Pinewood water-based oil-proof transparent primer as well as preparation method and application thereof

A transparent primer and oil-repellent technology, applied in the direction of coating, etc., can solve the problem that oil cannot be sealed, and achieve the effect of orderly film-forming structure and stable cross-linking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

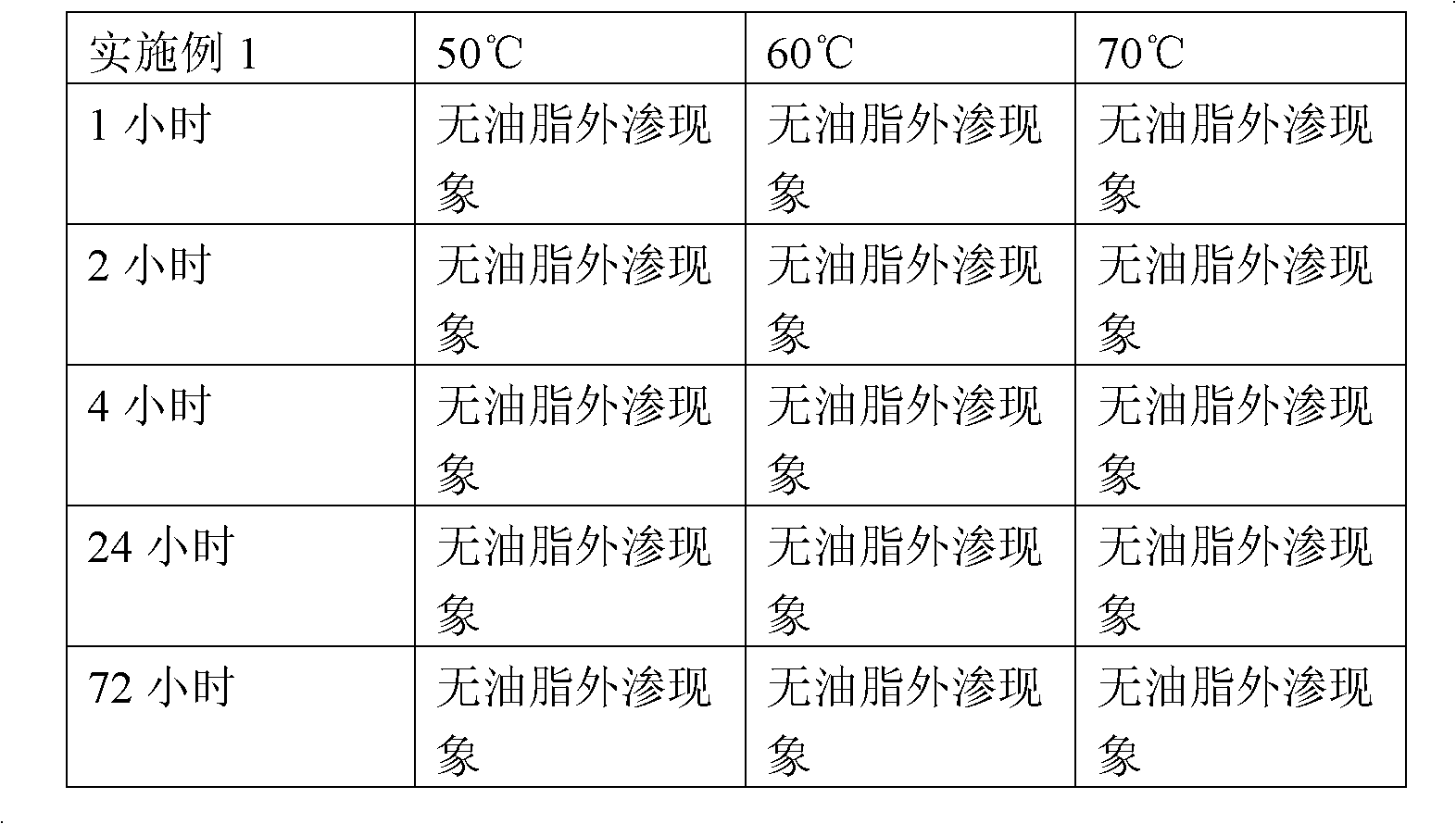

Embodiment 1

[0033] A preparation method for pine water-based oil-proof transparent primer, comprising the following steps:

