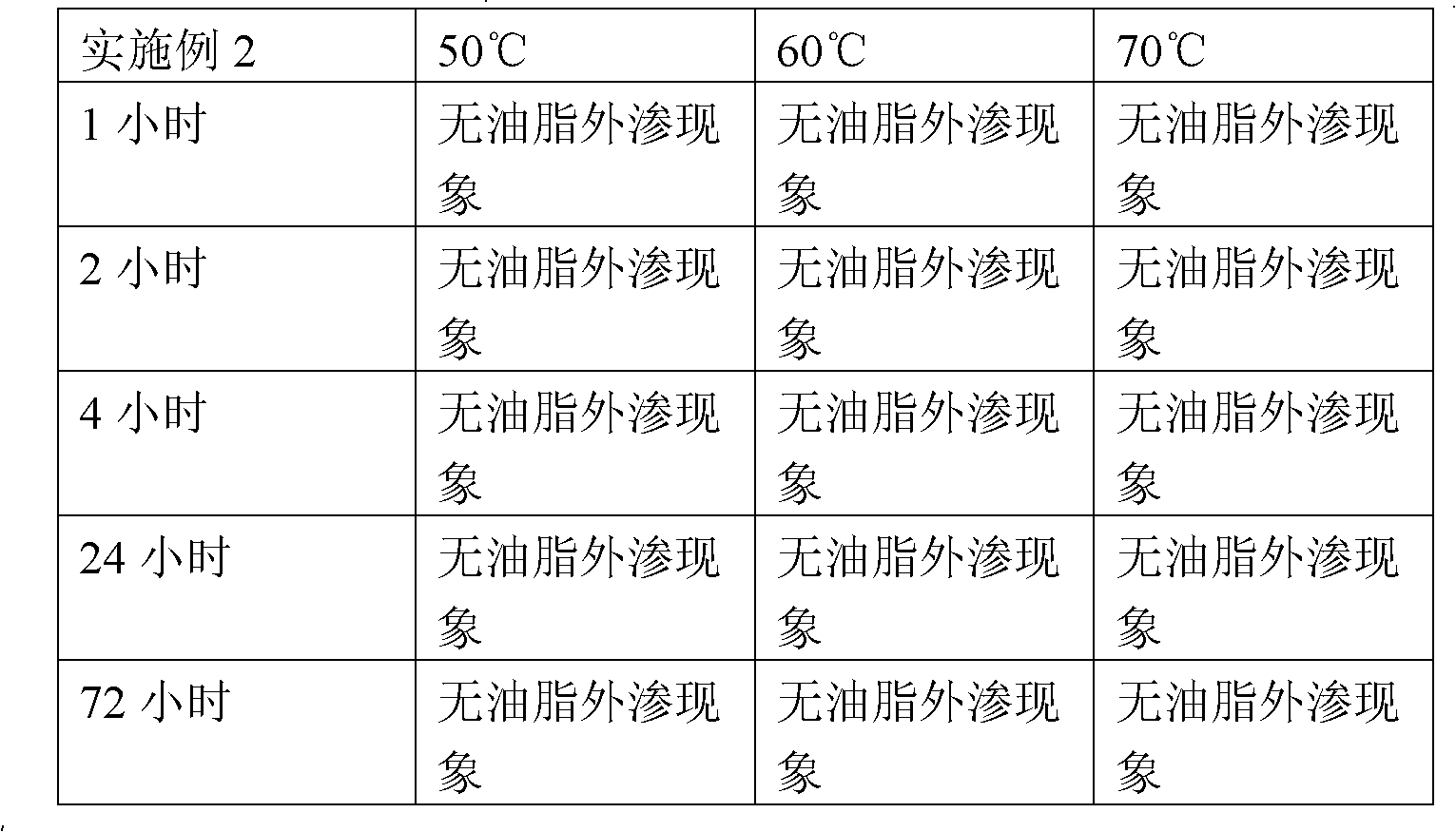

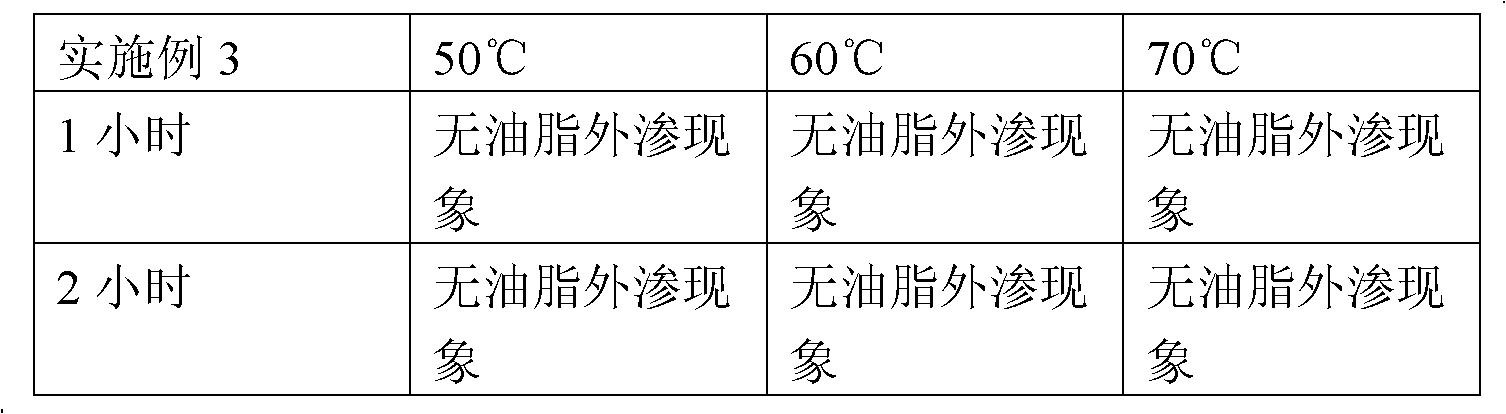

Pinewood water-based oil-proof transparent primer as well as preparation method and application thereof

The invention discloses pinewood water-based oil-proof transparent primer as well as a preparation method and an application thereof. The pinewood water-based oil-proof transparent primer is formed by mixing components A with components B according to the mass ratio of 100:(5-15), wherein the components A consist of 60 to 70 percent of waterborne polyurethane-acrylic ester graft oil-proof copolymers, 15.6 to 24.6 percent of acrylic resin, 14 to 19 percent of water and 0.4 percent of additives, and the components B are polyfunctional aziridine solution. Paint films formed by the pinewood water-based oil-proof transparent primer have the characteristics of high compactness, resistance to corrosion of various kinds of organic solutions and chemical corrosion, water resistance, no toxicity and no odor, and in addition, grease can be efficiently sealed. The oil bleeding problem of pinewood products existing for a long time is thoroughly solved. In addition, the pinewood water-based oil-proof transparent primer adopts the water as diluting agent, so no volatile organic compounds (VOC) are released in the production and use processes, and the environment-friendly coating is really realized.

Owner:深圳市雷巴环保材料有限公司

Process for making a stiffened paper

ActiveUS20120255696A1Improve mechanical propertiesIncrease stiffnessNatural cellulose pulp/paperSpecial paperPapermakingTitanium

A process for making a stiffened and rigid paper includes preparing a pulp slurry consisting essentially of water, a cellulosic pulp, a crosslinker, and a starch, and optionally a binder; draining the liquid from the pulp slurry to form a web; and drying the web. Alternatively, a process for making a stiffened and rigid paper includes the step of adding at least one crosslinker at one or more locations, such as at the wet-end, dry-end, or at both ends of the papermaking process. Suitable crosslinkers include a glyoxal-containing crosslinker, a gluteraldehyde, a polyfunctional aziridine, a zirconium-containing crosslinker, a titanium-containing crosslinker, and an epichlorohydrin, and mixtures thereof. When a binder is employed, it can be added either in the dry or wet form. Provided is a neutral or alkaline process to produce a paper product having the improved mechanical properties of a laminated product in the Z-direction, without a lamination step.

Owner:PIXELLE SPECIALTY SOLUTIONS LLC +1

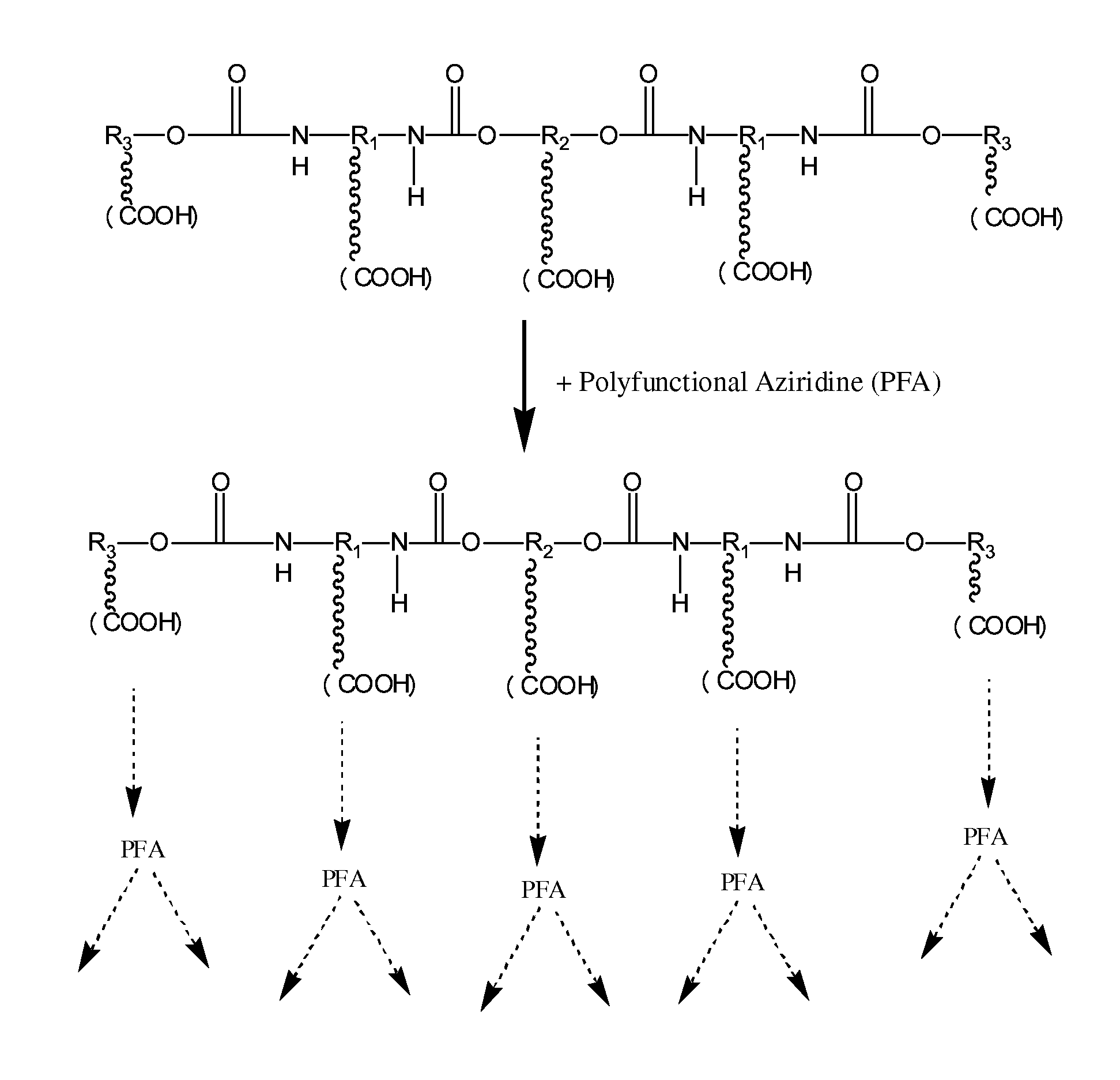

Ultraviolet-light cured high-temperature resistant pressure-sensitive adhesive

InactiveCN104449426AImprove peel forceHigh initial tackOrganic non-macromolecular adhesivePolymer scienceFunctional monomer

The invention relates to an ultraviolet-light cured high-temperature resistant pressure-sensitive adhesive. The pressure-sensitive adhesive comprises 5-20% of a solvent-free ultraviolet-light cured prepolymer, 0.1-2% of a functional crosslinking monomer, one or more functional monomers, an ultraviolet-light initiator, a pigment, a filler and a tackifying resin, wherein the solvent-free ultraviolet-light cured prepolymer comprises 80-90wt% of alkyl acrylate monomer and 10-20wt% of a polymerizable unsaturated monomer with a polar group, the functional crosslinking monomer is prepared from bifunctional or polyfunctional aziridines, and the one or more functional monomers are used for improving the adhering properties. No volatile organic solvent is added in the whole process of preparing the pressure-sensitive adhesive, and the pressure-sensitive adhesive complies with the requirements of laws and regulations on environmental protection. Compared with the pressure-sensitive adhesive prepared by adopting the conventional crosslinking method, the pressure-sensitive adhesive has good high-temperature shearing resistance and adhering properties, can be regulated in properties by regulating the use amount and overcomes the defects that the existing pressure-sensitive adhesive hardens quickly due to the large use amount of the crosslinking agent. The pressure-sensitive adhesive can be prepared into a lining-substrate free integral pressure-sensitive adhesive tape with a thickness of 3mm.

