Patents

Literature

32results about How to "Excellent resistance to ethanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

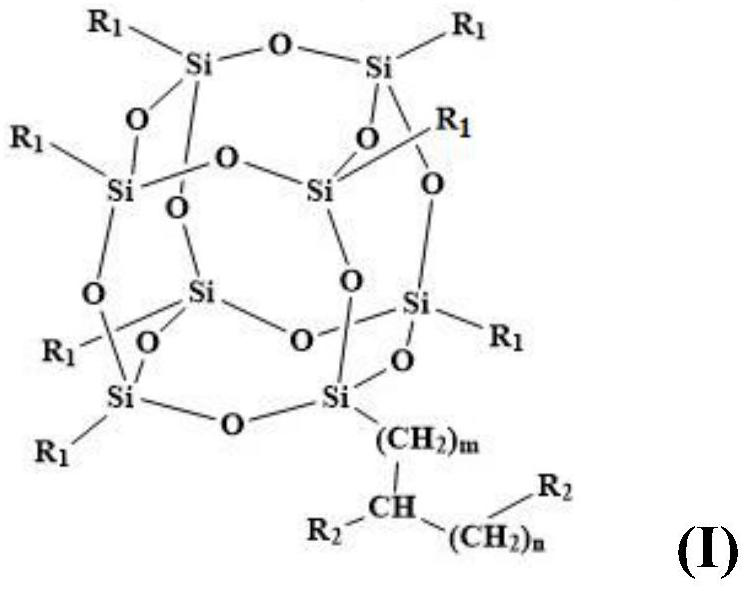

Waterborne polyurethane elastic dispersion and preparation method thereof

ActiveCN103087286AHigh tensile strengthIncrease elasticityFibre treatmentPolyurea/polyurethane coatingsPolyurethane dispersionPolymer science

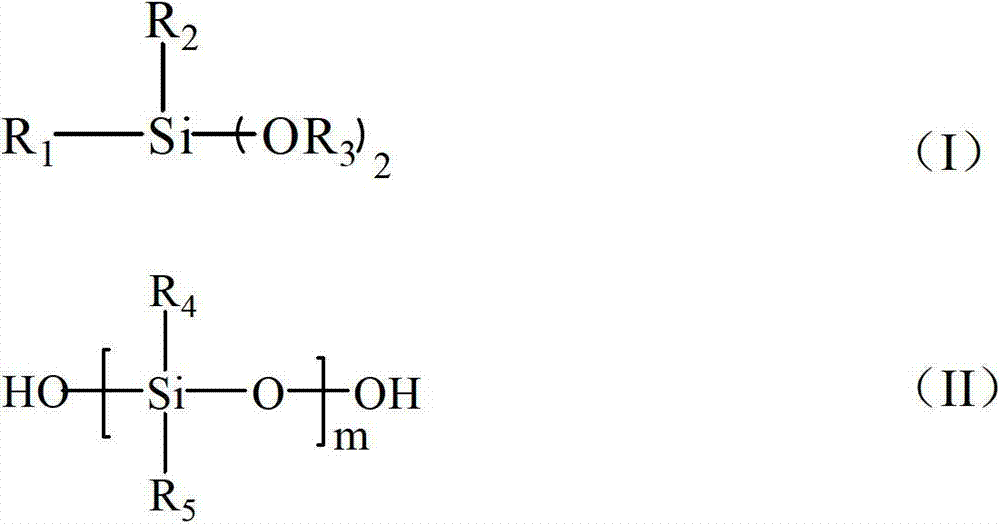

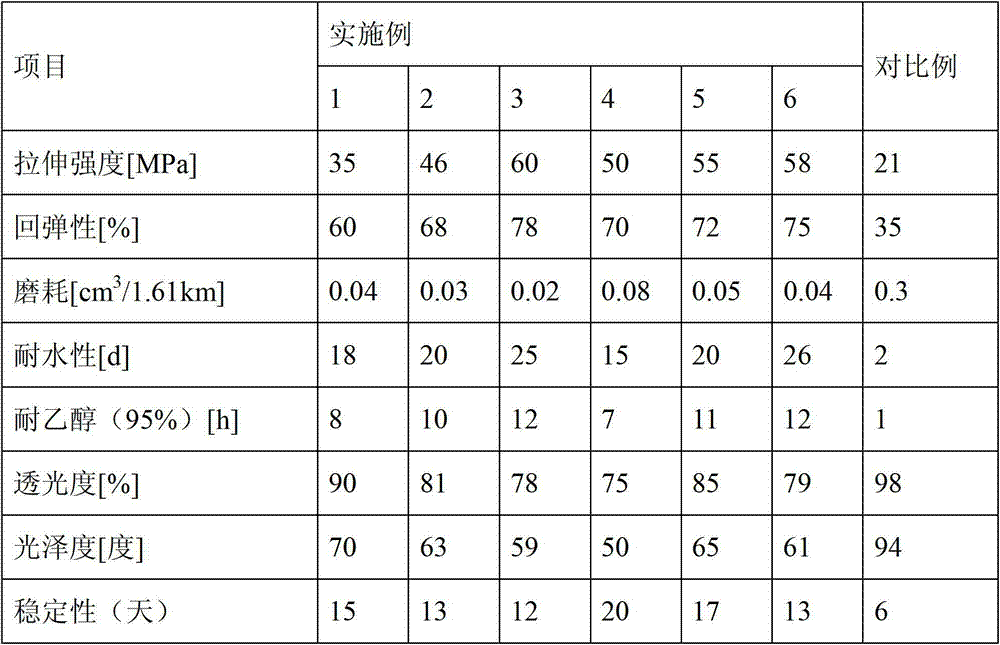

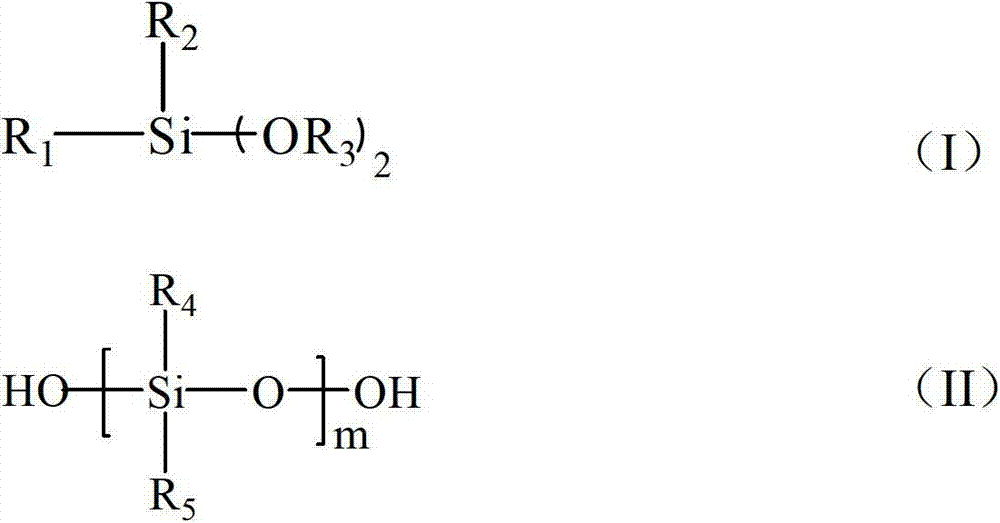

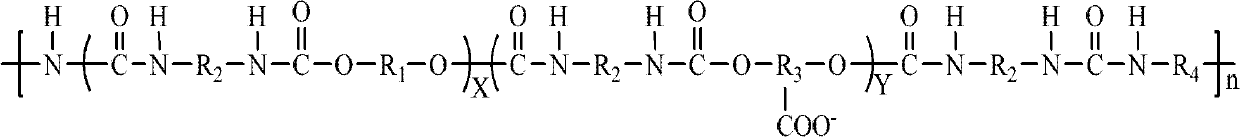

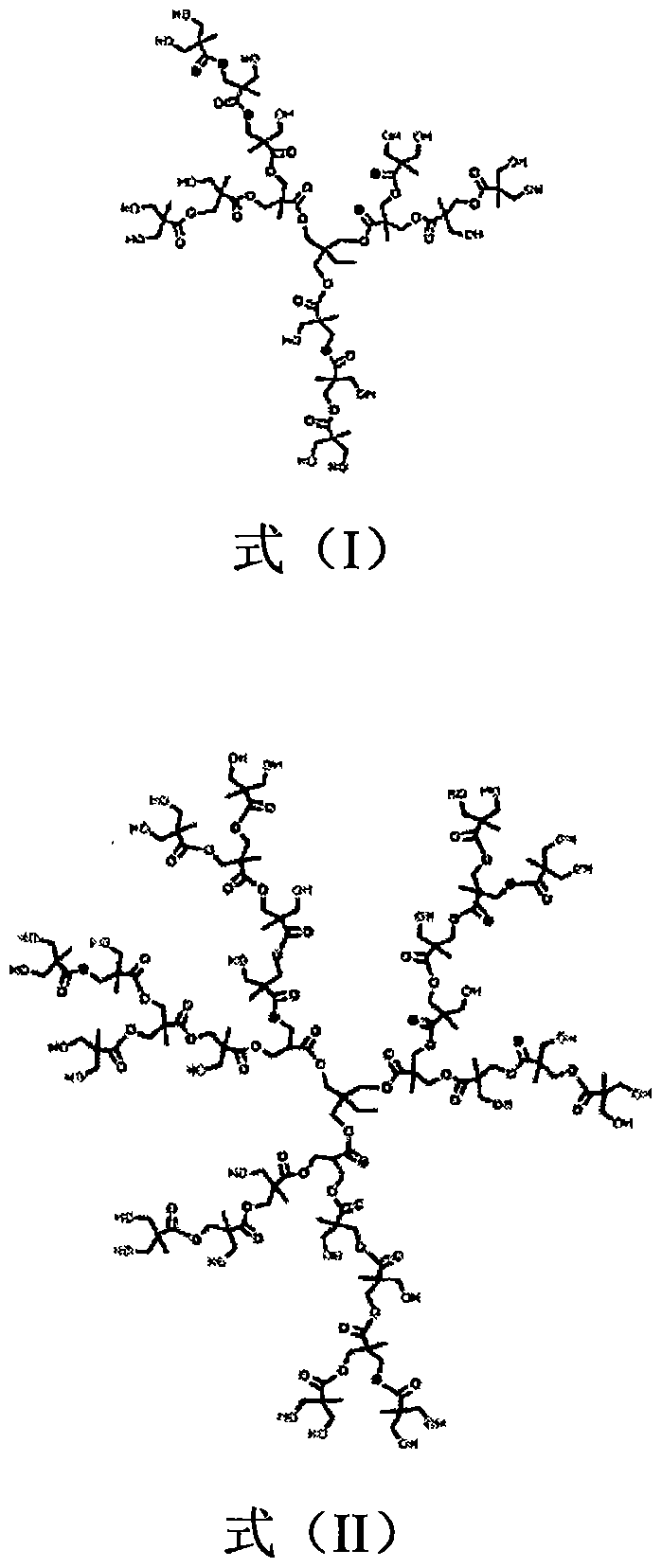

The invention relates to a preparation method of waterborne polyurethane elastic dispersion. The method comprises the following steps: (1) synthesizing a siloxane polymer: polymerizing a compound as shown in formula (I) and the compound as shown in formula (II) to get the siloxane polymer; and (2) preparing the waterborne polyurethane elastic dispersion, wherein the raw material comprises the siloxane polymer obtained in the step (1). After the elastic polyurethane dispersion provided by the invention forms a film, the waterborne polyurethane elastic dispersion has not only excellent tensile strength, rebound elasticity, wear resistance, water resistance and ethanol tolerance, but also soft and smooth hand feeling and high light transmission; and an additional filler is not required, a product has high light extinction or frosted appearance by only adjusting components, after the film is formed, the elastic polyurethane dispersion is soft, and the elastic polyurethane dispersion is suitable for paper, cloth, leather and other soft substrates, and the preparation process is simple and easy to operate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Waterborne antistatic coating and preparation method thereof

InactiveCN103305108AImprove antistatic performanceImprove water resistancePolyurea/polyurethane coatingsElectrically-conductive paintsAlcoholConductive polymer

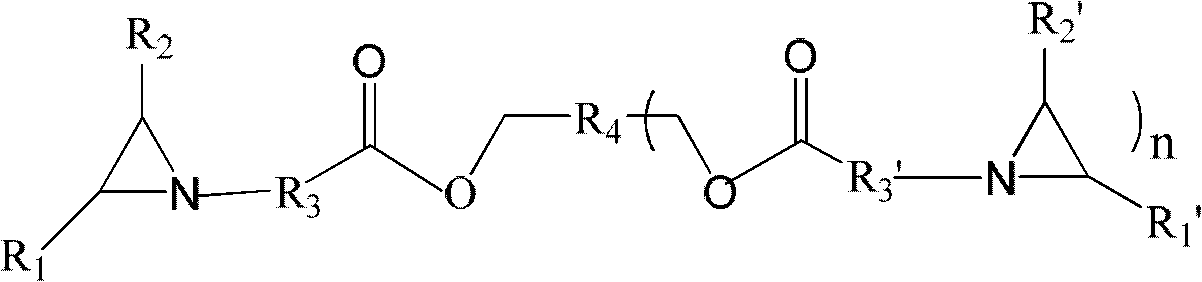

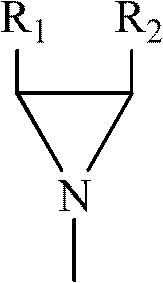

The invention relates to a waterborne antistatic coating and preparation method thereof. The method comprises the following steps: slowly adding the water solution of carboxylated waterborne polyurethane resin in a water solution of a carboxylated waterborne conductive polymer system, uniformly stirring, adding a polyfunctional aziridine compound, stirring to uniformly mix the components to obtain the waterborne antistatic coating, wherein the content of the carboxylated waterborne conductive polymer system in the waterborne antistatic coating is 0.1-2.5wt%, the content of the carboxylated waterborne polyurethane resin is 2-28wt%, the content of the polyfunctional aziridine compound is 0.1-3wt%, and the rest is water. The waterborne antistatic coating is tightly combined with the surfaces of substrates such as plastic, glass, wood, round and the wall to form the antistatic paintcoat with good antistatic effect, good water resistance and alcohol resistance; the antistatic coating can be widely applied to the fields of film negative film package, electron component package, display protective film and electromagnetic shielding.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

