Modified epoxy adhesive for stone combination and preparation method thereof

An epoxy adhesive and composite modification technology, which is applied in the direction of adhesive, epoxy glue, adhesive type, etc., can solve the problems of high energy consumption, low production efficiency, large production site, etc., and achieve good activity and adaptability Strong, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. The reactor is equipped with a stirring, regulating and condensing device. The condensing device is equipped with 100 parts by mass of calcium oxide water-absorbing agent in the lower part; 80 parts by mass of butanone, 100 parts by mass of diethylenetriamine, and strong acidic cation exchange resin SO 4 2 / TiO2 0.4 mass part, V85-P antioxidant 0.3 mass part, start stirring, raise the temperature to 60°C, then raise the temperature to 74°C within 30 minutes, keep the temperature at 74°C for 60 minutes, and then raise the temperature to 10°C in 15 minutes The speed was raised to 105° C., the temperature was kept for 30 minutes, and the temperature was lowered to 30° C., and the product was filtered through a 200-mesh sieve to obtain the light yellow liquid ketimine of the present invention.

[0026] 2. Add 100 parts by mass of nonylphenol glycidyl ether into a reactor with a stirring, tempering and reflux device, start stirring, and then add 25 parts by mass of diethy...

Embodiment 2

[0032]When preparing ketimine, butanone is 75 parts by mass, and the rest are the same as in Example 1; when preparing modified aliphatic amines, diethylenetriamine is 55 parts by mass, and the rest are the same as in Example 1; when preparing component A of the present invention When, epoxy resin E51 is 15 mass parts, F-51 4 mass parts, barite powder 34 mass parts, other conditions are the same as embodiment 1; When preparing the second component of the present invention, modified fatty amine is 13 mass parts, and first Cyclopentanediamine is 8 parts by mass, and the curing accelerator is changed into N, N-dimethyldipropylenetriamine 1.0 parts by mass, and other conditions are the same as in Example 1.

[0033] Weigh 10 parts by mass of component A and 3.3 parts by mass of component B, and mix them uniformly to obtain the stone composite modified epoxy adhesive of the present invention.

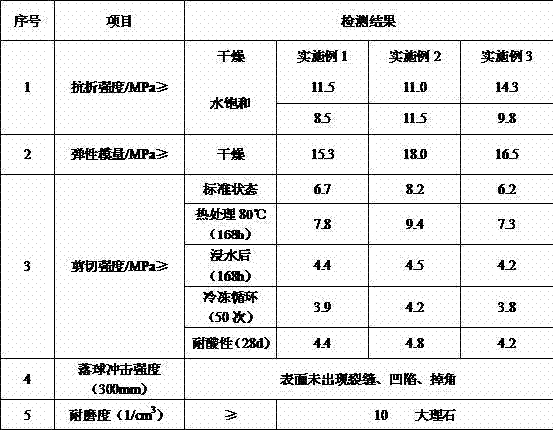

[0034] Product World JC / T "Ultra-thin Natural Stone Composite Board" test physical per...

Embodiment 3

[0037] When preparing ketimine, butanone is 88 parts by mass, and the remaining conditions are the same as in Example 1; when preparing modified fatty amines, diethylenetriamine is 42 parts by mass, and the remaining conditions are the same as in Example 1; to prepare Group A of the present invention 2 parts, bisphenol F epoxy resin F-51 is 3 parts by mass; Butyl glycidyl ether is 7 parts by mass, and wetting agent is 0.1 parts by mass of CA-165, and other conditions are with embodiment 1.

[0038] When preparing component B of the present invention, 18 parts by mass of modified aliphatic amine, 2 parts by mass of ketimine, and 5 parts by mass of methylcyclopentadiamine, and other conditions are the same as in Example 1.

[0039] Weigh 10 parts by mass of component A and 4.2 parts by mass of component B, and mix them uniformly to prepare the stone composite modified epoxy adhesive of the present invention. According to JC / T 1049-2007 "Ultra-thin Natural Stone Composite Board",...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com