Owner:TONSAN ADHESIVES INC

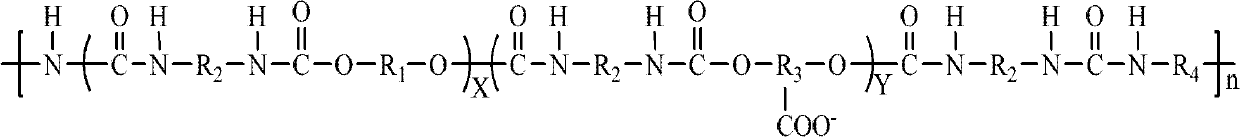

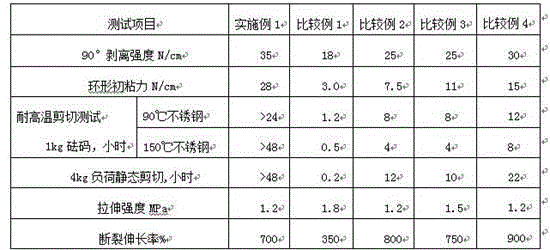

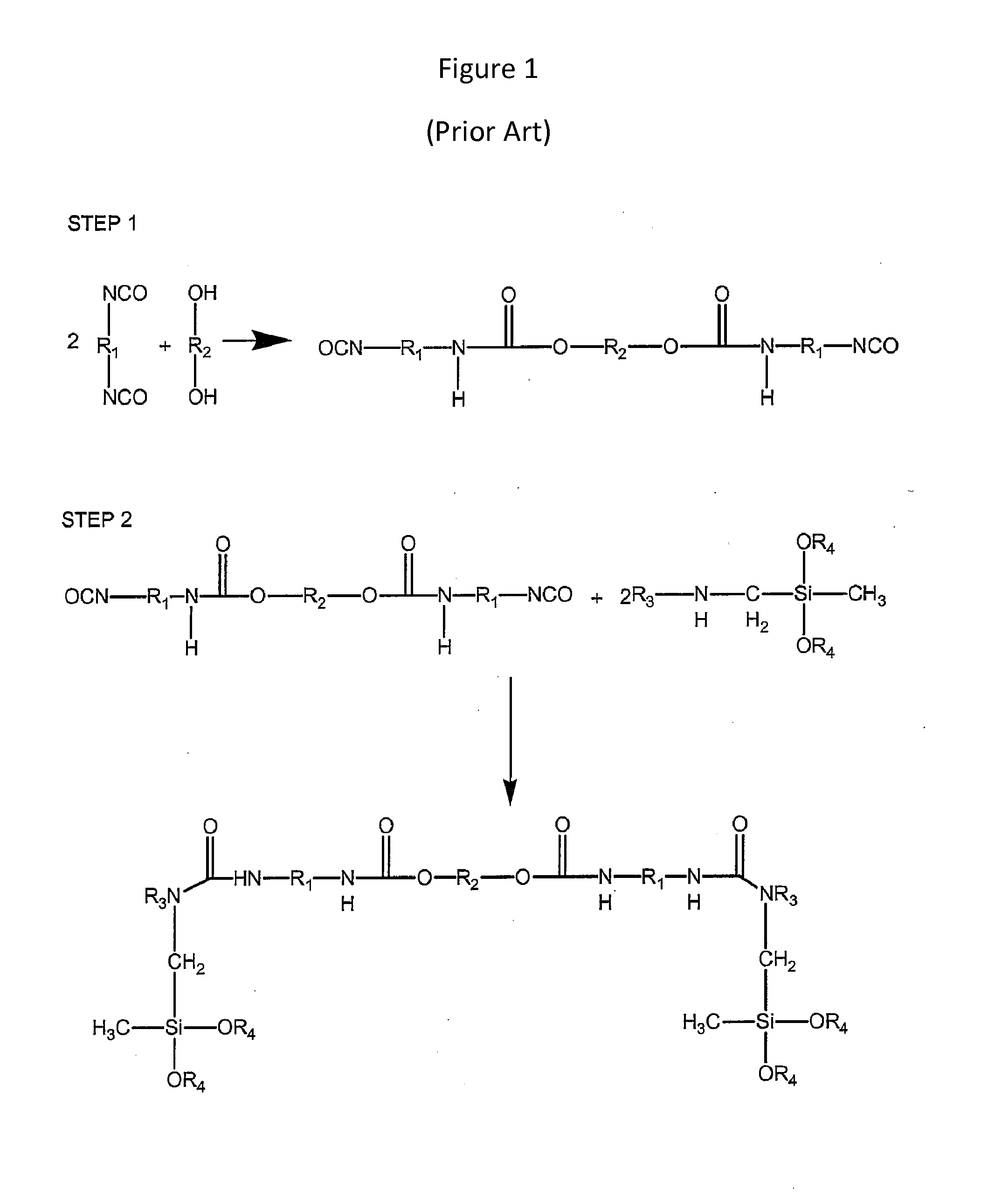

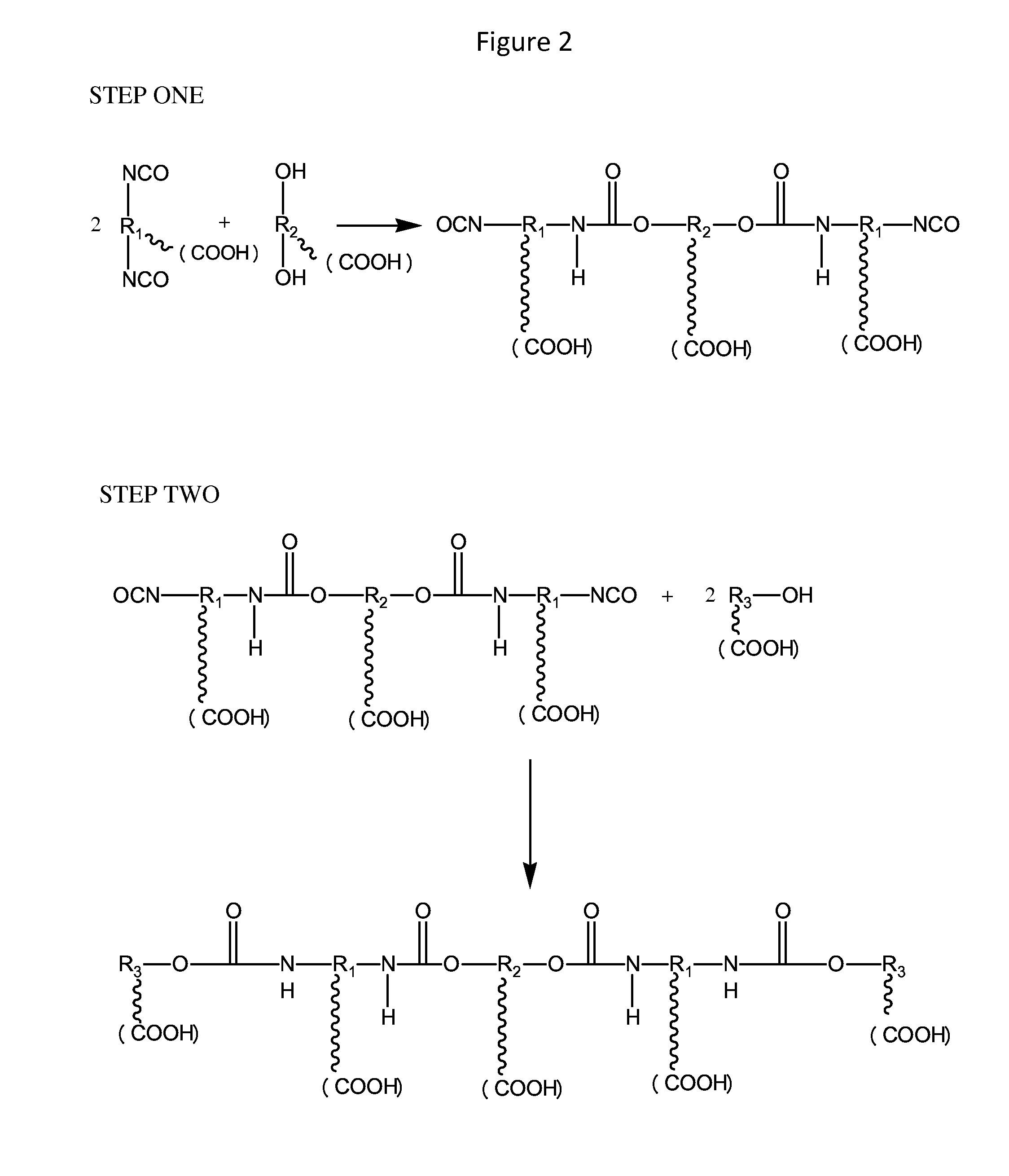

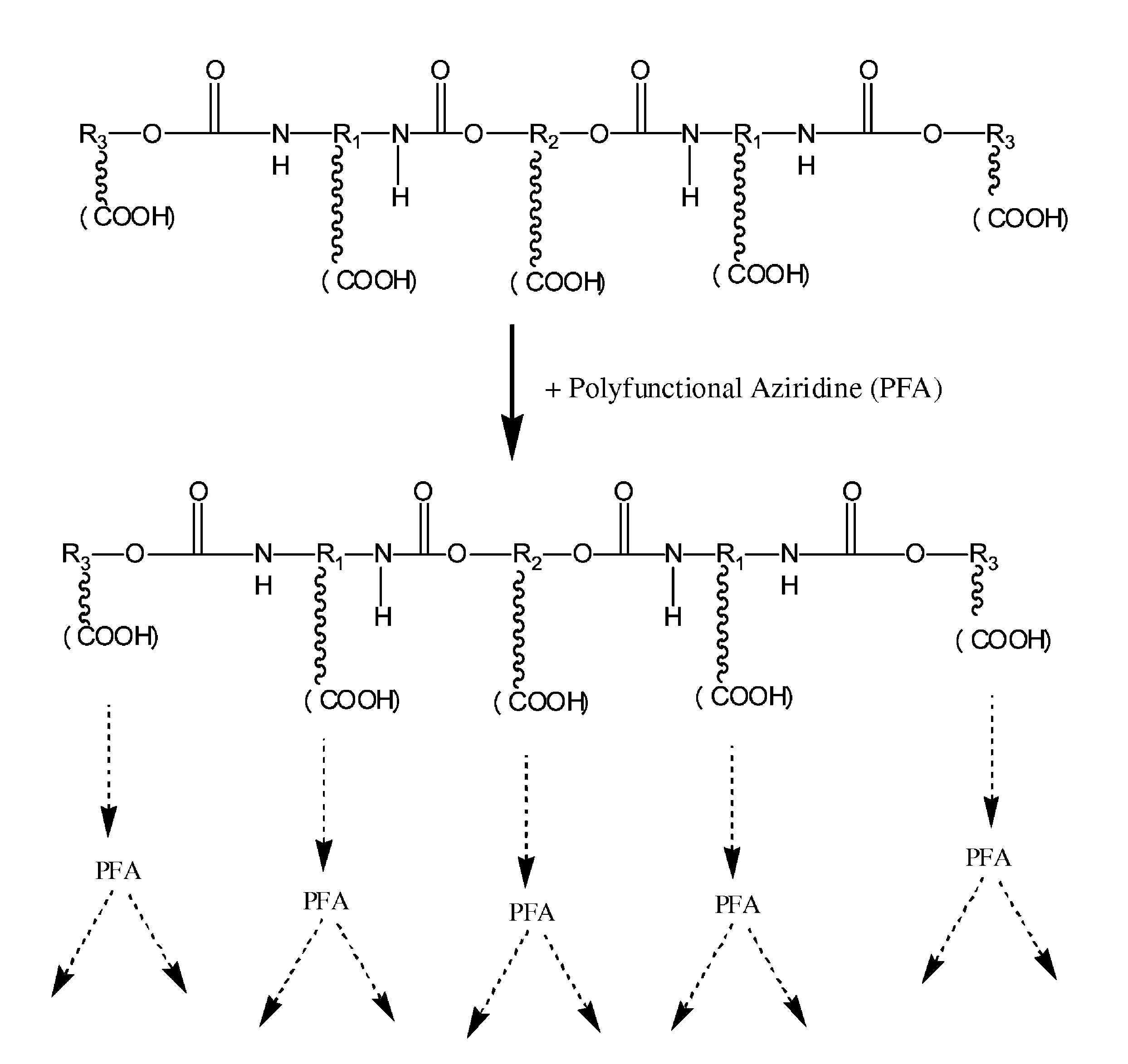

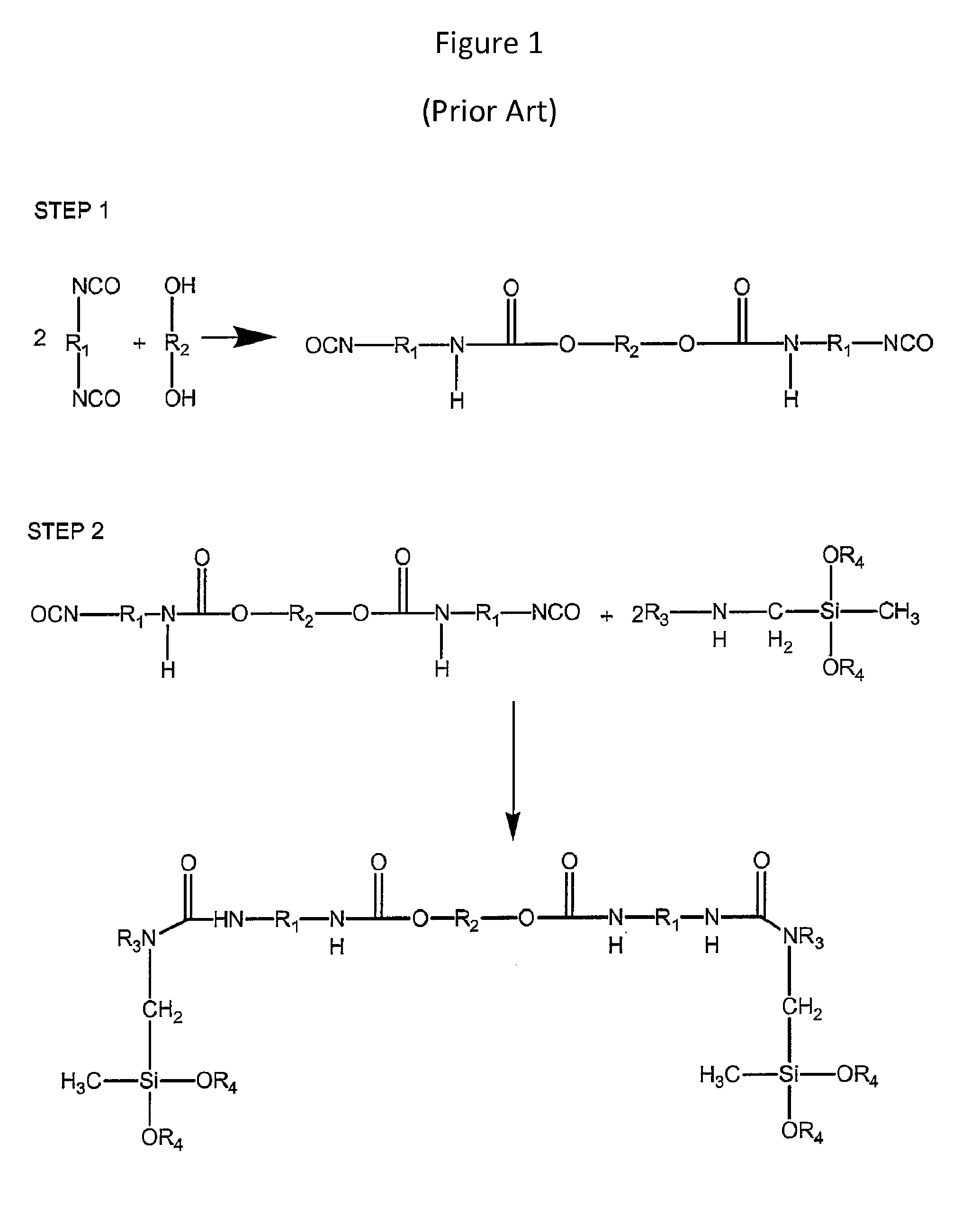

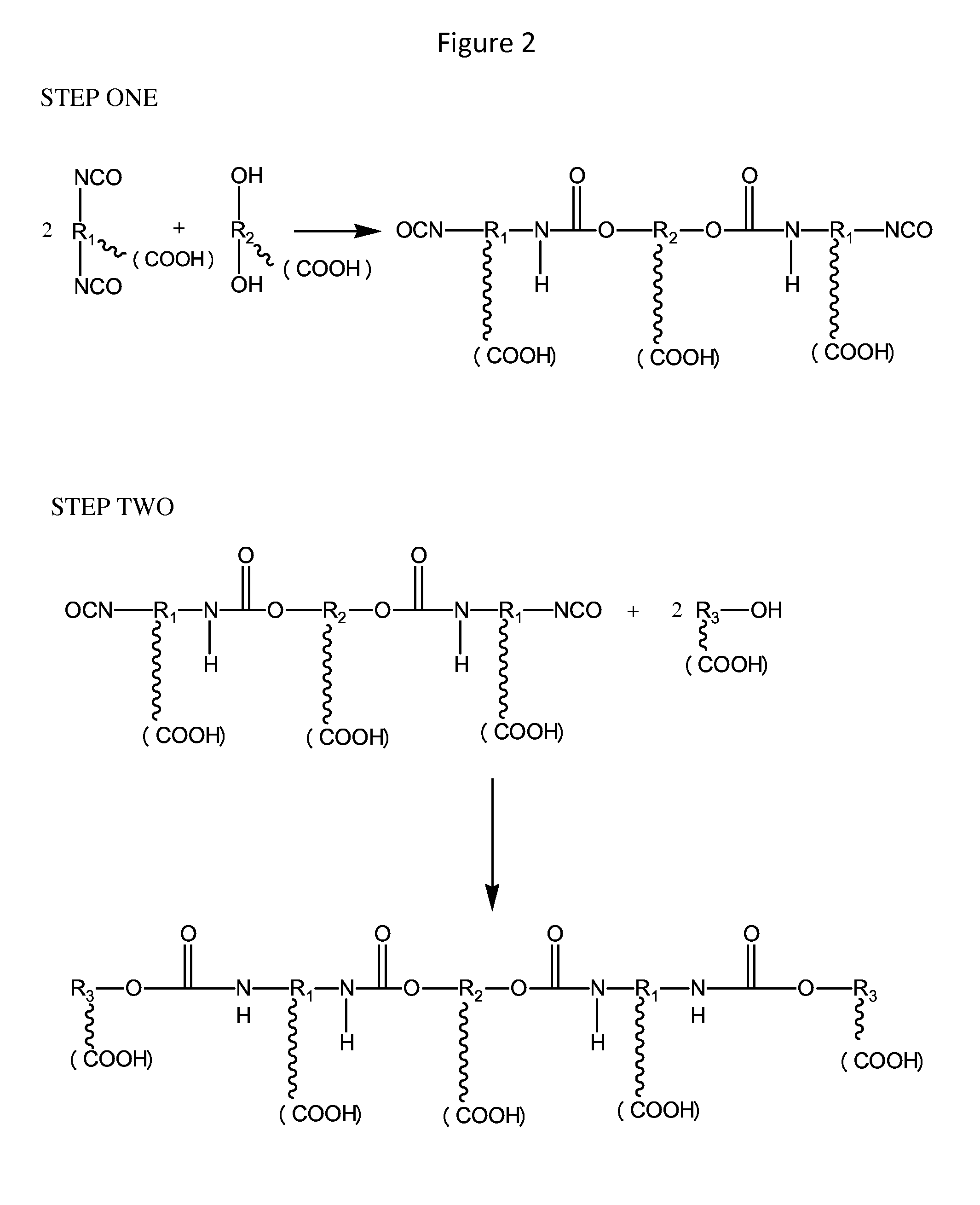

Non-isocyanate spray foam

One- and two-part spray non-isocyanate foams that include an amide-based oligomer containing pendant carboxylic acid and a polyfunctional aziridine crosslinking agent is provided. The amide oligomer typically contains urea links, urethane links or both groups. Additionally, the foams may include one or more plasticizer, a non-functionalized resin, a surfactant, and / or a thickening agent or rheology modifier. The amide oligomer does not contain any isocyanate groups, and, as a result, there are no free isocyanate moieties generated during formation of the foam that may be potentially hazardous to workers installing the foam. The presence of the urethane segments on the oligomer permits for the generation of a polyurethane foam without the drawbacks of conventional polyurethane foams. The foams may be used to fill cavities, cracks, gaps and crevices, such as around windows and doors, and may also be used in flash and batt systems.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

