Austenitic heat resistant alloy

A heat-resistant alloy and austenitic technology, applied in lighting and heating equipment, components of steam boilers, steam boiler accessories, etc., can solve problems such as poor bonding and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

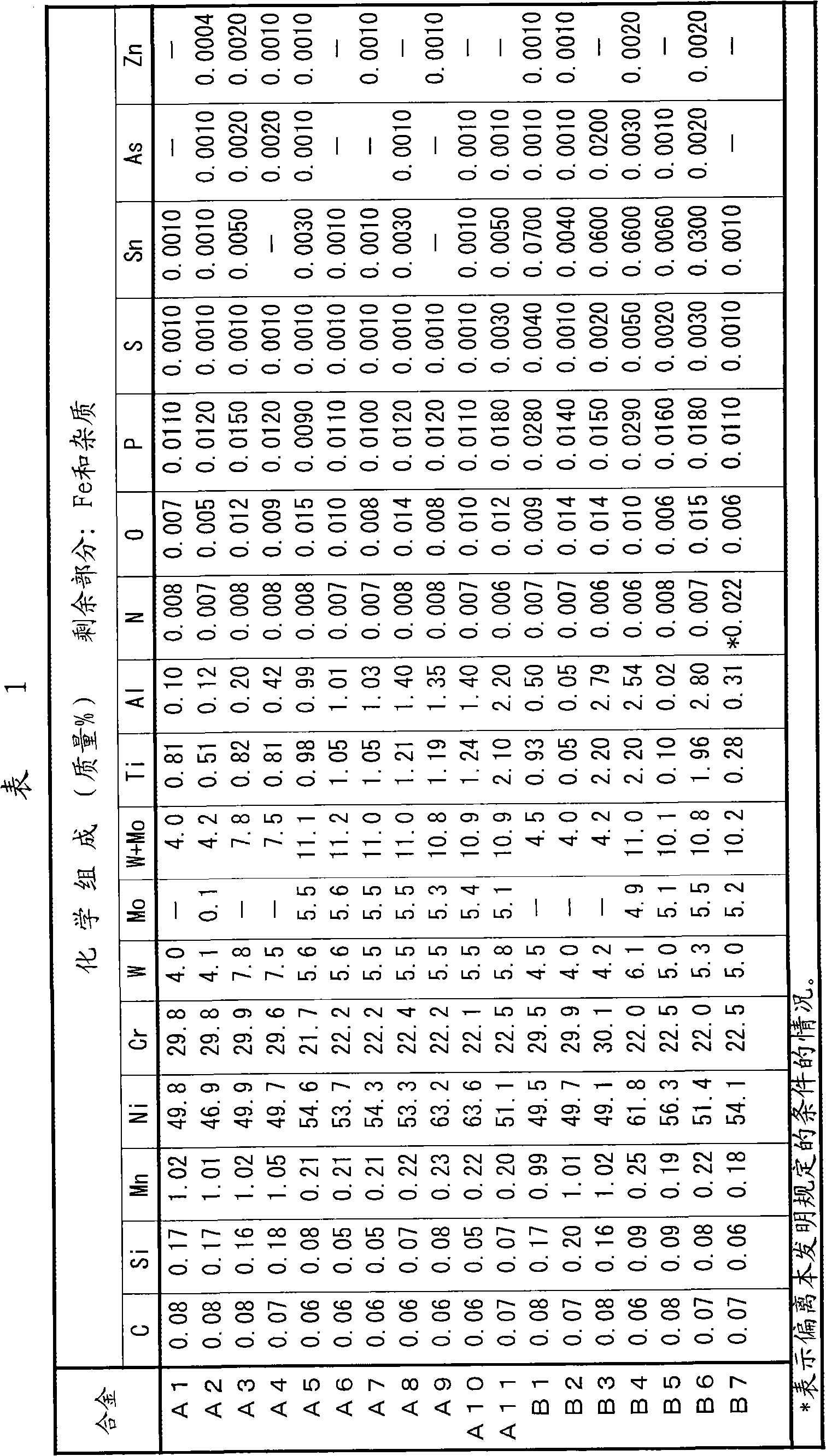

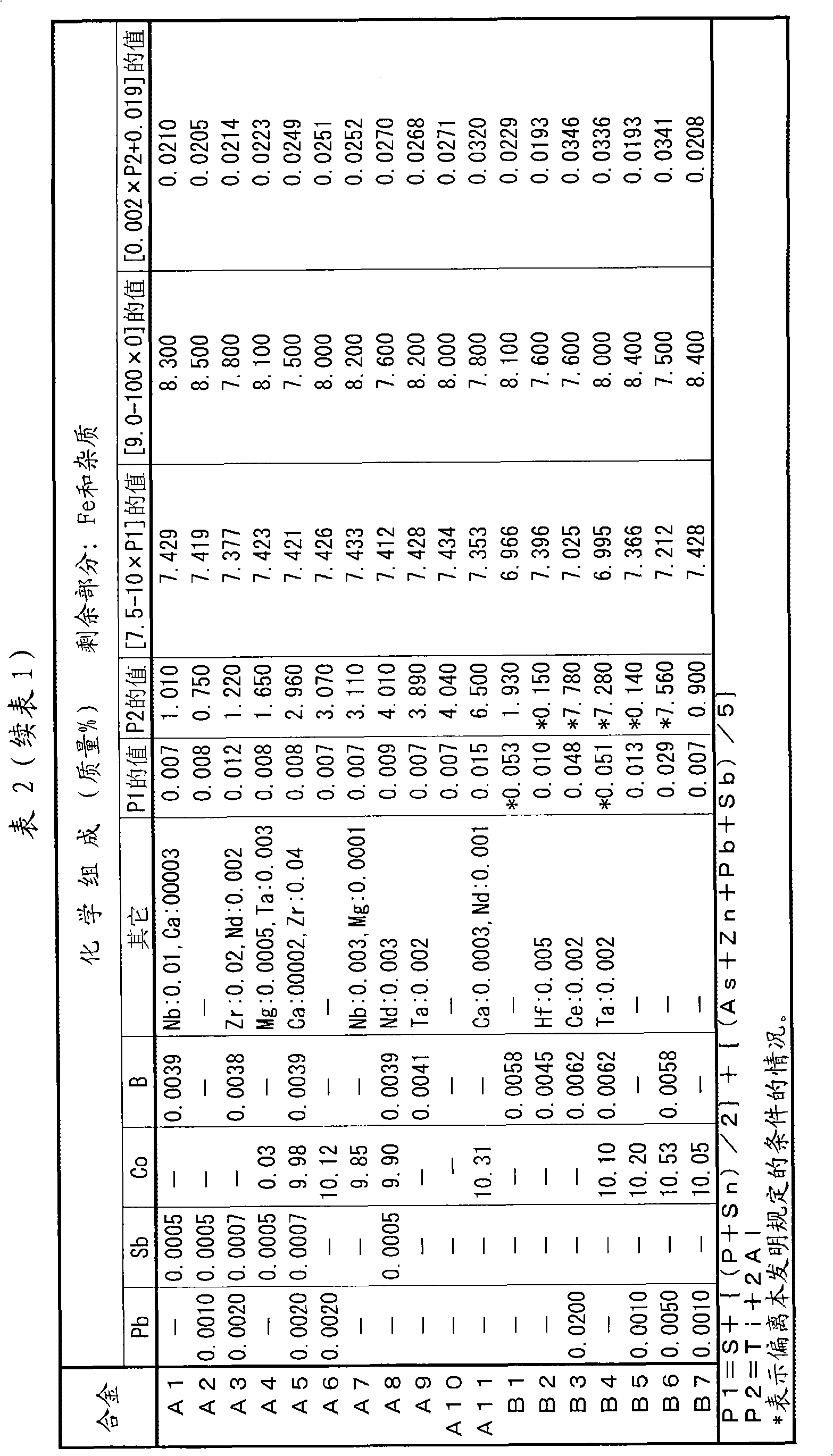

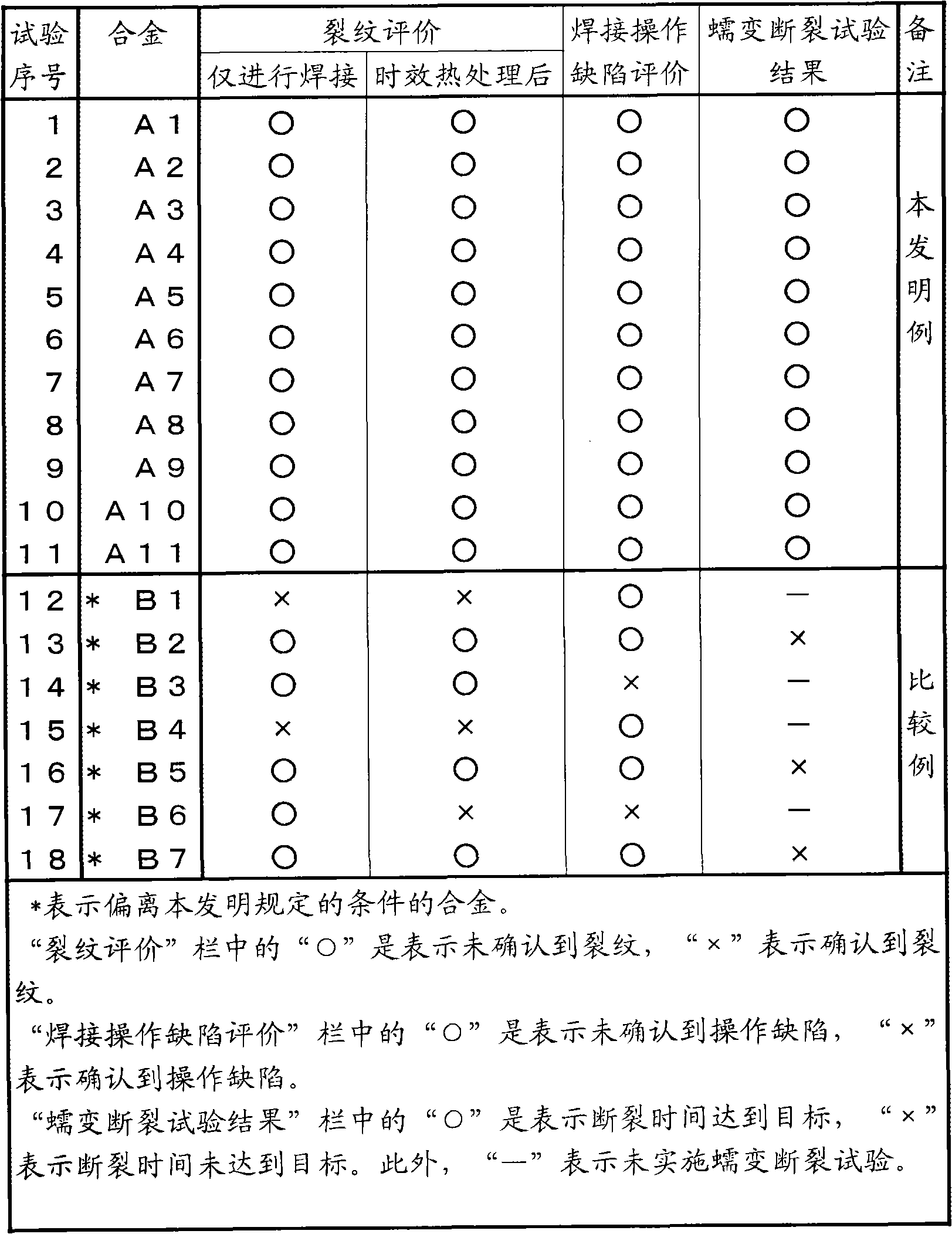

[0154] Austenitic alloys A1 to A11 and B1 to B7 having the chemical compositions shown in Table 1 and Table 2 were melted in a vacuum melting furnace to obtain 50 kg of ingots.

[0155] Alloys A1 to A11 in Table 1 and Table 2 are alloys whose chemical compositions are within the range specified by the present invention. On the other hand, alloys B1 to B7 are alloys whose chemical compositions deviate from the conditions specified in the present invention.

[0156] Table 1

[0157]

[0158] Table 2

[0159]

[0160] The ingot obtained above was manufactured into a plate material having a plate thickness of 20 mm, a width of 50 mm, and a length of 100 mm by hot forging, hot rolling, heat treatment, and machining. In addition, the same ingot was fabricated into a fully homogeneous welding material with an outer diameter of 2.4 mm by hot forging and hot rolling.

[0161] After processing a V-shaped groove with a bottom (root) depth of 1 mm and an angle of 30° along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com