Latex solution for producing lignin nonwoven cloth for cigarette

A technology of latex and non-woven fabrics, applied in the fields of application, tobacco, and non-woven fabrics, can solve the problems of high moisture regain, low wet strength, and poor compression resilience, and achieve low moisture regain, high wet strength, and compression Good resilience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

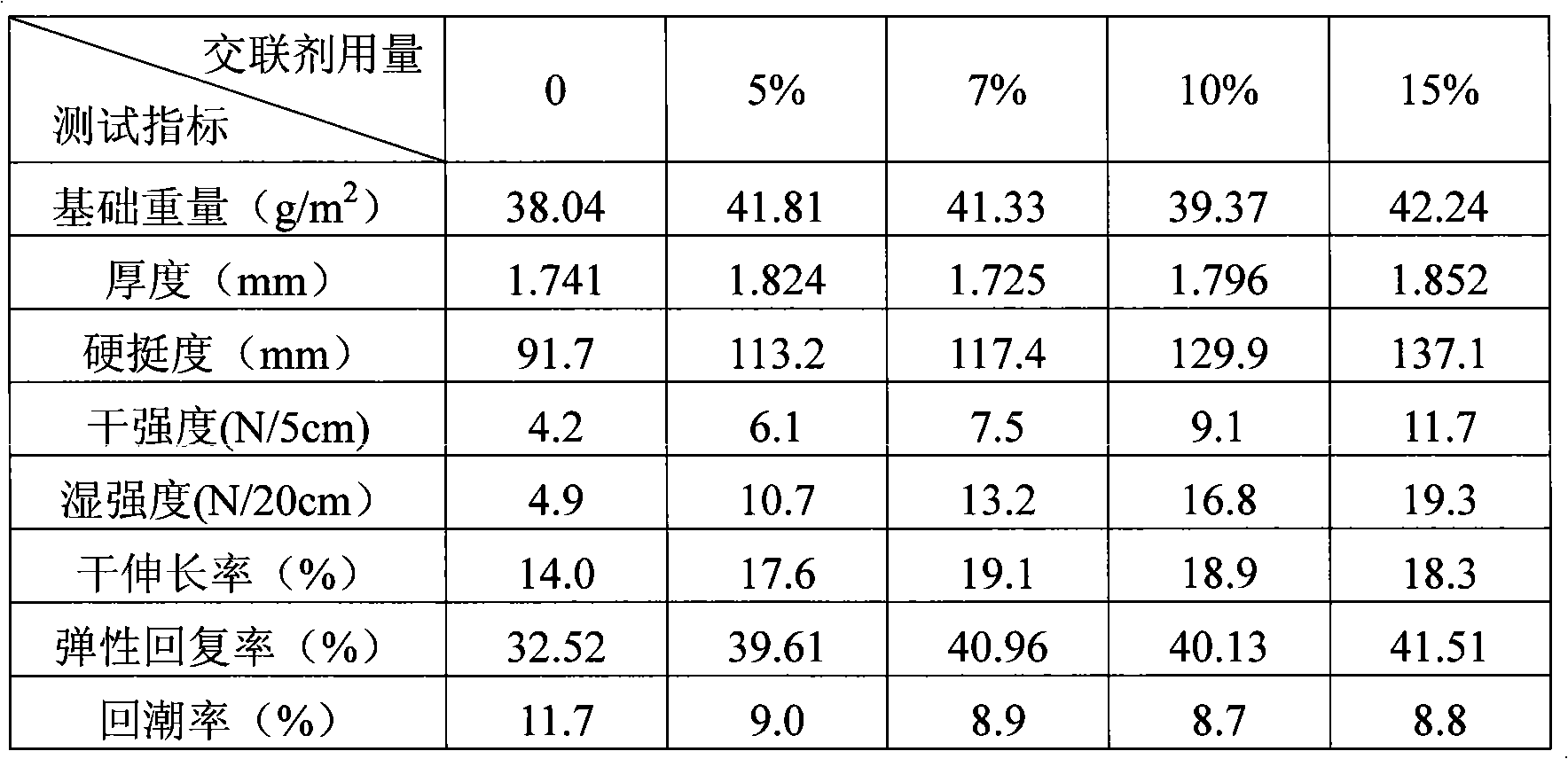

[0016] In the latex, mix vinyl acetate copolymer and vinyl acetate binder in a mass ratio of 5:5, apply HMMM cross-linking agent, and add stabilizer ammonia water, adjust the pH value of the latex within the range of 7.5 to 9.0, wherein The solid content of the vinyl acetate copolymer and the vinyl acetate adhesive is 55%, the crosslinking agent CPS4000~6000, and the solid content of the latex emulsion is 8%. The obtained latex emulsion was used to produce non-woven fabrics, and the test indexes of the non-woven fabrics are listed in Table 1.