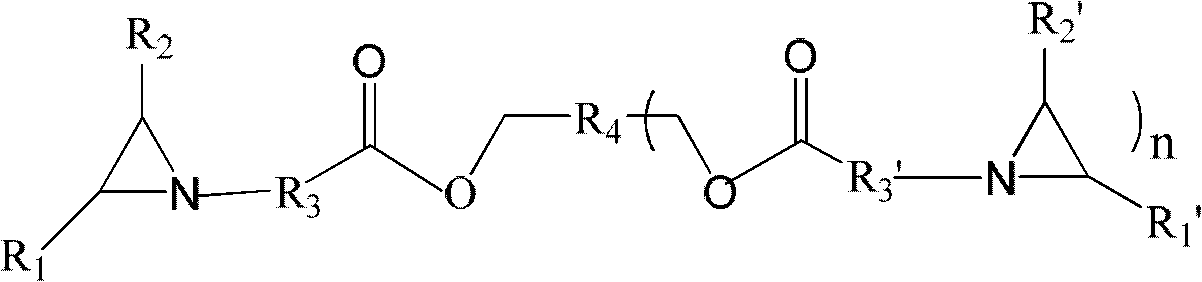

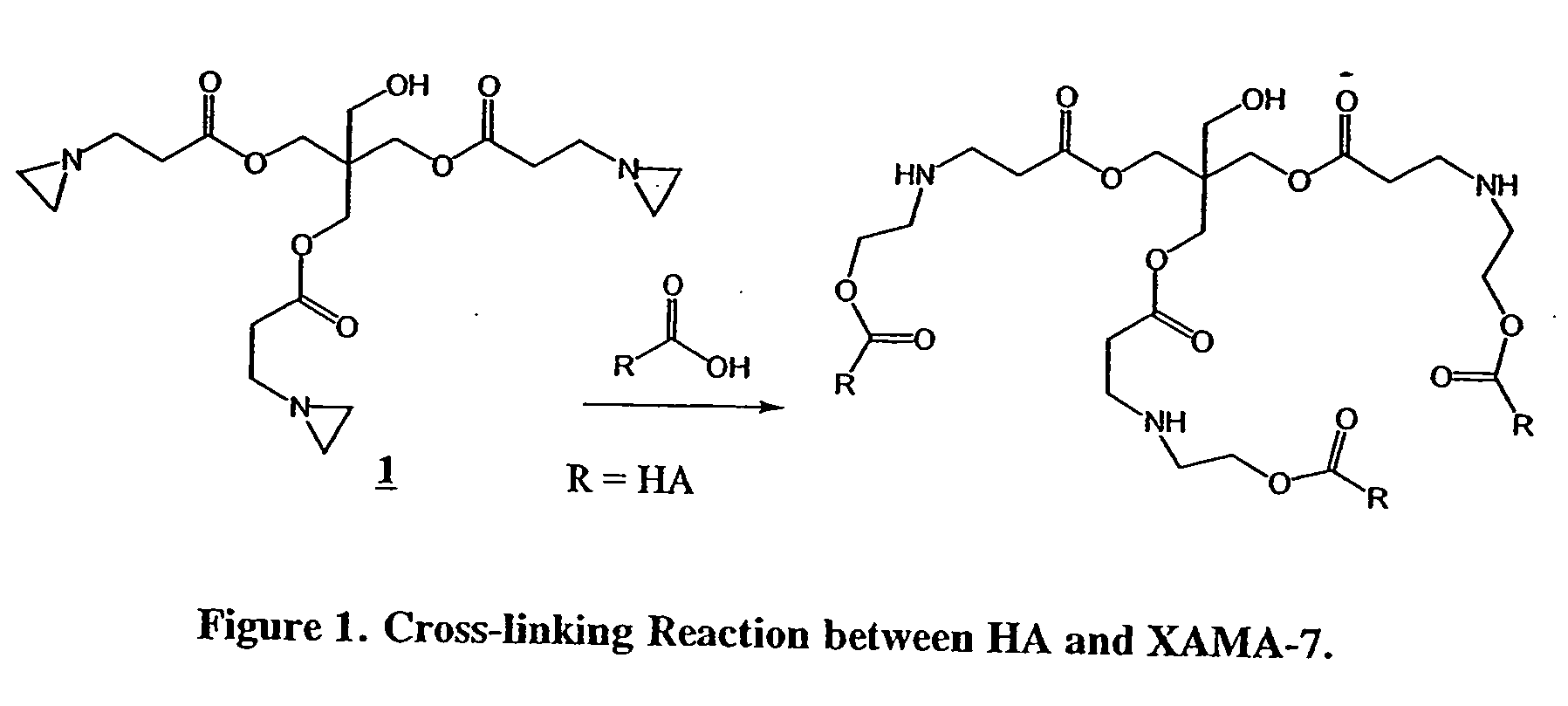

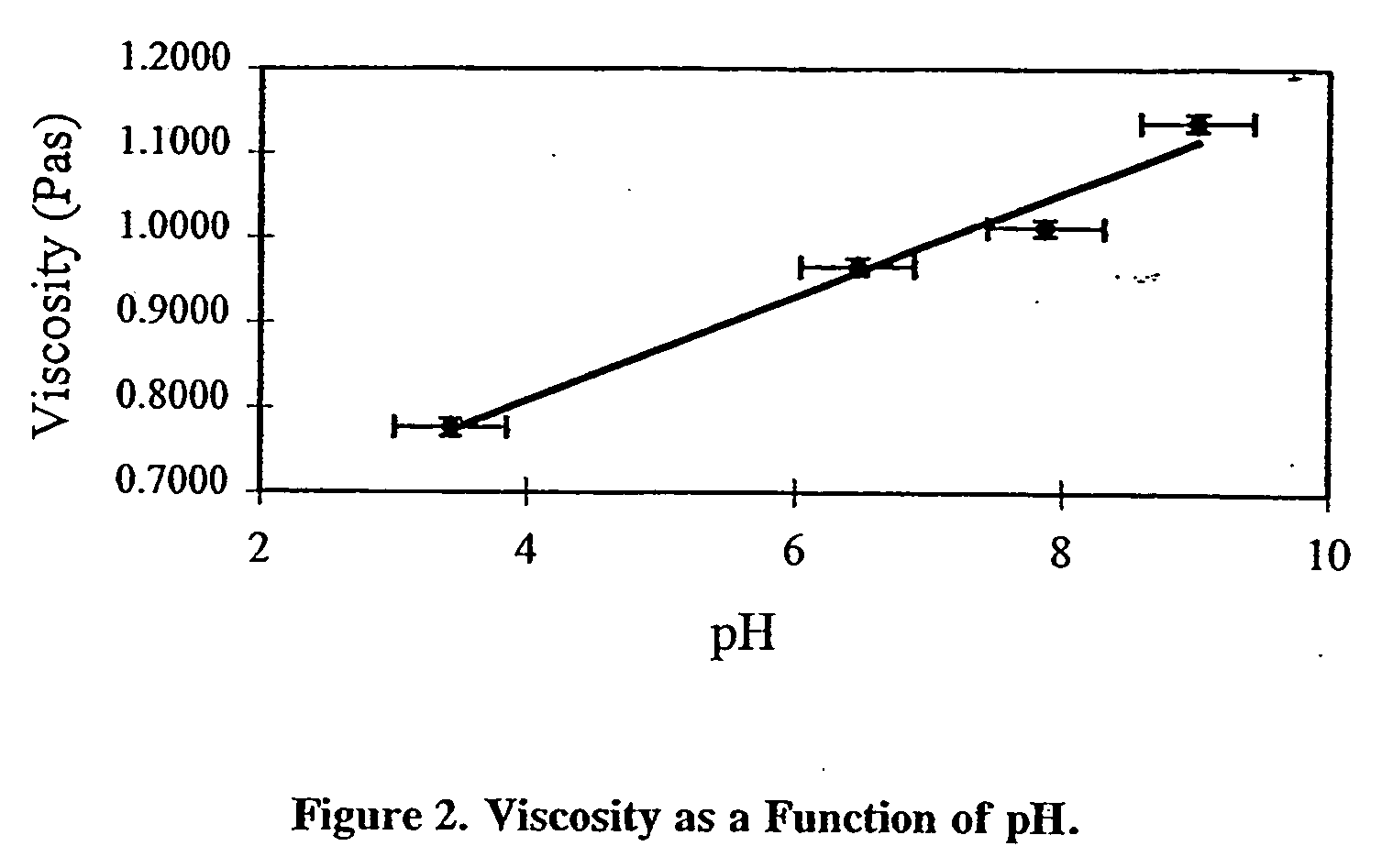

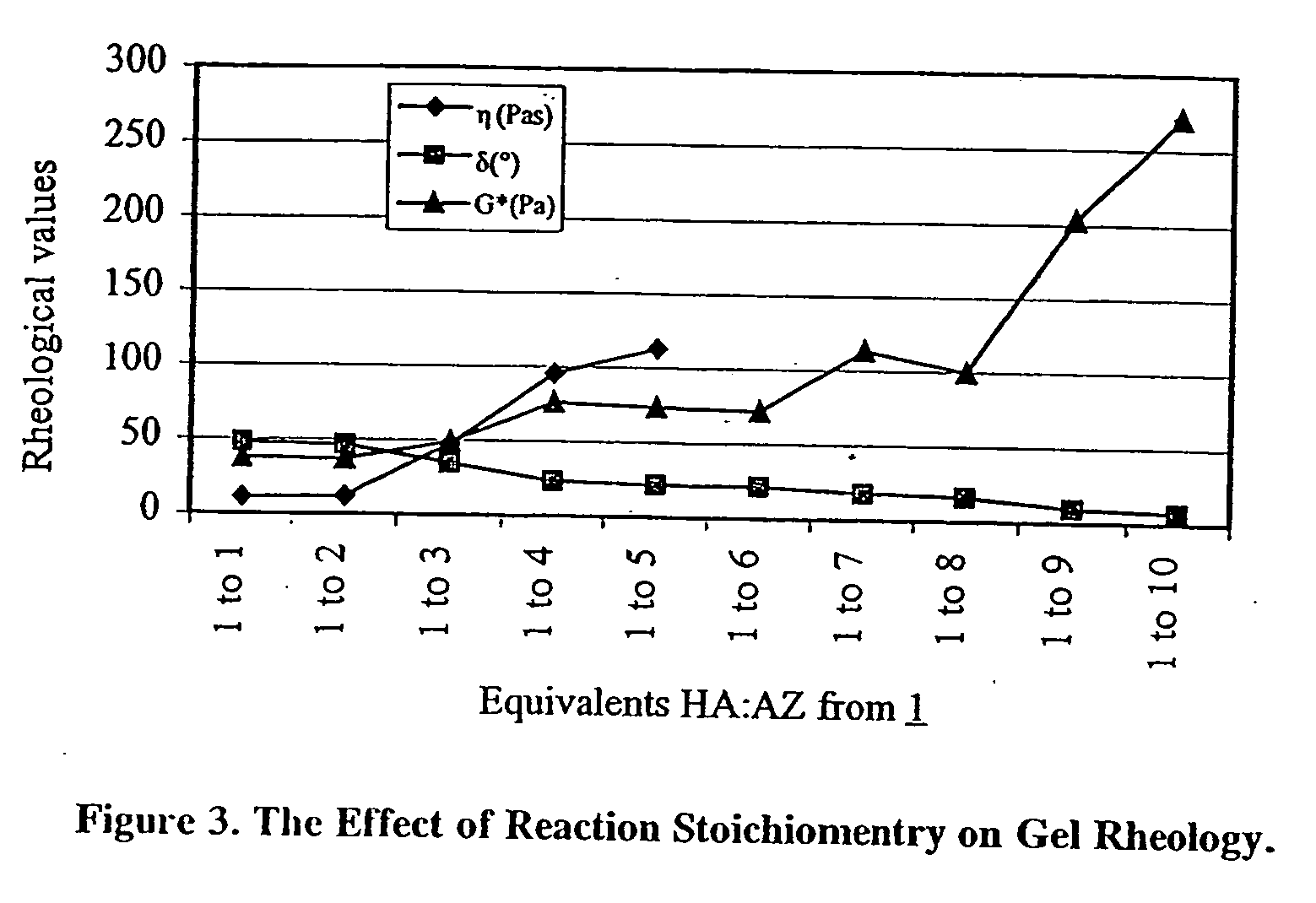

Cross-linked hyaluronate compounds

There is disclosed a cross-linked hyaluronate compound obtained by reacting a sodium hyaluronate compound with a polfunctional aziridine compound as a cross-linking agent. The polyfunctional aziridine compound was added to hyaluronan of various molecular weights in an equivalent ratio of HA / AZ of 1:1 to 1:10, preferably, 1:3 to 1:10, more preferably, 1:3 to 1:5; most preferably 1:4 to 1:5. The polymeric hydrogel compounds obtained are useful to prevent the formation of post-operative adhesions, designing tissue engineering applications, and the like.

Owner:GIANOLIO DIEGO A +2

Non-isocyanate spray foam

InactiveUS8604091B2Safe installationImprove propertiesBuilding constructionsCarbamateCarboxylic acid

One- and two-part spray non-isocyanate foams that include an amide-based oligomer containing pendant carboxylic acid and a polyfunctional aziridine crosslinking agent is provided. The amide oligomer typically contains urea links, urethane links or both groups. Additionally, the foams may include one or more plasticizer, a non-functionalized resin, a surfactant, and / or a thickening agent or rheology modifier. The amide oligomer does not contain any isocyanate groups, and, as a result, there are no free isocyanate moieties generated during formation of the foam that may be potentially hazardous to workers installing the foam. The presence of the urethane segments on the oligomer permits for the generation of a polyurethane foam without the drawbacks of conventional polyurethane foams. The foams may be used to fill cavities, cracks, gaps and crevices, such as around windows and doors, and may also be used in flash and batt systems.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Two part spray foam using a blowing agent as a plasticizer and a room temperature crosslinking agent

InactiveUS20110123717A1Non toxicLiquid surface applicatorsBuilding constructionsFoaming agentEmulsion

Latex spray foams formed from a non-aqueous two-part foamable composition are provided. The A-side contains includes a dry latex polymer, a multifunctional acid, and a liquid blowing agent and the B-side contains a polyfunctional aziridine crosslinking agent a plasticizer, and, optionally, a non-functionalized resin. The multifunctional acid may be a secondary emulsion that is added to the composition separately. The polyfunctional aziridine crosslinking agent may be diluted by a plasticizer, which reduces the viscosity of the B-side. The plasticizer should have no acidic protons to react with the crosslinking agent. When no acidic protons are present, the B-side is stable for extended periods of time. Additionally, the inventive foam and composition are desirably free of water. The lack of water or small amount of water in the inventive foam composition permits the foam to be sprayed at temperatures below freezing and to a greater thickness compared to water-containing compositions.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

