P-hydroxybenzoic acid glycidyl ester modified hydroxy acrylic acid dispersoid and preparation method thereof

A technology of p-hydroxybenzoic acid and glycidyl ester, which is applied in the field of materials, can solve problems such as high cost, and achieve the effects of low VOC content, high solid content and hydroxyl value, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

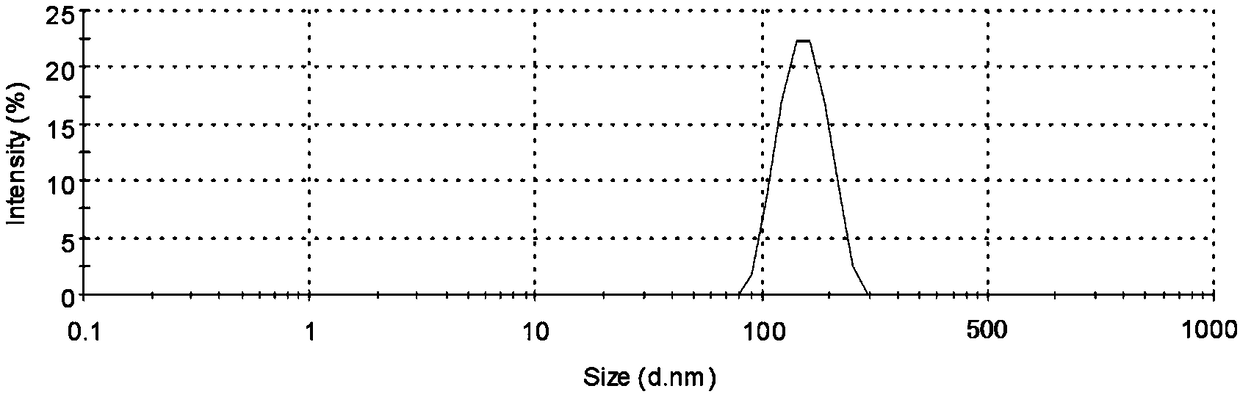

Image

Examples

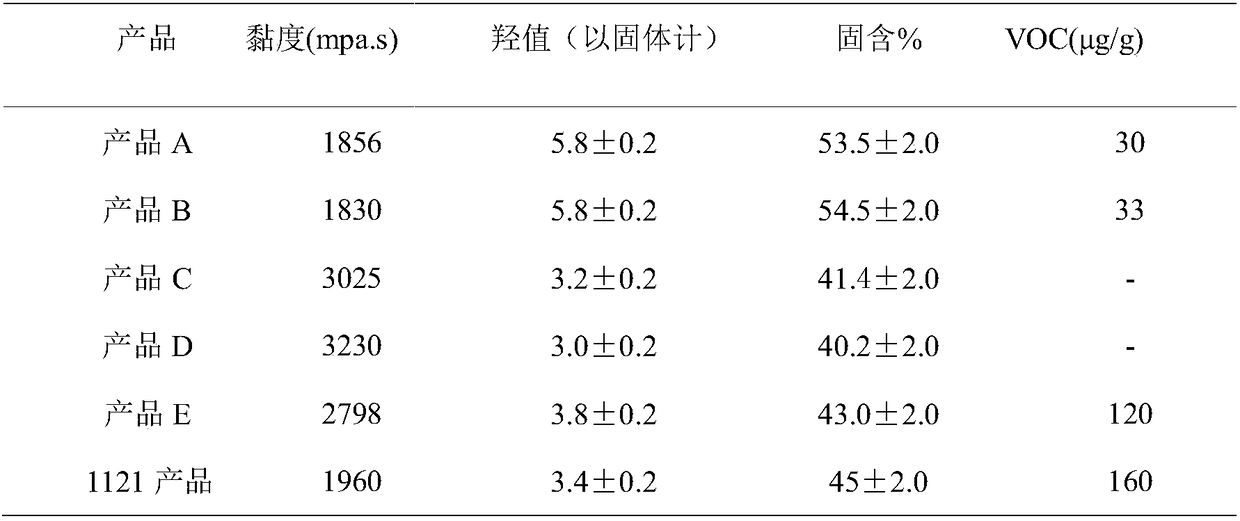

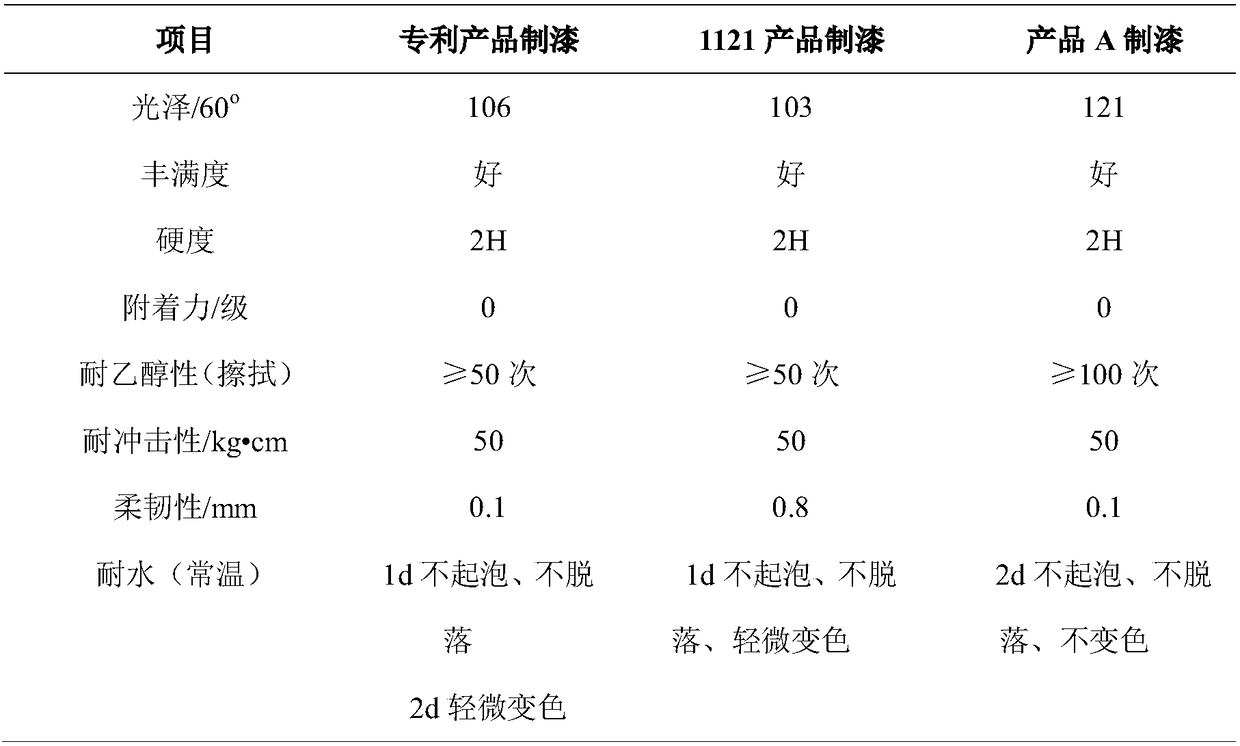

Embodiment 1

[0016] Mix 5g of glycidyl p-hydroxybenzoate, 1.5g of m-chloroperoxybenzoic acid, 2.0g of ethylene glycol butyl ether, 10g of methyl methacrylate, 10g of butyl acrylate, and 10g of hydroxyethyl methacrylate, and heat React at 50°C for 1.0h, then raise the temperature to 135°C and continue the reaction for 1h, then cool down to 80°C, add an appropriate amount of N,N dimethylethanolamine to neutralize, add an appropriate amount of deionized water to stir and disperse for 1-2h, and discharge , to obtain the hydroxyacrylic acid dispersion (hereinafter referred to as product A) modified by glycidyl p-hydroxybenzoate.

Embodiment 2

[0018] Mix 8g of glycidyl p-hydroxybenzoate, 2.5g of m-chloroperoxybenzoic acid, 3.0g of propylene glycol butyl ether, 18g of methyl methacrylate, and 22g of methyl acrylate, heat to 60°C for 0.5h and then heat up to 120°C After continuing to react at ℃ for 2 hours, lower the temperature to 70℃, add an appropriate amount of triethylamine to neutralize, add an appropriate amount of deionized water to stir and disperse for 1-2 hours, and discharge the material to obtain the modified glycidyl p-hydroxybenzoate The hydroxyacrylic acid dispersion (hereinafter referred to as product B).

Embodiment 3

[0020] Mix 5g of glycidyl p-hydroxybenzoate, 1.5g of m-chloroperoxybenzoic acid, 2.0g of ethylene glycol butyl ether, 10g of methyl methacrylate, 10g of butyl acrylate, and 10g of hydroxyethyl methacrylate, and directly Heat to 135°C and continue to react for 1 hour, then cool down to 80°C, add an appropriate amount of N,N dimethylethanolamine to neutralize, add an appropriate amount of deionized water to stir and disperse for 1-2 hours, and discharge to obtain product C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com