[0017] Table 1. The non-woven fabric index under the formula of embodiment 1

[0018]

Embodiment 2

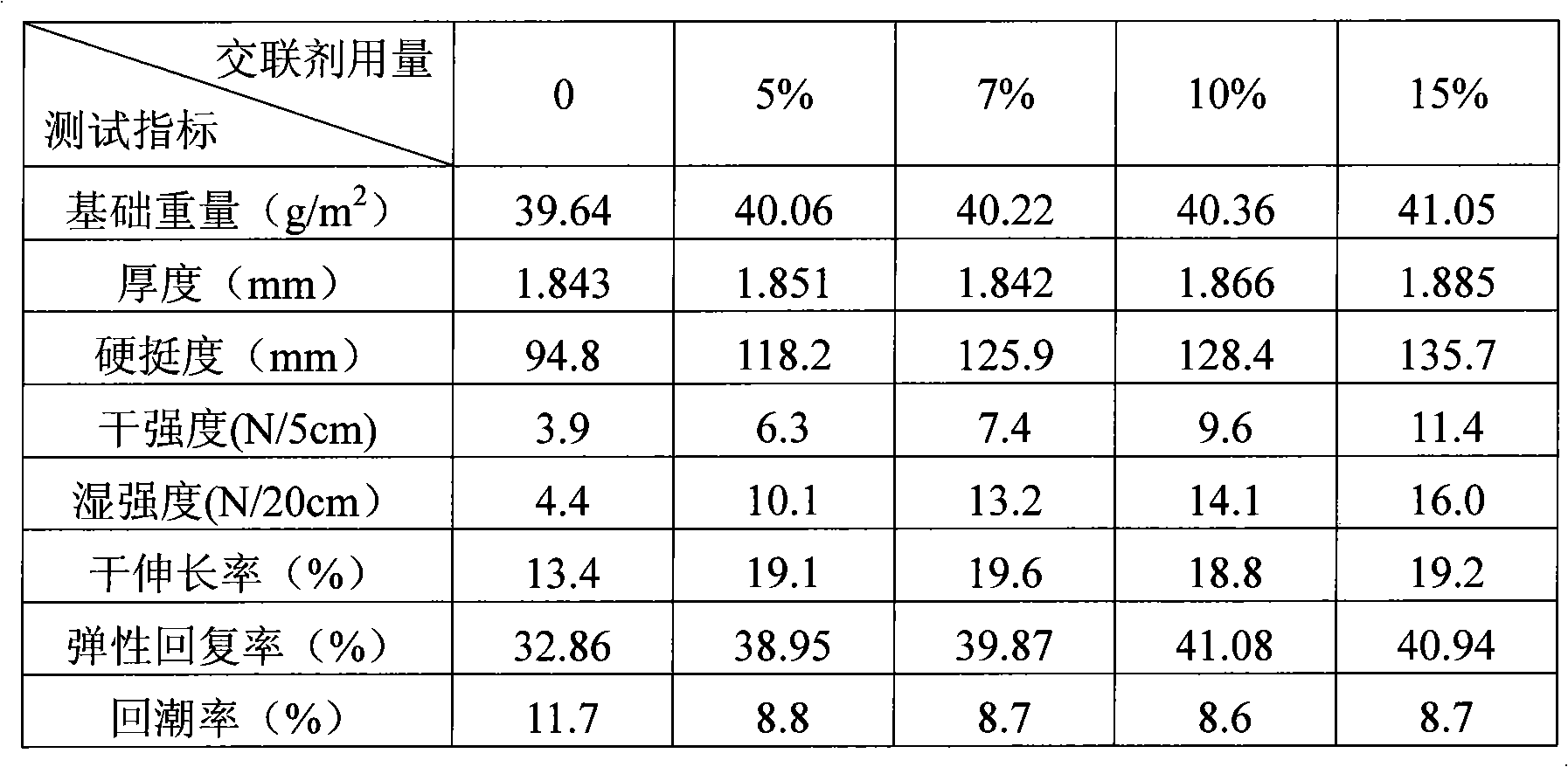

[0020] Vinyl acetate in embodiment 1 and the mass ratio of vinyl acetate copolymer adhesive are changed into 3: 7, and the non-woven fabric index produced under the latex emulsion formula formed under other conditions unchanged is listed in table 2 .

