A kind of high-gloss ethanol-resistant water-based acrylic amino glass wine bottle baking varnish and its preparation method and application

A technology of acrylic acid amino and water-soluble acrylic acid, which is applied in coatings, pigment pastes, epoxy resin coatings, etc., and can solve problems such as poor recoatability, low gloss, poor resistance to ethanol and high-alcohol liquor, etc. , to achieve the effect of excellent ethanol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

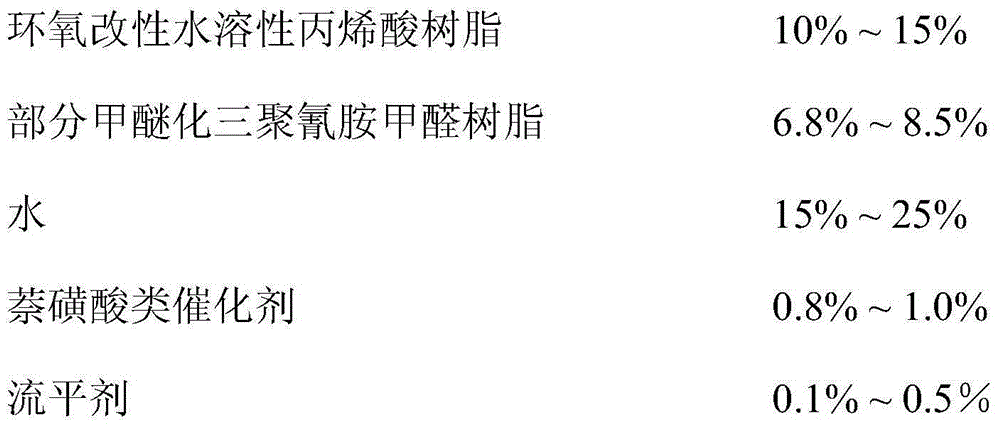

[0074] The preparation method of above-mentioned glass wine bottle baking varnish comprises the following steps:

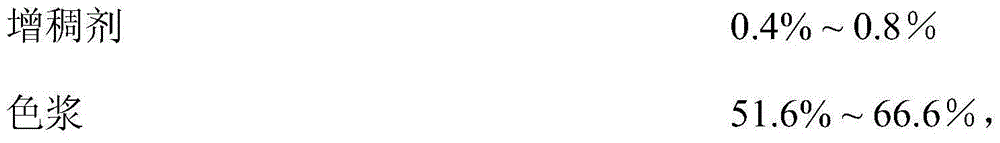

[0075] a. Preparation of color paste: Add epoxy modified water-soluble acrylic resin and water into the dispersion tank, disperse at a medium speed of 600-800r / min for 15 minutes, then slowly add co-solvent, toner, defoamer, dispersant and wetting agent agent, high speed 1000~1500r / min disperse for 25~35min, grind the high speed dispersed slurry twice with a sand mill, and prepare the color paste for later use;

[0076] b. Preparation of component 1: Add epoxy modified water-soluble acrylic resin, partially methylated melamine formaldehyde resin and water into the dispersion tank, disperse at a medium speed of 600-800r / min for 15min, then slowly add leveling agent to thicken agent and the color paste prepared in step a, disperse at a high speed of 1000-1500r / min for 30-35min, take a sample to detect that the finished product fineness of component 1 is less than or...

Embodiment 1

[0084] Prepare color paste:

[0085] Epoxy modified water-soluble acrylic resin 67%, water 15%, cosolvent 9%, toner 7%, defoamer 0.8%, dispersant 0.7%, wetting agent 0.5%;

[0086] Add epoxy-modified water-soluble acrylic resin and water into the dispersion tank, disperse at a medium speed of 800r / min for 15min, then slowly add cosolvent, toner, defoamer, dispersant and wetting agent, and disperse at a high speed of 1500r / min for 25min , use a sand mill to grind the high-speed dispersed slurry twice to prepare the color paste for later use;

[0087] Preparation component 1:

[0088] 12% epoxy modified water-soluble acrylic resin, 7.9% partially methylated melamine formaldehyde resin, 18.8% water, 0.8% naphthalenesulfonic acid catalyst, 0.1% leveling agent, 0.4% thickener, 60% color paste;

[0089] Add epoxy-modified water-soluble acrylic resin, partially methylated melamine formaldehyde resin and water into the dispersion tank, and disperse at a medium speed of 800r / min for ...

Embodiment 2

[0097] Prepare color paste:

[0098] Epoxy modified water-soluble acrylic resin 63.3%, water 16%, cosolvent 8%, toner 11%, defoamer 0.4%, dispersant 1.0%, wetting agent 0.3%;

[0099] Add epoxy-modified water-soluble acrylic resin and water into the dispersion tank, disperse at a medium speed of 700r / min for 15min, then slowly add cosolvent, toner, defoamer, dispersant and wetting agent, and disperse at a high speed of 1300r / min for 30min , use a sand mill to grind the high-speed dispersed slurry twice to prepare the color paste for later use;

[0100] Preparation component 1:

[0101] 13% epoxy modified water-soluble acrylic resin, 7% partially methylated melamine formaldehyde resin, 25% water, 0.8% naphthalenesulfonic acid catalyst, 0.1% leveling agent, 0.5% thickener, 53.6% color paste;

[0102] Add epoxy-modified water-soluble acrylic resin, partially methylated melamine formaldehyde resin and water into the dispersion tank, disperse at a medium speed of 700r / min for 15m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com