Coated abrasive article with tie layer, and method of making and using the same

A technology of abrasive products and bonding layers, which is applied in the direction of abrasives, manufacturing tools, metal processing equipment, etc., and can solve problems such as performance damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

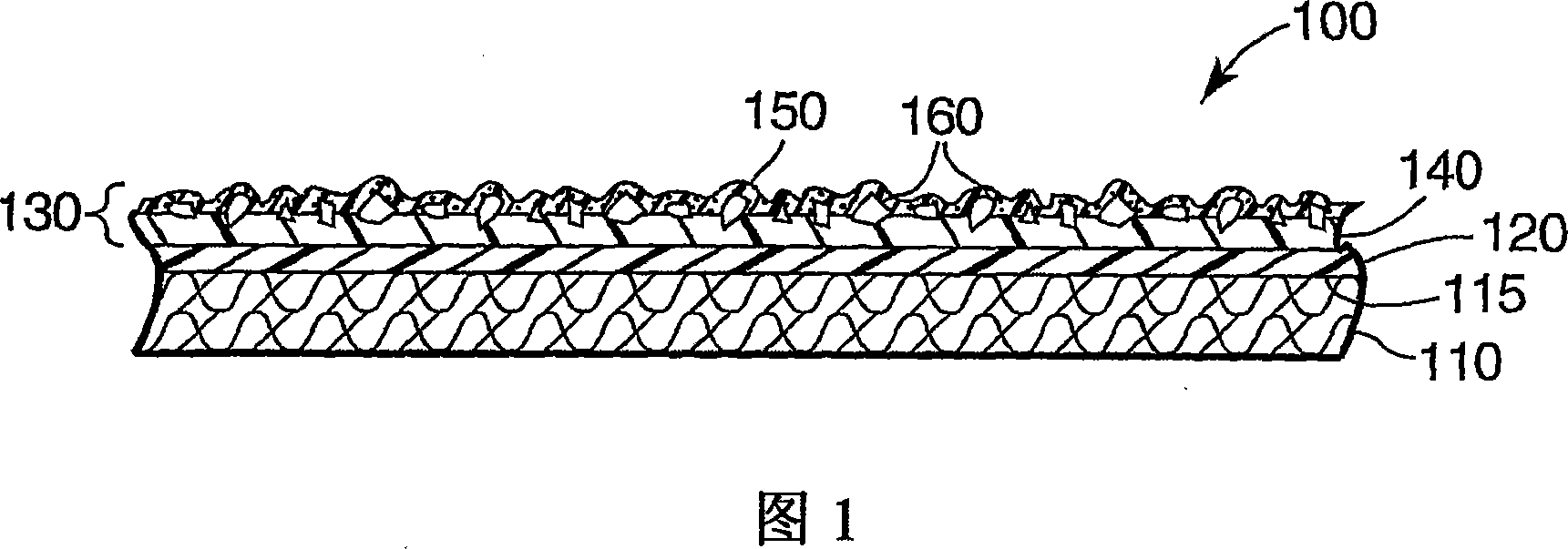

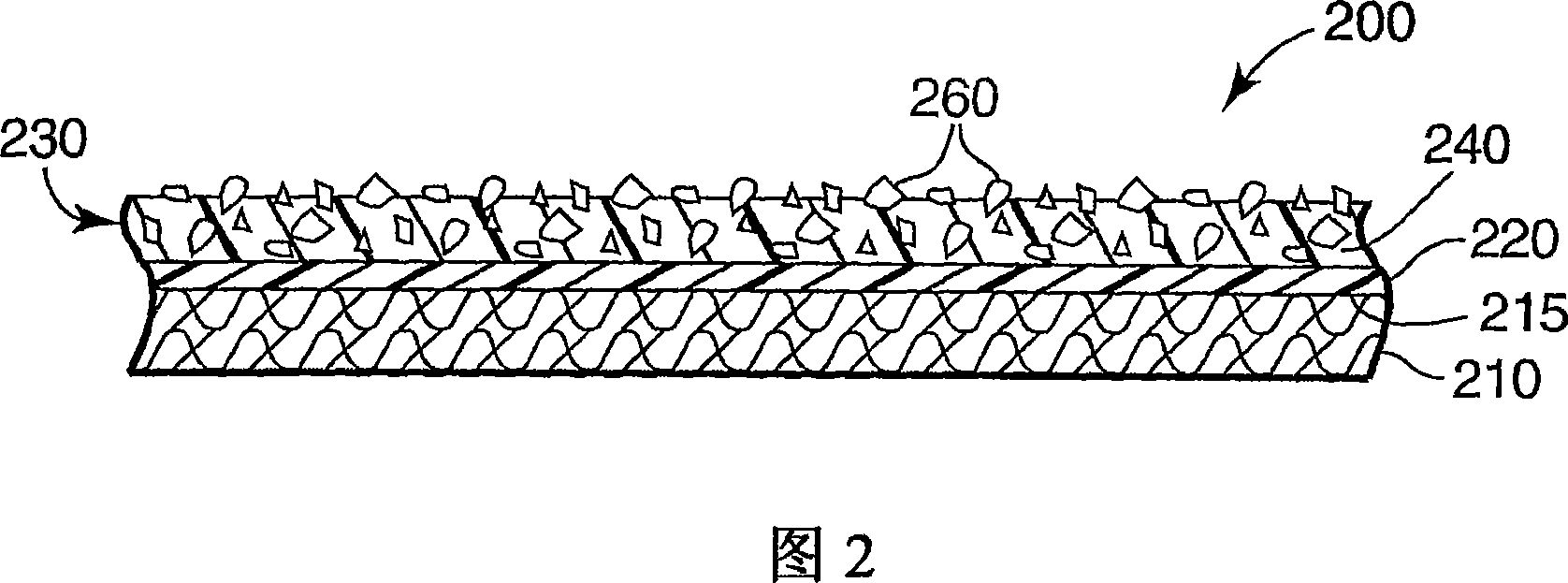

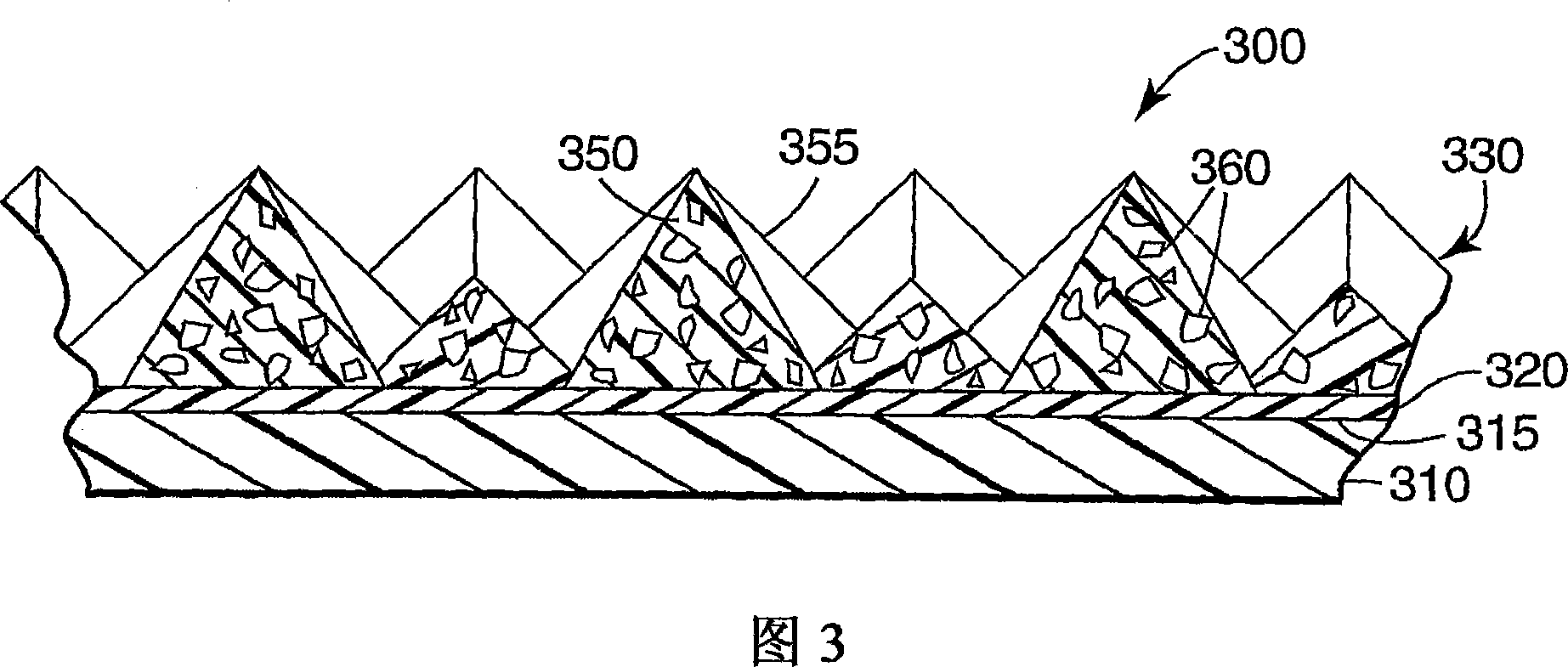

Image

Examples

preparation example Construction

[0047] Methods for the preparation of these oligomers are well known in the art and a variety of useful free radically polymerizable oligomers are commercially available. Examples include: aliphatic and aromatic urethane (meth)acrylate oligomers such as those available from UCBChemicals, Smyrna, Georgia, USA (trade names "EBECRYL 270", "EBECRYL 8804", "EBECRYL 8807" , "EBECRYL 4827", "EBECRYL 6700", "EBECRYL 5129" or "EBECRYL 8402"), and available from Sartomer Corporation, Exton, Pennsylvania, USA (trade names "CN 1963", "CN934", "CN 953B70", "CN 984", "CN 962", "CN 964", "CN 965", "CN 972" and "CN 978"); polyester (meth)acrylate oligomers, such as Available from UCB Chemicals (trade names "EBECRYL 80", "EBECRYL 81", "EBECRYL 657", "EBECRYL 810", "EBECRYL 450", "EBECRYL 870" or "EBECRYL 2870"), and available from Sand Dormer Company (trade name "CN 292"); polyether (meth)acrylate oligomers, such as available from Sartomer Company (trade name "CN 501", "CN 502", "CN 550 " an...

Embodiment 1-25

[0101] Tie layer precursors were prepared following the general procedure for preparing tie layer precursors as shown in Table 1. The tie layer precursor was then coated on the backing as shown and cured to form the tie layer following the general procedure for making backings with tie layers. An abrasive layer is then applied to the bond layer. The resulting coated abrasive articles were subjected to a 90° peel adhesion test. In Table 1, the coated abrasive articles failed over the range of the coated abrasive.

[0102] Example

[0103] *Abrasives and bonding layers adhere to the film beyond the internal strength of the film, causing the film to tear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com