A kind of preparation method of viscous water-based polyurethane dispersion

A technology of waterborne polyurethane and stickiness, which is applied in the field of sticky waterborne polyurethane dispersion and its preparation, which can solve the problems of uncoordinated initial tack, stickiness and peel strength, difficulty in microphase separation in the emulsification stage, and excessive proportion of soft segment Large and other problems, to achieve the effect of excellent initial tack, strong cohesion, and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method that keeps viscous aqueous polyurethane dispersion comprises the steps:

[0035] (1) Add hyperbranched active polymer, isocyanate and hydrophilic chain extender into the three-necked flask, heat up and stir to obtain hard shell layer prepolymer;

[0036] (2) Add macromolecular polyol, isocyanate, hydrophilic chain extender and catalyst into the three-necked flask, and stir and react at a certain temperature to obtain a viscous core prepolymer;

[0037] (3) in the there-necked flask, the prepolymer prepared by (1) is mixed with the prepolymer prepared by (2), and the two prepolymers are grafted to obtain the prepolymer of the graft network;

[0038] (4) After cooling the prepolymer of the grafted network prepared in (3) to a certain temperature in a three-necked flask, quickly add deionized water to carry out high-speed shear dispersion and emulsification, the rotation speed is greater than 1500rpm, and then add an appropriate amount of small...

Embodiment 1

[0041] A kind of preparation method of sticky aqueous polyurethane elastic dispersion comprises the steps:

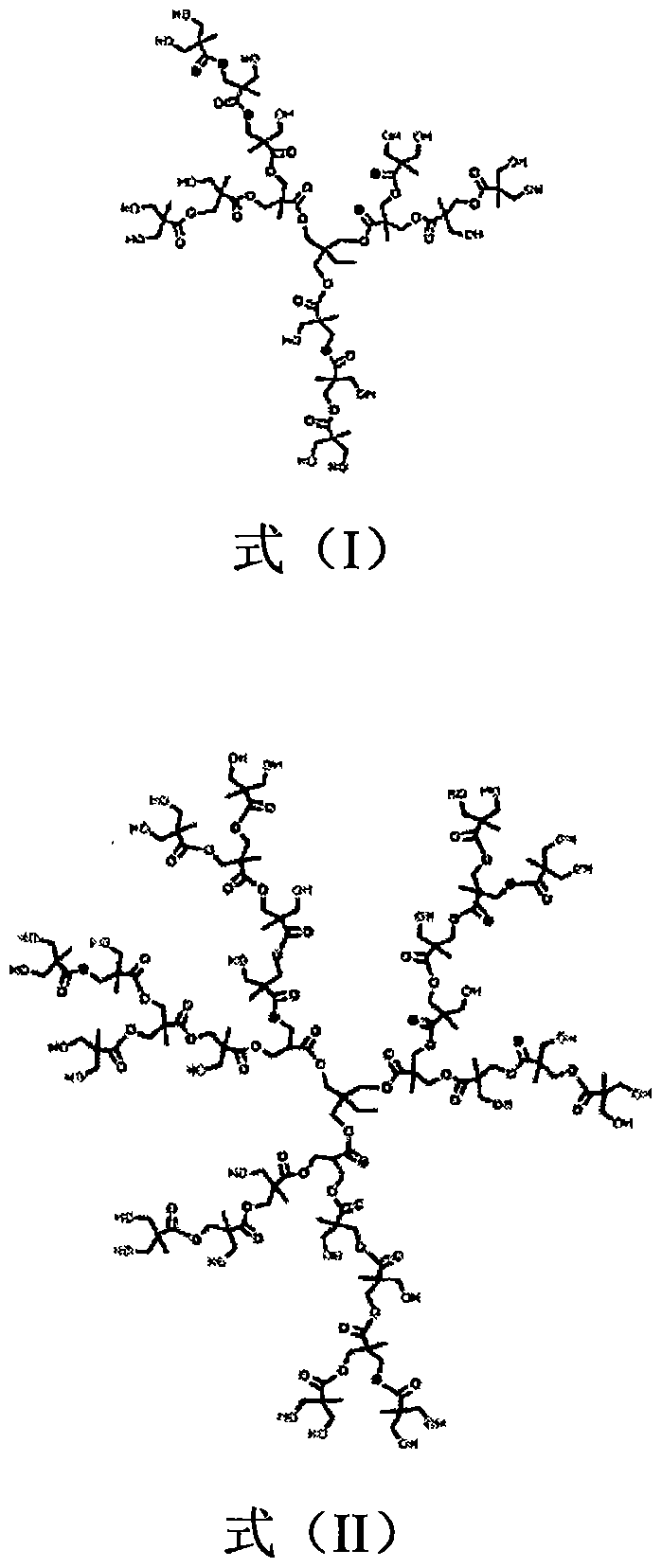

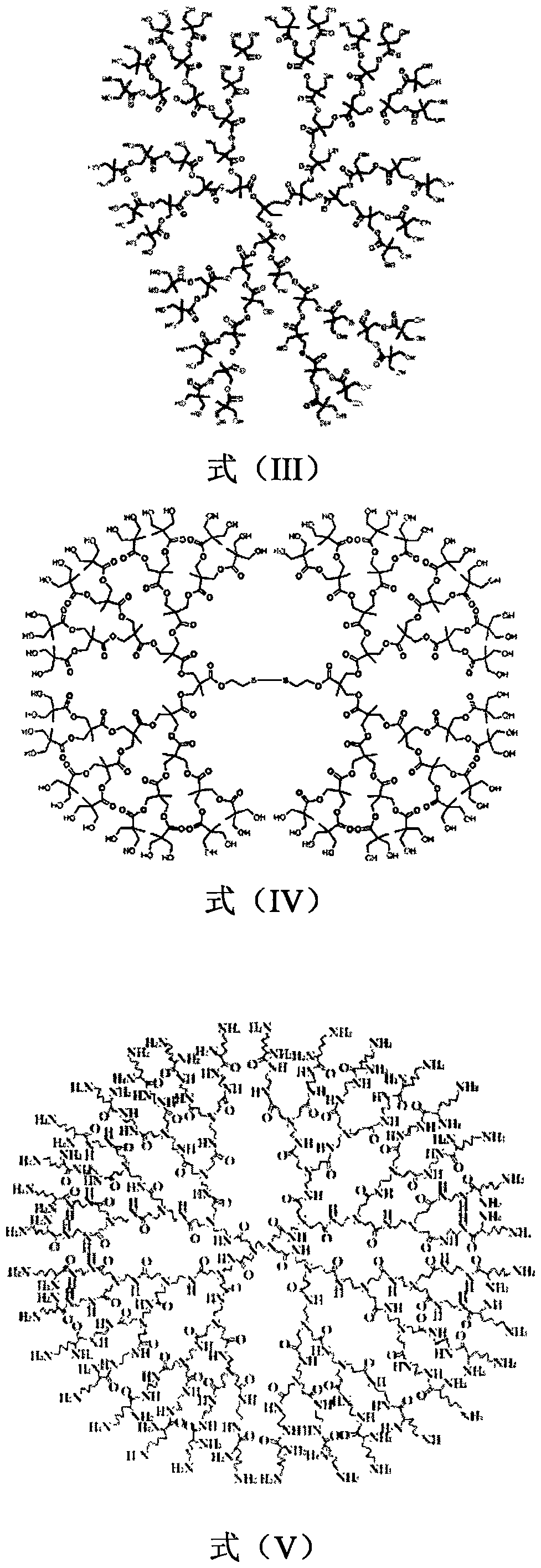

[0042] (1) Add 10 g of hyperbranched polyester polyol [Formula (I)] (Shanghai Xibao Biotechnology Co., Ltd.) into the three-necked flask, and after the temperature of the polyol in the flask is lowered to 10°C, add diphenylmethane diphenylmethane under stirring. Isocyanate (Shanghai Huntsman Polyurethane Co., Ltd.) 10g and sodium ethylenediaminoethanesulfonate ((Degussa)) 0.5g, the temperature of the reactant was controlled at 20°C and stirred for 1h to obtain a hard shell layer prepolymer;