[0034] Get 60 kilograms of commercially available water-based polyurethane-acrylate graft oil-repellent copolymer (1636T of Guangzhou Kangzheng Polymer Material Technology Co., Ltd.), 20.6 kilograms of dodecafluoroheptyl methacrylate, 19 kilograms of deionized water, and water-based fluid Leveling agent (0.2 kilogram, the Zonyl FSO of DuPont company), defoamer (0.1 kilogram, the Foamex 805 of Tego company) and surface additive (0.1 kilogram, mass concentration 75%, the Aerosol OT of Dexter company) mix and stir, obtain A component: Add 5 kg of B component multi-component aziridine solution (mass volume concentration: 40%) to A component, mix and stir evenly to obtain the pine wood water-based oil-proof transparent primer.

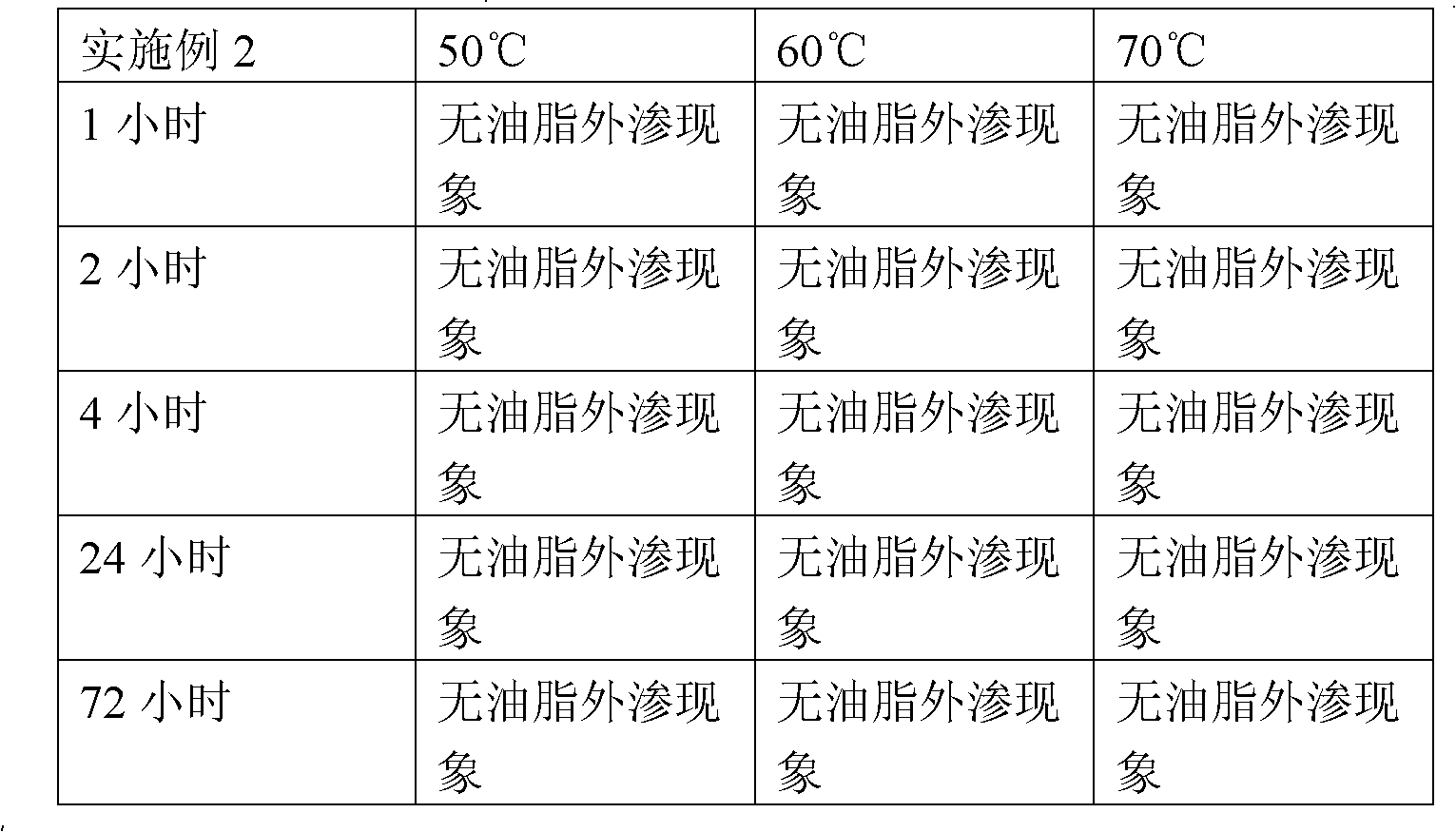

Embodiment 2

[0036] A preparation method for pine water-based oil-proof transparent primer, comprising the following steps:

[0037] Get 70 kilograms of commercially available water-based polyurethane-acrylate graft oil-repellent copolymer (1636T of Guangzhou Kangzheng Polymer Material Technology Co., Ltd.), 15.6 kilograms of dodecafluoroheptyl methacrylate, 14 kilograms of deionized water, and water-based fluid Leveling agent (0.2 kilogram, the Zonyl FSO of DuPont company), defoamer (0.1 kilogram, the Foamex 805 of Tego company) and surface additive (0.1 kilogram, mass concentration 75%, the Aerosol OT of Dexter company) mix and stir, obtain A component; then add 15 kg of B component multi-component aziridine solution (55% mass volume concentration) to A component, mix and stir evenly to obtain a pine wood water-based oil-proof transparent primer.

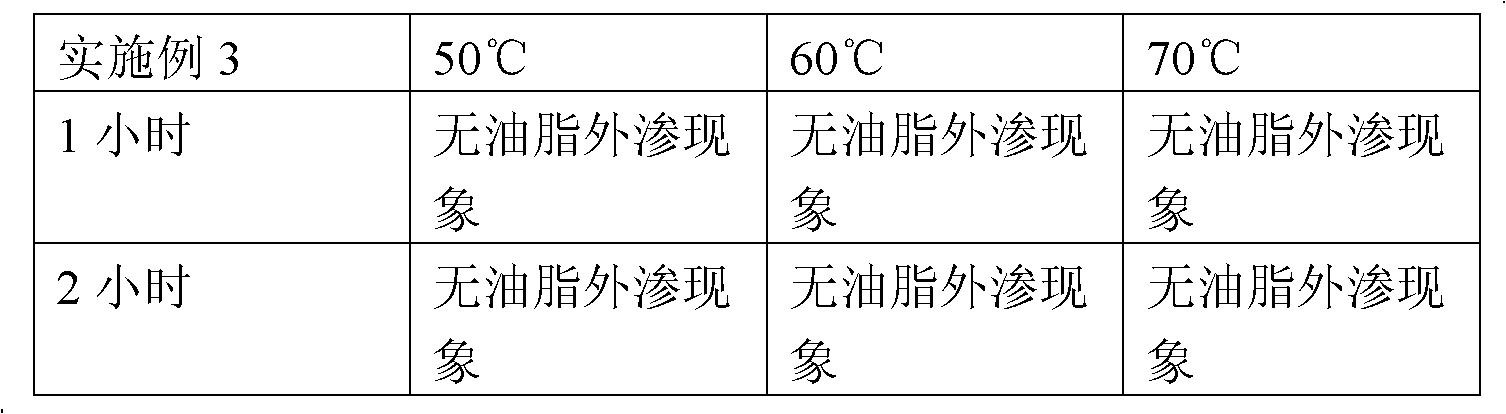

Embodiment 3

[0039] A preparation method for pine water-based oil-proof transparent primer, comprising the following steps:

[0040] Get 65 kilograms of commercially available water-based polyurethane-acrylate graft oil-repellent copolymer (1636T of Guangzhou Kangzheng Polymer Material Technology Co., Ltd.), 18.6 kilograms of dodecafluoroheptyl methacrylate, 16 kilograms of deionized water, and water-based fluid Leveling agent (0.2 kilogram, the Zonyl FSO of DuPont company), defoamer (0.1 kilogram, the Foamex 805 of Tego company) and surface additive (0.1 kilogram, mass concentration 75%, the Aerosol OT of Dexter company) mix and stir, obtain Component A: 10 kg of multi-component aziridine solution (mass volume concentration: 48%) of component B was added to component A, mixed and stirred evenly to obtain a pine wood water-based oil-proof transparent primer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com