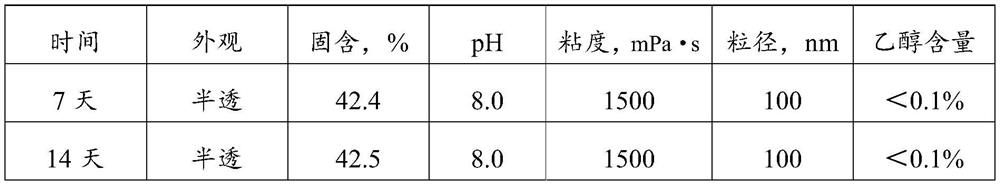

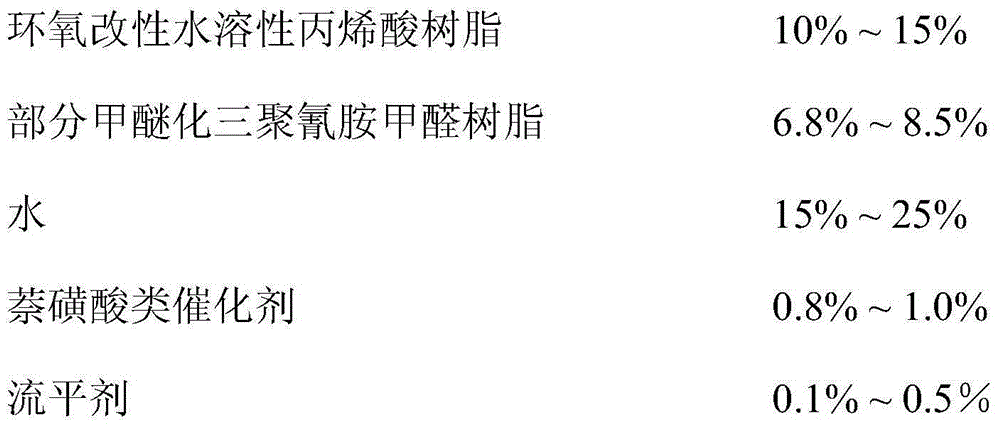

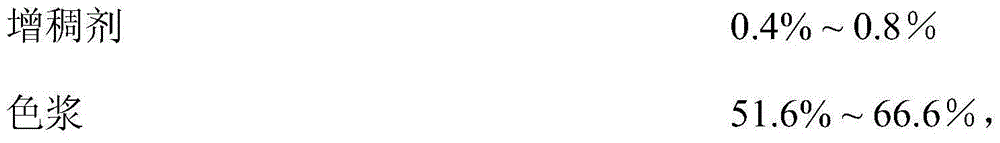

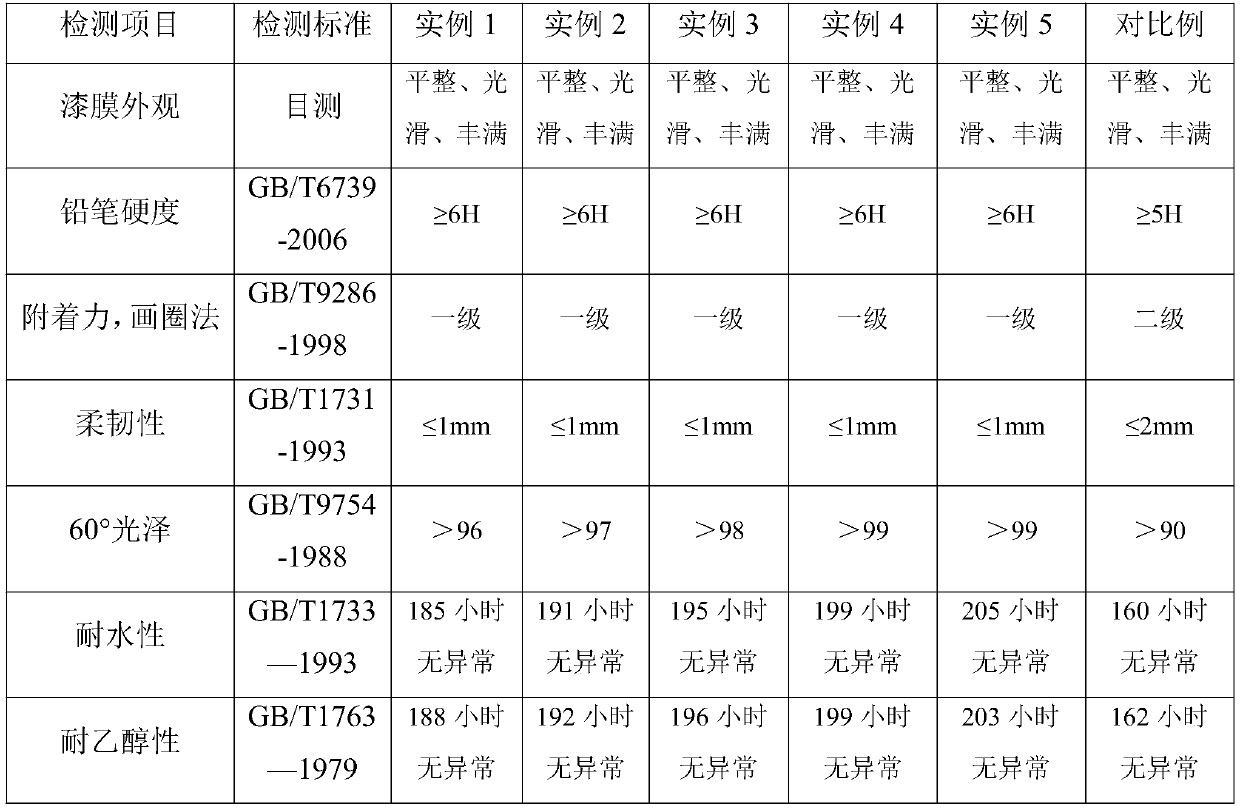

High-gloss ethanol-tolerance water-based acrylic acid amino glass winebottle stoving varnish as well as preparation method and application thereof

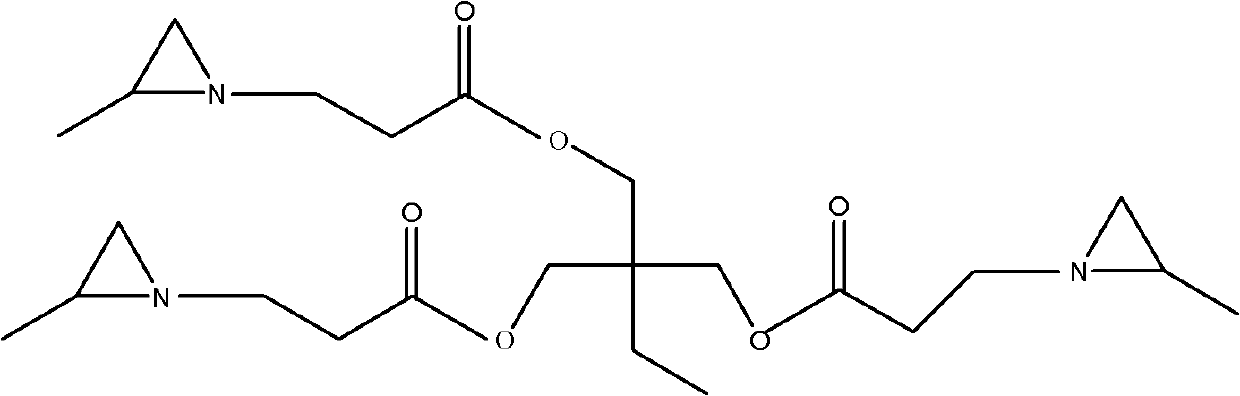

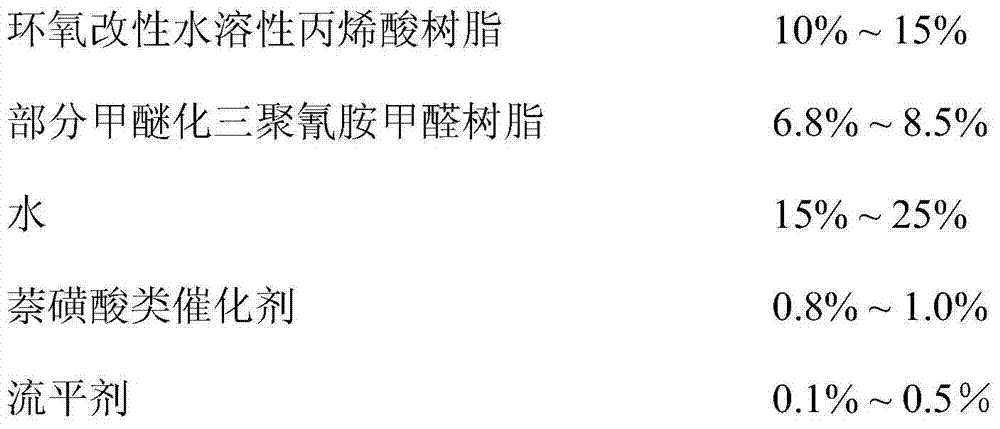

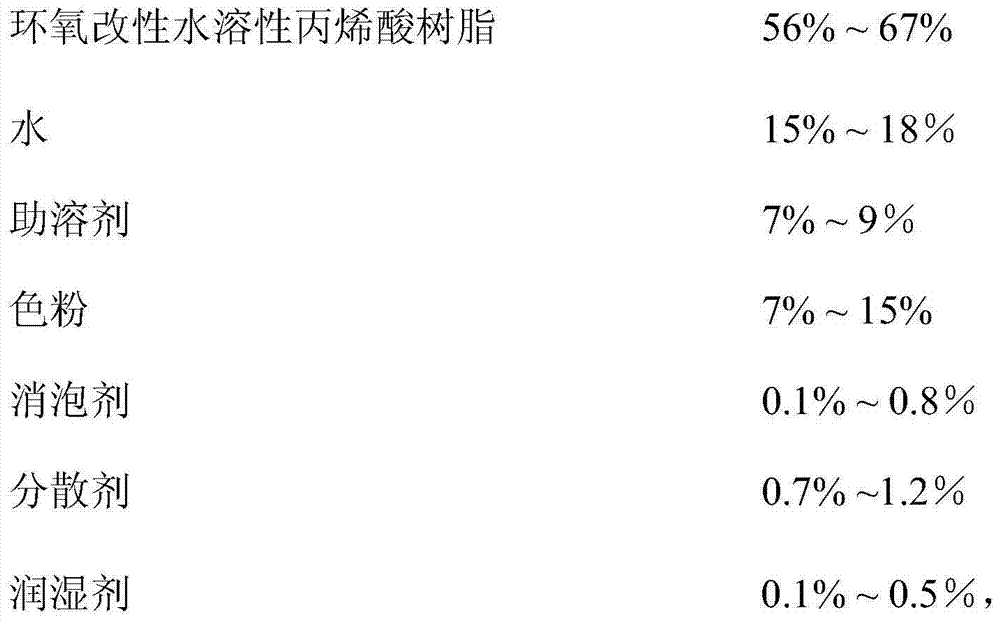

InactiveCN103483985AHigh glossSolve the technical problem that the glossiness is difficult to exceed 90°Epoxy resin coatingsPigment pastesEpoxyWater based

The invention discloses high-gloss ethanol-tolerance water-based acrylic acid amino glass winebottle stoving varnish as well as a preparation method and application thereof. The stoving varnish comprises compositions 1, a composition 2 and prepared slurry. Epoxy modified water-soluble acrylic resin is utilized to coordinate with partial methylated melamine formaldehyde resin and a naphthalene sulfonic acid catalyst, and before the use of the glass winebottle stoving varnish, the epoxy modified water-soluble acrylic resin, the partial methylated melamine formaldehyde resin and the naphthalene sulfonic acid catalyst are mixed with a glycidoxypropyltrimethoxysilane coupling agent to dilute, so that the glass winebottle stoving varnish baked at the temperature of 150-180 DEG C has sky-high paint film glossiness, excellent ethanol-tolerance and repainting performance, and outstanding paint film adhesive force, and the VOC content of the product is greatly reduced. According to the invention, the TVOC of the glass winebottle stoving varnish product can be controlled below 106 g / L, and is far smaller than the limited value of 250 g / L required by the strictest environmental protection standard (HJ / T201-2005) in the paint industry, so that the environmental protection performance of the water-based amino glass winebottle stoving varnish is greatly highlighted.

Owner:中山蓝海洋水性涂料有限公司

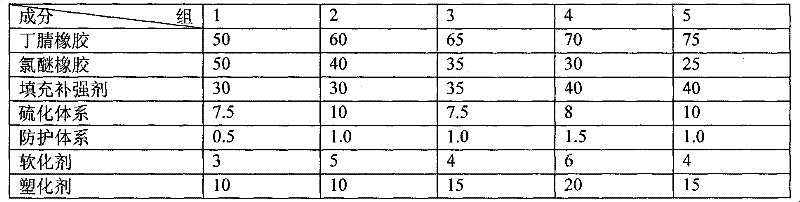

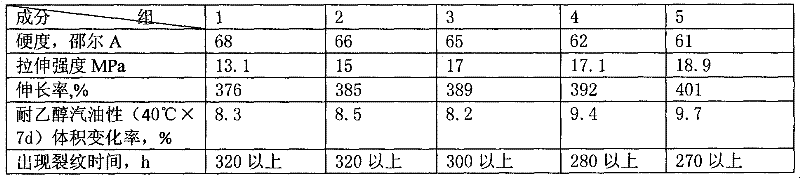

Rubber alloy material of ethanol-resisting gasoline diaphragm of fuel pressure regulator and preparation method of rubber alloy material

The invention provides a rubber alloy material of an ethanol-resisting gasoline diaphragm of a fuel pressure regulator and relates to a preparation method of the rubber alloy material of the ethanol-resisting gasoline diaphragm of the car fuel pressure regulator, which overcome the defects that the diaphragm which is used by the existing car fuel system regulator and takes butadiene-acrylonitrile rubber as a main material does not resist an ethanol solvent, and the cold resistance and the ozone aging resistance of the diaphragm are poor. The rubber alloy material is prepared from the butadiene-acrylonitrile rubber and chlorine ether rubber in an alloying way. The rubber alloy material is composed of the butadiene-acrylonitrile rubber, the chlorine ether rubber, a filling reinforcing agent, a vulcanizing system, a protection system, an activating agent and a plasticizer. The preparation method of the rubber alloy material comprises the following steps of: (1) plastifying; (2) mixing; and (3) vulcanizing and molding. The rubber alloy material of the ethanol-resisting gasoline diaphragm of the fuel pressure regulator, provided by the invention, has excellent oil resistance and solvent resistance and also has the cold resistance and the ozone aging resistance. The preparation method of the rubber alloy material has the advantages of simplicity, easiness in operation and less equipment investment.

Owner:HEILONGJIANG INST OF TECH

Water-based polyurethane emulsion with high water resistance and ethanol resistance and preparation method thereof

ActiveCN109721707AImprove water resistanceImprove ethanol resistancePolyurea/polyurethane coatingsWater basedEmulsion

The invention belongs to the technical field of fine chemical engineering, and particularly relates to a water-based polyurethane emulsion with high water resistance and ethanol resistance and a preparation method thereof. The invention provides the preparation method of the water-based polyurethane emulsion with high water resistance and ethanol resistance. The preparation method comprises the following steps: a) carrying out a first reaction on poly(propylene carbonate) polyol, diisocyanate, castor oil and a hydrophilic chain extender under the action of a catalyst to obtain a first product;b) adding a silane coupling agent into the first product to carry out a second reaction to obtain a second product; and c) adding a neutralizer into the second product to carry out a neutralization reaction, then adding deionized water for emulsifying, and then adding a non-hydrophilic chain extender to carry out a third reaction to obtain the water-based polyurethane emulsion. Experimental results show that a coating film formed by the water-based polyurethane emulsion disclosed by the invention has excellent boiling water resistance and ethanol resistance.

