Water-soluble triazinyl sulfuryl polyurethane and application thereof

A triazine-based, water-soluble technology, applied in the field of baking paint, can solve the problems of poor resistance to ethanol and alcohol, low gloss, poor wear resistance, etc., and achieve stable comprehensive performance of the paint film and recoatability Good, water-soluble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

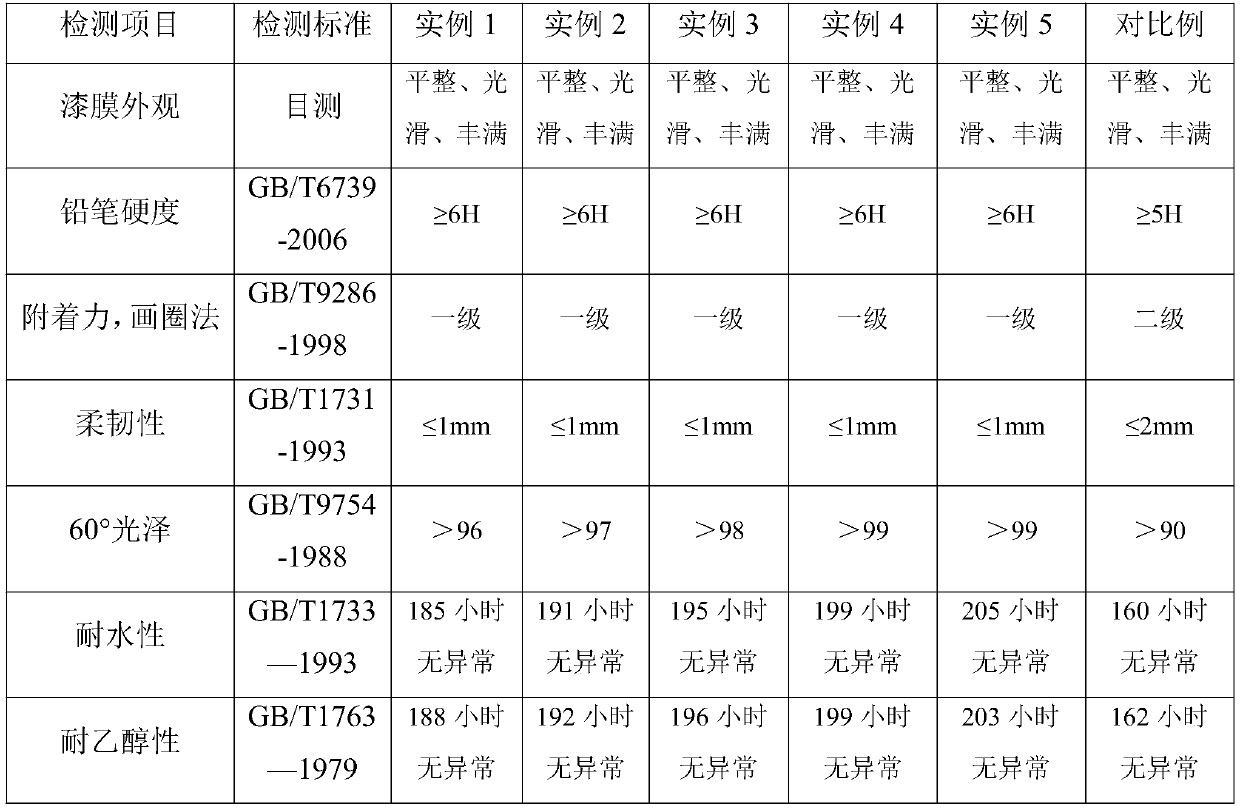

Examples

Embodiment 1

[0030] 50 parts of water-soluble triazine-based sulfone-based polyurethane, 10 parts of polymerizable monomer mixture, 1 part of azobisisobutylamidine hydrochloride, 1 part of polyacrylate leveling agent, 1 part of tributyl phosphate, styrene 1 part of phenol polyoxyethylene ether, 10 parts of deionized water, and 1 part of pigment.

[0031] The pigment is selected from titanium dioxide with a fineness of ≤15 μm;

[0032] The polymerizable monomer mixture is composed of 1,3-monoacrylate adamantanol, trimethylol propane ethoxylate triacrylate, 2,2,2-trifluoroethyl propylene, and methyl vinyl silfluorene .

[0033] The mass ratio of described 1,3-monoacrylic acid adamantanol, trimethylol propane ethoxylate triacrylate, 2,2,2-trifluoroethyl propylene, methyl vinyl silfluorene is 1:2:1: 0.2.

[0034] The preparation method of the water-soluble triazine-based sulfone-based polyurethane comprises the steps of: adding 10 g of vacuum dehydrated bis(4-isothiocyanate phenyl) sulfone,...

Embodiment 2

[0038] 53 parts of water-soluble triazine-based sulfone-based polyurethane, 13 parts of polymerizable monomer mixture, 2 parts of azobisisobutylimidazoline hydrochloride, 2 parts of cellulose acetate leveling agent, 31002 parts of Deqian defoamer, 2 parts of polyoxyethylene lauryl ether, 12 parts of deionized water, 2 parts of pigment.

[0039] The pigment is selected from carbon black with a fineness of ≤15 μm.

[0040] The polymerizable monomer mixture is composed of 1,3-monoacrylate adamantanol, trimethylol propane ethoxylate triacrylate, 2,2,2-trifluoroethyl propylene, and methyl vinyl silfluorene .

[0041] The mass ratio of described 1,3-monoacrylic acid adamantanol, trimethylol propane ethoxylate triacrylate, 2,2,2-trifluoroethyl propylene, methyl vinyl silfluorene is 1:2:1: 0.2.

[0042] The preparation method of the water-soluble triazine-based sulfone-based polyurethane comprises the steps of: adding 10 g of vacuum dehydrated bis(4-isothiocyanate phenyl) sulfone, po...

Embodiment 3

[0046] 57 parts of water-soluble triazine-based sulfone-based polyurethane, 15 parts of polymerizable monomer mixture, 3 parts of azodiisopropyl imidazoline, 3 parts of polyvinyl butyral leveling agent, 2 parts of defoamer BYK0888, oleic acid 3 parts of polyoxyethylene ester, 13 parts of deionized water, 3 parts of pigment.

[0047] The pigment is selected from polygonal effect pigments with a fineness of ≤15 μm.

[0048] The polymerizable monomer mixture is composed of 1,3-monoacrylate adamantanol, trimethylol propane ethoxylate triacrylate, 2,2,2-trifluoroethyl propylene, and methyl vinyl silfluorene .

[0049] The mass ratio of described 1,3-monoacrylic acid adamantanol, trimethylol propane ethoxylate triacrylate, 2,2,2-trifluoroethyl propylene, methyl vinyl silfluorene is 1:2:1: 0.2.

[0050] The preparation method of the water-soluble triazine-based sulfone-based polyurethane comprises the steps of: adding 10 g of vacuum dehydrated bis(4-isothiocyanate phenyl) sulfone,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com