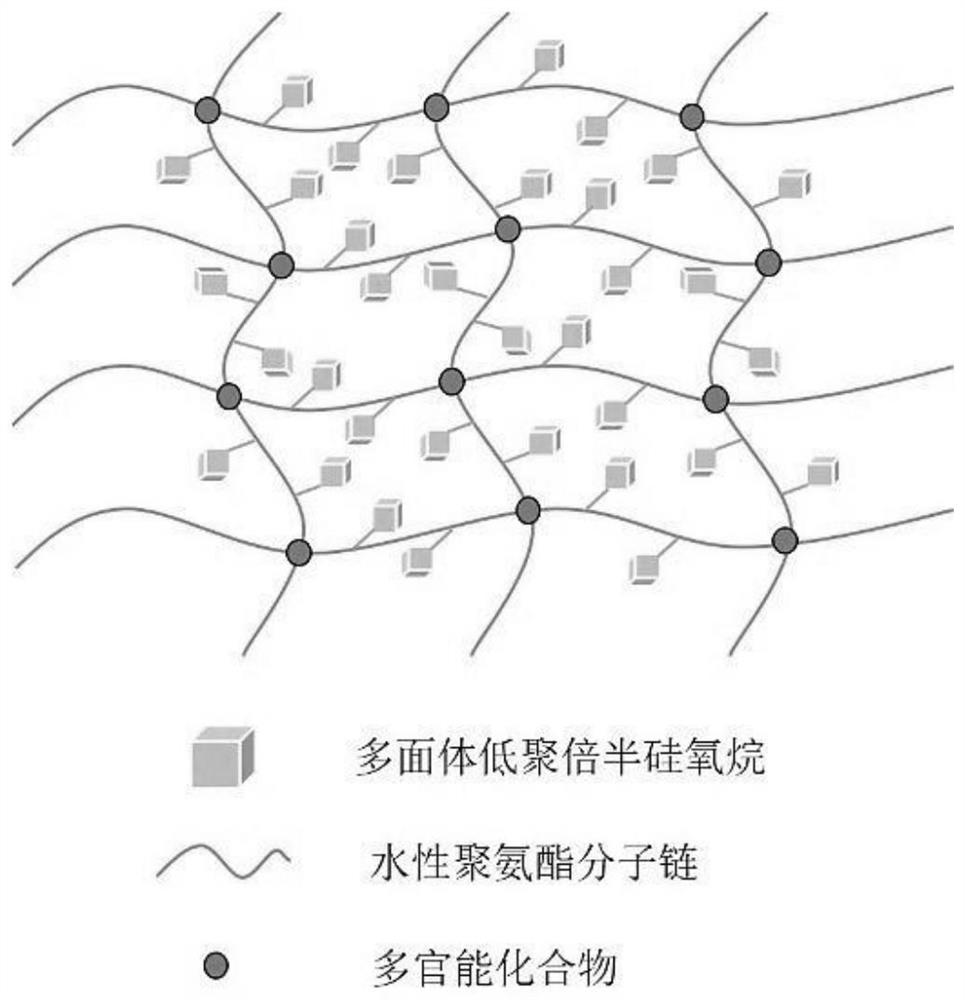

A kind of aqueous polyurethane and preparation method thereof

A water-based polyurethane, high-performance technology, applied in the field of polymer materials, can solve the problems of complicated preparation methods, no involvement, and reduction of effective chain extension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