Owner:GUANGDONG UNIV OF TECH

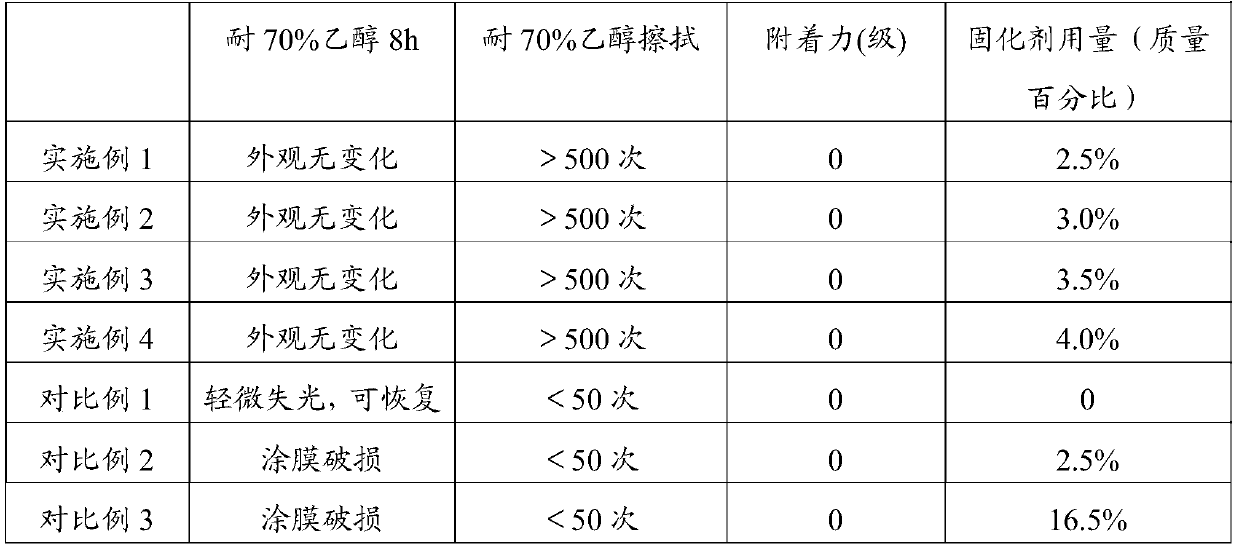

Double-component aqueous polyurethane, and preparation method and applications thereof

InactiveCN109824850AImproved ethanol resistanceImprove performancePolyureas/polyurethane adhesivesFoaming agentPolyol

The invention belongs to the technical field of fine chemical engineering, and especially relates to a double-component aqueous polyurethane, and a preparation method and applications thereof. The double-component aqueous polyurethane is prepared from following components: (Poly(propylenecarbonate)polyol, diisocyanate, a hydrophilic chain extender, a non-hydrophilic former chain extender, a non-hydrophilic later chain extender, a catalyst, a neutralizer, deionized water, castor oil, a silane coupling agent, a film forming auxiliary agent, a levelling agent, an anti-foaming agent, and an aqueous curing agent. After curing film forming of the double-component aqueous polyurethane, film ethanol resistance is improved greatly, so that aqueous curing agent using amount is reduced, preparation cost is reduced, and problems in the prior art that the using amount of conventional double-component aqueous polyurethane aqueous curing agent is large, and double-component aqueous polyurethane preparation cost is high are solved.

Owner:GUANGDONG UNIV OF TECH

Transparent hardening composition, TAC glasses film and preparation method of TAC glasses film

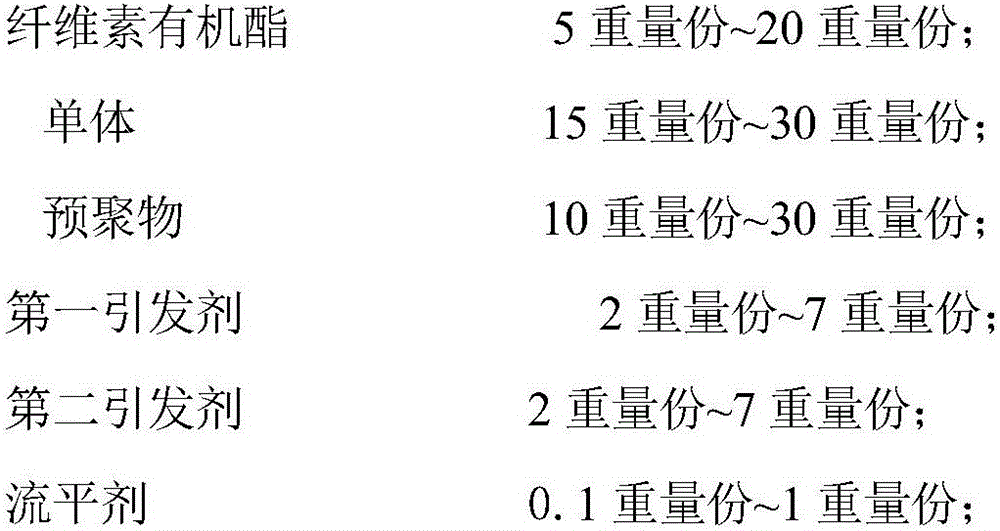

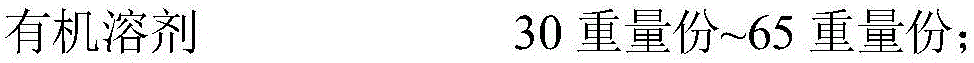

InactiveCN106675219AAvoid accumulationIncrease in sizePolyurea/polyurethane coatingsEpoxy resin coatingsCelluloseOrganic solvent

Transparent hardening composition is prepared from components in parts by weight as follows: 5-20 parts of organic cellulose ester, 15-30 parts of monomers, 10-30 parts of a prepolymer, 2-7 parts of a first initiator, 2-7 parts of a second initiator, 0.1-1 part of a leveling agent and 30-65 parts of an organic solvent, wherein the organic cellulose ester structurally contains, in percentage by mass, 2%-55% of an acyl functional group and 1%-5% of a hydroxyl functional group. The organic cellulose ester in the composition remarkably improves the weather fastness, crimpiness, film coating property, flexibility, adhesion and wear resistance of a hardened coating of a transparent hardened TAC film, and the transparent hardening composition can be widely applied to the field of glasses lenses.

Owner:HEFEI LUCKY SCI & TECH IND

Polyarylsulfone modified polyurethane resin emulsion

InactiveCN109535360AHigh temperature resistantHigh hardnessPolyurea/polyurethane coatingsPolymer modifiedEmulsion

The invention relates to a polyarylsulfone modified polyurethane resin emulsion. The hydroxy-terminated low molecular weight linear polyarylsulfone is first synthesized by stepwise polymerization, andthen the hydroxy-terminated low molecular weight linear polyarylsulfone is used as a polymer modifier to participate in the prepolymerization, chain extension and emulsification of the polyurethane.The molecular structure of the polyurethane resin of the invention contains a large amount of polyarylsulfone units, so the emulsion has the advantages of high hardness, good water resistance, good ethanol resistance and high temperature resistance.

Owner:SHAOGUAN HEZHONG CHEM CO LTD +1

Solvent-resistant polyvinyl butyral formula and preparation method thereof

The invention discloses a solvent-resistant polyvinyl butyral formula, which is prepared from the following components in parts by weight: 900 to 1,100 parts of polyvinyl alcohol, 3,900 to 4,100 parts of pure water, 90 to 110 parts of concentrated hydrochloric acid, 40 to 60 parts of hydrogen peroxide, 70 to 90 parts of n-butyl alcohol, 9 to 11 parts of formaldehyde aqueous solution, 4 to 6 parts of melamine and 4 to 6 parts of p-toluenesulfonic acid. A preparation method of the solvent-resistant polyvinyl butyral formula comprises the following steps of preparation of a primary polyvinyl alcohol solution; preparation of a polyvinyl alcohol solution; preparation of a polyvinyl butyral solution; preparation of a melamine formaldehyde solution; preparation of a mixture; curing. The invention provides a novel solvent-resistant polyvinyl butyral formula and a preparation method thereof. Solvent-resistant polyvinyl butyral thin film plastic produced by the method is good in transparency, excellent in film-forming performance and good in water-resistant and ethanol-resistant performance.

Owner:CHENGDU YULONG CHEM

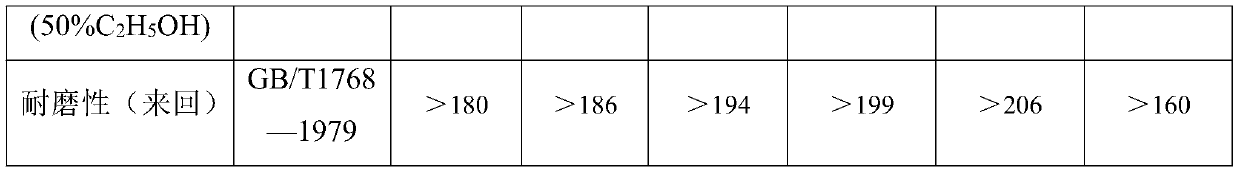

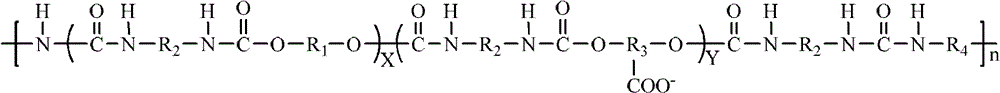

High-hardness ethanol-resistant waterborne polyurethane emulsion and preparation method thereof

InactiveCN109694456AHigh hardnessExcellent resistance to ethanolPolyurea/polyurethane coatingsEmulsionPolymer science

The invention belongs to the technical field of fine chemicals, and especially relates to a high-hardness ethanol-resistant waterborne polyurethane emulsion and a preparation method thereof. The preparation method of the high-hardness ethanol-resistant waterborne polyurethane emulsion comprises the following steps: a) performing a first reaction on poly(propylene carbonate)polyol, diisocyanate anda hydrophilic chain extender under the action of a catalyst to obtain a first product; b) adding a crosslinking agent and a non-hydrophilic chain extender to the first product, and performing a second reaction to obtain a second product; c) adding a silane coupling agent to the second product, and performing a third reaction to obtain a third product; d) adding a neutralizing agent to the third product, carrying out a neutralization reaction, adding deionized water, and carrying out an emulsification reaction to obtain a fourth product; and e) adding nano-silica to the fourth product to obtain the waterborne polyurethane emulsion. Results show that a film formed by the waterborne polyurethane emulsion has excellent hardness and excellent ethanol resistance.

Owner:GUANGDONG UNIV OF TECH

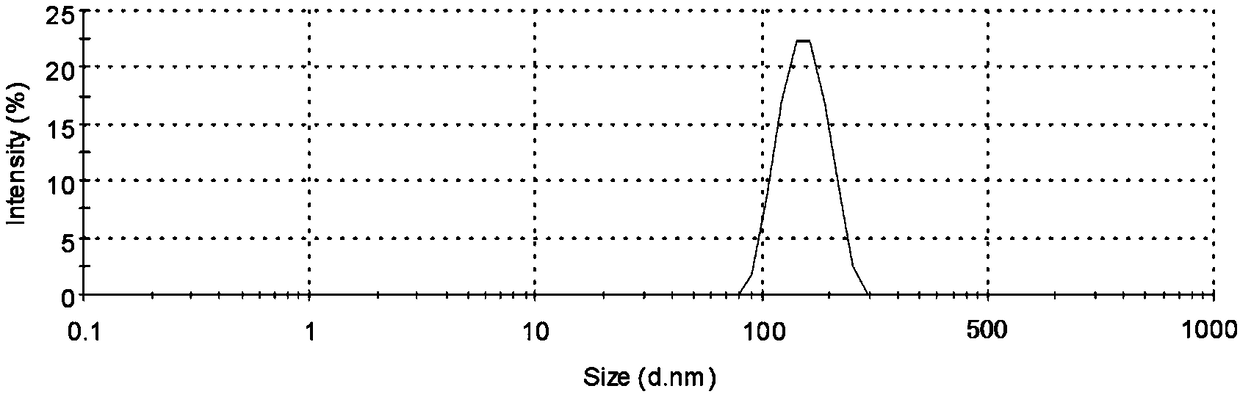

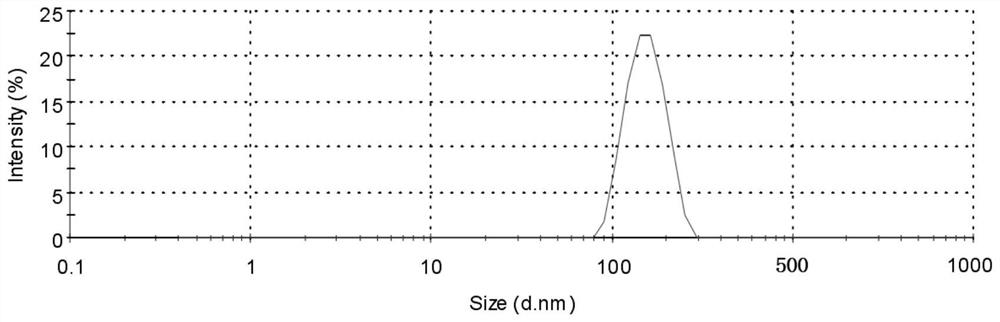

Aqueous latex containing polymer particles with core-shell structure, preparation method of aqueous latex and coating formed by aqueous latex

The invention relates to aqueous latex containing polymer particles with a core-shell structure, a preparation method of the aqueous latex and a coating formed by the aqueous latex. According to the polymer particles, at least one of a polymer core and a polymer shell is formed by a monomer mixture containing (methyl) isobornyl acrylate, and the (methyl) isobornyl acrylate exists in the monomer mixture in the amount accounting for 1-40% of the total weight of the monomer mixture used for forming the polymer core or the polymer shell.

