Earth loop heat exchange methods and systems

arth loop technology, applied in the field of earth loop heat exchange systems, can solve the problems of over-excavation or "mining out" of the borehole, the initial cost of such a heat exchange system, and the hydrostatic pressure exerted by the mud is not sufficient to offset the existing pressure, so as to reduce the number of personnel, increase drilling speed, and connect drill rods quickly and safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

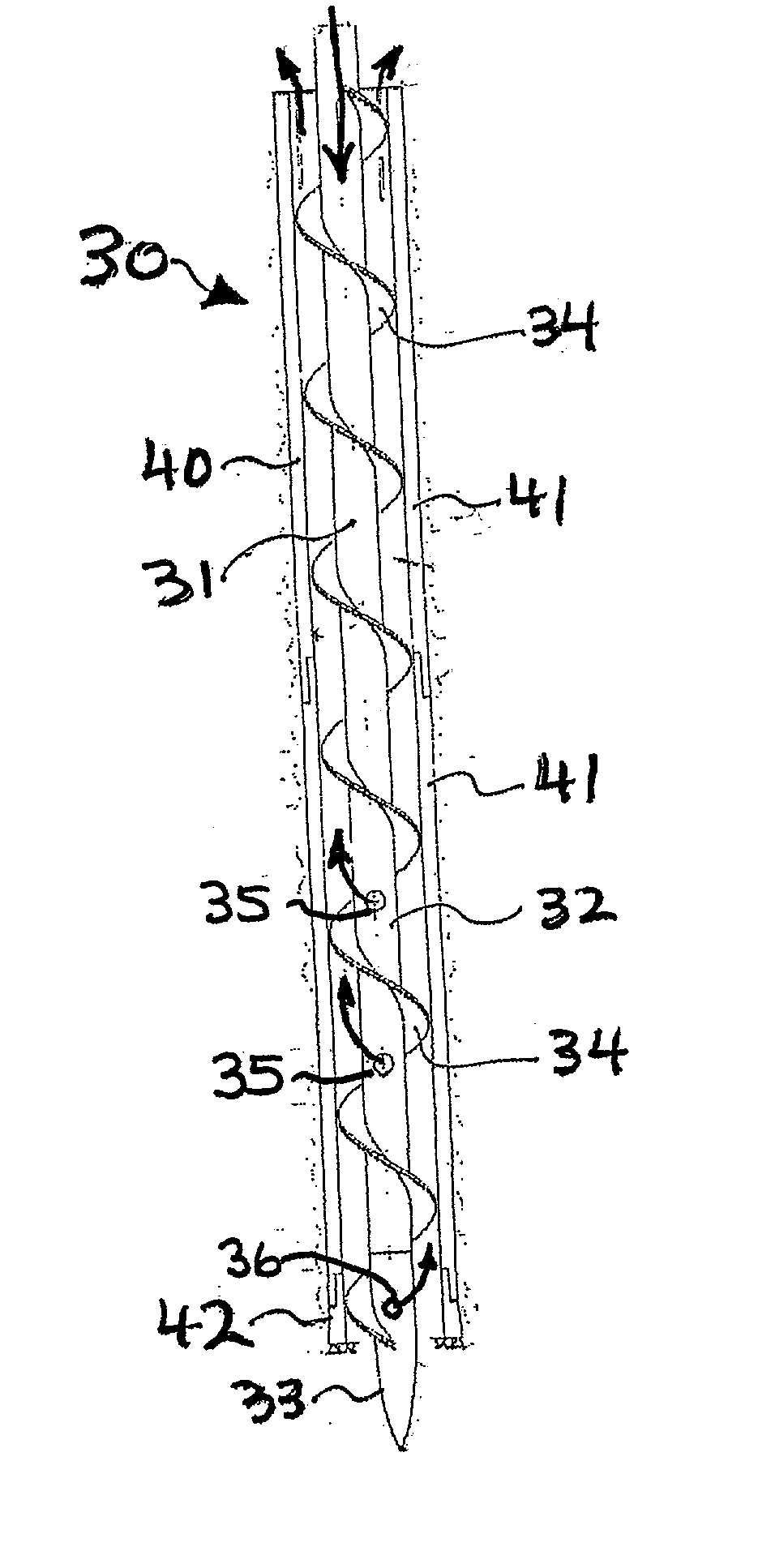