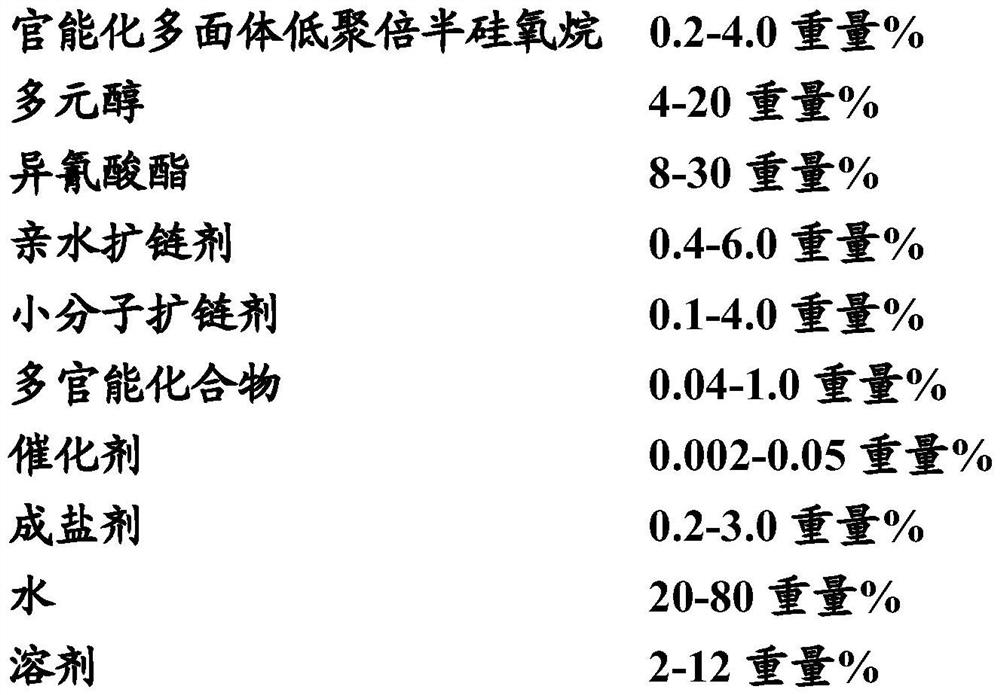

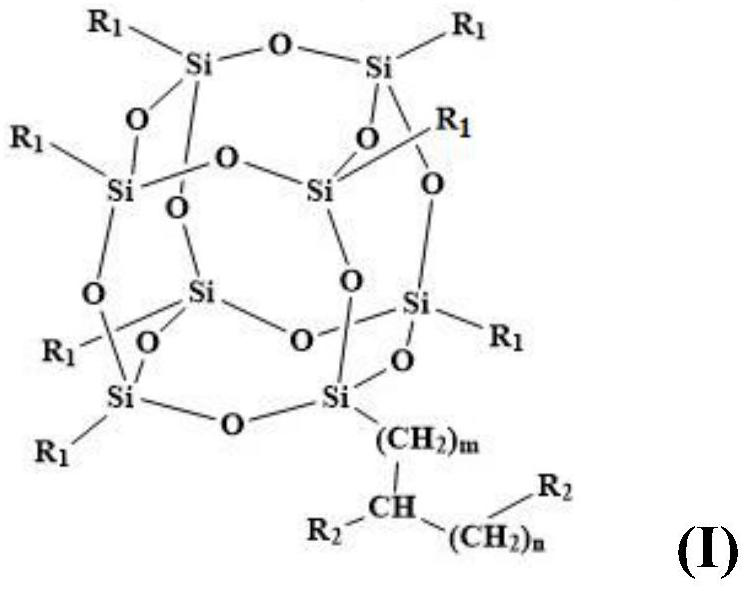

[0060] The present invention also provides the preparation method of high-performance waterborne polyurethane, it comprises the following steps:

[0061] a) Add solvent to the reactor, add functionalized POSS, hydrophilic chain extender, control the temperature at 30-70°C, stir to dissolve (preferably last 0.5-2.0 hours), and then add isocyanate dropwise (preferably slowly dropwise) In the reactor, react for 0.5-2.0 hours;

[0062] b) Add polyol, small molecule chain extender, and catalyst into the reactor, control the temperature at 60-100°C, and react for 1.5-5.0 hours;

[0063] c) continue to add the remaining solvent to the mixture obtained in step b), then add a metered multifunctional compound, control the temperature at 50-80° C., and react for 1.5-4.0 hours to obtain a high-performance water-based polyurethane prepolymer;

[0064] d) Control the temperature of the high-performance water-based polyurethane prepolymer obtained in step c) at 30-70°C, and add a salt-formi...

Embodiment 1

[0087] In a dry reactor equipped with a stirrer and a temperature measuring instrument, add 5 g of acetone (AC), 5 g of N,N-dimethylformamide (DMF), 2 g of isobutyl-substituted aminoethylaminopropyl-POSS (purchased from Hybrid Plastics, AM0275, Mw=917.65), 6g dimethylolpropionic acid (DMPA), controlled temperature at 50°C, stirring and dissolving for 0.5 hour, to a clear and transparent state, then 45g toluene diisocyanate (TDI) Slowly added dropwise to the reactor, the dropping time was controlled at 1 hour, and then reacted for 0.5 hour; 25g polybutylene adipate diol (Mw=1000, hydroxyl value 110mgKOH / g), 1g 1,6 -Add hexanediol (HDO) and 0.05g dibutyltin dilaurate into the reactor, stir and react at 70°C for 3 hours; add 5g N,N-dimethylformamide (DMF) to adjust the viscosity to 400mPa·s , and then add 0.5g of trimethylolpropane (TMP), and stir and react at 60°C for 2 hours to obtain a high-performance water-based polyurethane prepolymer. Gained high-performance water-based p...

Embodiment 2

[0089]In the drying reactor equipped with stirrer and temperature measuring instrument, add 12.5g butanone, 4g phenyl-substituted hydroxyethyl hydroxypropyl-POSS (purchased from Hangzhou Yajian Biotechnology Co., Ltd., P007, Mw=1127.53 ), 8g dimethylol butyric acid (DMBA), controlled temperature at 60°C, stirring and dissolving for 1 hour until clear and transparent, then 35g isophorone diisocyanate (IPDI), 5g hexamethylene diisocyanate ( After HDI) is mixed evenly, it is slowly added dropwise to the reactor, and the drop time is controlled at 2 hours, followed by 1 hour reaction; 40g polypropylene oxide glycol (Mw=2000, hydroxyl value 55mgKOH / g), 2g Add pentanediol (NPG) and 0.05g stannous octoate into the reactor, and stir and react at 80°C for 2.5 hours; add 5g N,N-dimethylformamide (DMF) to adjust the viscosity to 350mPa·s, then add 1g of pentaerythritol was stirred and reacted at 80°C for 2 hours to obtain a high-performance water-based polyurethane prepolymer. Gained hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com