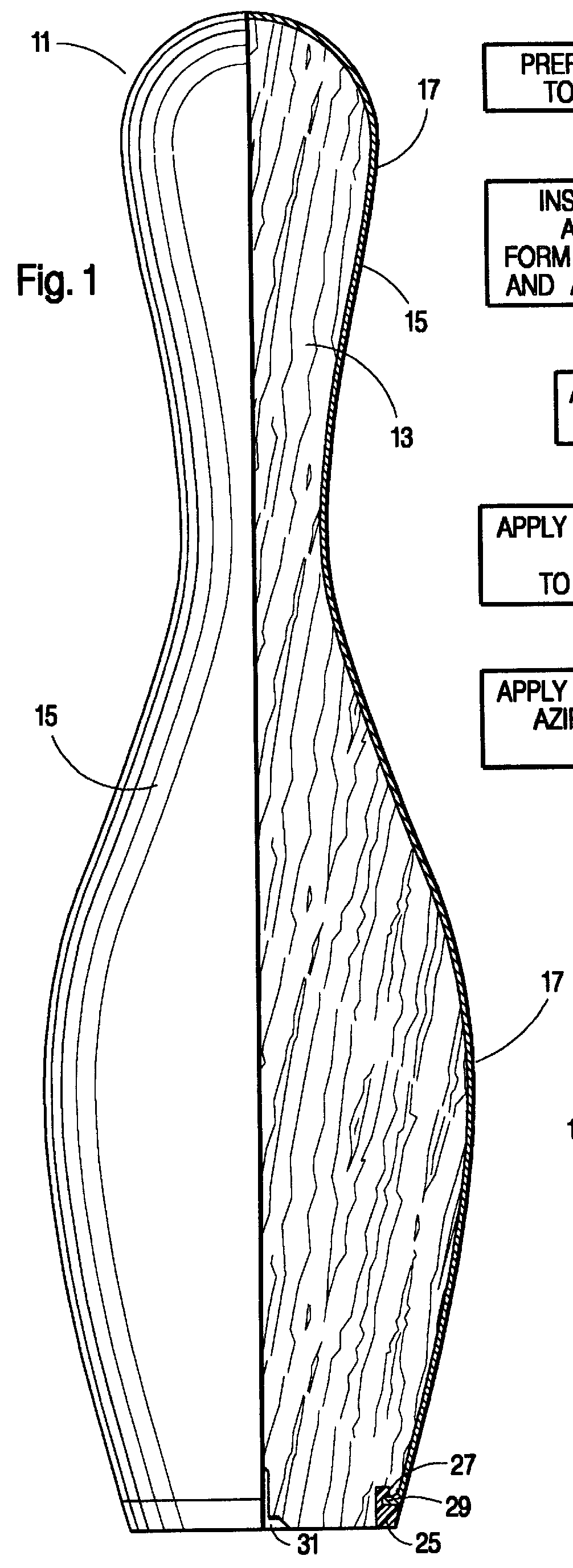

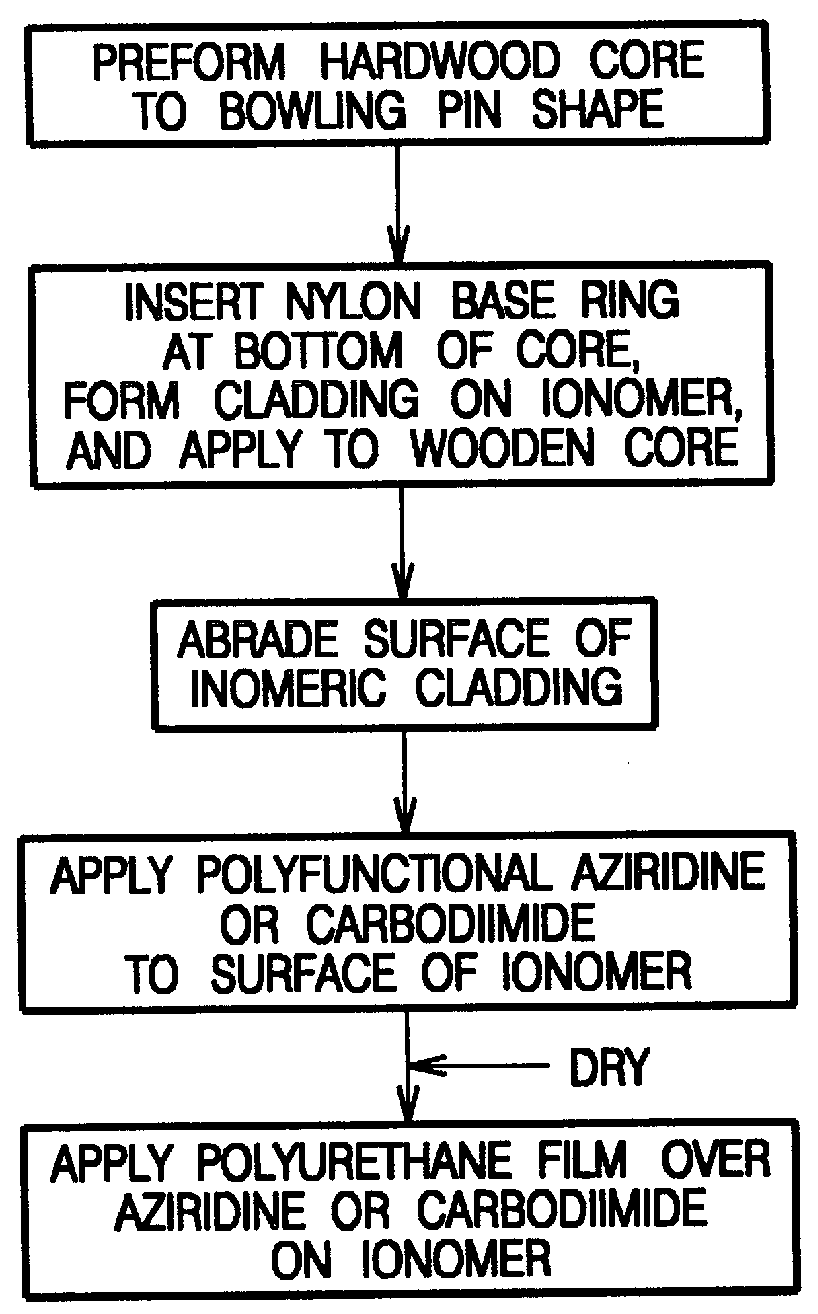

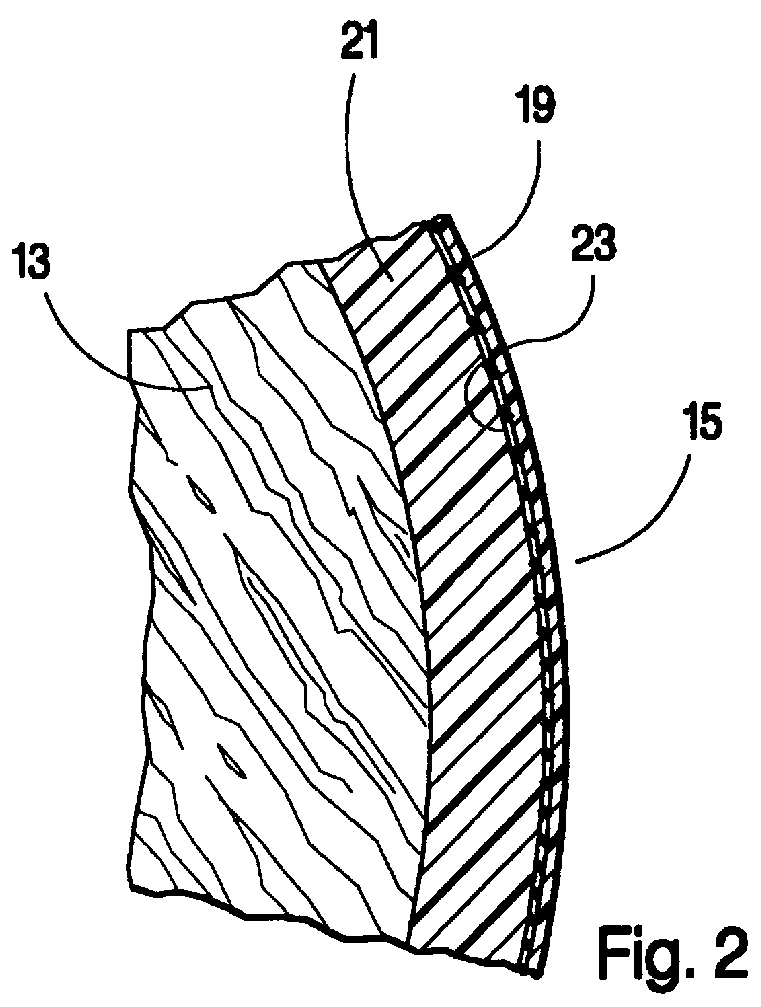

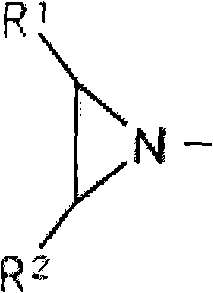

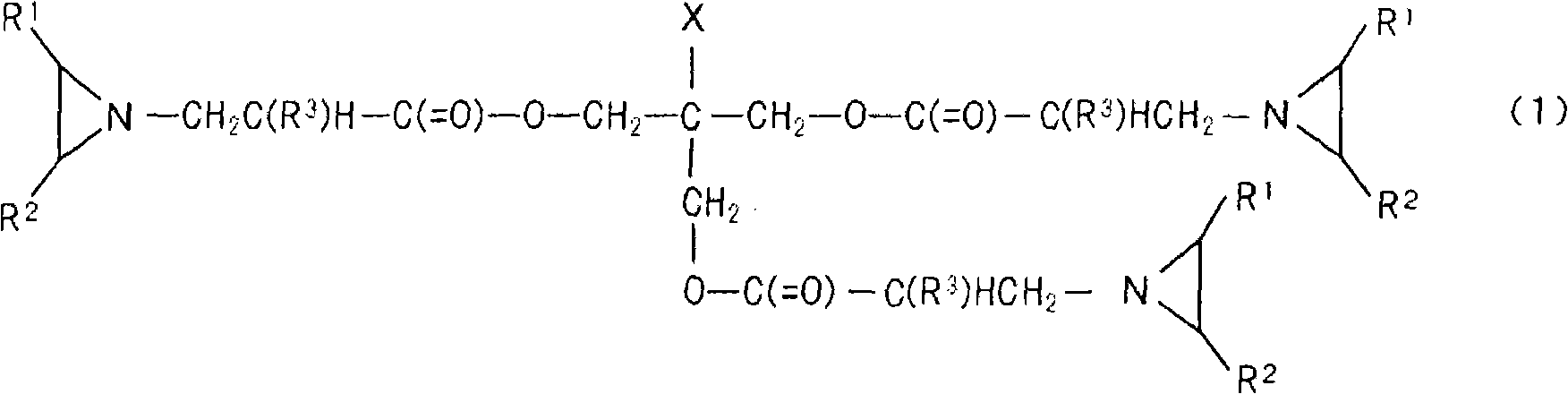

Bowling pin with improved polymeric coating and method of making

The outer two layers, composed of an undercoat of an ionomer and a topcoat of polyurethane, on a wooden core of a bowling pin are bonded together by use of either of a polyfunctional aziridine or polyfunctional carbodiimide providing superior adhesion under shock plus several shop advantages including lessened air pollution and ease of application.

Owner:CREDIT SUISSE FIRT BOSTON CAYMAN ISLANDS BRANCH

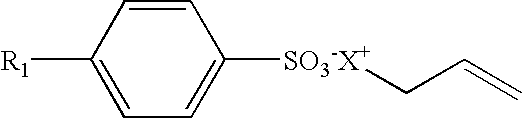

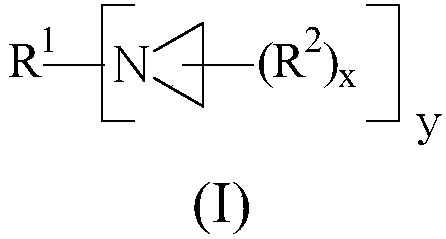

Conductive composition, conductive film and their producing methods

ActiveCN101831055AExcellent film performanceConductive materialNon-conductive material with dispersed conductive materialConductive polymerHeteroatom