Owner:GUANGDONG HUARUN PAINT CO LTD

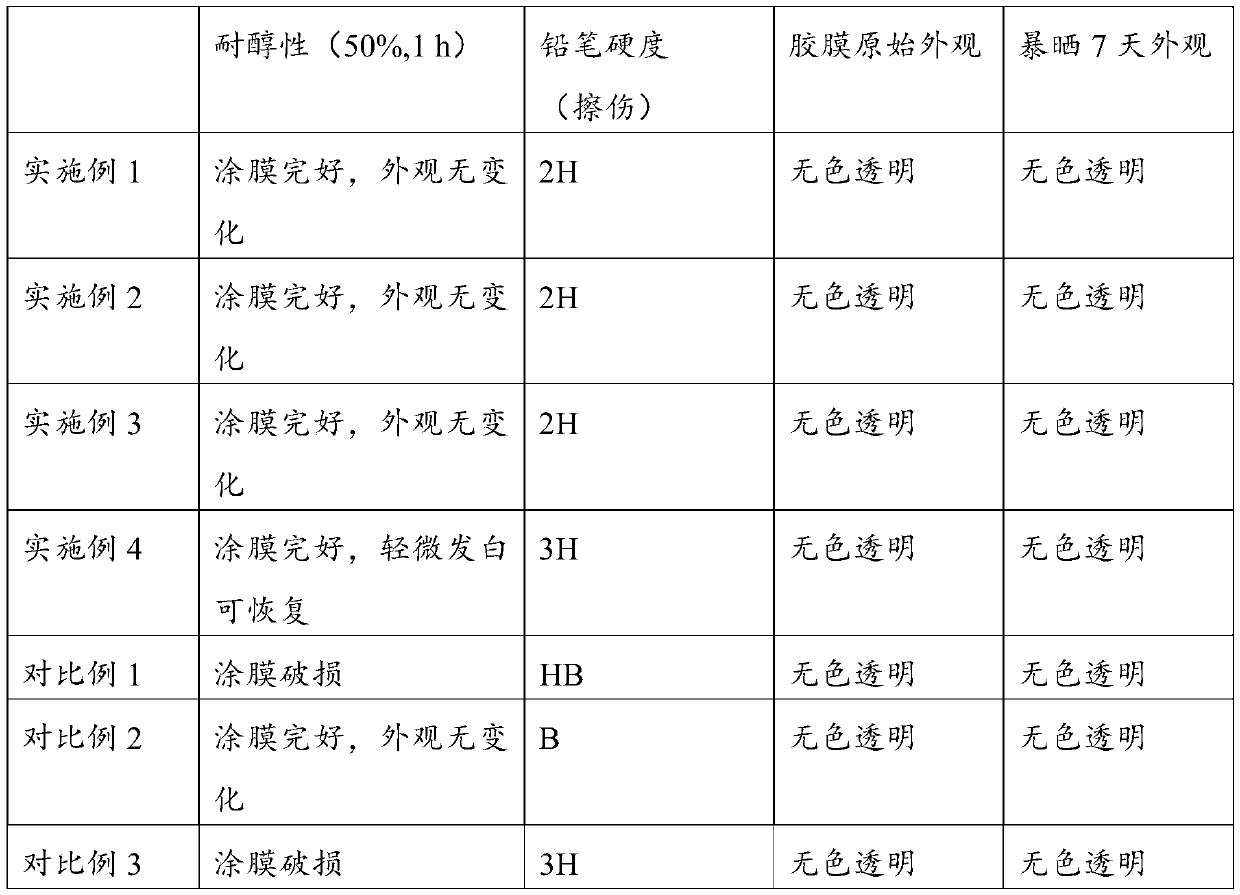

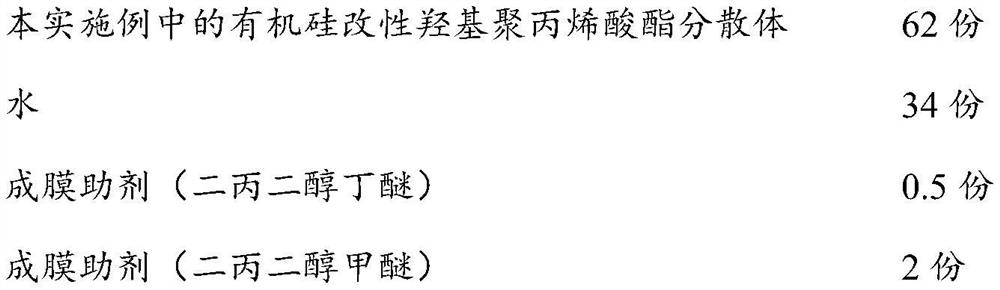

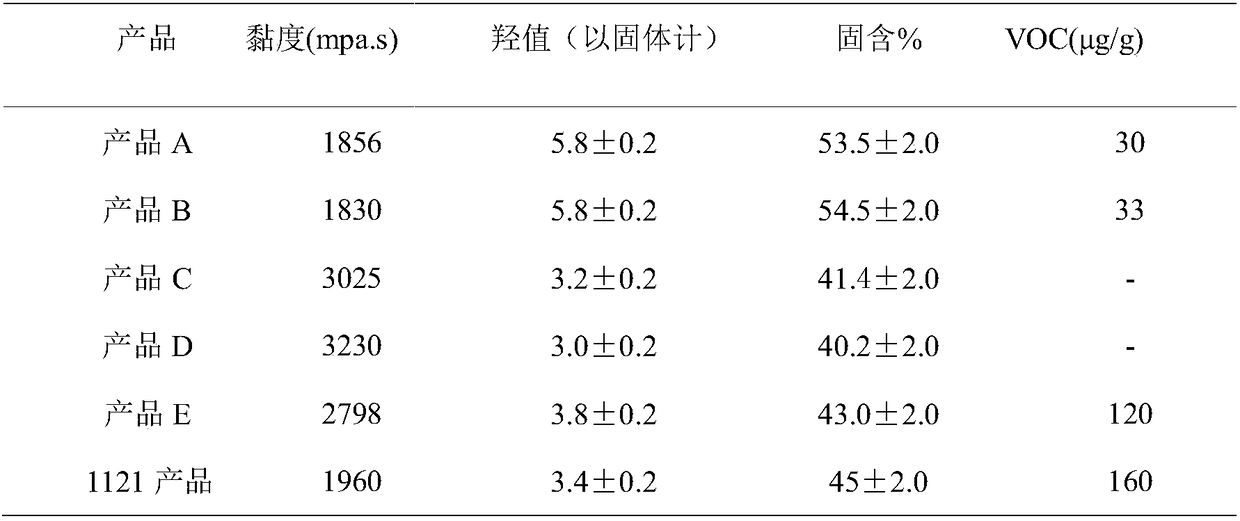

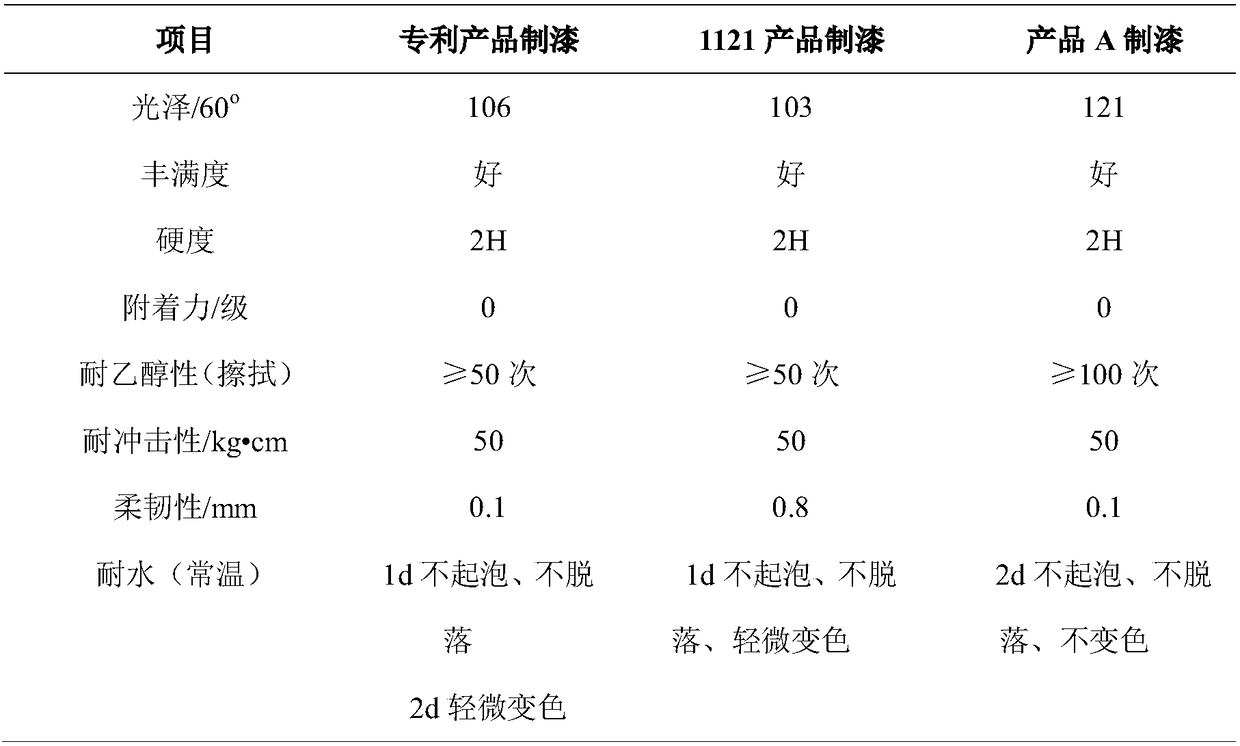

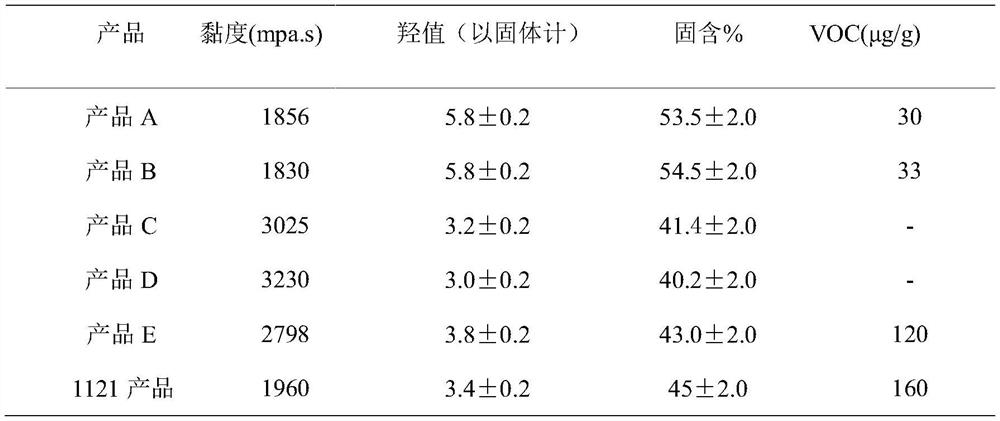

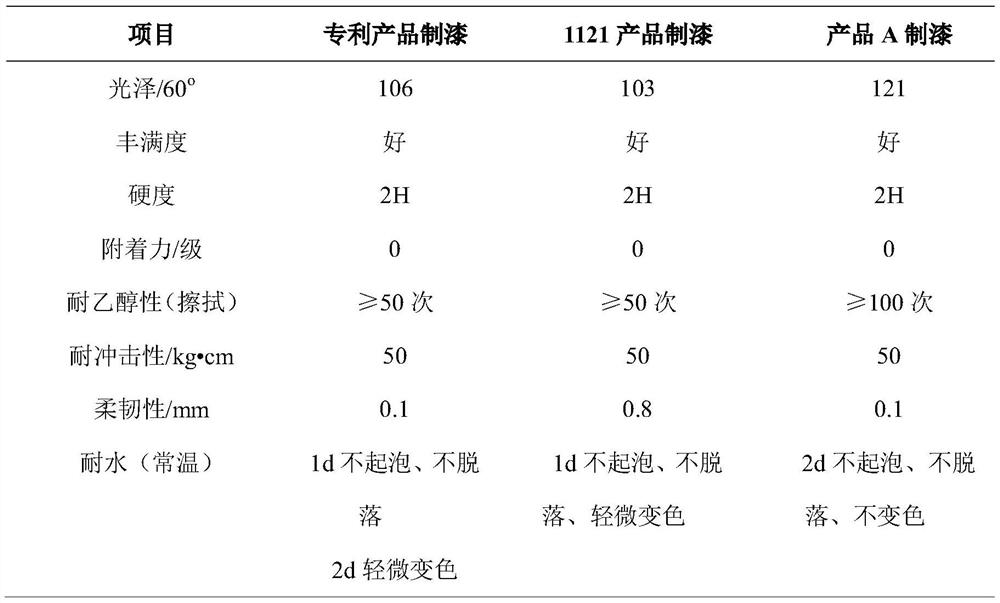

Organosilicon modified hydroxyl polyacrylate dispersion as well as preparation method and application thereof

ActiveCN114316173AHigh solid contentLow solid contentAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceAcrylic monomers

The invention belongs to the technical field of polyurethane coatings, and discloses an organic silicon modified hydroxyl polyacrylate dispersion as well as a preparation method and application thereof. The preparation method comprises the following steps: S1, mixing an acrylic monomer, an acrylate monomer, a vinyl monomer, an acrylate derivative monomer, an organic silicon monomer and an initiator to form a mixed solution A; s2, taking a reactive diluent, heating, dropwise adding the mixed solution A, and keeping the temperature; cooling, adding an isocyanate bridging agent, controlling the mass content of-NCO, and reacting to obtain a prepolymer; s3, adding a neutralizer into the prepolymer, adding water for dispersion, and filtering to obtain the product, the organic silicon monomer contains double bonds and does not contain epoxy groups. The organic silicon modified hydroxyl polyacrylate dispersoid prepared by the preparation method disclosed by the invention is low in small molecule alcohol content, high in storage stability and particularly excellent in high-temperature-resistant storage property; and a paint film prepared by using the paint is high in drying speed and high in hardness.

Owner:CARPOLY CHEM GRP

A kind of high-gloss ethanol-resistant water-based acrylic amino glass wine bottle baking varnish and its preparation method and application

InactiveCN103483985BHigh glossSolve the technical problem that the glossiness is difficult to exceed 90°Epoxy resin coatingsPigment pastesEpoxyPolymer science

The invention discloses high-gloss ethanol-tolerance water-based acrylic acid amino glass winebottle stoving varnish as well as a preparation method and application thereof. The stoving varnish comprises compositions 1, a composition 2 and prepared slurry. Epoxy modified water-soluble acrylic resin is utilized to coordinate with partial methylated melamine formaldehyde resin and a naphthalene sulfonic acid catalyst, and before the use of the glass winebottle stoving varnish, the epoxy modified water-soluble acrylic resin, the partial methylated melamine formaldehyde resin and the naphthalene sulfonic acid catalyst are mixed with a glycidoxypropyltrimethoxysilane coupling agent to dilute, so that the glass winebottle stoving varnish baked at the temperature of 150-180 DEG C has sky-high paint film glossiness, excellent ethanol-tolerance and repainting performance, and outstanding paint film adhesive force, and the VOC content of the product is greatly reduced. According to the invention, the TVOC of the glass winebottle stoving varnish product can be controlled below 106 g / L, and is far smaller than the limited value of 250 g / L required by the strictest environmental protection standard (HJ / T201-2005) in the paint industry, so that the environmental protection performance of the water-based amino glass winebottle stoving varnish is greatly highlighted.

