Double-component aqueous polyurethane, and preparation method and applications thereof

A water-based polyurethane, two-component technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of high preparation cost of two-component water-based polyurethane, large amount of water-based curing agent, etc. The effect of saving preparation cost and reducing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

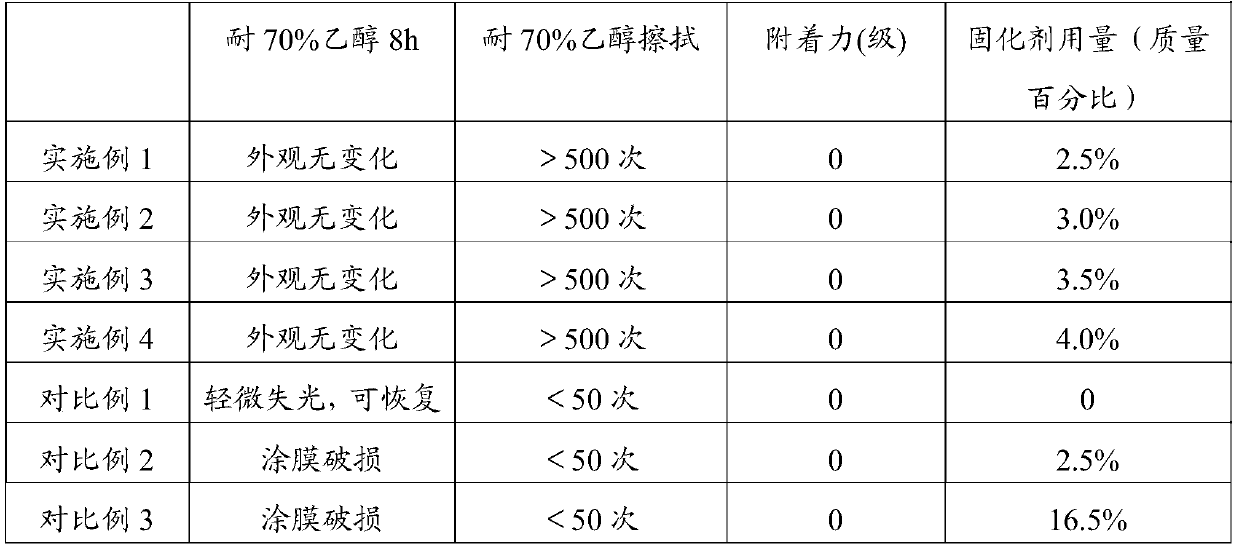

Examples

Embodiment 1

[0056] Take 40 parts of polypropylene carbonate diol with a molecular weight of 3000 and a hydroxyl functionality of 2, 20 parts of castor oil, after dehydration, add 53 parts of isophorone diisocyanate, 5.88 parts of dimethylolpropionic acid and 0.12 Part of stannous octoate catalyst, react at 85°C for 4 hours, cool down to 60°C, add 5.76 parts of 1,4-cyclohexanedimethanol, heat up to 75°C and react for 1 hour, add 20 parts of acetone to reduce viscosity, cool down to 50°C , add 4.13 parts of KH-550, keep warm for 30 minutes, lower to 40°C, add 4.43 parts of triethylamine to neutralize for 5 minutes, add 240 parts of deionized water to emulsify at high speed (1300r / min) for 15 minutes, add 3.12 parts of ethylene glycol After amine chain extension for 30 minutes (500r / min), the temperature was raised to 50°C to remove acetone under reduced pressure, and the temperature was raised to 60°C for aging for 2 hours to obtain a water-based polyurethane emulsion. Take 80 parts of emul...

Embodiment 2

[0058] Take 40 parts of polypropylene carbonate diol with a molecular weight of 3000 and a hydroxyl functionality of 2, 20 parts of castor oil, after dehydration, add 53 parts of isophorone diisocyanate, 5.88 parts of dimethylolpropionic acid and 0.12 Part of stannous octoate catalyst, react at 85°C for 4 hours, cool down to 60°C, add 5.76 parts of 1,4-cyclohexanedimethanol, heat up to 75°C and react for 1 hour, add 20 parts of acetone to reduce viscosity, cool down to 50°C , add 4.13 parts of KH-550, keep warm for 30 minutes, lower to 40°C, add 4.43 parts of triethylamine to neutralize for 5 minutes, add 240 parts of deionized water to emulsify at high speed (1300r / min) for 15 minutes, add 3.12 parts of ethylene glycol After amine chain extension for 30 minutes (500r / min), the temperature was raised to 50°C to remove acetone under reduced pressure, and the temperature was raised to 60°C for aging for 2 hours to obtain a water-based polyurethane emulsion. Take 80 parts of emul...

Embodiment 3

[0060] Take 40 parts of polypropylene carbonate diol with a molecular weight of 3000 and a hydroxyl functionality of 2, 20 parts of castor oil, after dehydration, add 53 parts of isophorone diisocyanate, 5.88 parts of dimethylolpropionic acid and 0.12 Part of stannous octoate catalyst, react at 85°C for 4 hours, cool down to 60°C, add 5.76 parts of 1,4-cyclohexanedimethanol, heat up to 75°C and react for 1 hour, add 20 parts of acetone to reduce viscosity, cool down to 50°C , add 4.13 parts of KH-550, keep warm for 30 minutes, lower to 40°C, add 4.43 parts of triethylamine to neutralize for 5 minutes, add 240 parts of deionized water to emulsify at high speed (1300r / min) for 15 minutes, add 3.12 parts of ethylene glycol After amine chain extension for 30 minutes (500r / min), the temperature was raised to 50°C to remove acetone under reduced pressure, and the temperature was raised to 60°C for aging for 2 hours to obtain a water-based polyurethane emulsion. Take 80 parts of emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com