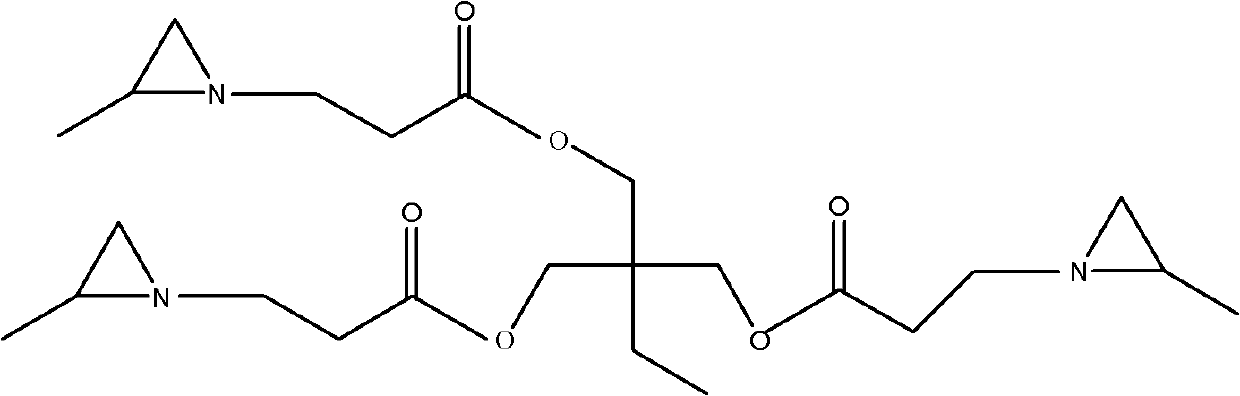

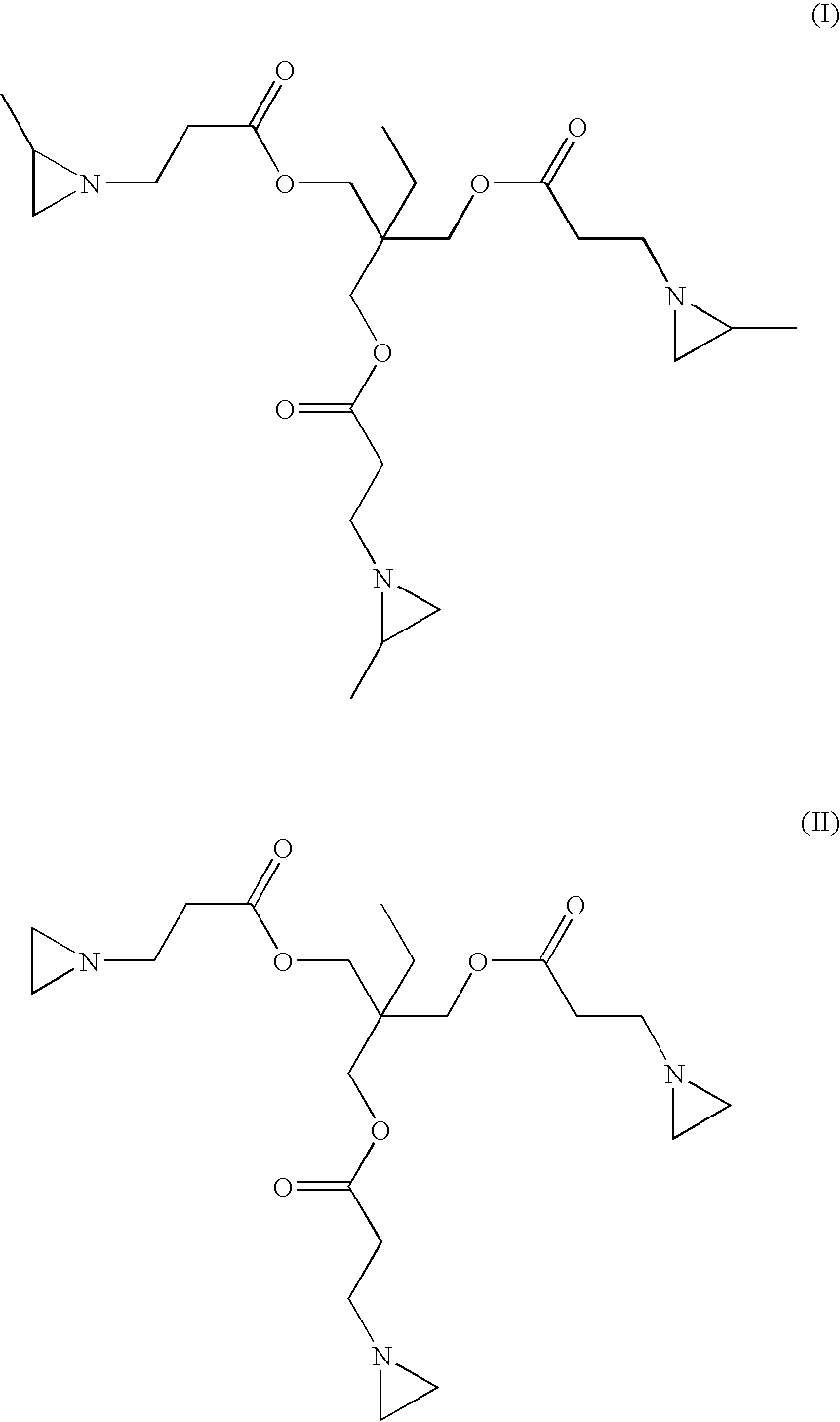

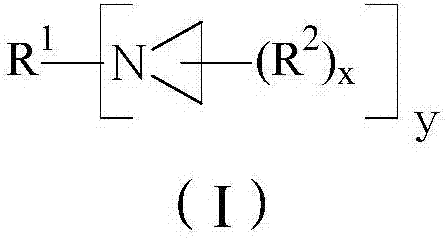

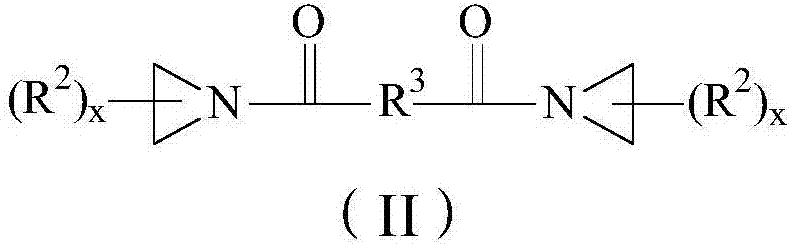

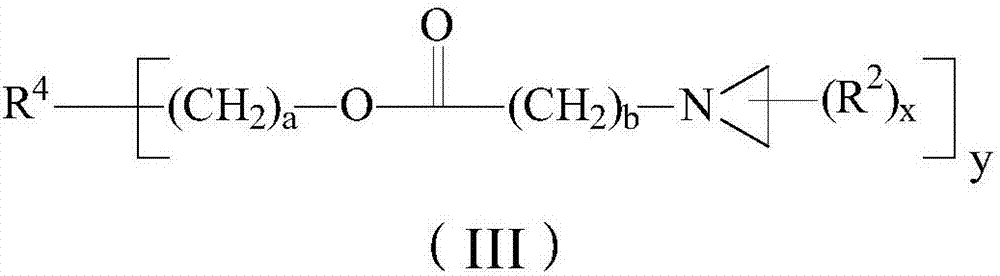

The invention provides a conductive composition for forming a conductive film with easily-adjusted conductivity-static resistance. The conductive composition comprises a polyfunctional aziridini derivative (A) comprising at least three aziridinyls of special structures, an aziridinyls open-loop catalyst (B), a Pi conjugated system conductive polymer (C) containing heteroatom and a solvent (D).

Owner:ARAKAWA CHEM IND LTD

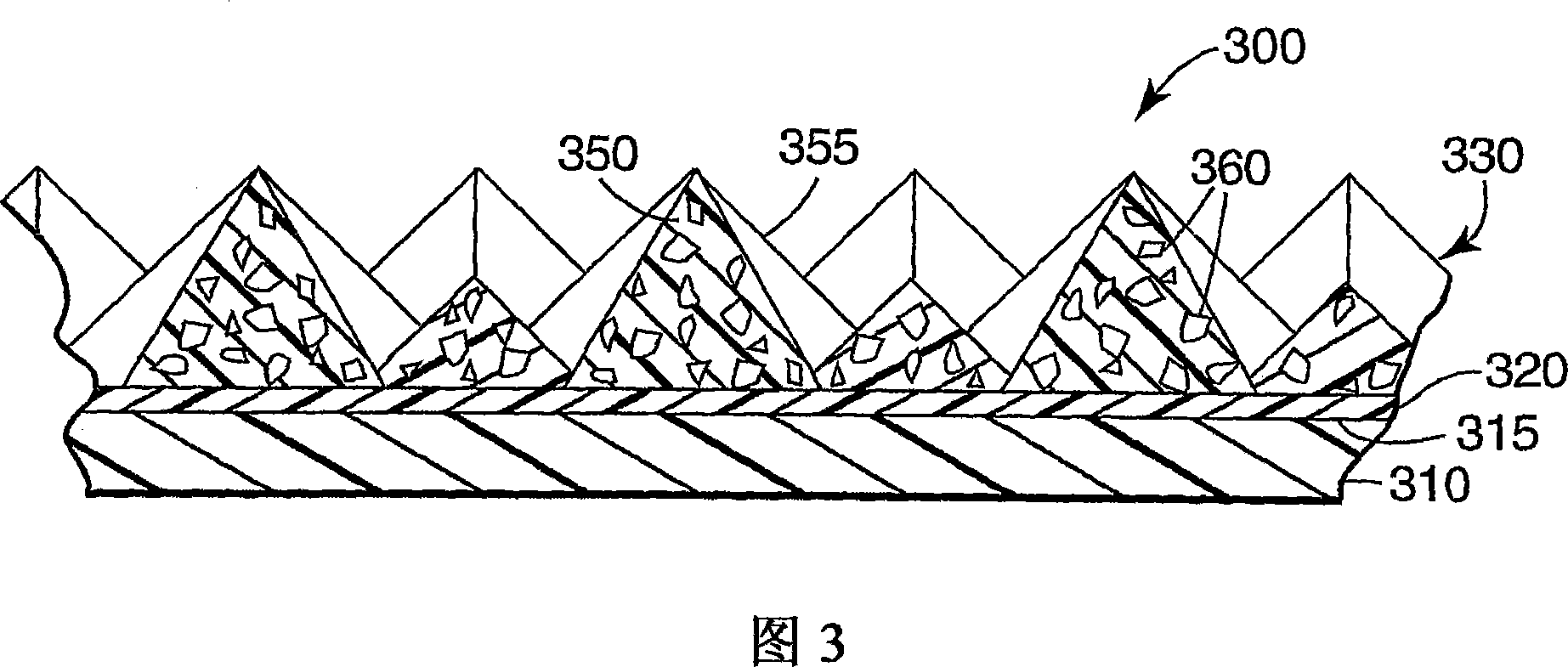

Coated abrasive article with tie layer, and method of making and using the same

Coated abrasive articles have a tie layer that is preparable by at least partially polymerizing an isotropic polymerizable composition comprising a polyfunctional aziridine, an acidic free-radically polymerizable monomer, and an oligomer having at least two pendant free-radically polymerizable groups, wherein homopolymerization of the oligomer results in a polymer having a glass transition temperature of less than 50 degrees Celsius.

Owner:3M INNOVATIVE PROPERTIES CO

Emulsion polymer binder with aziridine crosslinking agent for mineral fiber webs

A binder composition for mineral fiber mats or the like, where the binder composition includes a carboxylated emulsion resin and a polyfunctional aziridine crosslinking agent. The binder composition is formaldehyde free, exhibits good crosslinking density, and enables the economical production of strong, flexible fiberglass mats which may be used as thermal and acoustic insulation.

Owner:CELANESE INT CORP

Process for making a stiffened paper

ActiveUS8496784B2Improve mechanical propertiesIncreased stiffness and rigidityNatural cellulose pulp/paperSpecial paperPapermakingSlurry