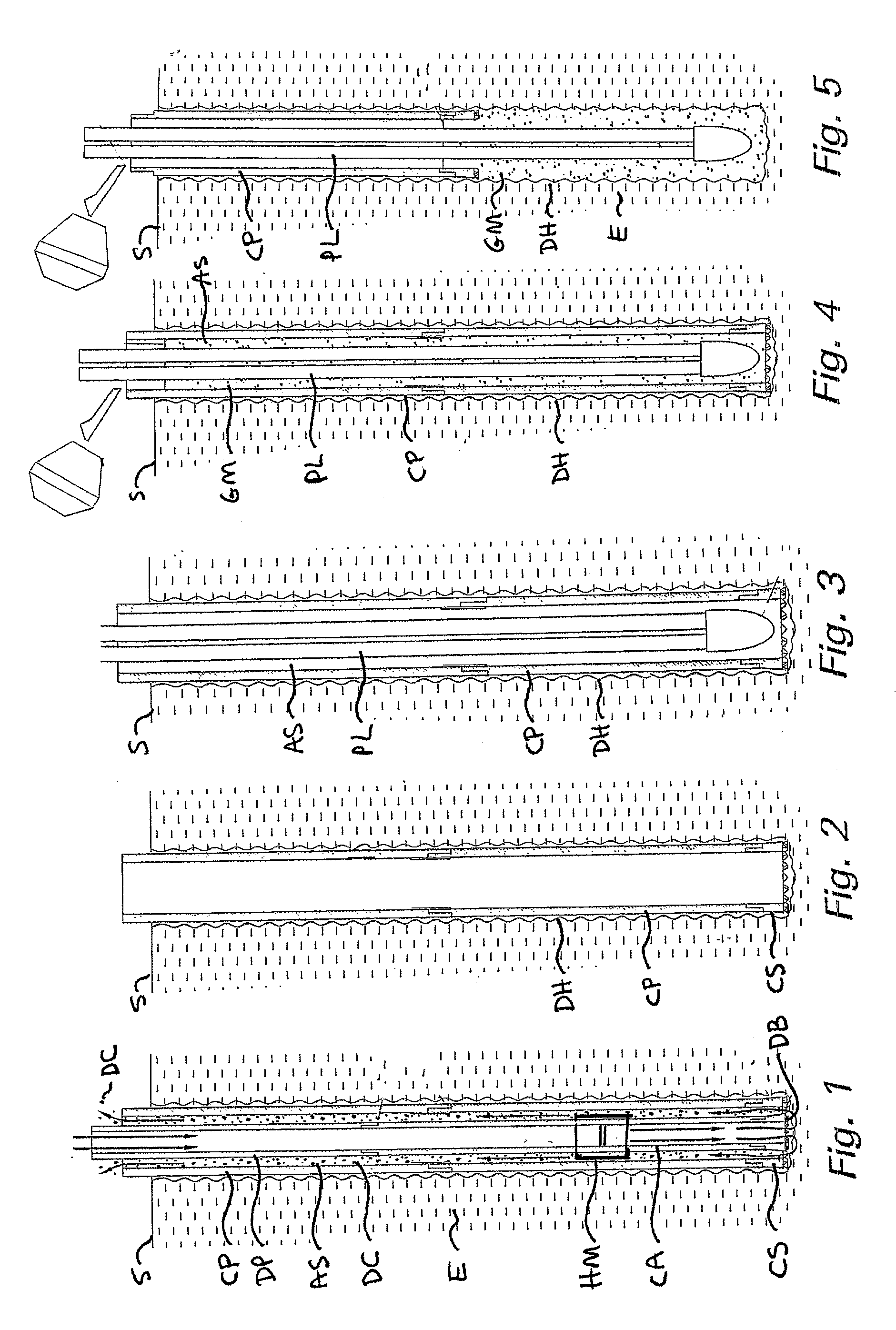

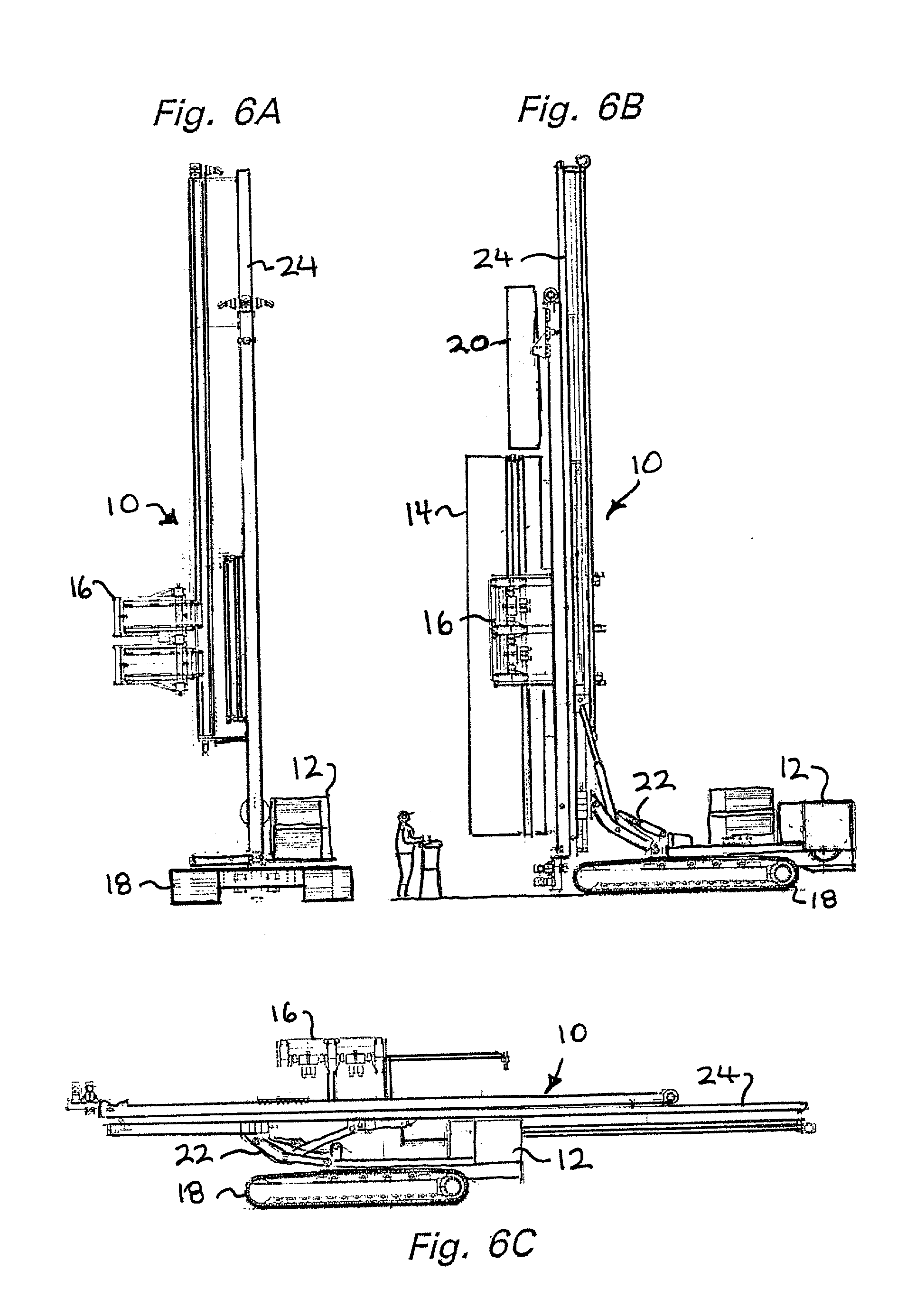

[0032] Five stages of a method according to the present invention, are illustrated in FIGS. 1-5.

[0033] In one dual pipe drilling method according to the present invention, a casing pipe CP is fitted with an open casing shoe as shown in FIG. 1. As the casing pipe CP is rotated and hammered, a plurality of cutters CT around the circumference of the drilling shoe DS remove material slightly thicker than the wall thickness of the following casing, allowing the casing to be advanced into the earth. Simultaneously, an inner drill pipe DP has a cutting bit member DB threadedly attached to the end of the drill pipe so that, when the inner drill pipe is rotated, remaining material inside of the casing pipe CP is removed, allowing the drill pipe DP and the casing pipe CP to be advanced through the earth E at the same rate. Compressed air CA is pumped down hole through the hollow drill pipe DP and out of the end of the drill bit DB, drill cuttings DC removed by the rotary (and hammering) actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com