Preparation method of single-component polyurethane foam joint mixture

A technology of polyurethane foam and caulking agent, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of affecting the construction effect, not easy to master and control, and the increase of material cost and labor cost, so as to save labor cost , Promote rapid curing and setting, and reduce material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Synthetic Composite Catalyst

[0031] In a 200ml three-necked flask equipped with a constant temperature water bath, a thermometer, a dropping funnel, and mechanical stirring, add 65.6 grams of 2-methylhexanoic acid, and start stirring. In the dropping funnel, add 77 grams of 1,8-diazabicyclo-bicyclo(5,4,0)-7-undecene, slowly add it dropwise into the three-necked flask at a controlled temperature of 10°C, and drop it over 30 minutes complete. The temperature was raised to 90° C., and after 2 hours of reaction, the temperature was lowered to room temperature and filtered to obtain a composite catalyst.

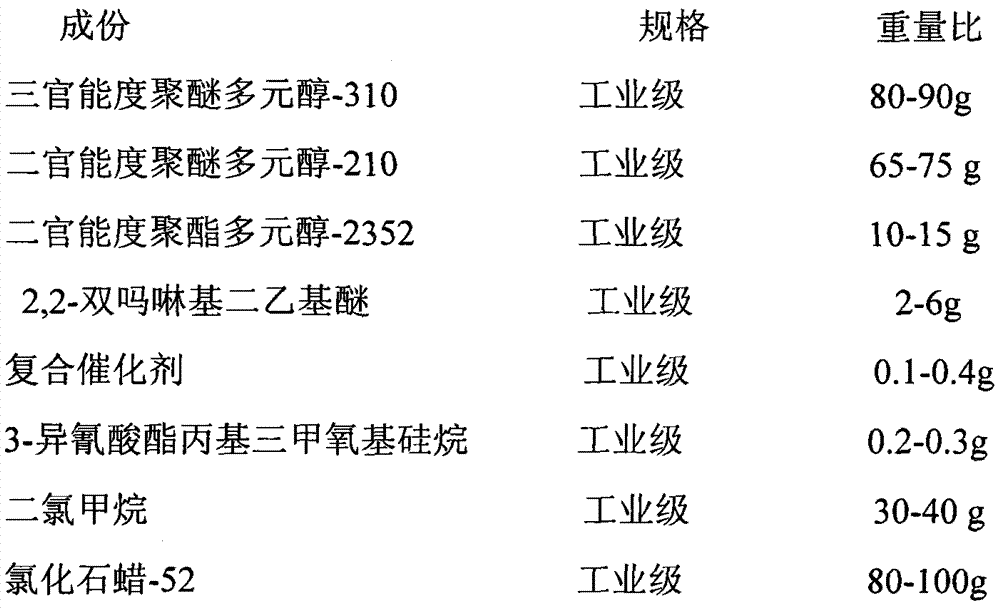

[0032] Preparation of composite polyethers

[0033] formula:

[0034]

[0035] Preparation

[0036] In a 500ml three-neck flask, after adding various raw materials in sequence according to the above formula, stir for 1 hour at room temperature.

[0037] Made of combined polyether.

[0038] Preparation of polyurethane foam sealant

[0039] In a 750mL aerosol can...

Embodiment 2

[0042] Synthetic Composite Catalyst

[0043] In a 200ml three-necked flask equipped with a constant temperature water bath, a thermometer, a dropping funnel, and mechanical stirring, add 65.6 grams of 2-methylhexanoic acid, and start stirring. In the dropping funnel, add 77 grams of 1,8-diazabicyclo-bicyclo(5,4,0)-7-undecene, and slowly drop it into the three-necked flask at a controlled temperature of 14°C for 28 minutes Drip finished. Raise the temperature to 85°C, react for 2 hours, cool down to room temperature, and filter to obtain a composite catalyst.

