Aqueous pressure-sensitive adhesive for heat-insulating broken bridge aluminum profile protection film and preparation method thereof

A technology for thermal insulation, bridge breaking and protective film, applied in pressure-sensitive films/sheets, adhesive types, ester copolymer adhesives, etc., to improve cohesive strength, improve heat and moisture resistance, and improve adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

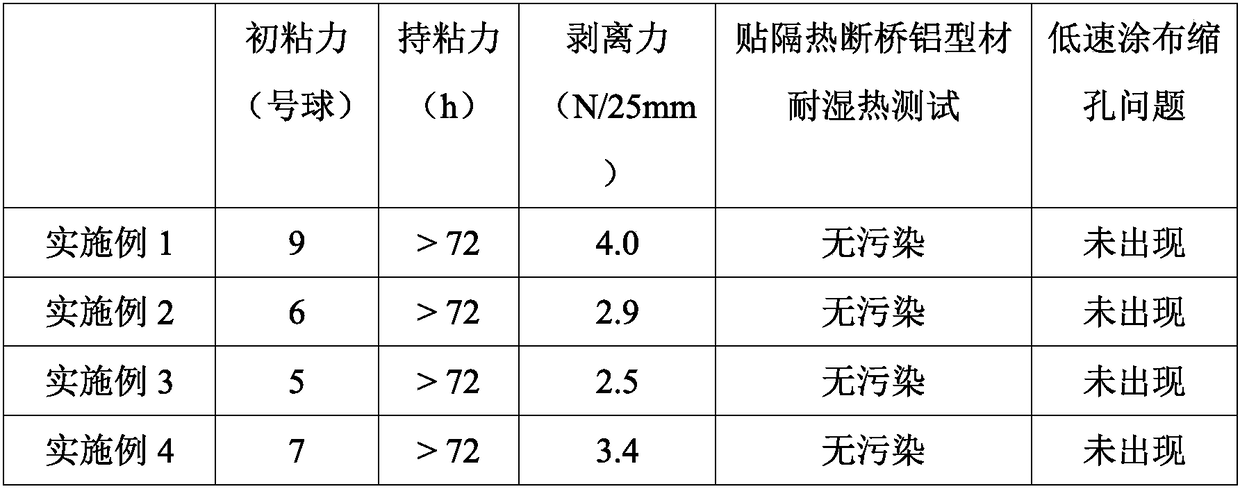

Examples

Embodiment 1

[0032] A water-based acrylic pressure-sensitive adhesive for the protective film of heat-insulating bridge-breaking aluminum profiles, the preparation steps of which are as follows:

[0033] 1. Preparation of seed emulsion: Mix 34 parts of deionized water and 2.0 parts of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, stir evenly at a stirring speed of 500 rpm, and then slowly mix 5 parts of Methyl methacrylate, 45 parts of 2-ethylhexyl acrylate, 45 parts of butyl acrylate, 2 parts of N-methylolacrylamide, 3 parts of hydroxyethyl acrylate, 0.1 part of n-dodecane Add mercaptan dropwise and stir for 20-30 minutes to obtain pre-emulsion I; mix 82 parts of deionized water, 0.3 parts of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, and put 5 parts of pre-emulsion I into In the reaction kettle, start to heat up to 85°C, then add 0.1 parts of initiator to the system, initiate the polymerization of the system, and react for 30 minutes; then dropwise add the ...

Embodiment 2

[0038] A water-based acrylic pressure-sensitive adhesive for the protective film of heat-insulating bridge-breaking aluminum profiles, the preparation steps of which are as follows:

[0039] 1. Preparation of seed emulsion: Mix 34 parts of deionized water and 2.0 parts of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, stir evenly at a stirring speed of 500 rpm, and then slowly mix 5 parts of Methyl methacrylate, 45 parts of 2-ethylhexyl acrylate, 45 parts of butyl acrylate, 2 parts of N-methylolacrylamide, 3 parts of hydroxyethyl acrylate, 0.1 part of n-dodecane Add mercaptan dropwise and stir for 20-30 minutes to obtain pre-emulsion I; mix 82 parts of deionized water, 0.3 parts of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, and put 7 parts of pre-emulsion I into In the reaction kettle, start to heat up to 85°C, then add 0.1 parts of initiator to the system, initiate the polymerization of the system, and react for 30 minutes; then dropwise add the ...

Embodiment 3

[0044] A water-based acrylic pressure-sensitive adhesive for the protective film of heat-insulating bridge-breaking aluminum profiles, the preparation steps of which are as follows:

[0045] 1. Preparation of seed emulsion: Mix 34 parts of deionized water and 2.0 parts of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, stir evenly at a stirring speed of 500 rpm, and then slowly mix 5 parts of Methyl methacrylate, 45 parts of 2-ethylhexyl acrylate, 45 parts of butyl acrylate, 2 parts of N-methylolacrylamide, 3 parts of hydroxyethyl acrylate, 0.1 part of n-dodecane Add mercaptan dropwise and stir for 20-30 minutes to obtain pre-emulsion I; mix 82 parts of deionized water, 0.3 parts of allyloxynonylphenol polyoxyethylene ether ammonium sulfate, and put 7 parts of pre-emulsion I into In the reaction kettle, start to heat up to 85°C, then add 0.1 parts of initiator to the system, initiate the polymerization of the system, and react for 30 minutes; then dropwise add the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com