Silica sol-organosilicone monomer capillary crystalline waterproof material and preparation method thereof

A technology for infiltrating crystalline and waterproof materials, applied in the field of construction engineering materials and their preparation, can solve the problems of reduced waterproof effect, poor adhesion of substrates, low penetration depth, etc., and achieve the effects of improving surface strength, low cost, and reducing volatilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

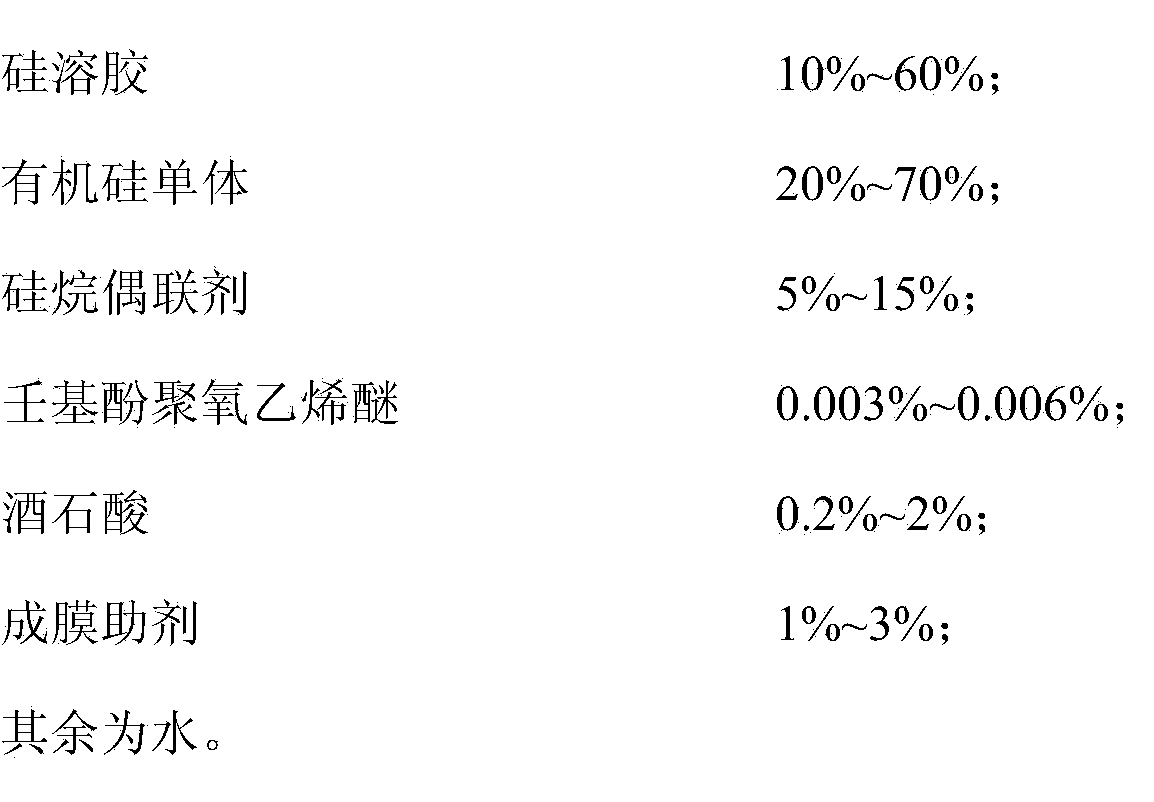

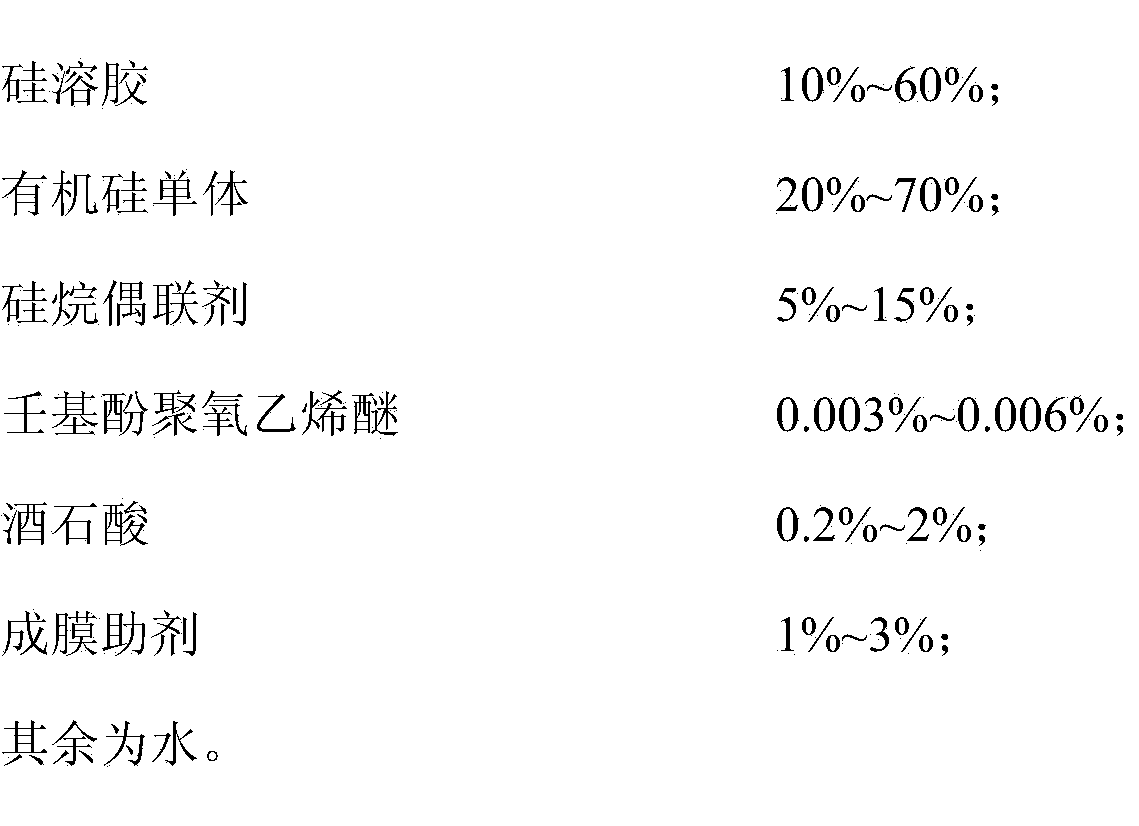

[0018] In this example, 1 kg of silica sol-organosilicon monomer permeated crystalline waterproof material was prepared. The raw materials used and the preparation process are as follows:

[0019] Mix 100g of silica sol and 50g of γ-aminopropyltriethoxysilane, and add 700g of n-butyltriethoxysilane, 0.05g of nonylphenol polyoxygen, 5g of tartaric acid, and 10g of polyoxysilane in sequence under stirring at 500r / min. Vinyl alcohol, then adjust the pH value to 4.0 with phosphoric acid, react at 50°C for 5 hours, and finally add water to make up to 1kg.

[0020] In this example, the prepared silica sol-organosilicon monomer infiltration crystalline waterproof material is painted on the surface of dry mortar test block and concrete at room temperature, and the amount of coating film is 0.4kg / m 2 , The water absorption rate of the mortar is reduced by 72.5%, the penetration depth of the waterproof material on the concrete surface reaches 5.6mm, the waterproof performance of the con...

Embodiment 2

[0022] In this example, 1 kg of silica sol-organosilicon monomer permeated crystalline waterproof material was prepared. The raw materials used and the preparation process are as follows:

