Conductive composition, conductive film and their producing methods

A technology of conductivity and composition, applied in the field of conductive composition, can solve the problems of film warping and curling, and achieve the effect of excellent film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 43 parts of an aqueous solution of PEDOT / PSS (non-volatile content 0.52% by weight), 46.3 parts of ion-exchanged water, 0.1 part of p-toluenesulfonic acid, and 0.6 part of triethylamine were added and mixed well. Then, 10 parts of an isopropanol solution of tetramethylolmethane-tris(1-aziridinylpropionate) (1.4% by weight of non-volatile matter) was mixed with the obtained aqueous solution to prepare a conductive composition 1 . Table 1 shows the types of raw materials of this composition 1 and their respective weight %. The value of component (D) is the total value of components derived from component (A) and component (C) and externally added components.

Embodiment 2~13、 comparative example 1~2

[0059] Conductive compositions 2 to 13 and comparative conductive compositions (i) to (□) were prepared in the same manner as in Example 1, except that the types of raw materials and weight % were changed as shown in Table 1.

[0060] 【Table 1】

[0061]

[0062] In Table 1, the meanings of each symbol are as follows.

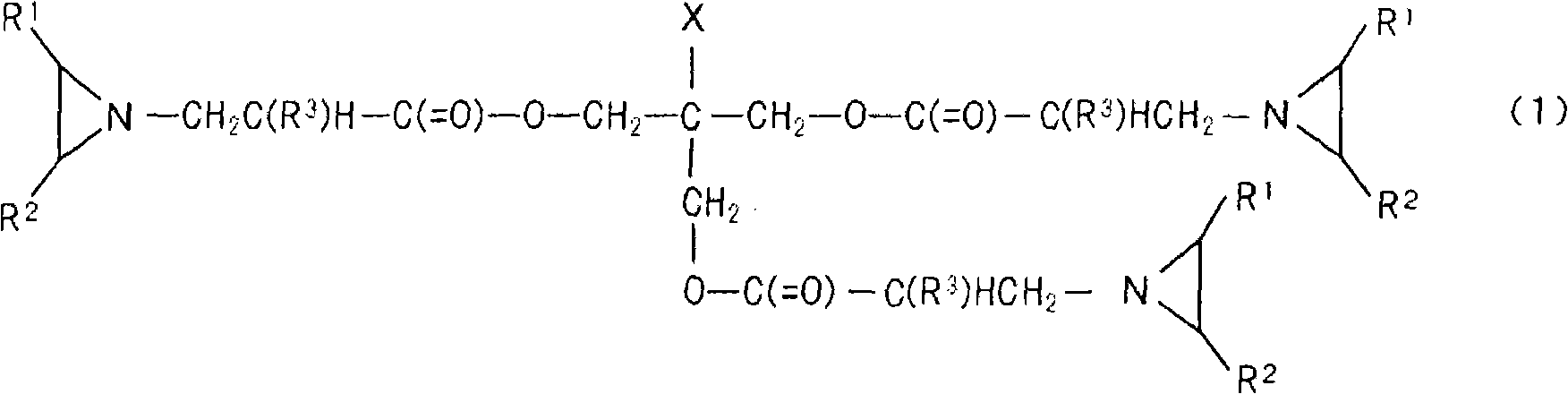

[0063] TMMTAP: Tetramethylolmethane-tris(1-aziridinylpropionate) (trade name "TAZO", manufactured by Mutual Pharmaceutical Co., Ltd.)

[0064] TMPTAP: Trimethylolpropane-tris(1-aziridinylpropionate) (trade name "TAZM", manufactured by Mutual Pharmaceutical Co., Ltd.)

[0065] PTS: p-toluenesulfonic acid

[0066] TFMS: Trifluoromethanesulfonic acid

[0067] PEDOT / PSS: poly(3,4-ethylenedioxythiophene) doped with polystyrene sulfonate (trade name "CLEVIOS P", manufactured by Starck Corporation)

[0068] PANI: Aqueous solution of polyaniline (trade name "ORMECON D 1031W", manufactured by Nissan Chemical Industry Co., Ltd.) (non-volatile content 2%)

[0069] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com