Owner:中山蓝海洋水性涂料有限公司

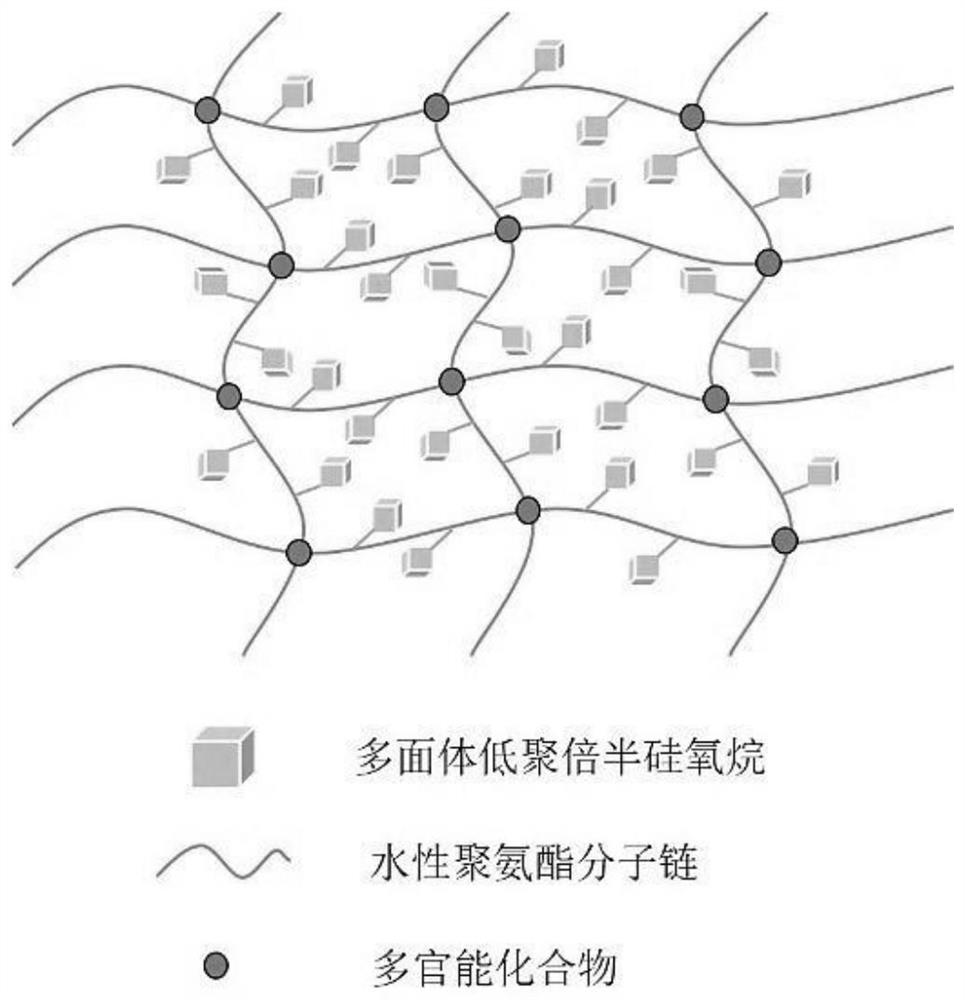

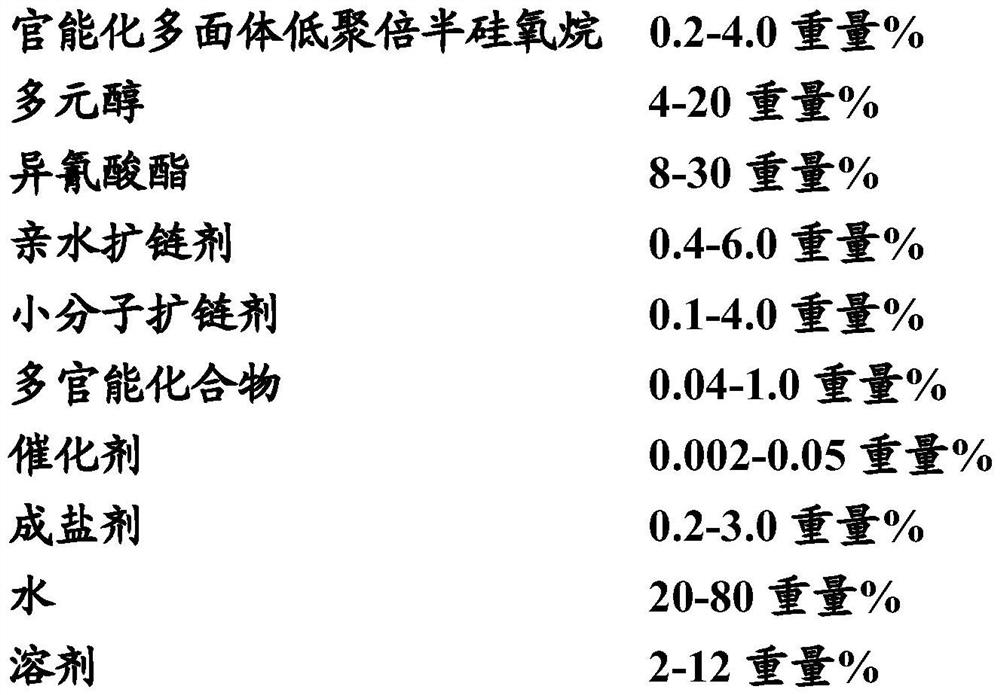

A kind of aqueous polyurethane and preparation method thereof

The invention relates to a water-based polyurethane, which is a high-performance water-based polyurethane chemically modified by functionalized polyhedral oligomeric silsesquioxane and a multifunctional compound, has a network structure, and exhibits improved mechanical properties and heat resistance, Lower water absorption rate and good solvent resistance; the present invention also relates to a preparation method of high-performance water-based polyurethane, which is prepared by introducing functionalized polyhedral oligomeric silsesquioxane for chemical side chain grafting, and through multifunctional The compound forms a network structure, the process is simple and the process is easy to control.

Owner:优美特(北京)环境材料科技股份公司

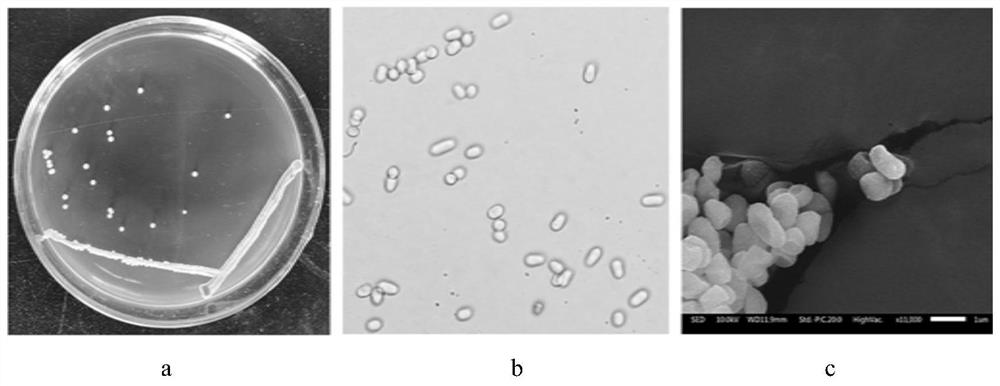

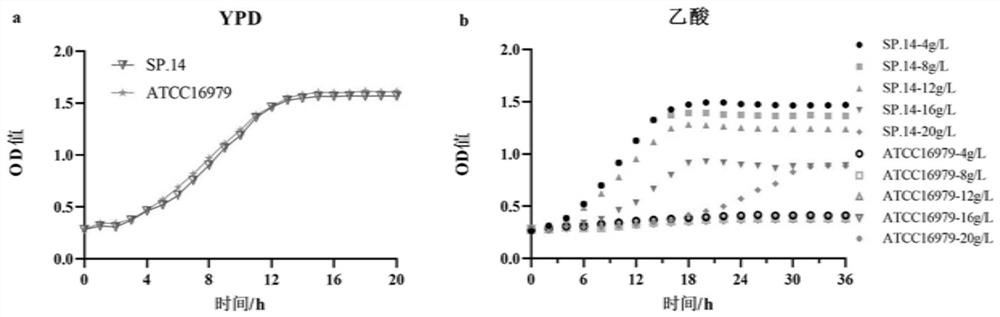

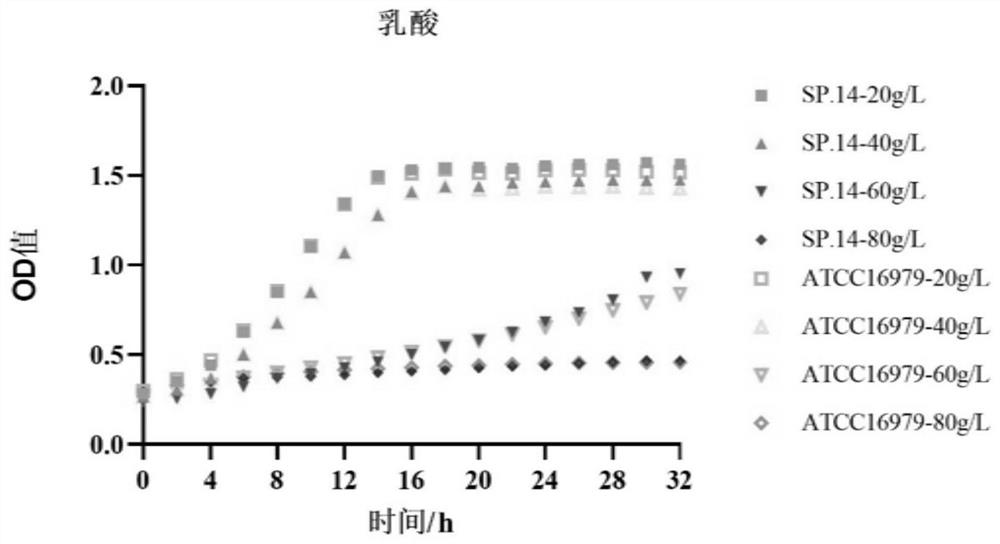

Schizosaccharomyces pombe with high acetic acid tolerance

ActiveCN112831426AStrong acetic acid toleranceStrong toleranceFungiBiofuelsBiotechnologySchizosaccharomyces pombe

The invention provides schizosaccharomyces pombe with high acetic acid tolerance, and belongs to the technical field of microorganisms. The invention relates to Schizosaccharomyces pombe Sujiu.014, in particular to Schizosaccharomyces pombe Sujiu.014, the strain is screened from Maotai-flavor liquor to produce fermented grains, and the preservation number is CGMCC (China General Microbiological Culture Collection Center) No.21791. The strain is schizosaccharomyces pombe which has extremely strong acetic acid tolerance and relatively good lactic acid tolerance, high temperature resistance and ethanol tolerance. The yeast strain can tolerate 20 g / L acetic acid, is a yeast strain with the highest acetic acid tolerance reported at present, and can tolerate 60 g / L lactic acid, 40 DEG C temperature and 8% ethanol at the same time. The problem that yeast fermentation is inhibited in a high-concentration acetic acid environment can be solved.