[0023] Mix 200g of silica sol and 80g of γ-aminopropyltriethoxysilane, and add 600g of n-butyltriethoxysilane, 0.05g of nonylphenol polyoxygen, 5g of tartaric acid, 10g of poly Vinyl alcohol, then adjust the pH value to 4.5 with phosphoric acid, react at 50°C for 6 hours, and finally add water to make up to 1kg.

[0024] In this example, the prepared silica sol-organosilicon monomer infiltration crystalline waterproof material is painted on the surface of dry mortar test block and concrete at room temperature, and the amount of coating film is 0.4kg / m 2 , The water absorption rate of the mortar is reduced by 64.9%, the penetration depth of the waterproof material on the concrete surface reaches 5.1mm, the waterproof performance of the concrete is improved, the capillary water absorption coe...

Embodiment 3

[0026] In this example, 1 kg of silica sol-organosilicon monomer permeated crystalline waterproof material was prepared. The raw materials used and the preparation process are as follows:

[0027] Mix 300g of silica sol and 100g of γ-aminopropyltriethoxysilane, and add 500g of n-butyltriethoxysilane, 0.04g of nonylphenol polyoxygen, 10g of tartaric acid, 20g of Vinyl alcohol, then adjust the pH value to 4.5 with phosphoric acid, react at 50°C for 6 hours, and finally add water to make up to 1kg.

[0028] In this example, the prepared silica sol-organosilicon monomer infiltration crystalline waterproof material is painted on the surface of dry mortar test block and concrete at room temperature, and the amount of coating film is 0.4kg / m 2 , The water absorption rate of the mortar is reduced by 68.2%, the penetration depth of the waterproof material on the concrete surface reaches 3.7mm, the waterproof performance of the concrete is improved, the capillary water absorption coeffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com