Owner:PIXELLE SPECIALTY SOLUTIONS LLC +1

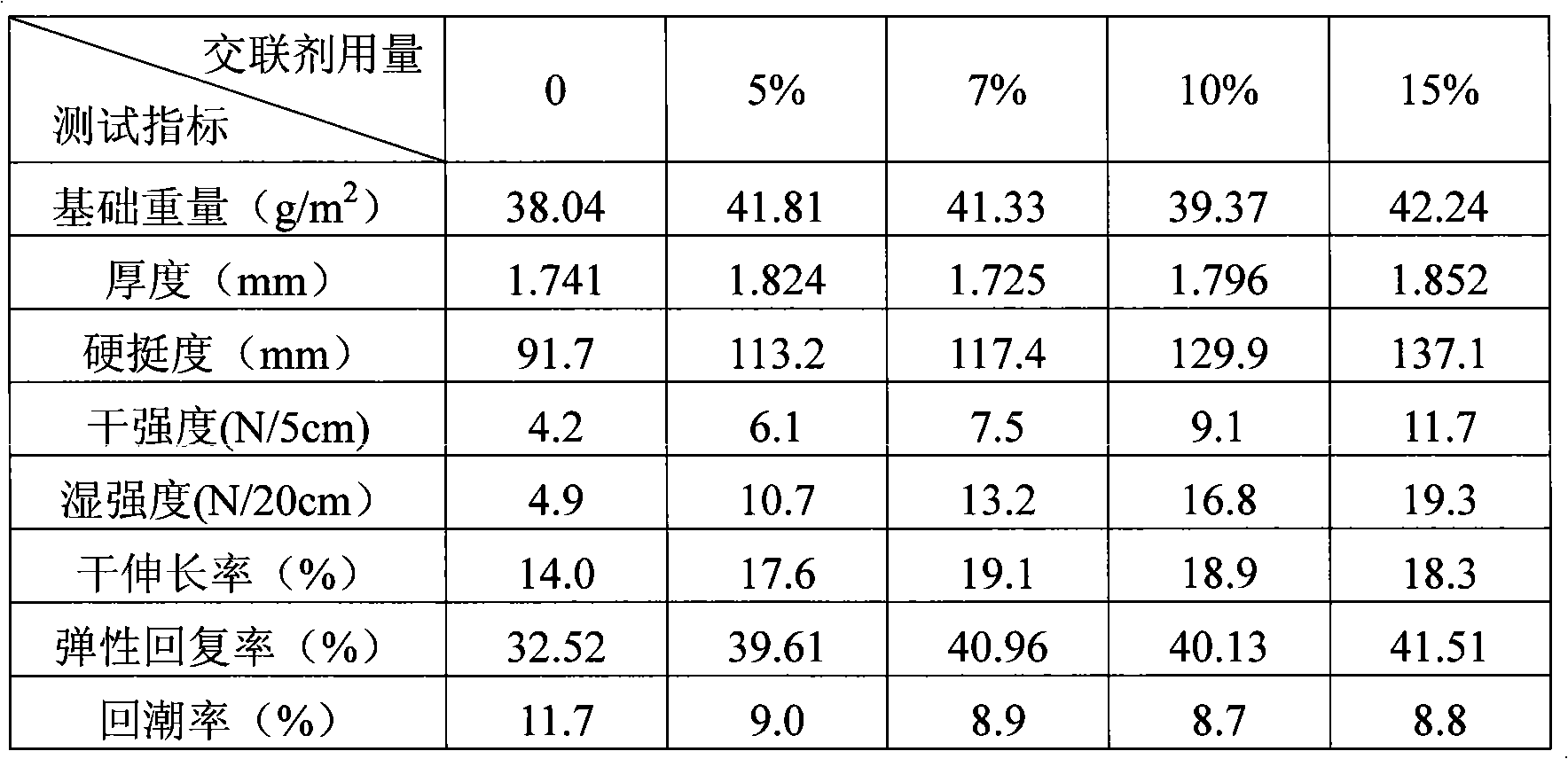

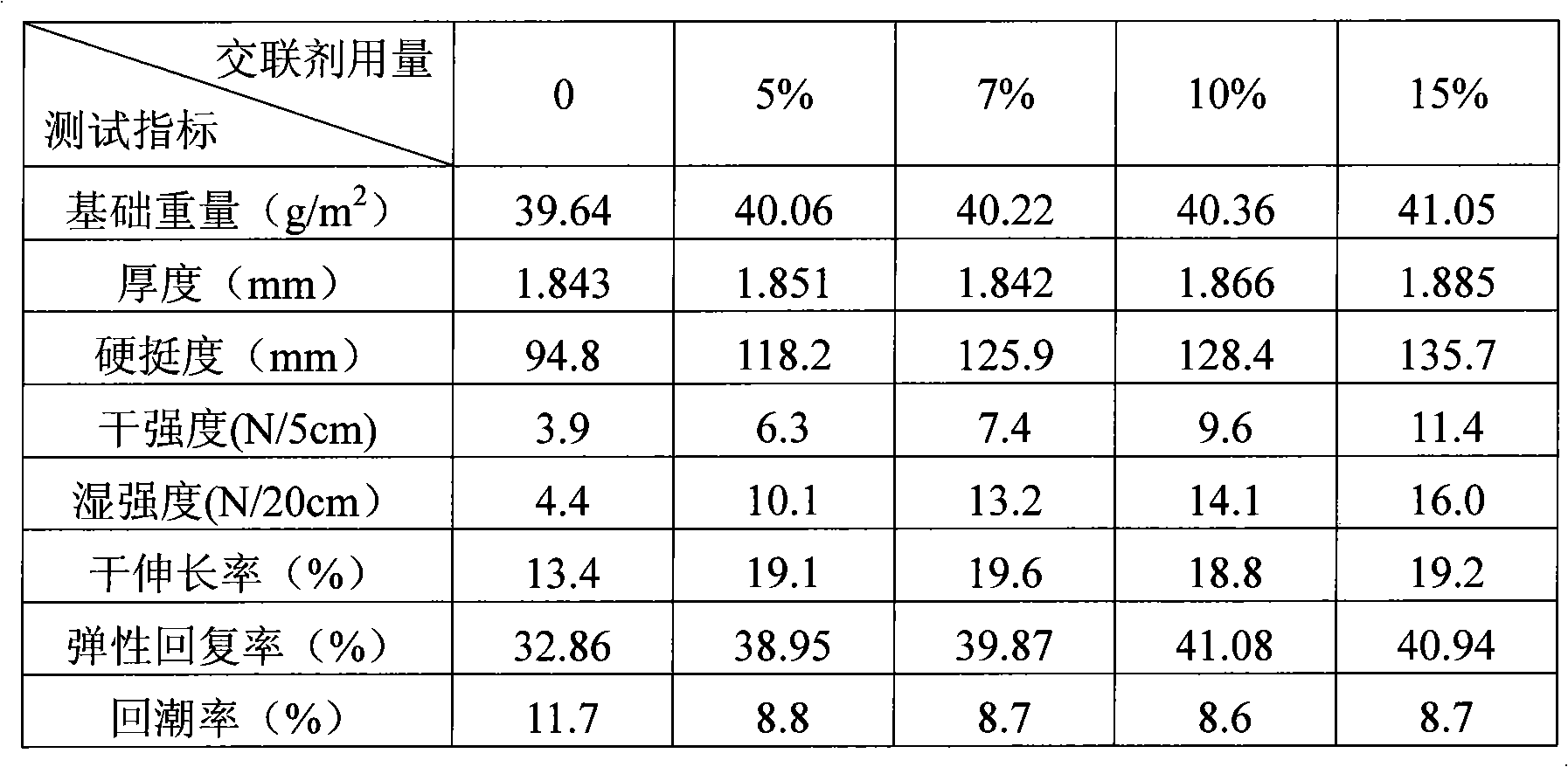

Latex solution for producing lignin nonwoven cloth for cigarette

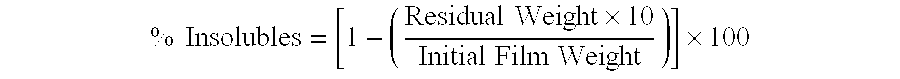

ActiveCN101402773AImprove wet strengthLow moisture regainMonocarboxylic acid ester polymer adhesivesTobacco smoke filtersCross-linkAdhesive

The invention discloses latex used for the production of tobacco used wood pulp non-woven, which consists of an adhesive, a cross-linking agent, water and a curing agent and a stabilizer; the adhesive is any one of the following substances: vinyl acetate, vinyl acetate copolymer, acrylic ester and acrylic copolymer or the mixture of vinyl acetate and vinyl acetate copolymer or the mixture of acrylic ester and acrylic copolymer; the cross-linking agent is any of the following substances: HMMM, polyfunctional aziridine, bifunctional end aziridine or closed isocyanate; the curing agent is ammonium chloride; and the stabilizer is ammonia water. Compared with the prior art, the tobacco used wood pulp non-woven produced with the latex has the advantages of higher humidity and strength, lower moisture regain, good compression elasticity, as well as good stiffness and filtering performance when being used as cigarette holder so that the cigarette is not apt to occur hot collapse or generate foreign odor when being smoked.

Owner:JIANGSU DAYA CIGARETTE FILTER MATERIAL CO LTD

A matte finish composition

A matte finish composition exhibiting superior qualities of maintaining a matting agent in dispersion without significantly increasing viscosity, which includes a polymer, a water-based solvent, a matting agent and a crosslinking agent. The polymer may include urethane monomers. The matting agent may be silicon dioxide. The matting agent may be a fine dust. The crosslinking agent may include a polyfunctional aziridine such as pentaerythrito-tris-(β-N-aziridinyl propionate).

Owner:HARRIS RES INC

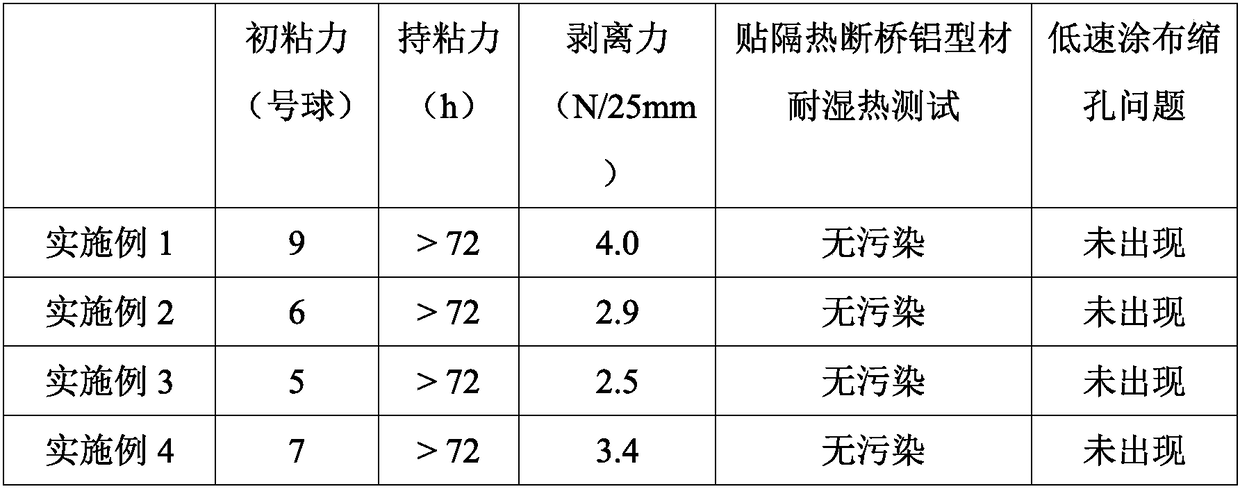

Aqueous pressure-sensitive adhesive for heat-insulating broken bridge aluminum profile protection film and preparation method thereof

ActiveCN109021886AImprove adhesionImprove heat and humidity resistanceEster polymer adhesivesPressure sensitive film/foil adhesivesTectorial membraneLow speed

The invention discloses an aqueous pressure-sensitive adhesive for a heat-insulating broken bridge aluminum profile protection film and a preparation method thereof. The preparation method comprises:preparing a seed emulsion through a seed emulsion polymerization method, adding a pre-emulsion into the seed emulsion drop by drop, then adding an initiator into the emulsion in the later stage so that the reaction is full, cooling the system, adjusting pH, adding a defoaming agent and a wetting agent into the system, filtering the mixture and discharging the product. The invention also provides apreparation method of the heat-insulating broken bridge aluminum profile protection film. The preparation method comprises: adding a polyfunctional aziridine crosslinking agent into the aqueous pressure-sensitive adhesive, carrying out full mixing, uniformly coating a polyethylene film with the glue, carrying out baking through a baking channel and carrying out rolling. The protection film has good adhesion to a heat-insulating broken bridge aluminum profile and good high temperature and high humidity aging resistance. The pressure-sensitive adhesive emulsion utilizes the appropriate defoaming agent and wetting agent and is especially suitable for low-speed coating with a protective film (at 9-15 m / min).

Owner:南京科开新材料有限公司

Post-curable precursor of acrylic-based pressure-sensitive adhesive

InactiveCN108291127AFilm/foil adhesivesEster polymer adhesivesPressure sensitivePolyfunctional aziridine

The present disclosure is directed to a curable precursor of a pressure-sensitive adhesive comprising: a) a (co)polymeric material comprising the reaction product of a (co)polymerizable material comprising a (meth)acrylate ester monomer; and optionally, a co-monomer having an ethylenically unsaturated group; b) a polyfunctional aziridine curing agent; c) a thermal acid generating agent; and d) magnetic particles. The present disclosure is also directed to a method of applying such pressure-sensitive adhesives to a substrate and uses thereof.

Owner:3M INNOVATIVE PROPERTIES CO

Preparation method and application of water-based acrylate pressure-sensitive adhesive

ActiveCN105219311AImprove the level ofSmall particle sizeNon-macromolecular adhesive additivesFilm/foil adhesivesWater basedIsooctyl acrylate

The invention relates to a preparation method of a water-based acrylate pressure-sensitive adhesive, and an application of the adhesive in household appliance protective films. A component A of the pressure-sensitive adhesive is an alkyl (methyl) acrylate polymer, and a component B of the pressure-sensitive adhesive is a polyfunctional aziridine-series crosslinking agent. The component A is obtained through polymerization of butyl acrylate, isooctyl acrylate, methyl methacrylate, butyl methacrylate, 2-hydroxypropyl acrylate, acrylic acid and (methyl) acrylate containing two double bonds, wherein the polymerization is initiated by ammonium sulfate. The pressure-sensitive adhesive provided by the invention has the advantages of good leveling property, less foam, fisheye-free property in coating, and the like. When the adhesive is applied on a needed substrate to prepare a household appliance protective film, the protective film has good high-temperature resistance, good high-humidity resistance and good aging resistance. When the protective film is torn from the surface of a household appliance, no residual adhesive or spot is left.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

A kind of coating of interpenetrating network structure hydrophilic coating and its preparation and application method

ActiveCN105985720BSolve the lack of firmnessTightly boundPolyurea/polyurethane coatingsSpecial surfacesVinyl etherEndovascular treatment

The invention relates to a coating of an interpenetrating network structure hydrophilic coating and a method for preparing and using the coating. The coating includes a primer and a top coating. The primer contains water-based polyurethane, multifunctional aziridine derivatives and deionized water. The top coating The coating contains pendant carboxyl polyurethane, polymethyl vinyl ether-maleic anhydride, acrylic acid, hydroxyethyl acrylate, multifunctional acrylate derivatives, free radical initiators and organic solvents, and the components form cross-linked interconnections during curing. Through the network structure, the coating has excellent hydrophilic lubricity and wear resistance, and is suitable for hydrophilic lubrication treatment of interventional devices in the field of endovascular interventional diagnosis and treatment technology.

