Urethane resin composition, surface treatment agent, and article

A urethane, resin composition technology, applied in fiber treatment, polyurea/polyurethane coatings, textiles and papermaking, etc., can solve the problems of poor ethanol resistance, insufficient ethanol resistance, poor chemical resistance, etc. Excellent effect of ethanol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

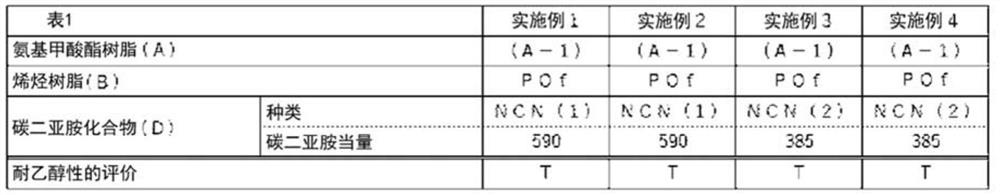

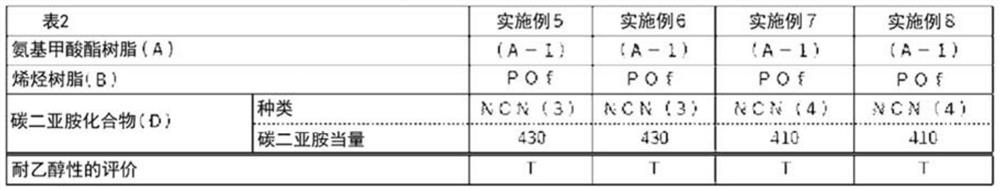

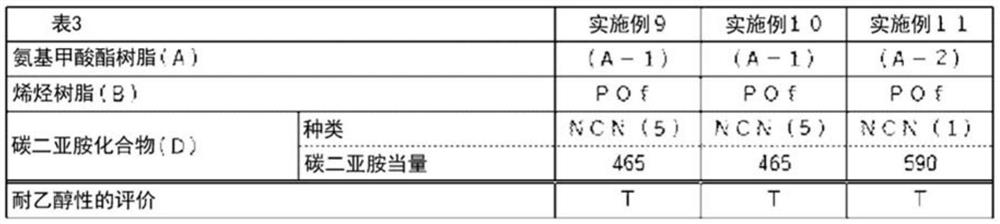

[0077] Hereinafter, the present invention will be described in more detail using examples.

Synthetic example 1

[0078] [Synthesis Example 1] Preparation of Urethane Resin (A-1) Aqueous Dispersion

[0079] Add 250 parts by mass of methyl ethyl ketone and 0.001 part by mass of stannous octoate in a four-necked flask equipped with a stirrer, a thermometer and a nitrogen reflux tube, and then add polycarbonate polyol-1 (with 1,4-butanediol and 1,6 - Hexylene glycol as raw material, number average molecular weight: 1000) 200 parts by mass, 15 parts by mass of 2,2-dimethylolpropionic acid, 49 parts by mass of isophorone diisocyanate, 34 parts by mass of hexamethylene diisocyanate , reacted at 70° C. for 1 hour to obtain a methyl ethyl ketone solution of the urethane prepolymer.

[0080] Next, after mixing 6.8 parts by mass of hydrazine and 15 parts by mass of triethylamine in the methyl ethyl ketone solution of the urethane prepolymer, 820 parts by mass of ion-exchanged water was added to obtain a urethane resin dispersed in water (A -1) Emulsion.

[0081] Next, methyl ethyl ketone was dist...

Synthetic example 2

[0083] [Synthesis Example 2] Preparation of Urethane Resin (A-2) Aqueous Dispersion

[0084] Add 250 parts by mass of methyl ethyl ketone and 0.001 part by mass of stannous octoate in a four-necked flask equipped with a stirrer, a thermometer and a nitrogen reflux tube, and then add polycarbonate polyol-3 (with 1,6-hexanediol as raw material, Number average molecular weight: 2000) 220 parts by mass, 12 parts by mass of 2,2-dimethylolpropionic acid, 70 parts by mass of dicyclohexylmethane diisocyanate, react at 70°C for 1 hour to obtain a urethane prepolymer solution of methyl ethyl ketone.

[0085] Next, after mixing 4.5 parts by mass of piperazine and 9 parts by mass of triethylamine in the methyl ethyl ketone solution of the urethane prepolymer, 880 parts by mass of ion-exchanged water was added to obtain a urethane resin dispersed in water ( A-2) Emulsion.

[0086] Next, methyl ethyl ketone was distilled off from the said emulsion liquid, and the ion-exchange water was fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com