Owner:贵州国台酒业集团股份有限公司 +1

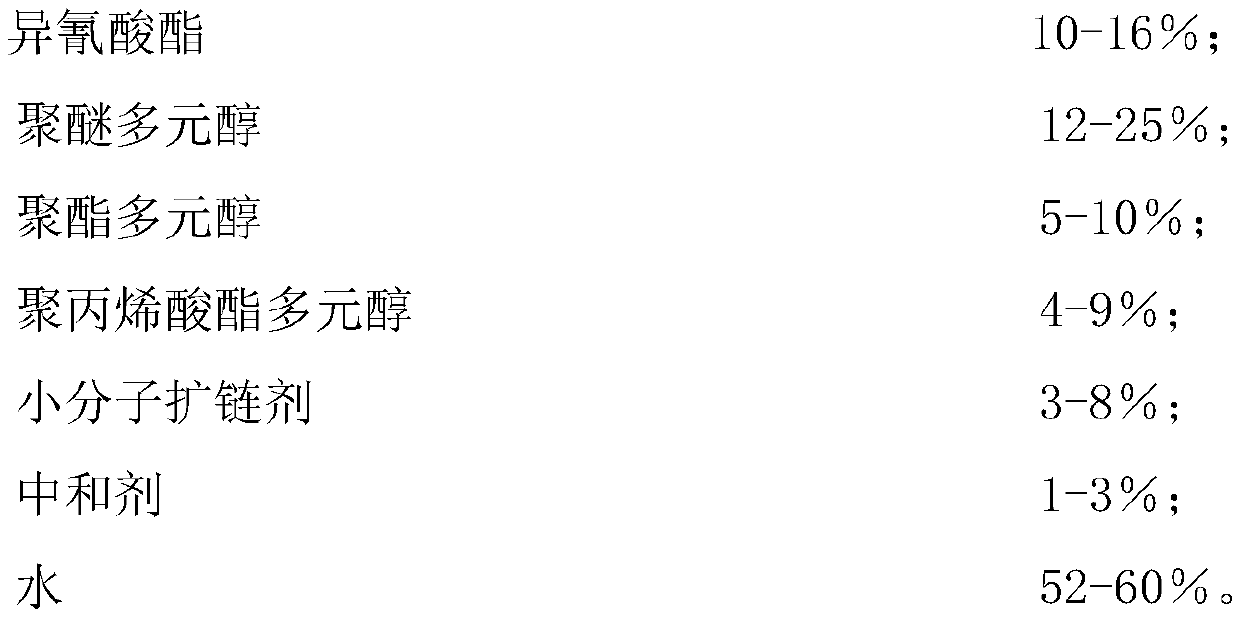

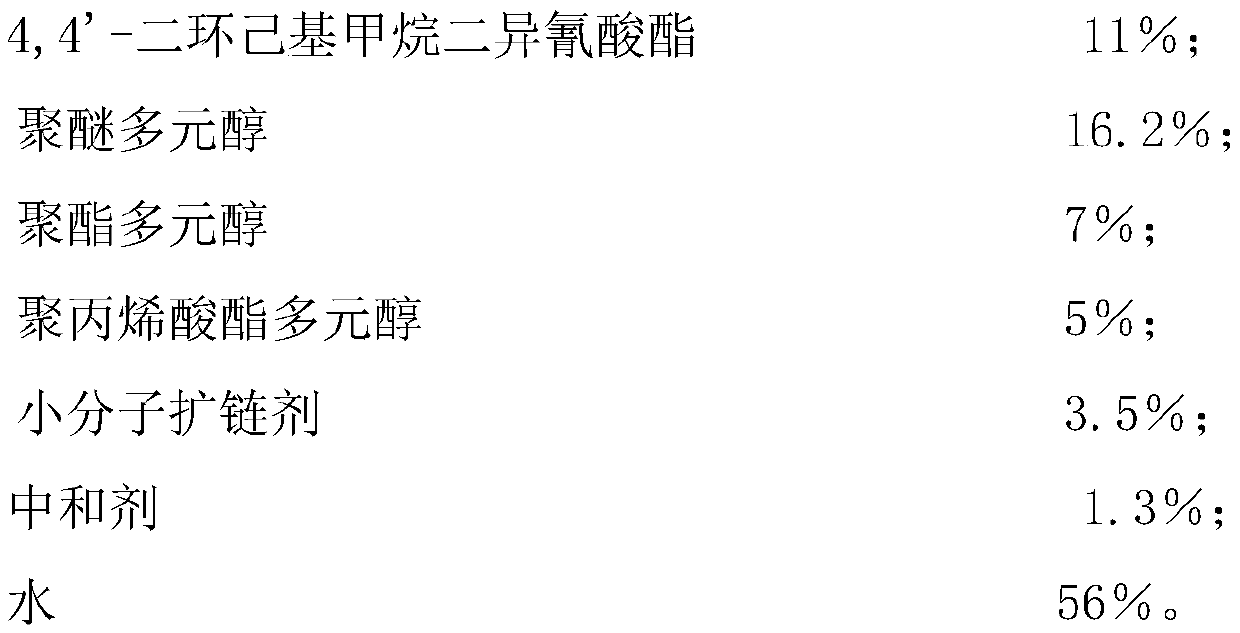

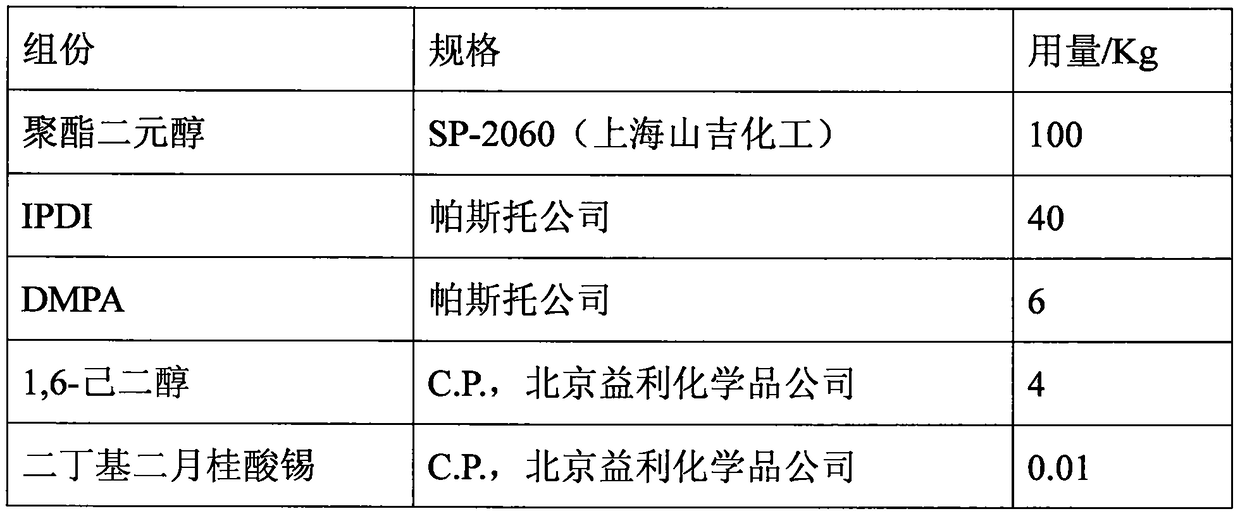

Waterborne polyurethane for flocking adhesive and preparation method thereof

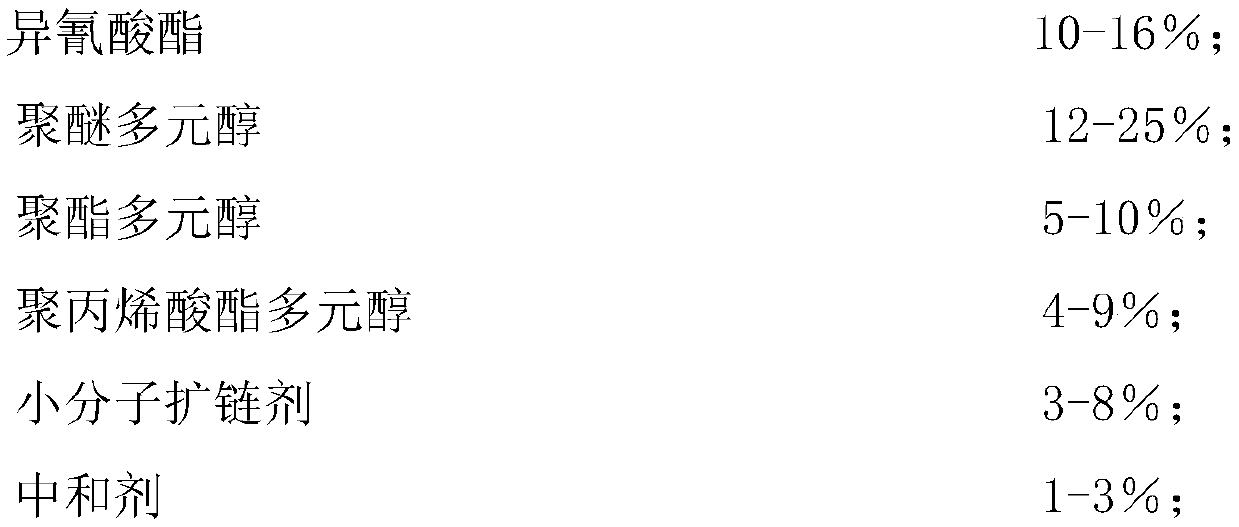

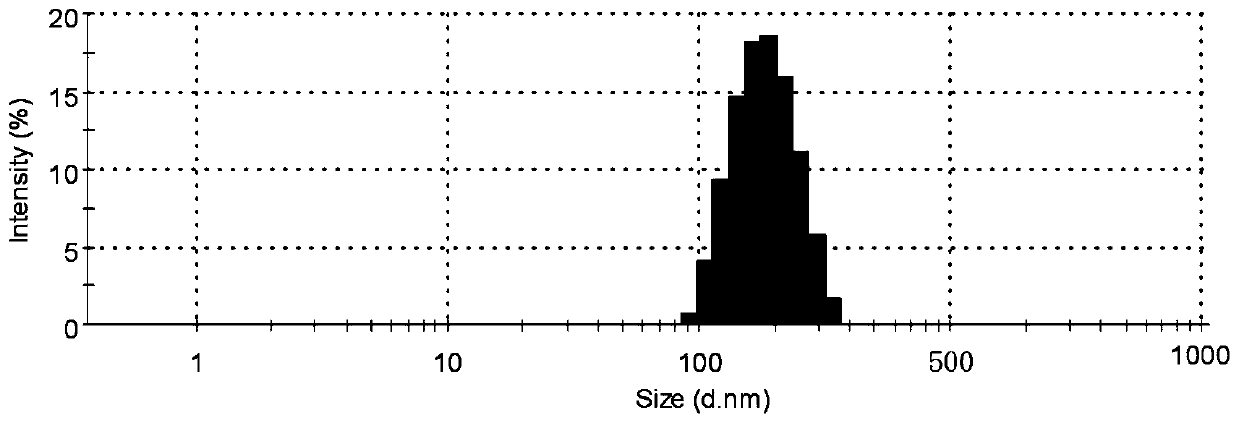

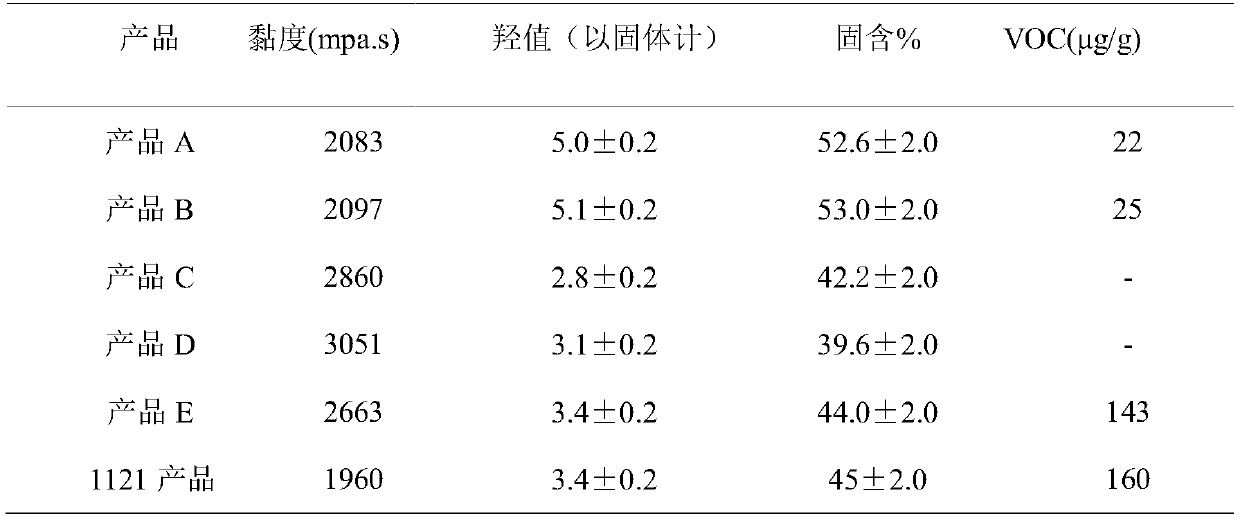

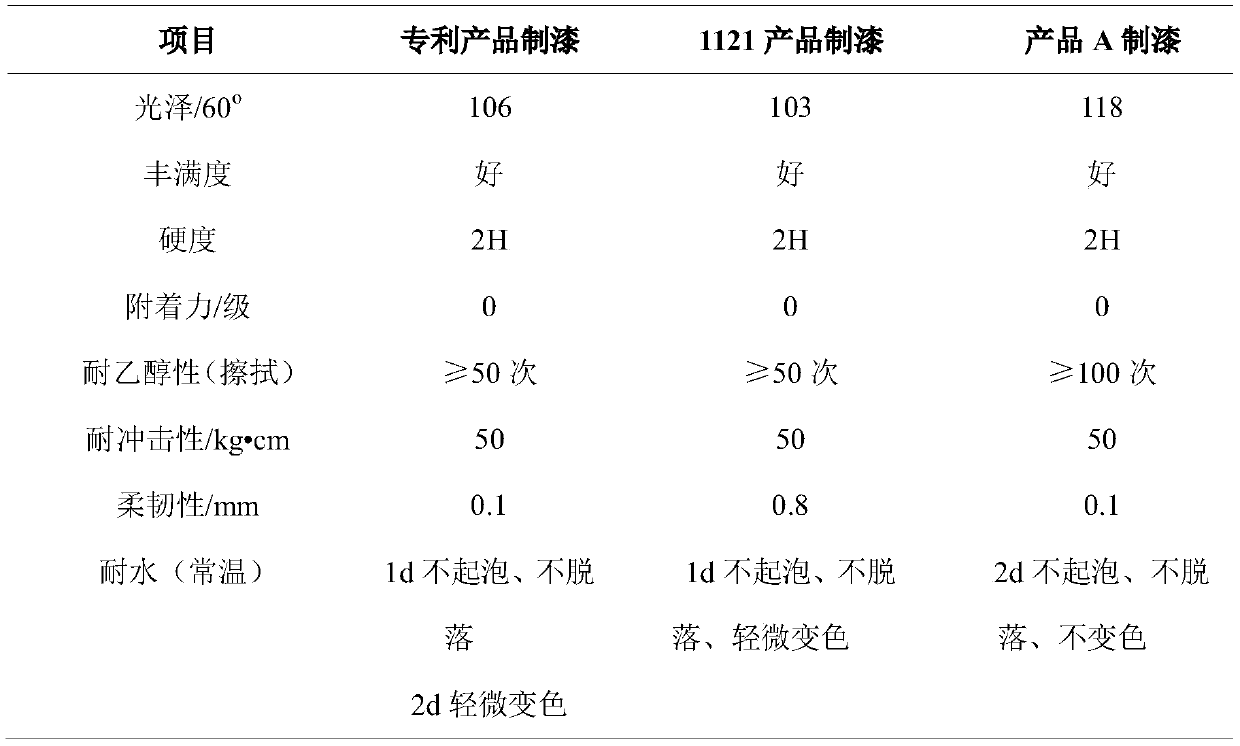

InactiveCN110982035AImprove water resistanceExcellent resistance to ethanolPolyureas/polyurethane adhesivesPolyesterPolymer chemistry

The invention discloses waterborne polyurethane for a flocking adhesive and a preparation method thereof. The waterborne polyurethane comprises the following components: isocyanate, polyether polyol,polyester polyol, polyacrylate polyol, a micromolecular chain extender and water, wherein the isocyanate is 4,4'-dicyclohexylmethane diisocyanate or isophorone diisocyanate. The preparation method comprises the following steps: melting the polyether polyol, the polyester polyol and the polyacrylate polyol, carrying out mixing, vacuumizing and dehydrating until the water content of a material is lower than 400 ppm, and carrying out pre-polymerization, chain extension, neutralization emulsification and post-chain extension so as to prepare the waterborne polyurethane used for the flocking adhesive. The waterborne polyurethane provided by the invention has good water resistance and ethanol resistance, keeps wear resistance and low-temperature resistance at the same time, and has good flexibility.

Owner:SHANGHAI 3N CHEM

Environment-friendly glass paint

InactiveCN109749547ASimple preparation processEasy to operateEpoxy resin coatingsWater solubleHardness

The invention discloses an environment-friendly glass paint, made from waterborne resin, modified amino resin, a coupling agent, a leveling agent, water, an acid catalyst, a film-forming aid, a pigment, and a defoaming agent. The environment-friendly glass paint is made by: mixing part of the defoaming agent by weight and part of the deionized water by weight, adding the water-soluble resin, the pigment and the coupling agent, grinding with a grinder until fineness reaches 20 mu m and below, adding the amino resin, the film-forming aid, the acid catalyst, the leveling agent, the rest of the deionized water and the rest of the defoaming agent, dispersing with a high-speed disperser for 20-30 min, adding the balance of the water by weight, and filtering with 200-mesh filter cloth. By modifying traditional water-soluble resin and modified amino resin, the glass paint is prepared, which has good ethanol resistance, good recoating property, high adhesion, good toughness and high hardness.

Owner:吴春燕

Barrier coating for food paper and paperboard as well as food paper and paperboard

InactiveCN113957750ALow solubility parameterImprove securityNon-fibrous pulp additionFlexible coversPolymer sciencePaperboard

In order to solve the problem of insufficient water barrier and oil barrier properties of an existing polyacrylate coating for food paper and a paperboard, the invention provides a barrier coating for food paper and a paperboard. The barrier coating comprises the following components: a component A: an acrylate copolymer emulsion, wherein the average particle size of emulsion particles is 0.02-0.2 micron, the Tg value is -20 DEG C to 10 DEG C; and a component B: an acrylate copolymer emulsion, wherein the average particle size of emulsion particles is 0.02-0.2 micron, and the Tg value is 10 DEG C to 120 DEG C. Meanwhile, the invention further discloses the food paper and the paper board comprising the barrier coating for the food paper and the paper board. The barrier coating for the food paper and the paperboard, provided by the invention, has relatively good water and grease barrier performance and also has excellent heat sealing performance.

Owner:GUANGZHOU HUMAN CHEM

A kind of glycidyl methacrylate modified hydroxyacrylic acid dispersion and its synthesis process

ActiveCN108383939BGood dispersionHigh solid contentPolyurea/polyurethane coatingsPolymer scienceOrganic chemistry

The invention relates to a glycidyl methacrylate modified hydroxy acrylate dispersion and a new synthesis technology thereof. The synthesis technology comprises the following steps: evenly mixing 3-5parts of glycidyl methacrylate, 1.5-2.5 parts of peracid, 2-3 parts of cosolvent and 30-40 parts of acrylate monomers, heating up to 50-60 DEG C, carrying out a reaction for 0.5-1.0h, then heating upto 120-135 DEG C, and continuously reacting for 1-2h; cooling to 70-80 DEG C, adding a neutralizing agent, adding deionized water, stirring and dispersing for 1-2h, and discharging to obtain the glycidyl methacrylate modified hydroxy acrylic dispersion.

Owner:上海元邦化工制造有限公司

LED lamp sheet capable of displaying three-dimensional picture, and processing technology thereof

ActiveCN112226110AGood ink absorptionImprove drying ratePhotomechanical apparatusInksPrinting inkLED lamp

The invention discloses an LED lamp sheet capable of displaying a three-dimensional picture, and a processing technology thereof. The processing technology comprises the steps: taking a lamp sheet base body, coating the upper surface of the base body with a photoresist in a spin-coat manner after pretreatment, and carrying out baking and exposure development, wherein a photoetching pattern existson the surface of the base body at the moment; placing the base body in a surface treatment liquid, soaking, spraying ultraviolet fluorescent ink after soaking, and removing the photoresist, wherein asprayed ultraviolet fluorescent pattern exists on the surface of the base body, and an ultraviolet fluorescent ink layer is formed; on the upper surface of the ultraviolet fluorescent ink layer, placing the base body in the surface treatment liquid again, soaking, repeating photoetching and ink spraying steps after soaking, spraying a layer of infrared fluorescent ink on the ultraviolet fluorescent pattern, and forming an infrared fluorescent pattern to obtain an infrared fluorescent ink layer; and spraying conventional printing ink on the lower surface of the base body to obtain a conventional ink pattern. According to the invention, the LED lamp sheet prepared by the method is excellent in pattern durability, relatively good in heat resistance and ethanol resistance, and relatively highin practicability.

Owner:SHANGHAI EDGE LIGHT IND

P-hydroxybenzoic acid glycidyl ester modified hydroxy acrylic acid dispersoid and preparation method thereof

The invention relates to a p-hydroxybenzoic acid glycidyl ester modified hydroxy acrylic acid dispersoid and a preparation method thereof. The selected peracid compound not only can provide reactive hydrogen, but also can serve as an initiator, and the p-hydroxybenzoic acid glycidyl ester modified novel hydroxy acrylic acid dispersoid is prepared by a one-pot method; in a preparation process, useof a reaction reagent, a cosolvent and the like is reduced, and the prepared hydroxy acrylic acid dispersoid is excellent in performance, high in solid content and hydroxyl value and low in VOC content; and moreover, hydroxy acrylic acid dispersoid paint prepared by the invention is excellent in waterproofness and ethanol resistance.

