Method for manufacturing zinc-coating-steel grounding electrode continuously

A manufacturing method and grounding electrode technology, which are applied in the direction of connecting contact materials, coatings, metal material coating processes, etc., can solve the problems of short life, poor performance of zinc-clad steel grounding electrodes, and low production efficiency, and achieve contact resistance. The effect of low, easy core layer thickness and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

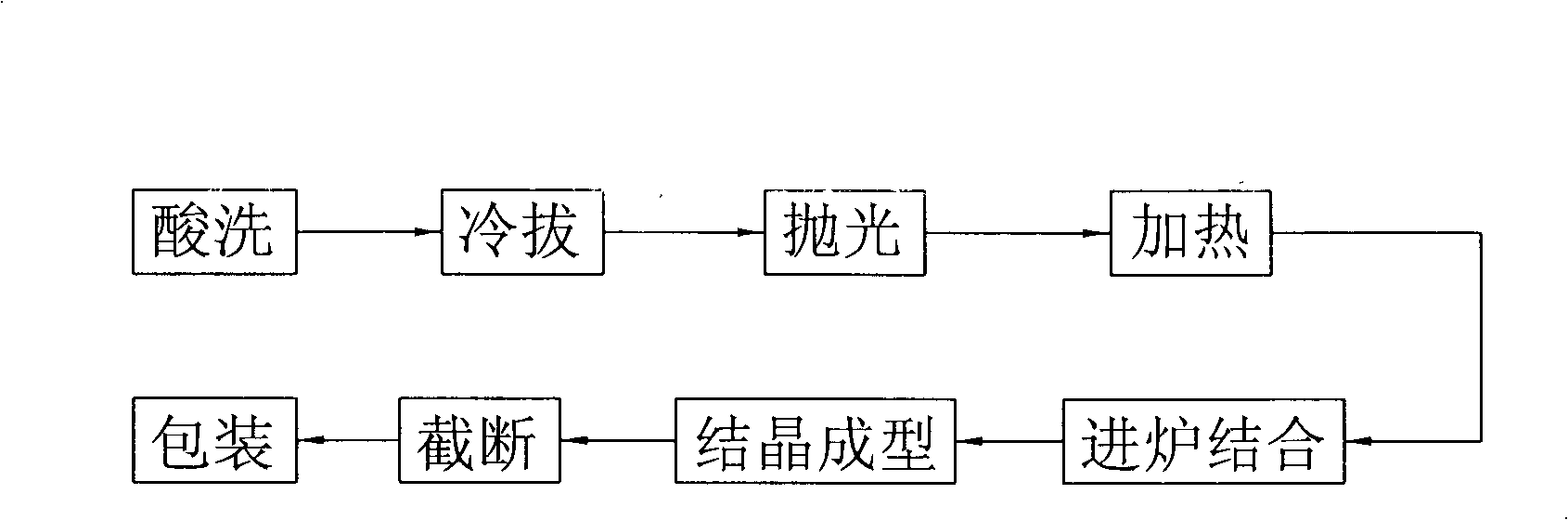

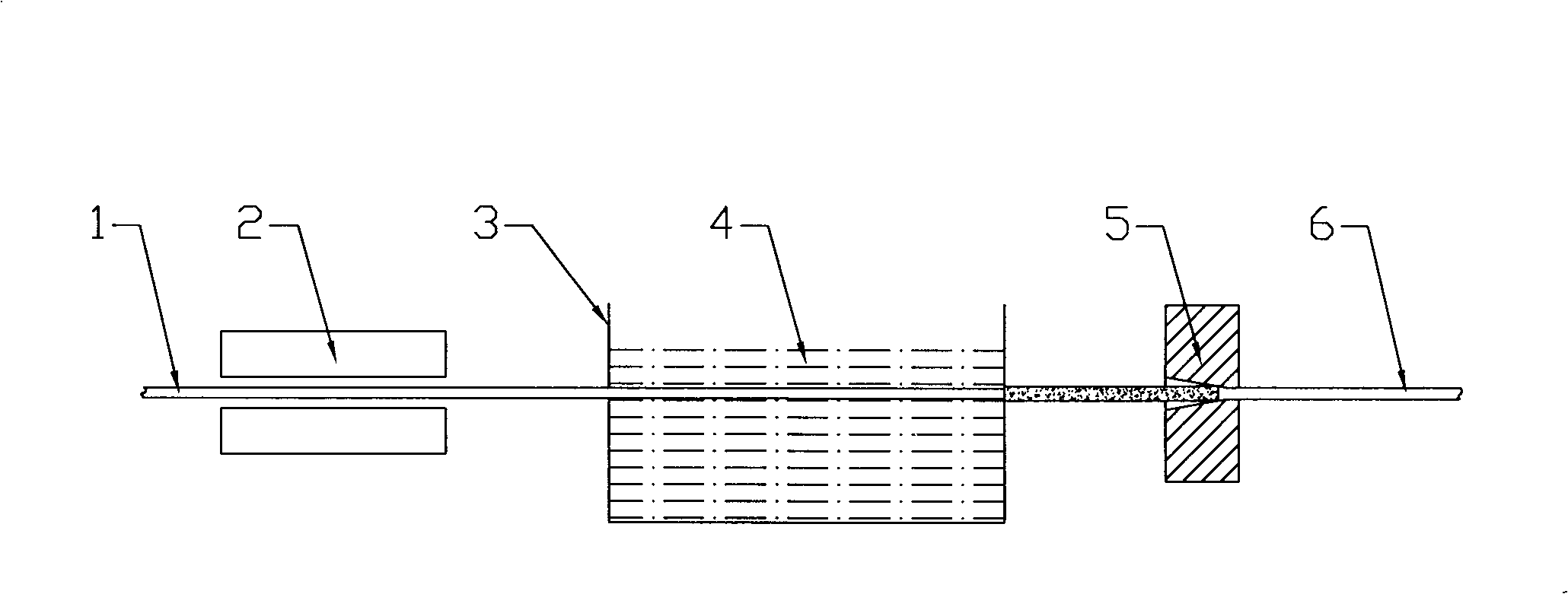

[0014] refer to figure 1 , the zinc-clad steel ground electrode continuous manufacturing method is to carry out the following processes in turn on the round steel: pickling→cold drawing→polishing→heating→into the furnace combination→crystallization forming→cutting→packaging, wherein: pickling is used to clean the round steel The surface can be well combined with zinc to ensure the bonding strength of zinc and steel, reduce contact resistance and prevent steel corrosion; cold drawing is used to make round steel into required specifications, and can avoid round steel being oxidized during processing; polishing is used for Decontamination and cleaning surface again; heating is carried out with heater 2, one is to make the temperature of round steel 1 close to the temperature of molten zinc, avoiding that round steel 1 stays in the molten zinc 4 of melting furnace 3 for too long, which affects production efficiency , the second is to prevent the round steel from being oxidized due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com