Waterborne antistatic coating and preparation method thereof

An antistatic, water-based technology, applied in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of large usage and unfavorable environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1. prepares the aqueous solution of carboxylated aqueous conductive polymer system

[0074] The aqueous solution of the carboxylated waterborne conductive polymer system P3TCa / DBSA whose solid content is 0.5wt% is prepared:

[0075] Step 1): Dissolving 0.25g DBSA in 49.75mL deionized water to obtain a DBSA aqueous solution with a concentration of 0.5wt%;

[0076] Step 2): Add 0.125g 3TCa to the DBSA aqueous solution obtained in step 1), and stir evenly to obtain a DBSA aqueous solution dispersed with 3TCa, wherein the concentration of 3TCa is 0.25wt%;

[0077] Step 3): Add 0.5 g of ferric sulfate to the DBSA aqueous solution dispersed with 3TCa obtained in step 2), and react for 48 hours to obtain the initial product system;

[0078] Step 4): Add 17.5g 201*7 type anion exchange resin to the initial product system obtained in step 3), after soaking for 10 minutes, remove the anion exchange resin by suction filtration, then add 16g 001*7 type cation exchange r...

Embodiment 2

[0144] Embodiment 2. prepares the aqueous solution of the aqueous conductive polymer system PEDOT / PSS not containing carboxyl group

[0145] Step 1): Dissolving 0.75g PSS (weight average molecular weight 500000) in 49.25mL deionized water to obtain a PSS aqueous solution with a concentration of 1.5wt%;

[0146] Step 2): Add 0.25g EDOT to the PSS aqueous solution obtained in step 1), and stir evenly to obtain a PSS aqueous solution with EDOT dispersed, wherein the concentration of EDOT in the PSS aqueous solution with EDOT dispersed is 0.5wt%;

[0147] Step 3): Add 1.25 g of sodium persulfate to the PSS aqueous solution dispersed with EDOT obtained in step 2), and react for 24 hours to obtain the initial product system;

[0148] Step 4): Add 25g 201*7 type anion exchange resin to the initial product system obtained in step 3), after soaking for 5 hours, remove the anion exchange resin by suction filtration, then add 25g 001*7 type cation exchange resin to the filtrate, After s...

Embodiment 3

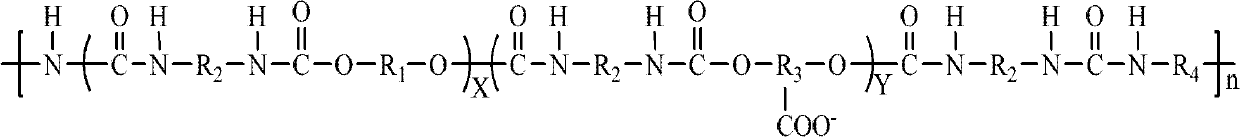

[0149] Embodiment 3. prepare the aqueous solution of carboxylation waterborne polyurethane resin

[0150] Preparation weight average molecular weight is the aqueous solution of the carboxylated waterborne polyurethane resin of 10000:

[0151] Step 1): Under the protection of dry nitrogen, 13 g of dimethylol propionic acid was dissolved in 30 mL of N-methylpyrrolidone to obtain a dimethylol propionic acid solution;

[0152] Step 2): add 52g Polyethylene Glycol (weight average molecular weight 600) in the dimethylolpropionic acid solution that step 1) obtains, after stirring, then add 65g isophorone diisocyanate in above-mentioned system, in Constant temperature reaction at 80°C for 1 hour;

[0153] Step 3): Lower the temperature to 50° C., slowly add 6.5 g of tripropylamine dropwise to the system obtained in step 2), and continue the reaction for 1 hour;

[0154] Step 4): Cool to room temperature, add 163 mL of acetone to the system obtained in step 3), stir evenly, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com