Owner:BEIJING DEMAX MEDICAL TECH

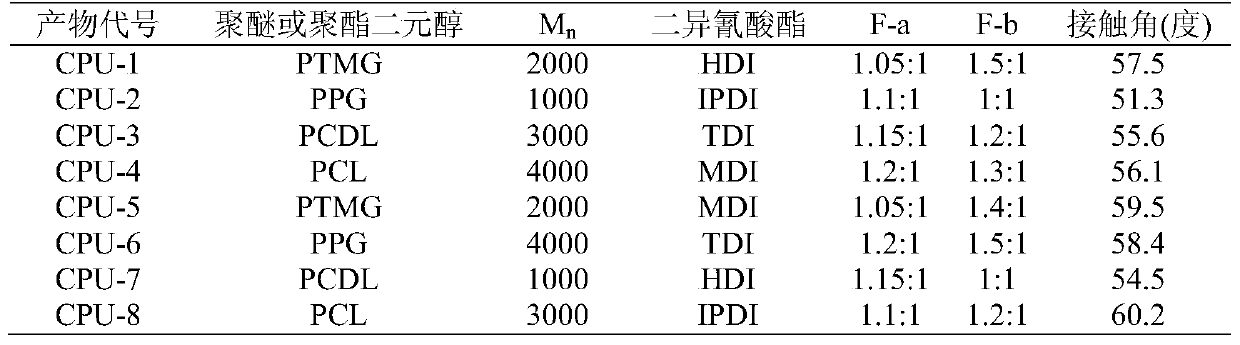

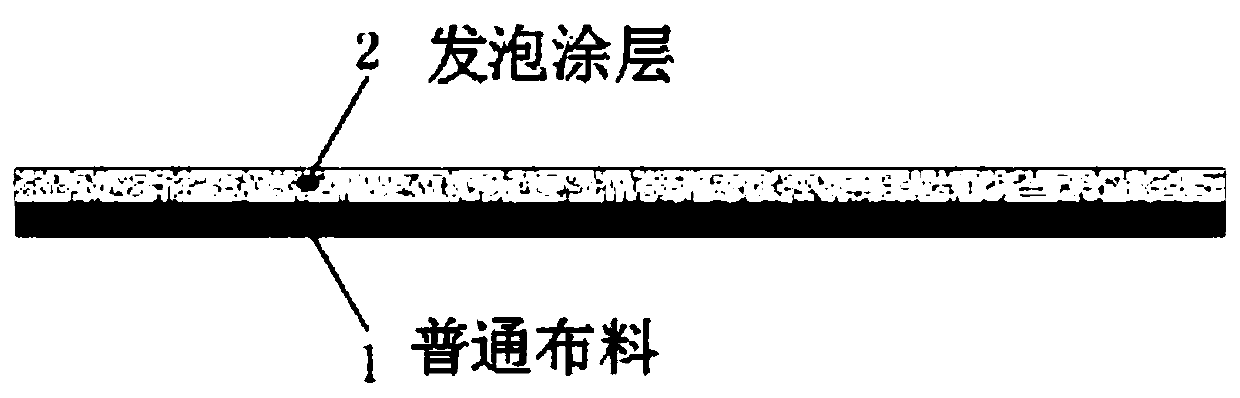

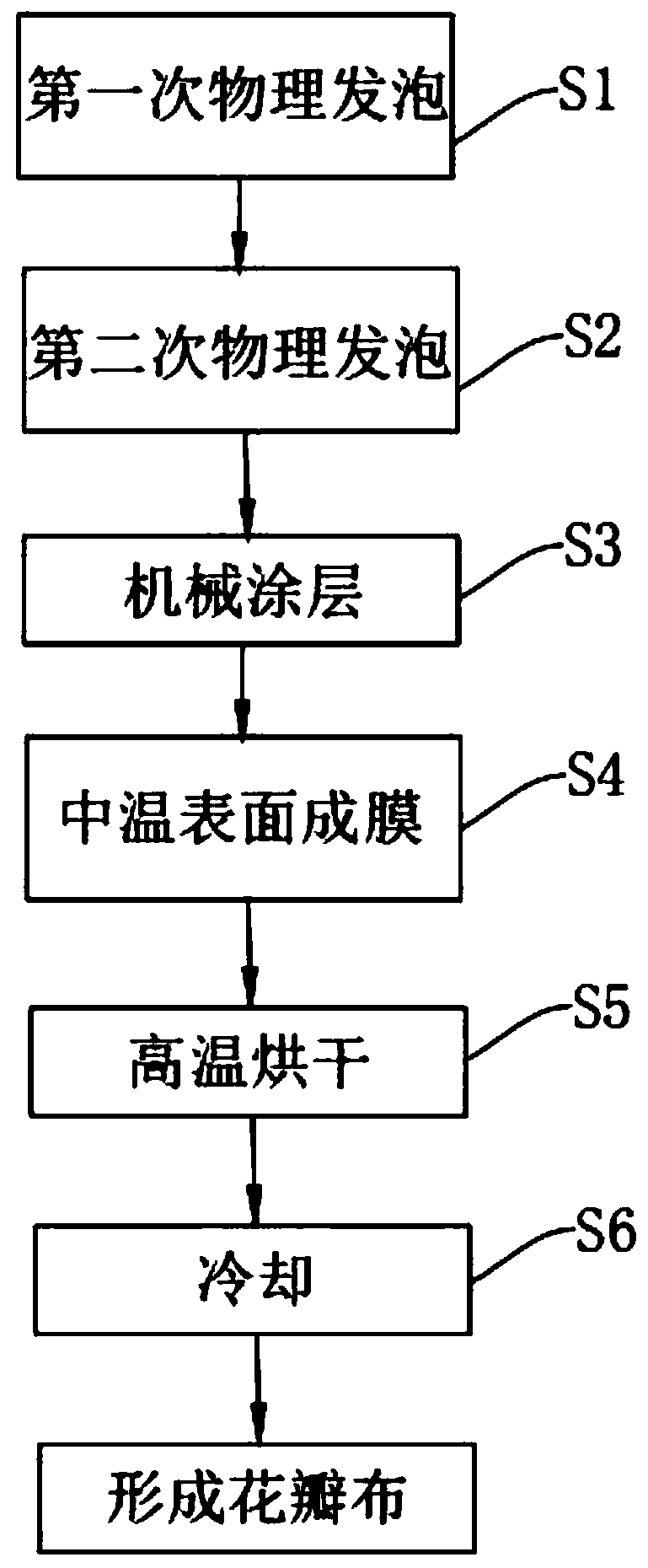

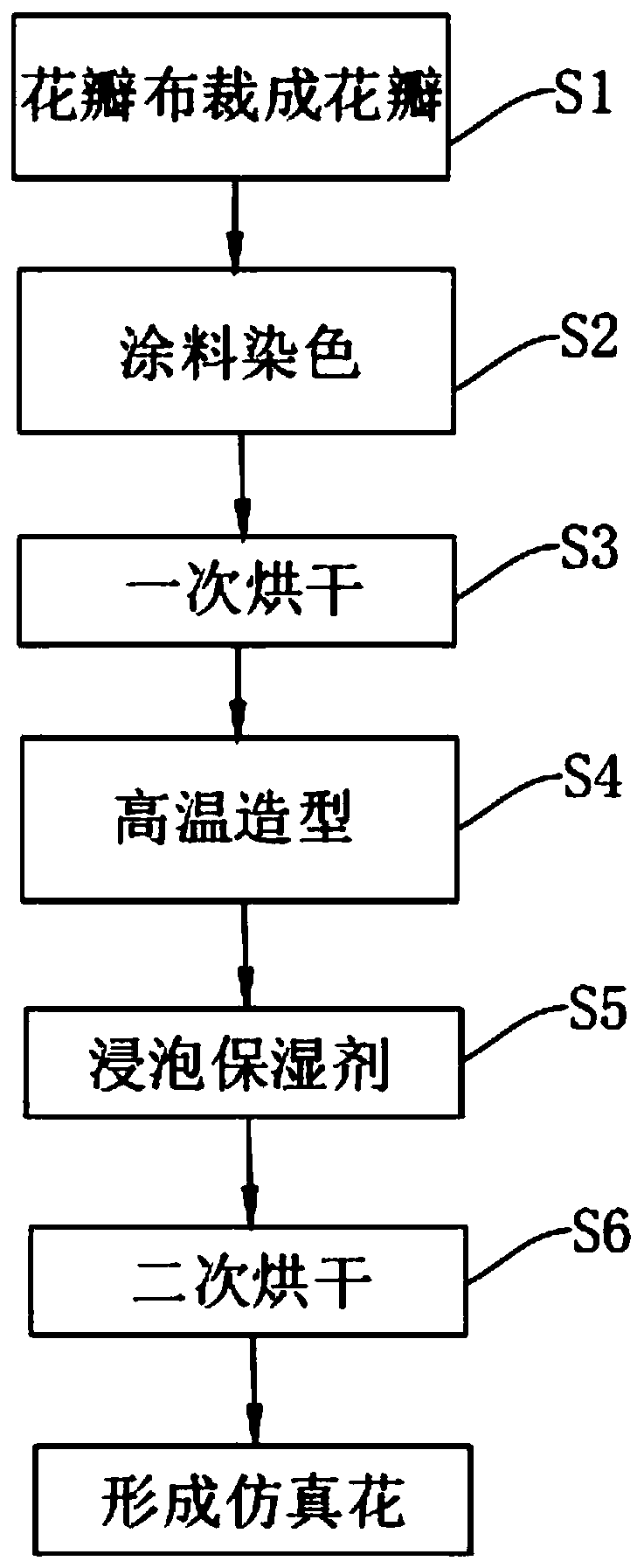

Petal cloth with real flower touch and preparation method of petal cloth and artificial flowers

InactiveCN111455678ATactile realEasy to dyeArtificial flowers and garlandsTextiles and paperAziridineCross linker

The invention discloses petal cloth with real flower touch. The petal cloth comprises ordinary cloth. An intumescent coating with real flower touch covers one side or both sides of the ordinary cloth.The intumescent coating is composed of 40%-50% of styrene-butadiene rubber latex (50% of solid content), 15%-20% of talcum powder (800 meshes), 20%-25% of vegetable starch, 1% of calcium stearate, 3%of sodium lauryl sulfonate, 2% of alkylolamides, 0.5% of a polyfunctional aziridine cross-linking agent and 5%-15% of water. The invention further discloses a preparation method of the petal cloth with the real flower touch and a preparation method of artificial flowers with the real flower touch. According to the method, the technical problem that the tactile sensation of the artificial flowersis quite different from that of real flowers is solved. The cloth has the advantages of a smooth and delicate surface, a porous plant structure in the middle, real tactile sensation of the petal clothas the real flowers, easy dyeing, saturated and bright colors, and easy modeling, and the high-end market demand is met.

Owner:东莞东业工艺制品有限公司

Post-curable rubber-based pressure-sensitive adhesive

InactiveCN107108955ANon-macromolecular adhesive additivesOther rubber adhesivesElastomerPressure sensitive

The present disclosure is directed to a curable precursor of a pressure sensitive adhesive comprising a) a (co)polymeric material comprising a rubber-based elastomeric material; b) a polyfunctional aziridine curing agent; and c) an acid generating agent. The present disclosure is also directed to a method of manufacturing such pressure sensitive adhesives and uses thereof.

Owner:3M INNOVATIVE PROPERTIES CO

Insulation-coated electroconductive particles

ActiveUS20060261315A1Easy to optimizeReliable conductionNon-insulated conductorsConductive materialAnisotropic conductive adhesiveAziridine

To provide both an excellent solvent-resistance and a conduction reliability to an insulation coated conductive particle that is suitable for use as a conductive particle in an anisotropic conductive adhesive, the insulation coated conductive particle is configured such that the surface of a conductive particle is coated with an insulating resin layer formed of an insulating resin having a carboxyl group, and the insulating resin layer is surface-treated with a polyfunctional aziridine compound. Examples of the aziridine compound include trimethylolpropane-tri-β-aziridinylpropionate, tetramethylolmethane-tri-β-aziridinylpropionate, and N,N-hexamethylene-1, 6-bis-1-aziridinecarboxamide. The insulating resin layer is preferably composed of an insulating resin having an acrylic acid monomer unit or a methacrylic acid monomer unit. Specifically, the preferable insulating resin is an acrylic acid-styrene copolymer.

Owner:SONY CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com