Graphene material of ordered structure and preparing method thereof

An ordered structure, graphene technology, applied in the field of carbon materials, can solve problems such as inability to mass manufacture, inability to obtain macroscopic materials, and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of the graphene material of ordered structure, comprises the following steps:

[0030] A) after mixing the graphene oxide solution with the electrolyte, a mixed solution is obtained;

[0031] B) after the mixed solution that above-mentioned steps is obtained is filtered, obtain mixed graphene material;

[0032] C) Freeze-drying the mixed graphene material obtained in the above steps, and then annealing the mixed graphene material obtained in the above steps under vacuum or a protective atmosphere to obtain a graphene material with an ordered structure.

[0033] In the present invention, firstly, the graphene oxide solution and the electrolyte are mixed to obtain a mixed solution.

[0034] The present invention has no special limitation on the graphene oxide solution, and the graphene oxide solution well known to those skilled in the art can be used. Those skilled in the art can select and adjust according to actual pr...

Embodiment 1

[0051] 1. Take 0.1 mg / mL graphene oxide solution, measure ammonium bicarbonate according to the mass ratio of graphene oxide and ammonium bicarbonate 1:400, add it to deionized water, stir to completely dissolve the ammonium bicarbonate, and obtain a mixed solution.

[0052] 2. Mix the solution. Pour it into a sand core suction filter device, and filter under a pressure of 0.5MPa to form a membrane.

[0053] 3. Freeze-dry the above material at -60°C for 12h to obtain a mixed graphene material of graphene oxide / ammonia bicarbonate, and then place it in a tube furnace with an argon protective atmosphere and anneal at 800°C for 10h to obtain ordered porous graphite vinyl material.

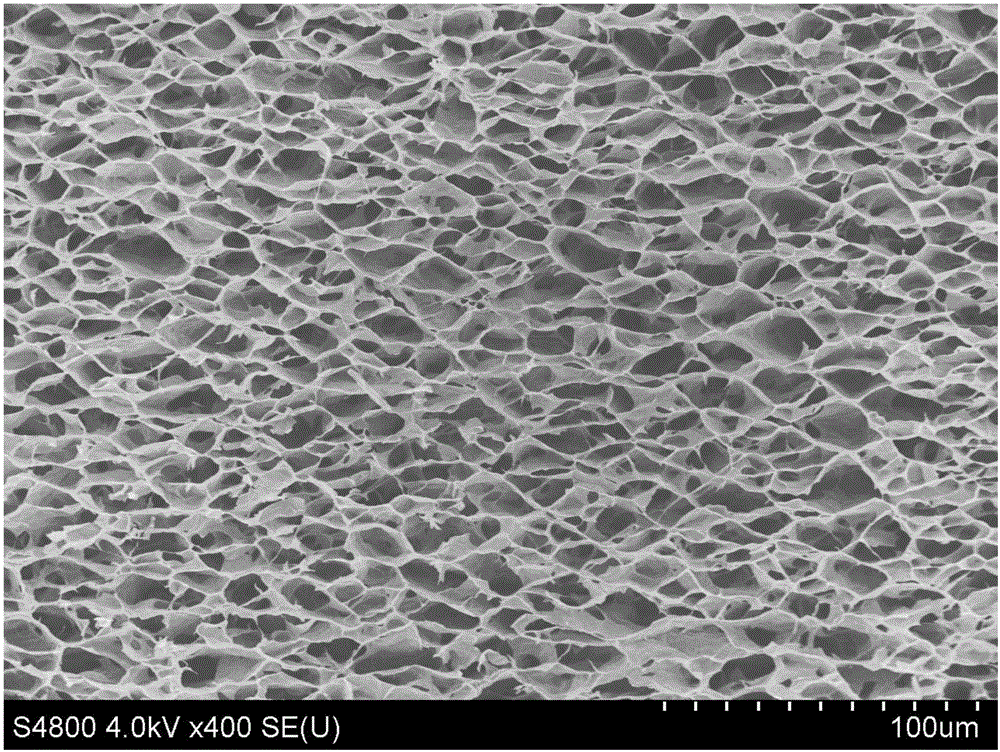

[0054] The ordered porous graphene material prepared in Example 1 of the present invention is detected, see figure 1 , figure 1 Scanning electron microscope image of the graphene material prepared for Example 1 of the present invention. Depend on figure 1 It can be seen that the graphene material...

