Acid-wash additive for iron and steel

A pickling additive and steel pickling technology, applied in the field of steel pickling additives, can solve problems such as over-corrosion, human irritation, and easily corroded equipment, and achieve the effects of preventing over-corrosion, inhibiting acid mist, and improving rust removal speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with specific embodiments.

[0013] 1. Preparation of "FSD-7001" pickling additive

[0014] 4000 grams of "FSD-7001" pickling additive ratio:

[0015] Accelerator: oxalic acid or citric acid, 200-250g; phosphoric acid, 900-1000g;

[0016] Anionic surfactant: sodium lauryl sulfate, 200-250g;

[0017] Corrosion inhibitor: urotropine, 150-200g;

[0018] Fog suppressant: nonylphenol polyoxyethylene ether, 150-200g;

[0019] water, balance.

[0020] Preparation steps: firstly mix phosphoric acid, anionic surfactant and water and stir evenly, then add the remaining components and stir to dissolve.

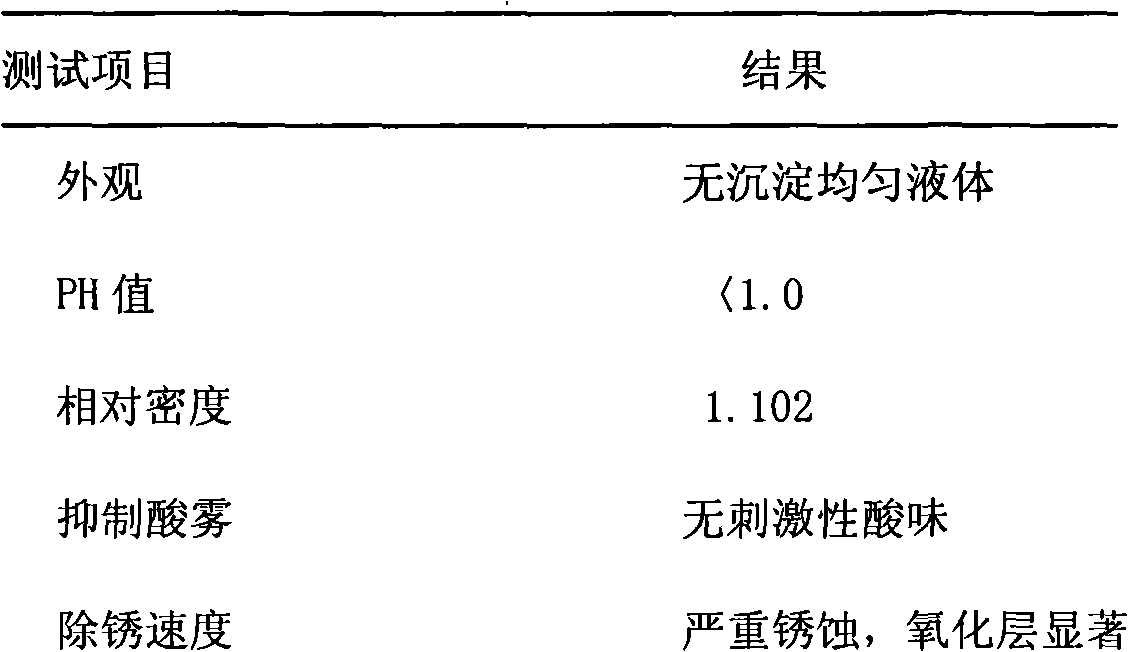

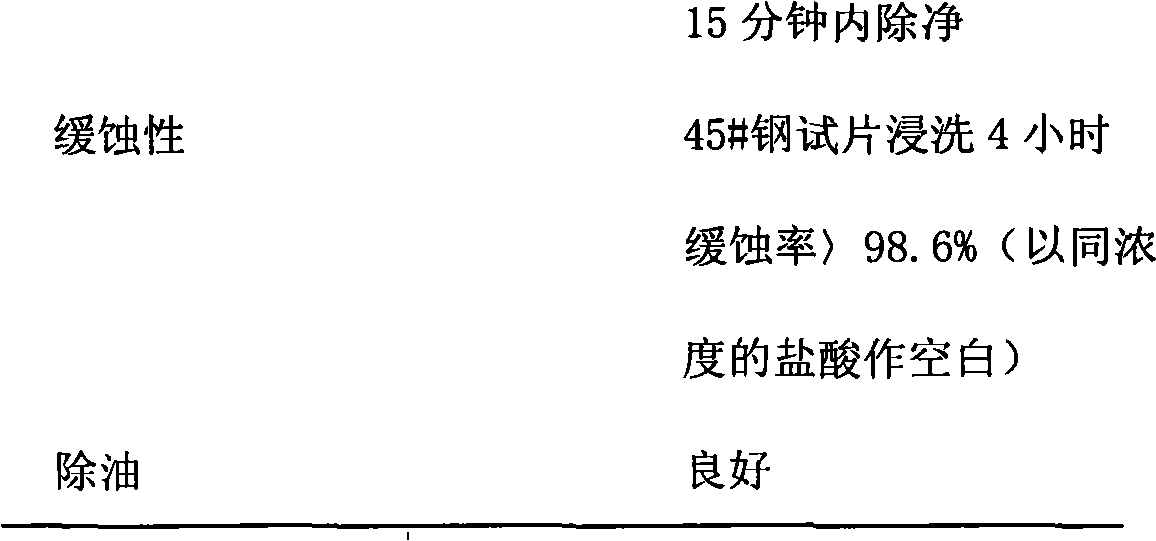

[0021] 2. Performance indicators

[0022] According to "FSD-7001" pickling additive : hydrochloric acid: water=1: 5: 4 (preparation according to volume ratio, hydrochloric acid selects industrial grade for use) prepare pickling solution, its performance has been assessed in the laboratory, and the result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com