A kind of preparation method of adhesive coating

A technology for adhesives and coatings, applied in the direction of adhesives, adhesive additives, polyurea/polyurethane coatings, etc., can solve problems such as poor bonding performance, and achieve the effects of easy operation, wide sources, and convenient procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

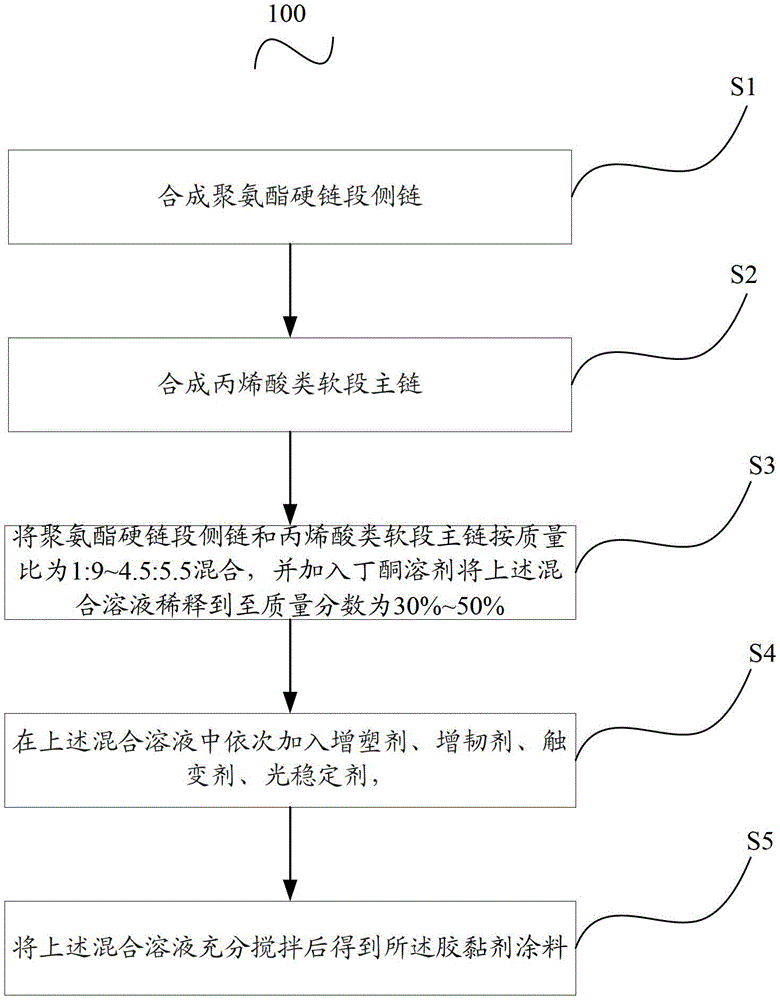

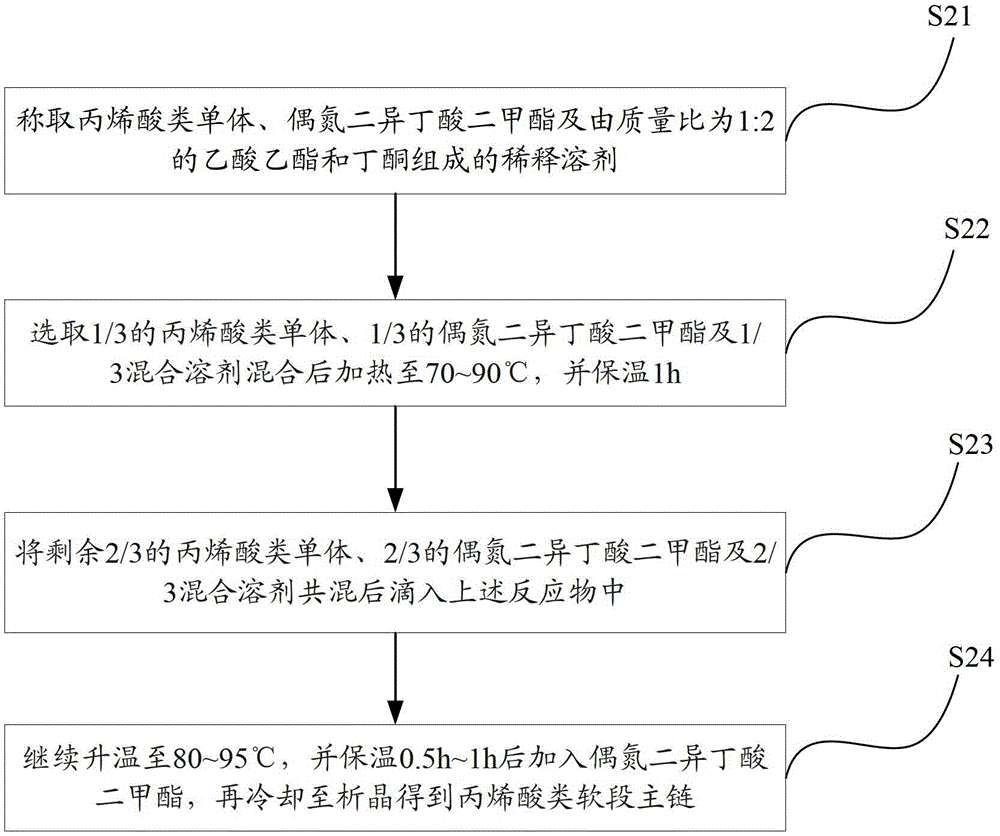

[0034] see figure 1 , figure 1 The step flow chart 100 of the preparation method of the adhesive coating provided by the embodiment of the present invention, from figure 1 Visible in, the preparation method of adhesive coating comprises the following steps:

[0035] Step S1: synthesizing polyurethane hard segment side chains;

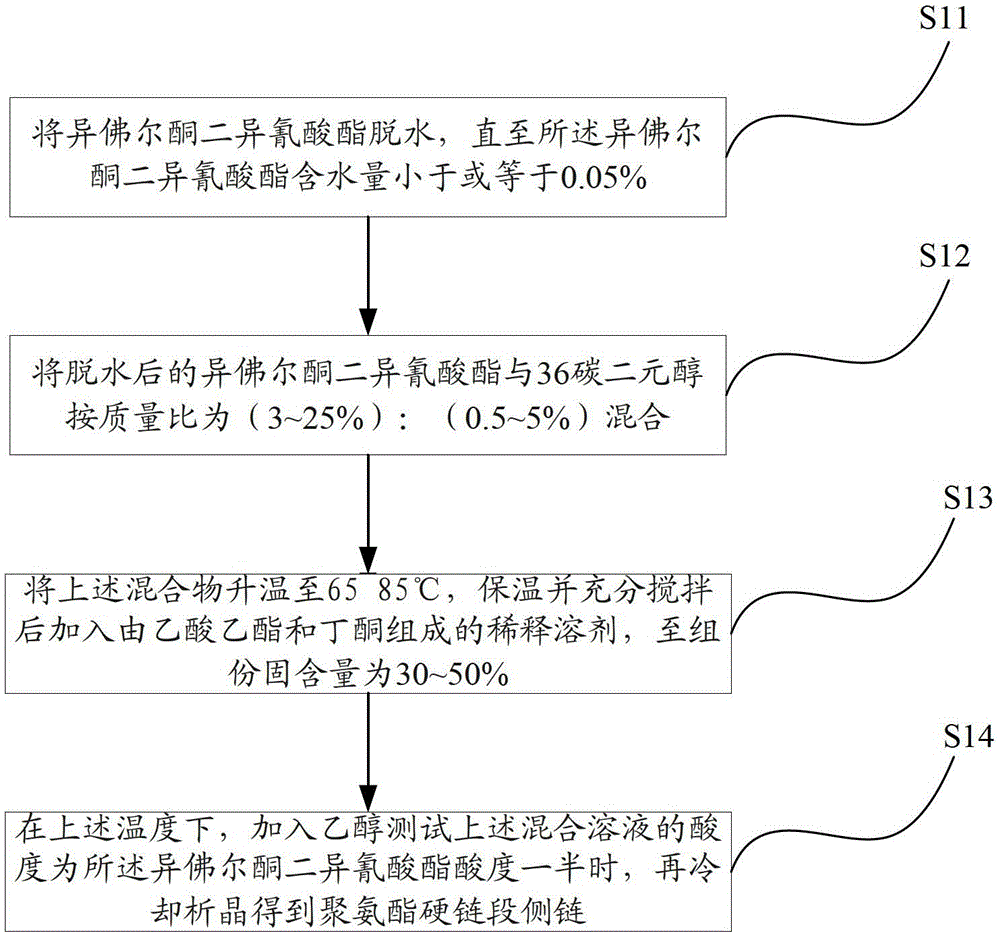

[0036] see figure 2 , figure 2 The flow chart of steps for synthesizing polyurethane hard segment side chains provided by the embodiments of the present invention includes the following steps:

[0037] Step S11: dehydrating isophorone diisocyanate until the water content of isophorone diisocyanate is less than or equal to 0.05%;

[0038] Specifically, isophorone diisocyanate (isophoronediisocyanate; IPDI) was depressurized to 15 mmHg and then distilled and dehydrated at 120° C. for 2 hours until the water content was no more than 0.05% before use.

[0039] Step S12: mixing dehydrated isophorone diisocyanate and 36-carbon dihydric alcohol in a ma...

Embodiment 1

[0065] After the IPDI is decompressed to 15mmHg, it is distilled and dehydrated at 120°C for 2 hours until the water content is 0.01% for use; then the dehydrated IPDI and 36-carbon dihydric alcohol are mixed at a mass ratio of 3%:0.5%; the mixed The mixture is placed in a reaction kettle, and a polyurethane catalyst with a mass fraction of 0.01% is added, and the temperature is slowly raised to 65°C. After the temperature is kept at 65°C and the reaction is fully stirred for 3 hours, a composition composed of ethyl acetate and methyl ethyl ketone is added. dilute solvent, adjust the solid content of the components in the above reactants to 30%; continue to stir at 65°C for 0.5h, and then add an ethanol solution with a mass fraction of 0.015%. Under the above conditions, ethanol and the above reactants The isocyanate reacts, and the acid value of the above-mentioned mixed solution is tested after the reaction is complete. When the acid value is half of the IPDI acid value, cool...

Embodiment 2

[0069] After IPDI is decompressed to 15mmHg, it is distilled and dehydrated at 120°C for 2 hours until the water content is 0.05% for use; then the dehydrated IPDI is mixed with 36-carbon dihydric alcohol at a mass ratio of 10%: 3%; after mixing The mixture is placed in a reaction kettle, and a polyurethane catalyst with a mass fraction of 0.06% is added, and the temperature is slowly raised to 85°C. After the temperature is kept at 85°C and the reaction is fully stirred for 3 hours, a composition composed of ethyl acetate and butanone is added. dilute solvent, adjust the solid content of the components in the above reactant to 50%; continue to stir at 85°C for 0.5h, then add 0.06% ethanol, under the above conditions, ethanol and the isocyanate in the above reactant The reaction occurs, and the acid value of the above-mentioned mixed solution is tested after the reaction is complete. When the acid value is half of the IPDI acid value, it is cooled to crystallization to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com