Ultraviolet-light cured high-temperature resistant pressure-sensitive adhesive

A technology of pressure-sensitive adhesives and ultraviolet light, which is applied in the direction of adhesives, non-polymer organic compound adhesives, etc., and can solve problems such as unfocused research on cross-linking modification

Inactive Publication Date: 2015-03-25

TONSAN ADHESIVES INC

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Patent CN102015948A discloses a method for manufacturing a foamed acrylate pressure-sensitive adhesive tape. The foaming method and foaming size that are mainly introduced are controlled, and the cross-linking modification is not focused on.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

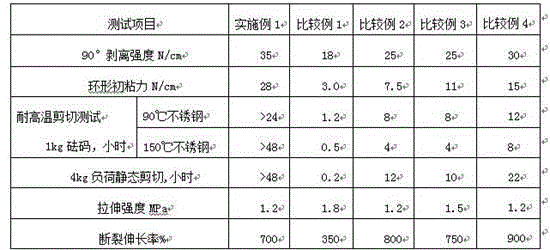

Embodiment 1

[0054] Add 1.0 parts of self-made crosslinking agent and 0.1 to 0.5 parts of photoinitiator to 100 parts of the above prepolymer, add pigments, fillers and hollow microspheres, stir evenly and remove air bubbles, and apply on two layers with a thickness of 1.0mm Between the transparent polyethylene terephthalate release films, put them into a 40W UV lamp for UV curing.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an ultraviolet-light cured high-temperature resistant pressure-sensitive adhesive. The pressure-sensitive adhesive comprises 5-20% of a solvent-free ultraviolet-light cured prepolymer, 0.1-2% of a functional crosslinking monomer, one or more functional monomers, an ultraviolet-light initiator, a pigment, a filler and a tackifying resin, wherein the solvent-free ultraviolet-light cured prepolymer comprises 80-90wt% of alkyl acrylate monomer and 10-20wt% of a polymerizable unsaturated monomer with a polar group, the functional crosslinking monomer is prepared from bifunctional or polyfunctional aziridines, and the one or more functional monomers are used for improving the adhering properties. No volatile organic solvent is added in the whole process of preparing the pressure-sensitive adhesive, and the pressure-sensitive adhesive complies with the requirements of laws and regulations on environmental protection. Compared with the pressure-sensitive adhesive prepared by adopting the conventional crosslinking method, the pressure-sensitive adhesive has good high-temperature shearing resistance and adhering properties, can be regulated in properties by regulating the use amount and overcomes the defects that the existing pressure-sensitive adhesive hardens quickly due to the large use amount of the crosslinking agent. The pressure-sensitive adhesive can be prepared into a lining-substrate free integral pressure-sensitive adhesive tape with a thickness of 3mm.

Description

technical field [0001] The invention relates to an acrylate crosslinking agent synthesized by an aziridine compound as an acrylate polymer glue used in an ultraviolet-curable high-temperature-resistant pressure-sensitive adhesive tape and a pressure-sensitive adhesive tape prepared therefrom product. In particular, it relates to a pressure-sensitive glue and a pressure-sensitive adhesive tape product synthesized by using an aziridine compound with two or more unsaturated double bond compounds that can be radically polymerized as a crosslinking agent. Background technique [0002] In recent years, with the advancement of industrial technology and the improvement of labor production efficiency, traditional pressure-sensitive adhesive tape products have failed to meet the requirements in some applications. Such as: higher static shear strength, higher peeling force, high temperature resistance, long-term aging resistance, better adherence to the bonding surface, low organic ga...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J4/06C09J4/00C09J4/02C09J11/00C08F220/18

Inventor 王林青李印柏林新松翟海潮王兵

Owner TONSAN ADHESIVES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com