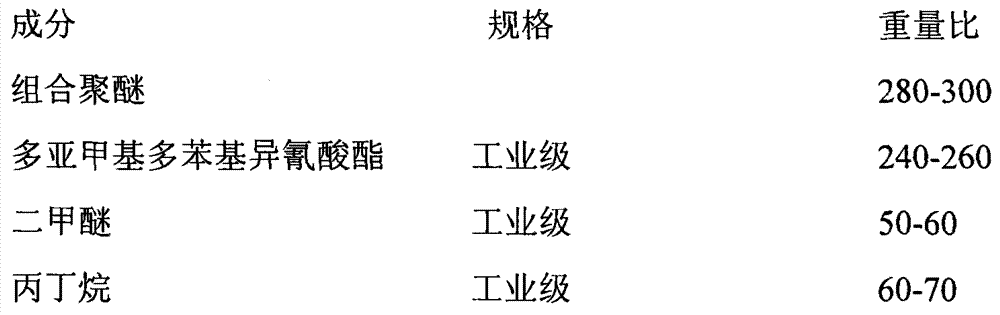

[0044] Preparation of composite polyethers

[0045] formula:

[0046]

[0047] Preparation

[0048] In a 500ml three-neck flask, after adding various raw materials in sequence according to the above formula, stir for 1 hour at room temperature.

[0049] Made of combined polyether.

[0050] Preparation of polyurethane foam sealant

[0051] In a 750mL aerosol can, add 300g of combined polyether and 240g of polyme...

Embodiment 3

[0054] Synthetic Composite Catalyst

[0055] In a 200ml three-necked flask equipped with a constant temperature water bath, a thermometer, a dropping funnel, and mechanical stirring, add 65.6 grams of 2-methylhexanoic acid, and start stirring. In the dropping funnel, add 77 grams of 1,8-diazabicyclo-bicyclo(5,4,0)-7-undecene, and slowly drop it into the three-necked flask at a controlled temperature of 12°C for 33 minutes Drip finished. The temperature was raised to 93° C., and after 2.5 hours of reaction, the temperature was lowered to room temperature and filtered to obtain a composite catalyst.

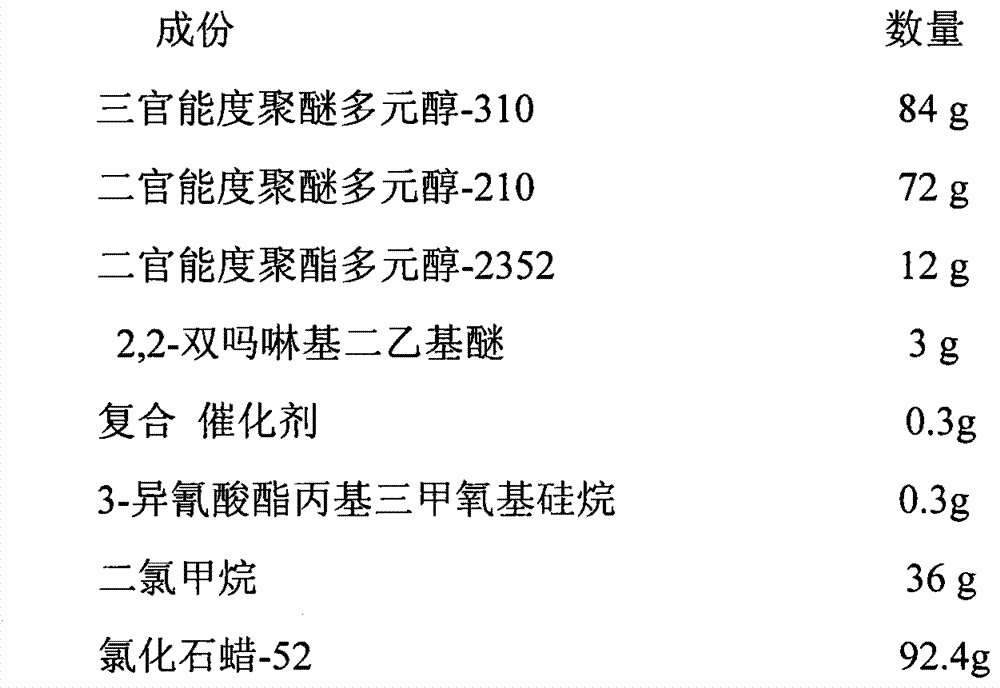

[0056] Preparation of composite polyethers

[0057] formula:

[0058]

[0059] In a 500ml three-neck flask, after adding various raw materials in sequence according to the above formula, stir for 1 hour at room temperature.

[0060] Made of combined polyether.

[0061] Preparation of polyurethane foam sealant

[0062] In a 750mL aerosol can, add 300g of combined polyether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com