High-hardness ethanol-resistant waterborne polyurethane emulsion and preparation method thereof

A water-based polyurethane, ethanol-resistant technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of ethanol resistance and poor hardness, and achieve the effect of excellent hardness and ethanol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

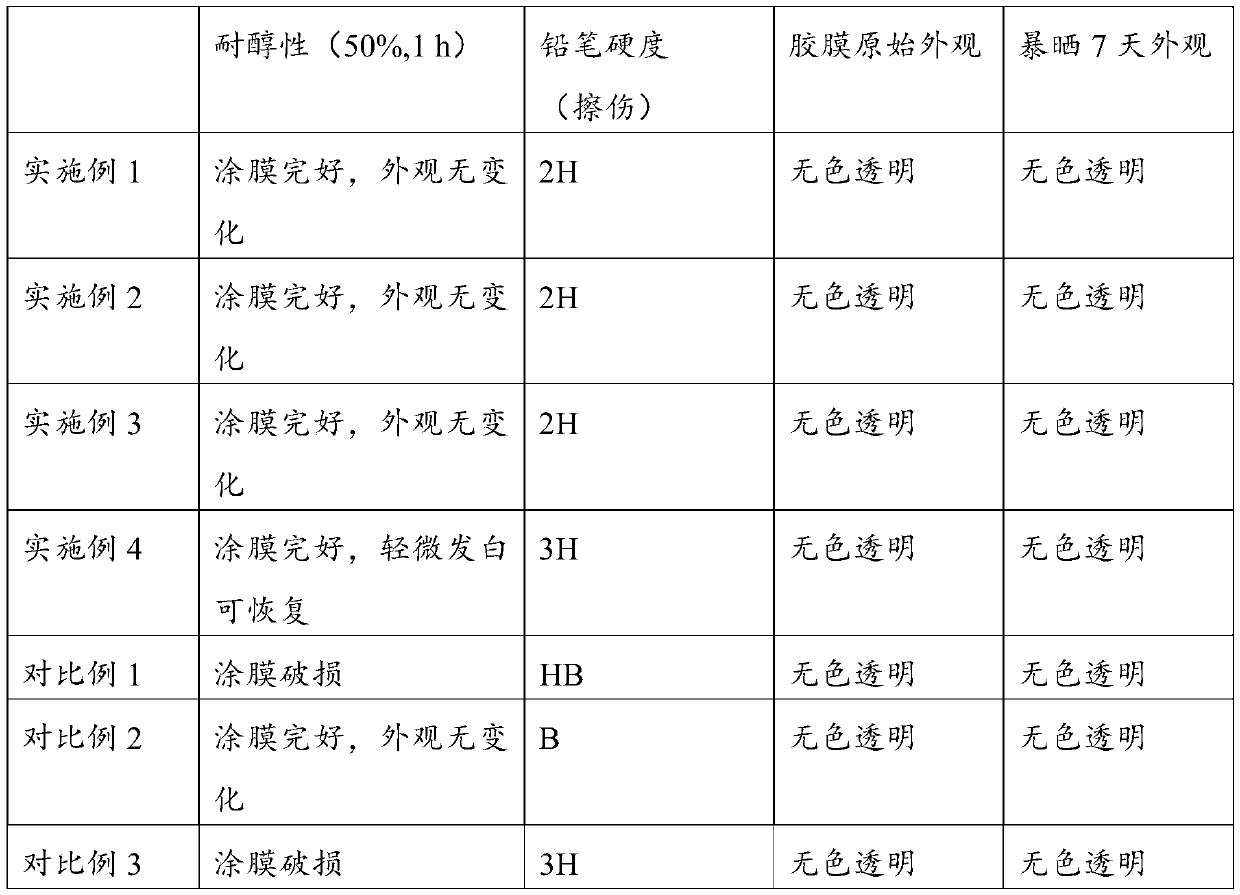

Examples

Embodiment 1

[0054]In parts by mass, take 60 parts of polypropylene carbonate diol with a molecular weight of 3000 and a hydroxyl functionality of 2, 53 parts of isophorone diisocyanate, 5 parts of dimethylolpropionic acid in 0.12 parts of stannous octoate Under the action of , the first reaction was carried out at 85 °C for 4 h, the temperature was lowered to 60 °C, 1.3 parts of trimethylolpropane, 3.1 parts of neopentyl glycol, 4.3 parts of 1,4-cyclohexanedimethanol and 10 parts of Acetone, heat up to 75°C for 1h second reaction, lower the temperature to 50°C, add 20 parts of acetone to reduce viscosity, add 3.9 parts of KH-550, carry out the third reaction for 30min, lower the temperature to 40°C, add 3.8 parts of triethylamine Carry out neutralization reaction for 5min, then add 250 parts of deionized water at 1500r / min for 15min emulsification reaction, then add 2.56 parts of ethylenediamine at 800r / min to carry out chain extension reaction for 30min, heat up to 50 ℃ and remove acetone...

Embodiment 2

[0056] In parts by mass, take 60 parts of polypropylene carbonate diol with a molecular weight of 3000 and a hydroxyl functionality of 2, 53 parts of isophorone diisocyanate, 5 parts of dimethylolpropionic acid in 0.12 parts of stannous octoate Under the action of , the first reaction was carried out at 85 °C for 4 h, the temperature was lowered to 60 °C, 1.3 parts of trimethylolpropane, 3.1 parts of neopentyl glycol, 4.3 parts of 1,4-cyclohexanedimethanol and 10 parts of Acetone, heat up to 75°C for 1h second reaction, lower the temperature to 50°C, add 20 parts of acetone to reduce viscosity, add 3.9 parts of KH-550, carry out the third reaction for 30min, lower the temperature to 40°C, add 3.8 parts of triethylamine Carry out neutralization reaction for 5min, then add 250 parts of deionized water at 1500r / min for 15min emulsification reaction, then add 2.56 parts of ethylenediamine at 800r / min to carry out chain extension reaction for 30min, heat up to 50 ℃ and remove aceton...

Embodiment 3

[0058] In parts by mass, take 60 parts of polypropylene carbonate diol with a molecular weight of 3000 and a hydroxyl functionality of 2, 53 parts of isophorone diisocyanate, 5 parts of dimethylolpropionic acid in 0.12 parts of stannous octoate Under the action of , the first reaction was carried out at 85 °C for 4 h, the temperature was lowered to 60 °C, 1.3 parts of trimethylolpropane, 3.1 parts of neopentyl glycol, 4.3 parts of 1,4-cyclohexanedimethanol and 10 parts of Acetone, heat up to 75°C for 1h second reaction, lower the temperature to 50°C, add 20 parts of acetone to reduce viscosity, add 3.9 parts of KH-550, carry out the third reaction for 30min, lower the temperature to 40°C, add 3.8 parts of triethylamine Carry out neutralization reaction for 5min, then add 250 parts of deionized water at 1500r / min for 15min emulsification reaction, then add 2.56 parts of ethylenediamine at 800r / min to carry out chain extension reaction for 30min, heat up to 50 ℃ and remove aceton...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com