[0043] (2) Add 410g of polyether diol (weight average molecular weight 2000, Shandong Bluestar Dongda Chemical Industry Co., Ltd.) and 41g of 1,6-hexamethylene diisocyanate (Shanghai Chunxiao Biotechnology Co., Ltd.) into the three-necked flask, and heat up under stirring After reacting at 60°C for 5 minutes, add 0.082 g of stannous octoate (Beijing Yili Chemical Company, C.P.), an...

Embodiment 2

[0047] A kind of preparation method of aqueous polyurethane elastic dispersion comprises the steps:

[0048] (1) 10 g of hyperbranched polyester polyol [formula (II)] (Shanghai Xibao Biotechnology Co., Ltd.) was added to the three-necked flask, and after the temperature of the polyol in the flask was lowered to 10° C., p-phenylene diisocyanate ( Shanghai Shanji Chemical Co., Ltd.) 24g, heated up to 26°C and reacted for 25 minutes, then added 1.8g of dimethylol butyric acid (Shanghai Yanyu Bioengineering Co., Ltd.) and continued to react for 47 minutes to form a hard shell prepolymer;

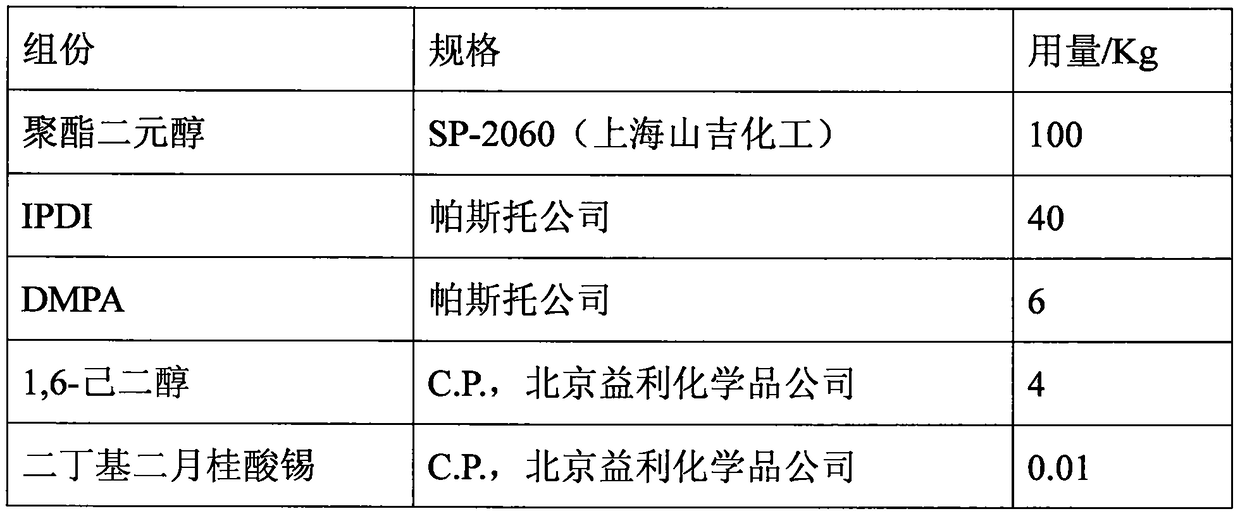

[0049] (2) Add 238.6g of polyester diol (weight average molecular weight 3000, Qingdao Xinyutian Chemical Co., Ltd.) and 71.6g of isophorone diisocyanate (Pastor Company) into the three-necked flask, and heat up to 110°C for reaction under stirring. After 10 minutes, add 0.0716 g of dibutyltin dilaurate (Beijing Yili Chemical Company, C.P.), and after stirring evenly, dissolve 4.7 g of dimethyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com