[0021] Table 2. The non-woven fabric index under the formula of embodiment 2

[0022]

Embodiment 3

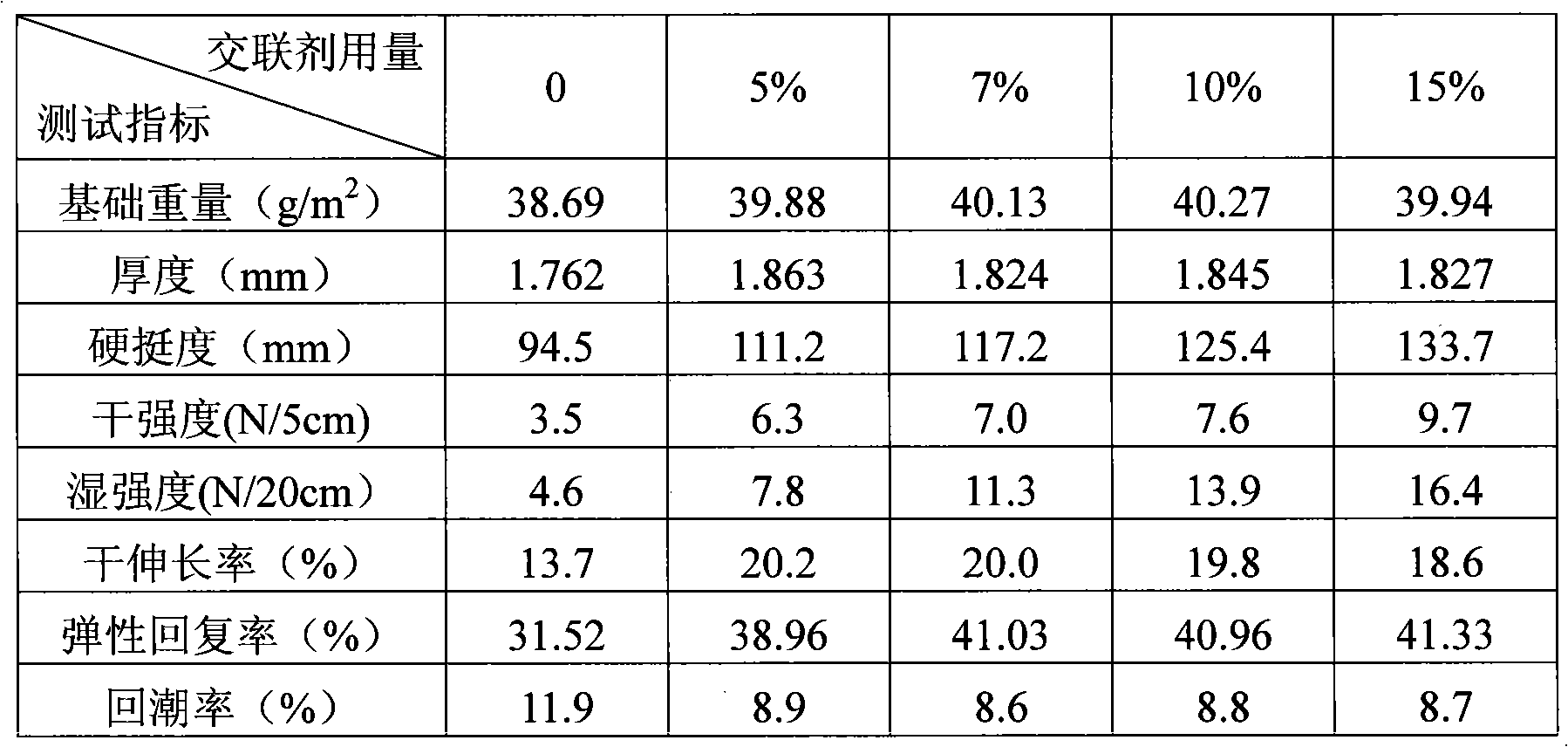

[0024] In the latex emulsion of Example 1, the mass ratio of vinyl acetate and vinyl acetate copolymer was changed to 7: 3, and the indicators of the non-woven fabric produced under the latex emulsion formula formed under other conditions were listed in Table 3.

[0025] Table 3. The non-woven fabric index under the formula of embodiment 3

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com