New preparation method of intermediate alloy for bonding gold wire

An intermediate alloy and bonding wire technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of easy oxidation of micro-alloying elements, fast alloying speed, good dispersibility, etc. Good controllability and improved machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

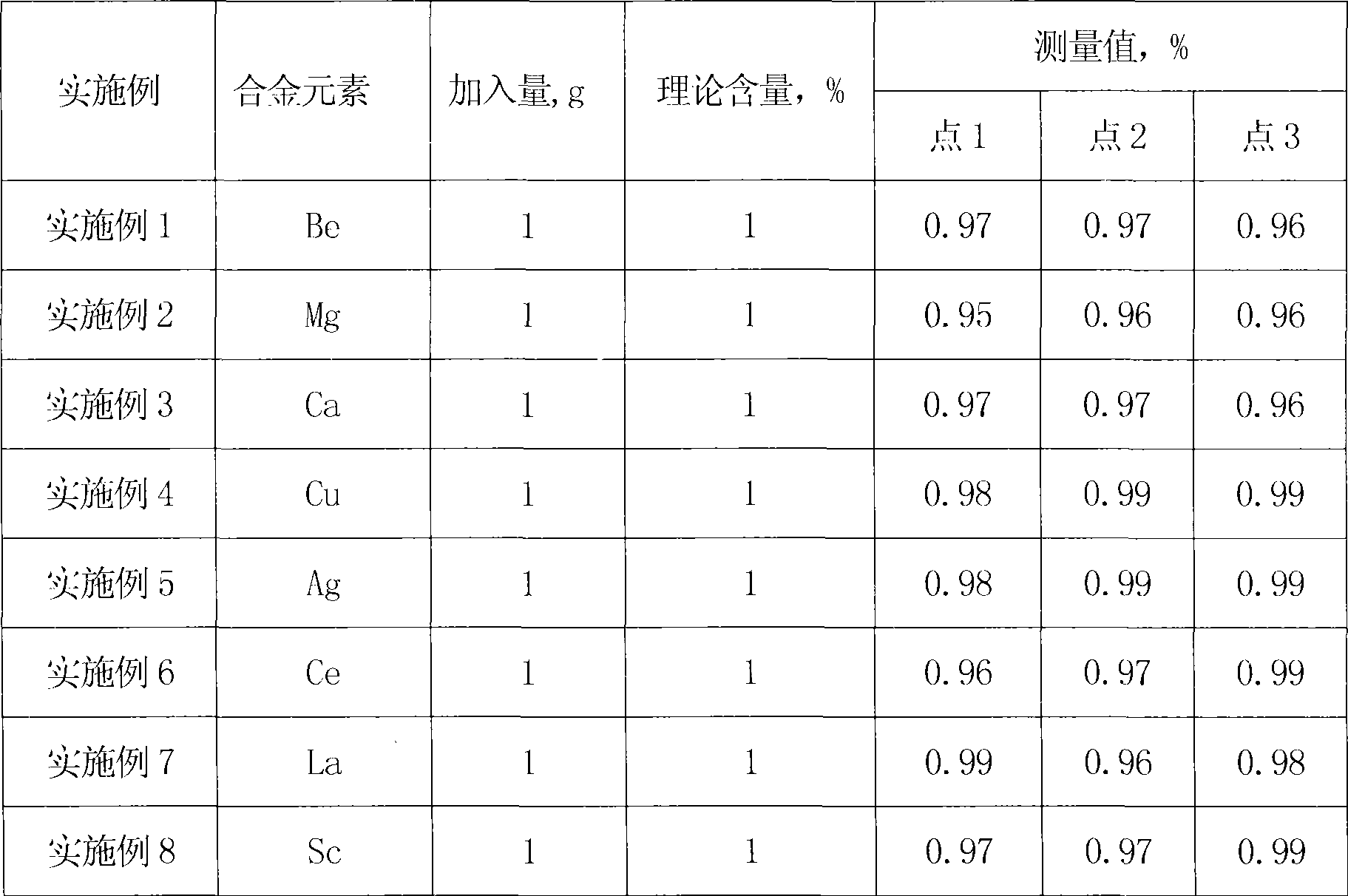

Examples

Embodiment Construction

[0010] 1. Process

[0011] (1) Material preparation: high-purity gold (≥99.999%) is cast into a billet under vacuum conditions using a high-purity crucible and a mold, and the billet is rolled into a thin strip, heated and boiled with 5% dilute hydrochloric acid for 15 minutes for later use.

[0012] (2) Ingredients: Weigh 99g high-purity gold strip and 1gCa, or 1gBe, or 1gCe, or 1gGa and other microalloying elements (microalloying element purity ≥ 99.95%) for batching. During the process, attention should be paid to pollution and microalloying elements oxidation problem.

[0013] (3) Preparation: Tightly wrap the micro-alloy elements with rolled high-purity gold strips, align them with the quenching tower and the leakage gate, and place them in a vacuum induction melting furnace. Pre-evacuate to 1×10 1 Pa, and filled with inert gas Ar to clean repeatedly, and then evacuated to 1×10 -3 Pa, then filled with argon, and immediately heated up for melting. When the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com