Owner:上海祥越实业有限公司

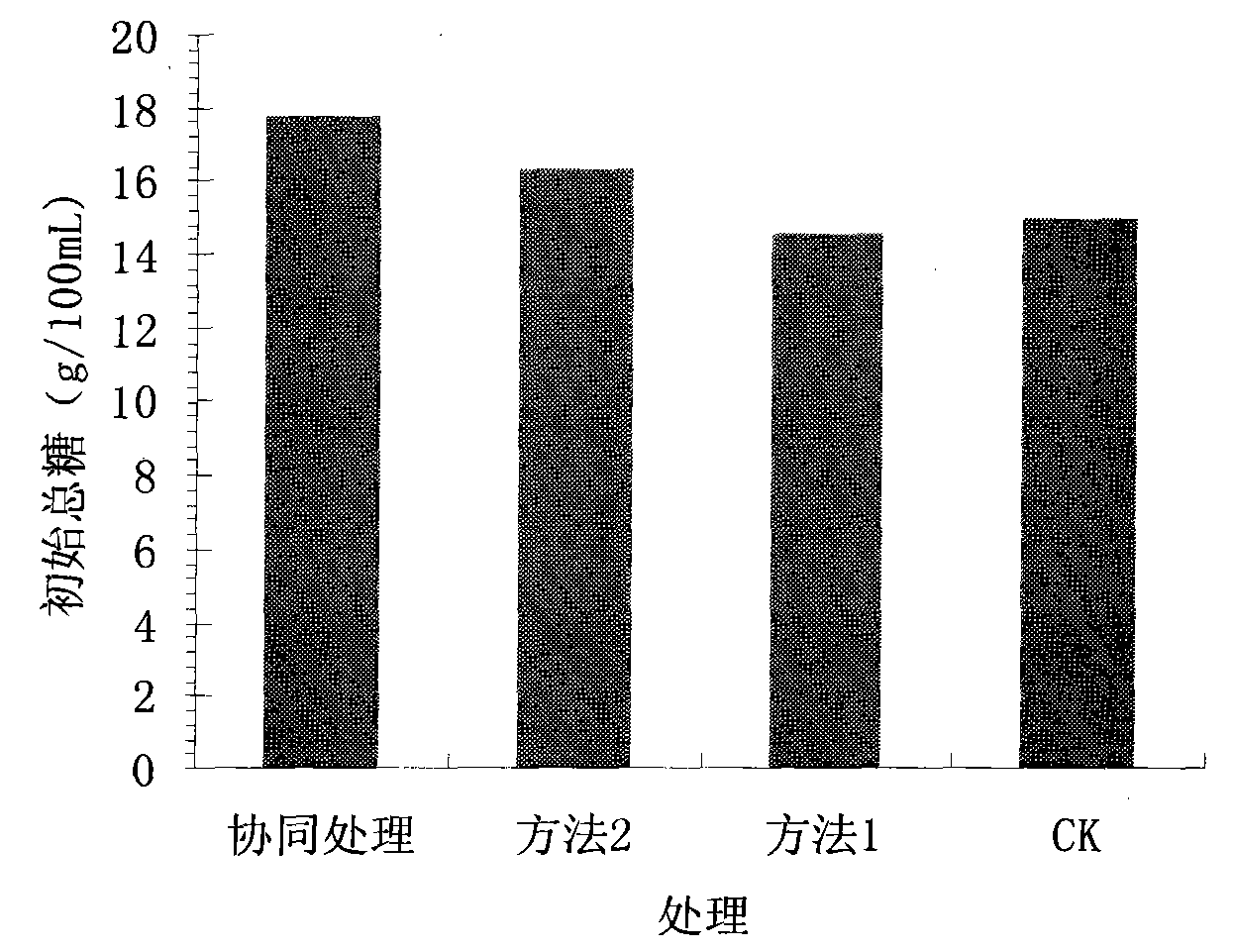

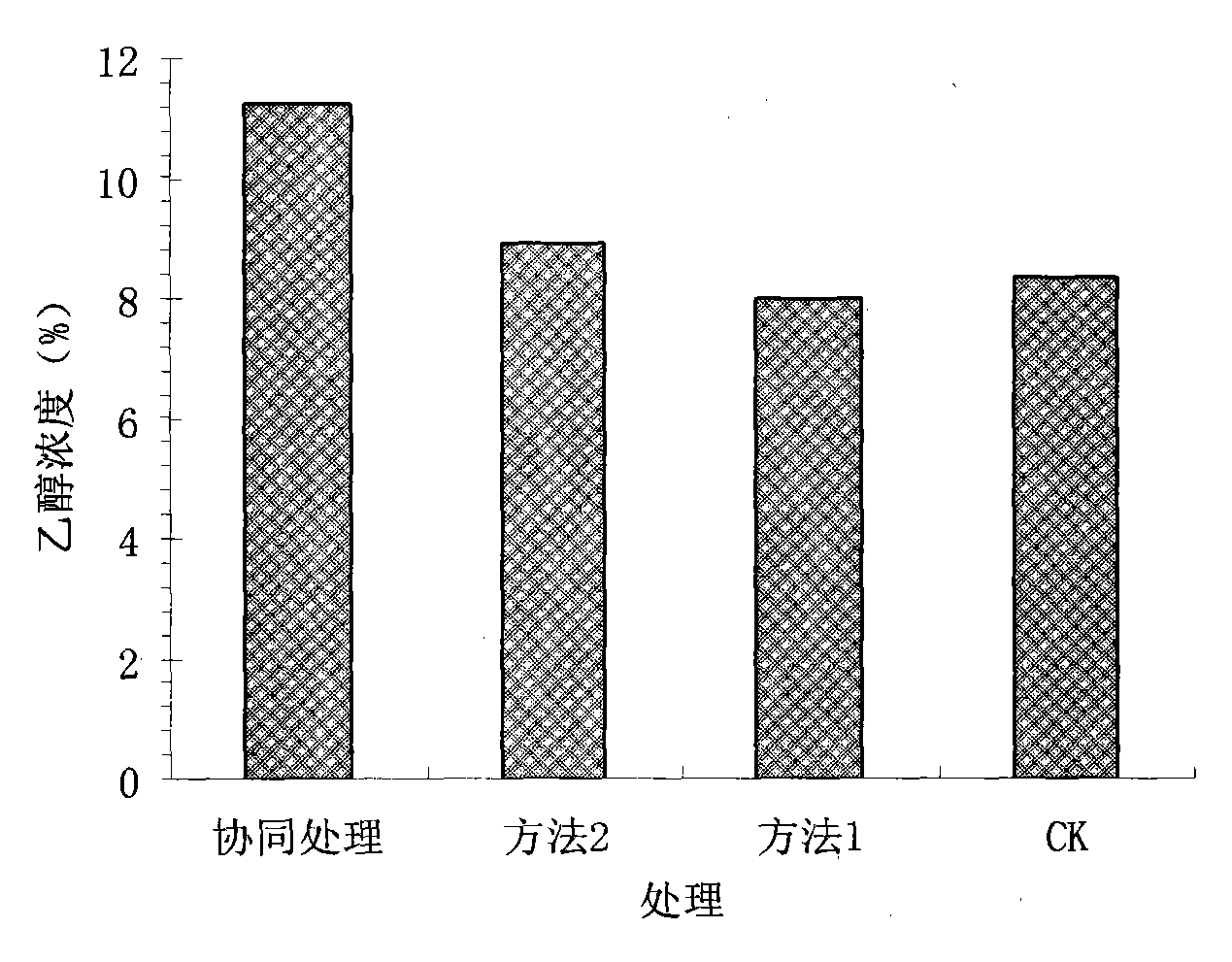

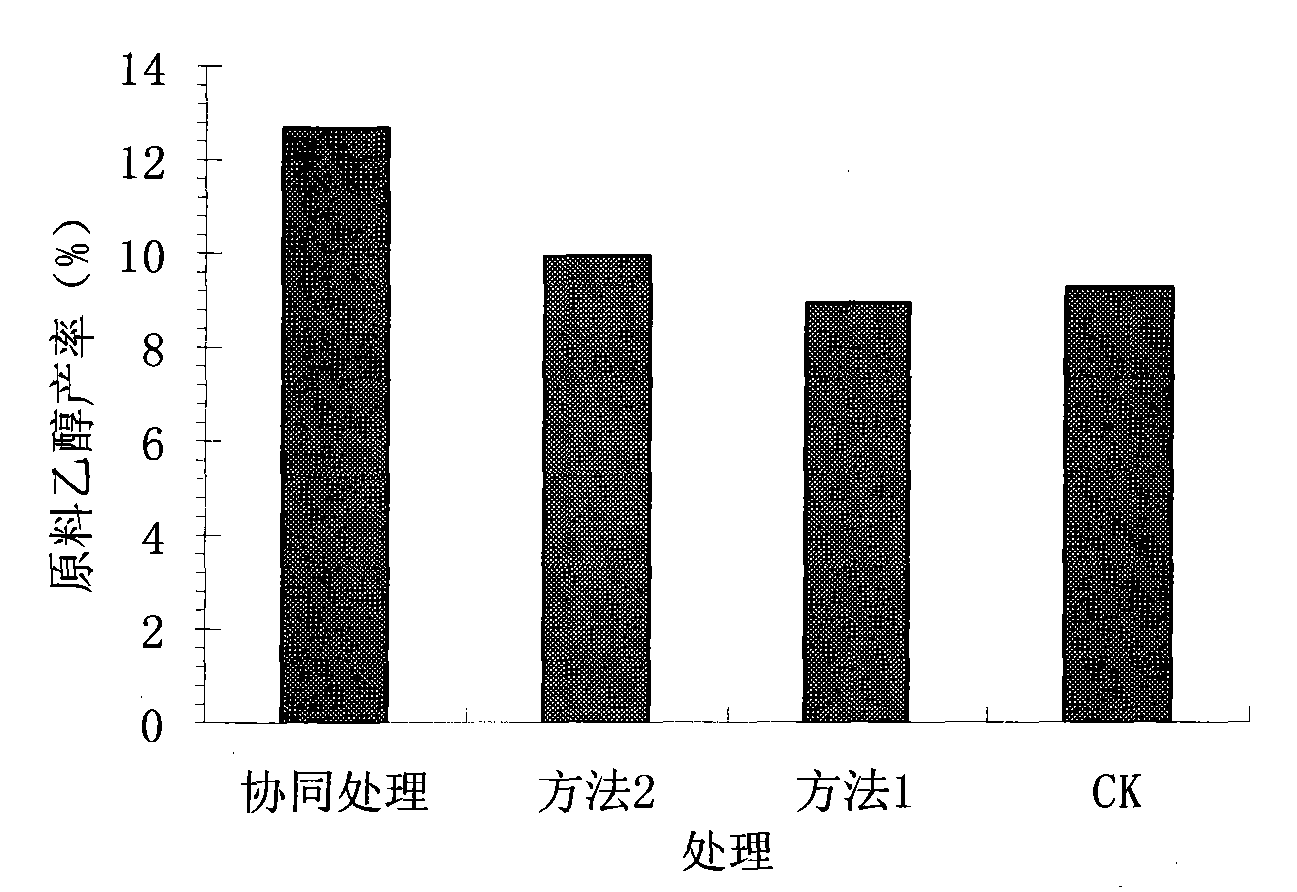

Method for improving yield of ethanol produced by sugar beet fermentation

InactiveCN102174631BIncrease growth rateImprove reproductive performanceBiofuelsMicroorganism based processesAmino acid synthesisDipeptide

