Weak-gel synthetic drilling fluid and preparation method thereof

A technology for synthesizing base and drilling fluid, applied in the field of drilling fluid, can solve the problems of low shear rate, low viscosity, difficulty in tripping, and poor ability to carry drill cuttings, etc., and achieves the effects of good thixotropy and high drilling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

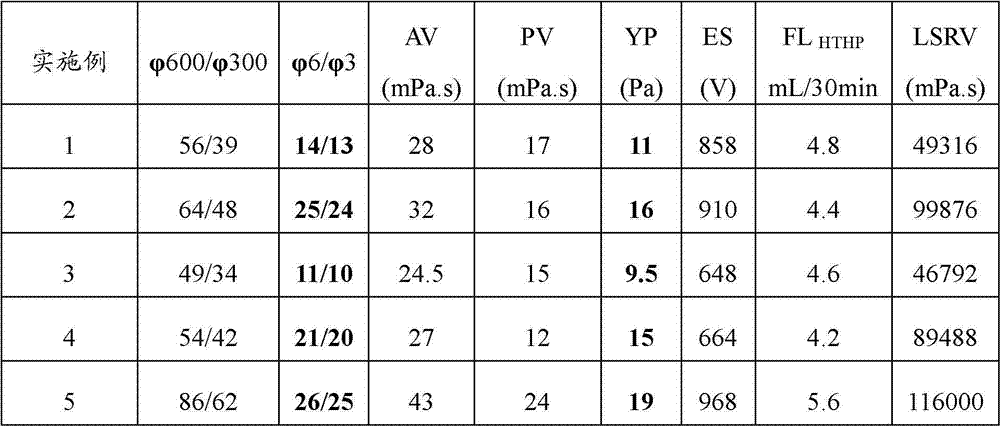

Examples

preparation example Construction

[0035] Drilling Fluid Preparation

[0036] The organoclay used in the examples is PF-MOGEL, provided by COSL; the main emulsifier is PF-MOEMUL-P, provided by COSL; the secondary emulsifier PF-MOCOAT is provided by COSL; the wetting agent is PF-MOWET, Provided by COSL; fluid loss control agent is PF-MOHFL, provided by COSL.

Embodiment 1

[0038] a. Formulation:

[0039] Gas oil: 70 parts;

[0040] Mass fraction is 30% calcium chloride aqueous solution: 30 parts; And

[0041] Based on the total parts by volume (100 parts) of gas-to-oil and aqueous calcium chloride solution, it is each component of the following mass volume ratios:

[0042] PF-MOGEL: 2.5%;

[0043] PF-MOEMUL-P: 1.0%;

[0044] PF-MOCOAT: 1.5%;

[0046] PF-MOWET: 0.8%;

[0047] PF-MOHFL: 2.5%;

[0048] Weighting Agent: Barite 32.5%.

[0049] b. Preparation process: Add the PF-MOGEL of the mass volume ratio to the gas-to-oil in the volume fraction and stir at a medium speed for 8 minutes, add PF-MOEMUL-P and PF-MOCOAT at the mass volume ratio and stir at a high speed for 2 minutes ; Add the calcium chloride aqueous solution whose mass fraction of the volume fraction is 30% under the condition of high-speed stirring, and stir at a high speed for 20 min; add the calcium oxide of the mass-volume ratio and stir for ...

Embodiment 2

[0051] a. Formulation:

[0052] Gas oil: 70 parts;

[0053] Mass fraction is 30% calcium chloride aqueous solution: 30 parts; And

[0054] Based on the total parts by volume (100 parts) of gas-to-oil and aqueous calcium chloride solution, it is each component of the following mass volume ratios:

[0055] PF-MOGEL: 2.5%;

[0056] PF-MOEMUL-P: 1.0%;

[0057] PF-MOCOAT: 1.5%;

[0059] PF-MOWET: 0.8%;

[0060] PF-MOHFL: 2.5%;

[0061] PF-MOVIS: 0.3% (a high molecular polymer with a nonlinear network structure formed by polycondensation reaction of adipic acid and triethylenetetramine under the protection of nitrogen, with a molecular weight of 87000, provided by Guangdong Kaiping United Technology Chemical Co., Ltd. );

[0062] Weighting Agent: Barite 32.5%.

[0063] b. Preparation process: Add the PF-MOGEL of the mass volume ratio to the gas-to-oil in the volume fraction and stir at a medium speed for 8 minutes, add PF-MOEMUL-P and PF-MOCOAT...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com