Embodiment 2

[0056] 1. Take 1.0 mg / mL graphene oxide solution, measure potassium hydroxide according to the mass ratio of graphene oxide and potassium hydroxide 1:5, add it to deionized water, stir to completely dissolve potassium hydroxide, and obtain a mixed solution.

[0057] 2. Pour the mixed solution into a sand core suction filter device, and filter under a pressure of 0.05MPa to form a film.

[0058] 3. The above materials were freeze-dried at -10°C for 20h to obtain a graphene oxide / potassium hydroxide mixed graphene material, and then placed in a tube furnace with an argon protective atmosphere and annealed at 900°C for 1.5h to obtain an ordered porous Graphene material.

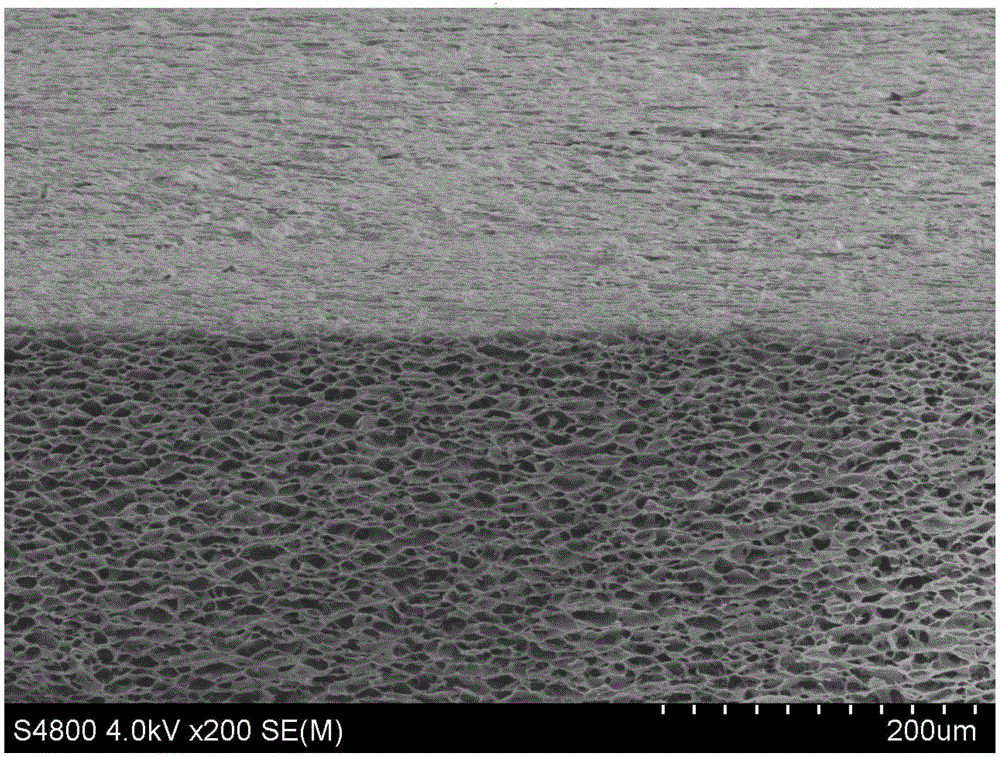

[0059] The ordered porous graphene material prepared in Example 2 of the present invention is detected, see figure 2 , figure 2 Scanning electron microscope image of the graphene material prepared for Example 2 of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com