Owner:JILIN ACAD OF AGRI SCI

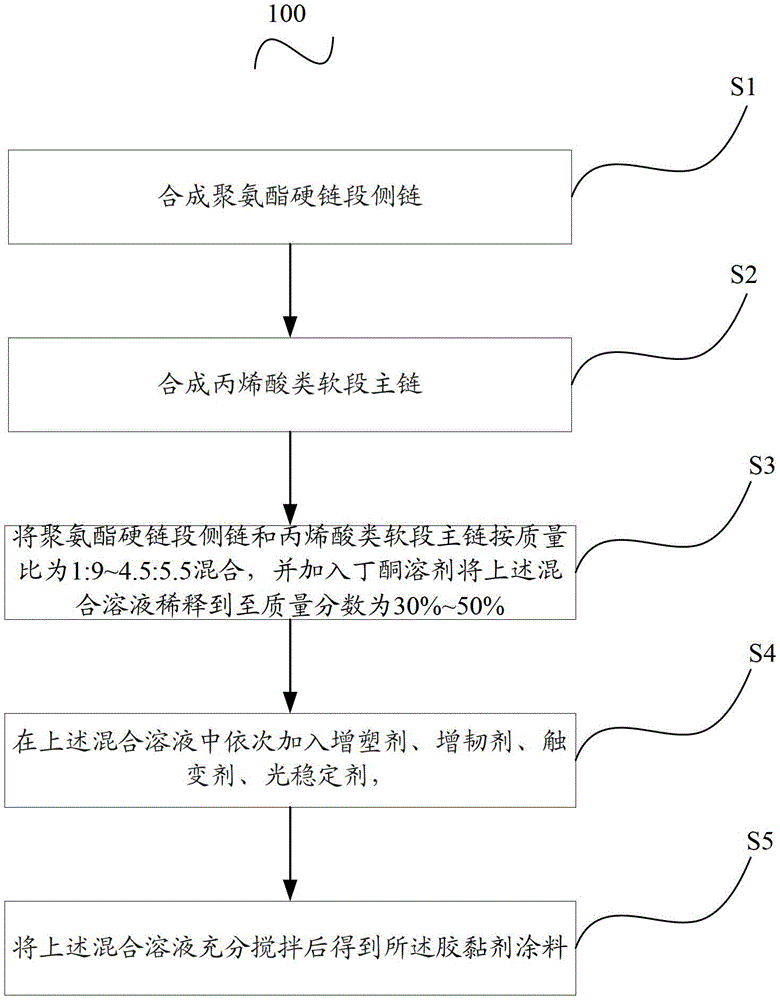

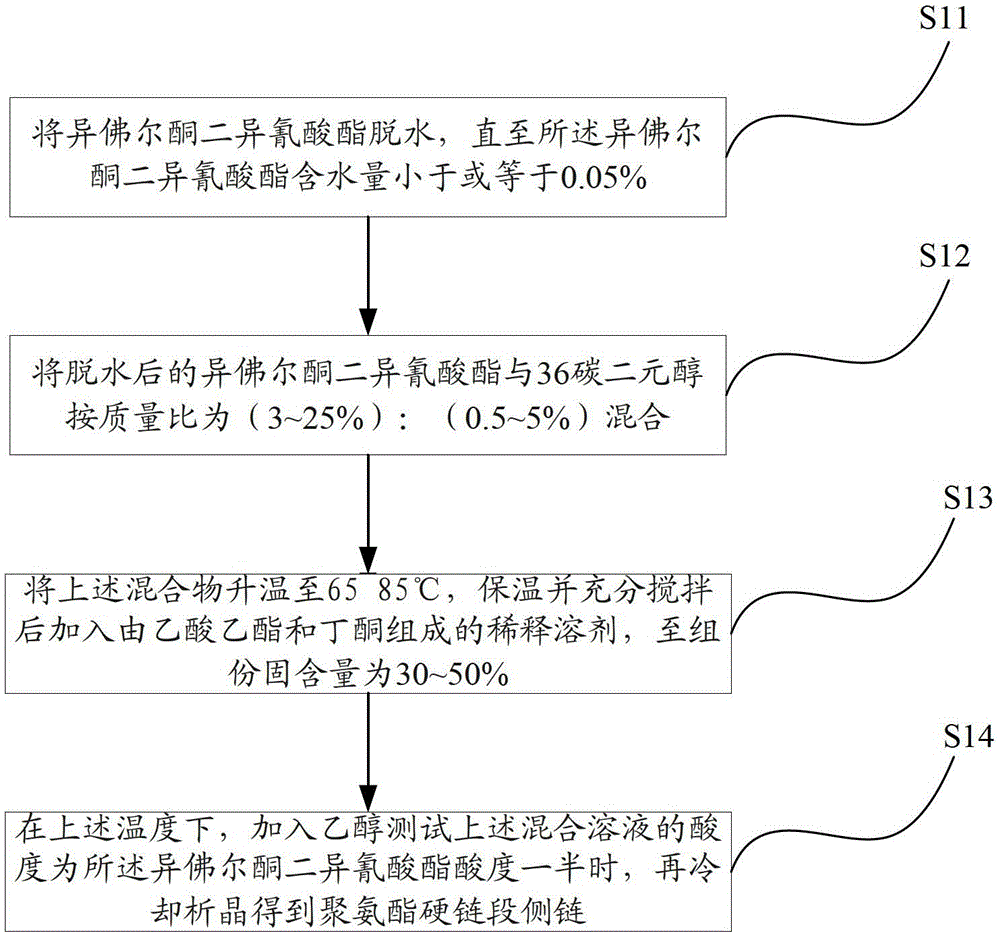

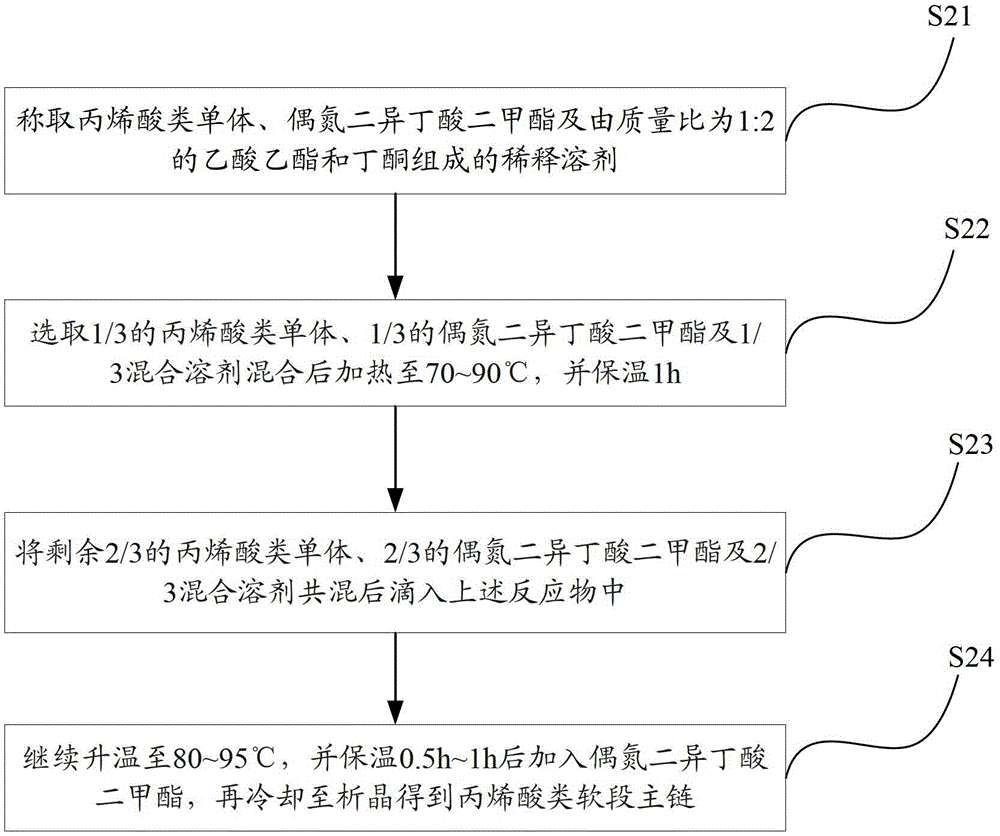

A kind of preparation method of adhesive coating

ActiveCN103360891BImprove wettabilityImprove high temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesHot stampingAlcohol

The invention provides a preparation method of an adhesive paint. The method comprises: taking a polyurethane hard segment as a side chain, taking an acrylic acid soft segment as a main chain, mixing the polyurethane hard segments and the acrylic acid soft segment according to a certain mass ratio, then adding various auxiliary-agent filling materials such as a plasticizer, a flexibilizer, a thixotropic agent and a light stabilizer, to finally obtain the adhesive paint for a plastic package gold-stamping film. By using the preparation method of the adhesive paint, the prepared adhesive pain has the advantages of being good in wetability, resistant in high temperature, resistant in rub, tolerant in acid and alkali, tolerant in alcohol, resistant in ultraviolet radiation aging, resistant in yellowing, and good in hot stamping and cutting performances.

Owner:SHENZHEN SHENDA AURORA TECH

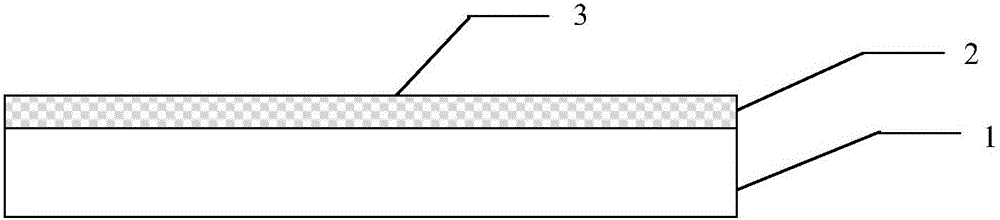

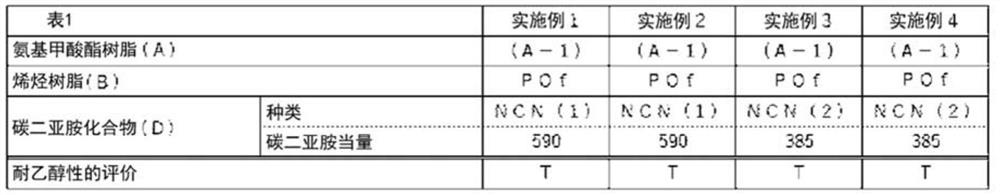

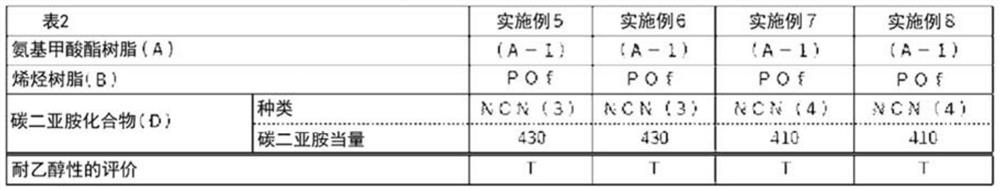

Urethane resin composition, surface treatment agent, and article

ActiveCN113242875AExcellent resistance to ethanolFibre treatmentPolyurea/polyurethane coatingsPolymer scienceCarbamate

The present invention provides a urethane resin composition characterized by comprising a urethane resin (A), an olefin resin (B), water (C), and a carbodiimide compound (D) having a carbodiimide equivalent of 340 or higher. The present invention further provides a surface treatment agent characterized by comprising the urethan resin composition. The present invention furthermore provides an article characterized by including a layer formed from the surface treatment agent. The urethane resin (A) has a urethane bond content preferably in the range of 980-4,000 mmol / kg. The urethane resin (A) has a urea bond content preferably in the range of 315-850 mmol / kg.

Owner:DIC CORP

Water-soluble triazinyl sulfuryl polyurethane and application thereof

InactiveCN111534216ASimple processEasy to operatePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

Owner:HUNAN QIWEI TECH CO LTD

A kind of water-based antistatic coating and preparation method thereof

InactiveCN103305108BImprove antistatic performanceImprove water resistancePolyurea/polyurethane coatingsElectrically-conductive paintsWater basedAlcohol

The invention relates to a waterborne antistatic coating and preparation method thereof. The method comprises the following steps: slowly adding the water solution of carboxylated waterborne polyurethane resin in a water solution of a carboxylated waterborne conductive polymer system, uniformly stirring, adding a polyfunctional aziridine compound, stirring to uniformly mix the components to obtain the waterborne antistatic coating, wherein the content of the carboxylated waterborne conductive polymer system in the waterborne antistatic coating is 0.1-2.5wt%, the content of the carboxylated waterborne polyurethane resin is 2-28wt%, the content of the polyfunctional aziridine compound is 0.1-3wt%, and the rest is water. The waterborne antistatic coating is tightly combined with the surfaces of substrates such as plastic, glass, wood, round and the wall to form the antistatic paintcoat with good antistatic effect, good water resistance and alcohol resistance; the antistatic coating can be widely applied to the fields of film negative film package, electron component package, display protective film and electromagnetic shielding.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A kind of water-based polyurethane emulsion with high water resistance and ethanol resistance and preparation method thereof

ActiveCN109721707BImprove water resistanceLower surface energyPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention belongs to the technical field of fine chemicals, and in particular relates to a water-based polyurethane emulsion with high water resistance and ethanol resistance and a preparation method thereof. The invention provides a kind of preparation method that has high water resistance, the waterborne polyurethane emulsion of ethanol resistance, comprises the following steps: a) polypropylene carbonate polyol, diisocyanate, castor oil and hydrophilic chain extender are in catalyst Under the action of the first reaction, the first product is obtained; b) a silane coupling agent is added to the first product, and the second reaction is carried out to obtain the second product; c) the middle product is added to the second product After the neutralization reaction with the neutralizing agent, deionized water is added for emulsification, and then a non-hydrophilic chain extender is added for the third reaction to obtain a water-based polyurethane emulsion. Experimental results show that the coating film formed by the water-based polyurethane emulsion of the present invention has excellent boiling water resistance and ethanol resistance.

Owner:GUANGDONG UNIV OF TECH

A kind of preparation method of viscous water-based polyurethane dispersion

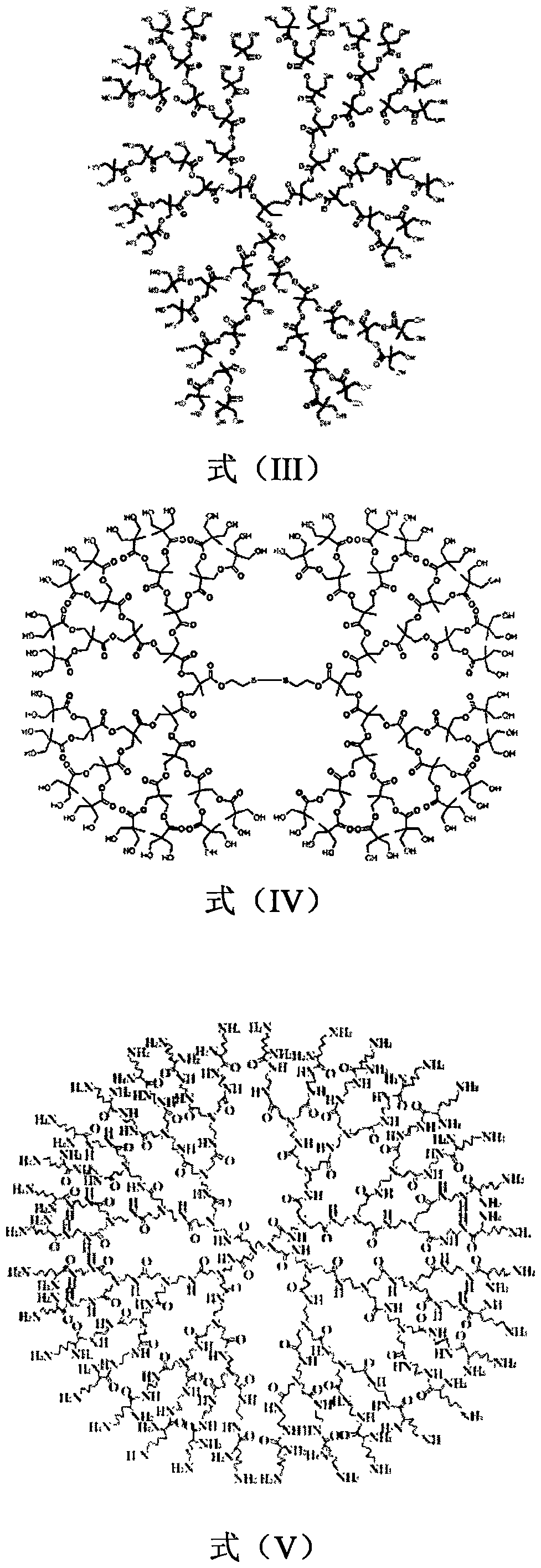

The invention discloses a preparing method for persistent viscosity waterborne polyurethane dispersoid. The method includes the following steps of 1 synthesizing hard shell layer prepolymer, wherein a hyperbranched active polymer, isocyanate and a hydrophilic chain extender react to obtain the hyperbranched active prepolymer; 2, synthesizing a viscous core prepolymer, wherein macromolecule polyhydric alcohol, isocyanate and a hydrophilic chain extender react under the action of a catalyst to prepare the hyperbranched active prepolymer; 3, grafting the core-shell prepolymers, wherein the prepolymer prepared in the step 1 and the prepolymer prepared in the step 2 are mixed to react; 4, preparing the persistent viscosity dispersoid, wherein after deionized water is added, the prepolymer of the grafted network prepared in the step 3 is dispersed at a high speed to be emulsified, an appropriate amount of micromolecule amine is added according to needs to further conduct a chain extension reaction to obtain the product finally. The product prepared through the method has excellent initial viscosity, persistent viscosity, peeling strength, water tolerance and ethanol tolerance and is high in cohesion, and no adhesive residue exists after a matrix is peeled.

Owner:平顶山正植科技有限公司

A kind of hydroxyacrylic acid dispersion modified by glycidyl p-hydroxybenzoate and preparation method thereof

ActiveCN108409904BGood dispersionHigh solid contentPolyurea/polyurethane coatingsBenzoic acidPolymer science

The invention relates to a p-hydroxybenzoic acid glycidyl ester modified hydroxy acrylic acid dispersoid and a preparation method thereof. The selected peracid compound not only can provide reactive hydrogen, but also can serve as an initiator, and the p-hydroxybenzoic acid glycidyl ester modified novel hydroxy acrylic acid dispersoid is prepared by a one-pot method; in a preparation process, useof a reaction reagent, a cosolvent and the like is reduced, and the prepared hydroxy acrylic acid dispersoid is excellent in performance, high in solid content and hydroxyl value and low in VOC content; and moreover, hydroxy acrylic acid dispersoid paint prepared by the invention is excellent in waterproofness and ethanol resistance.

Owner:上海祥越实业有限公司

Urethane resin composition, surface treatment agent, and article

PendingUS20220025211A1Excellent resistance to ethanolFibre treatmentPolyurea/polyurethane coatingsPolymer scienceCarbamate

The present invention provides a urethane resin composition including a urethane resin (A), an olefin resin (B), water (C), and a carbodiimide compound (D) having a carbodiimide equivalent of 340 or more. Also, the present invention provides a surface treatment agent including the urethane resin composition described above. Further, present invention provides an article including a layer formed of the surface treatment agent. The content of urethane bond in the urethane resin (A) is preferably within a range of 980 to 4,000 mmol / kg. The content of urea bond in the urethane resin (A) is preferably within a range of 315 to 850 mmol / kg.

Owner:DAINIPPON INK & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com