Method for producing copper sheet grating of lead acid battery, and dedicated die

A technology for lead-acid batteries and production methods, which is applied in the direction of lead-acid battery electrodes, electrode carriers/collectors, etc., which can solve the problems of thin lead-coated layers, high production costs, and poor compactness, and achieve uniform thickness and good compactness , the effect of high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

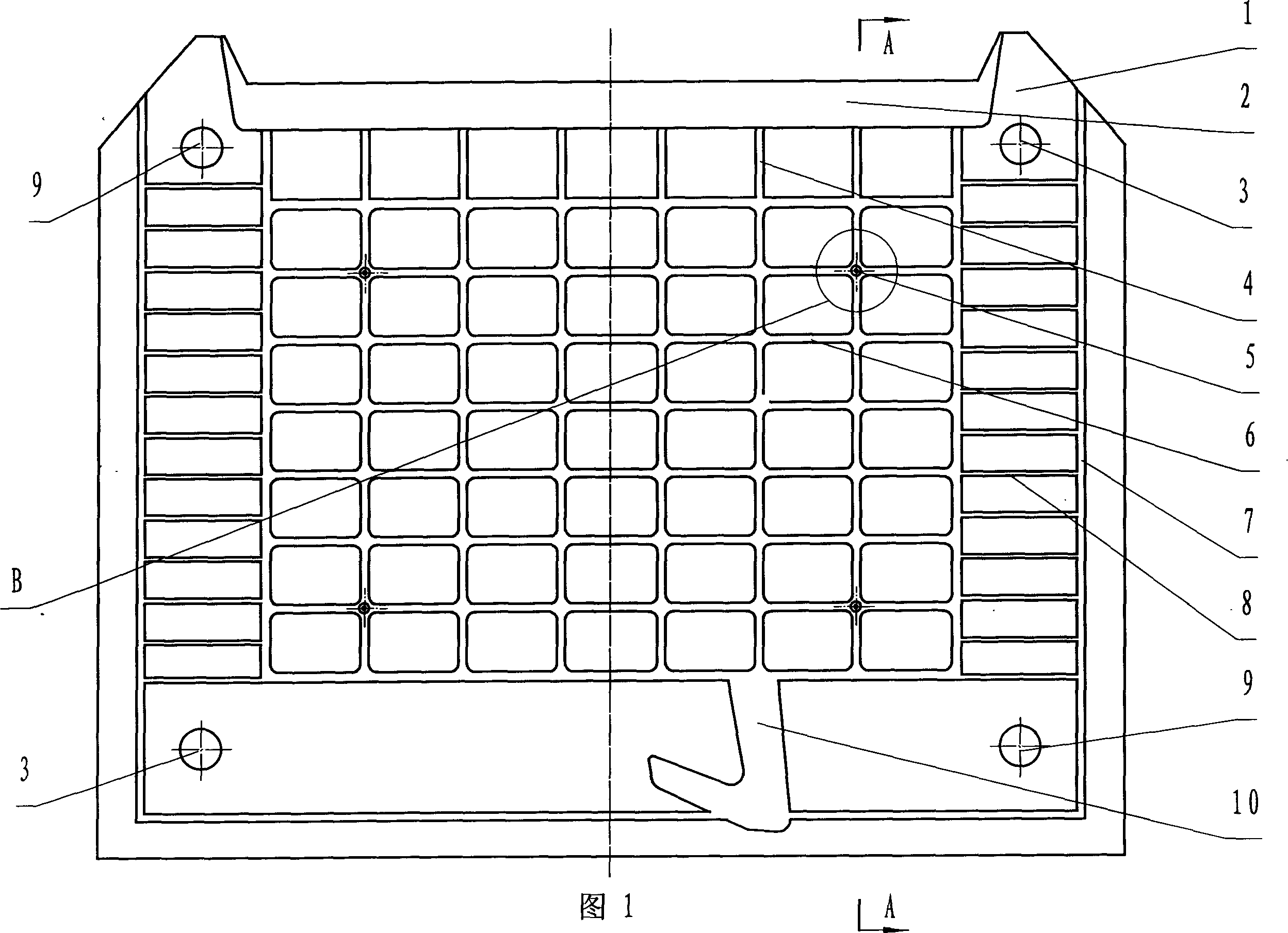

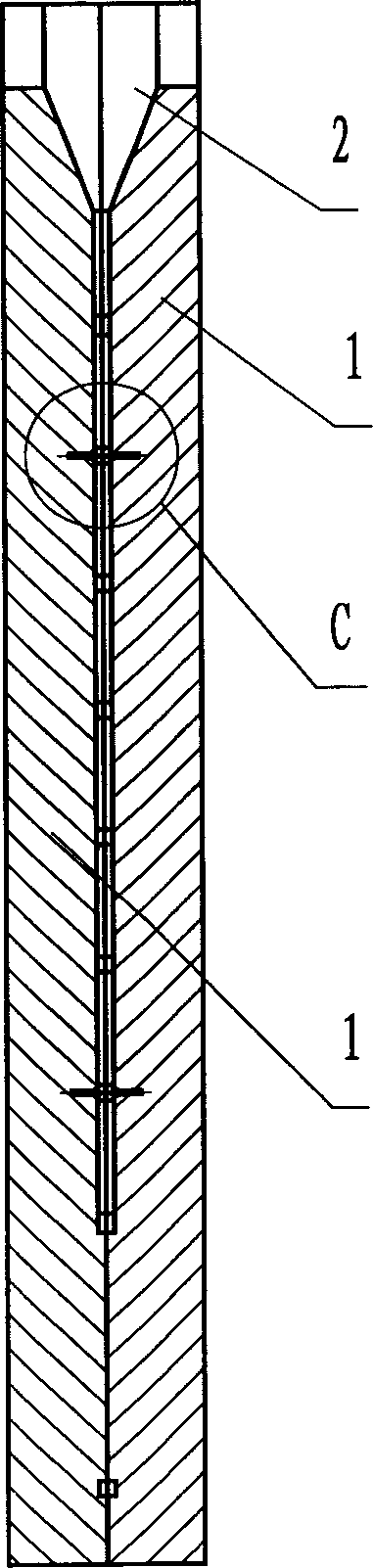

[0023] The invention adopts a casting method to produce the copper grid of a lead-acid battery, and the specific production method is as follows:

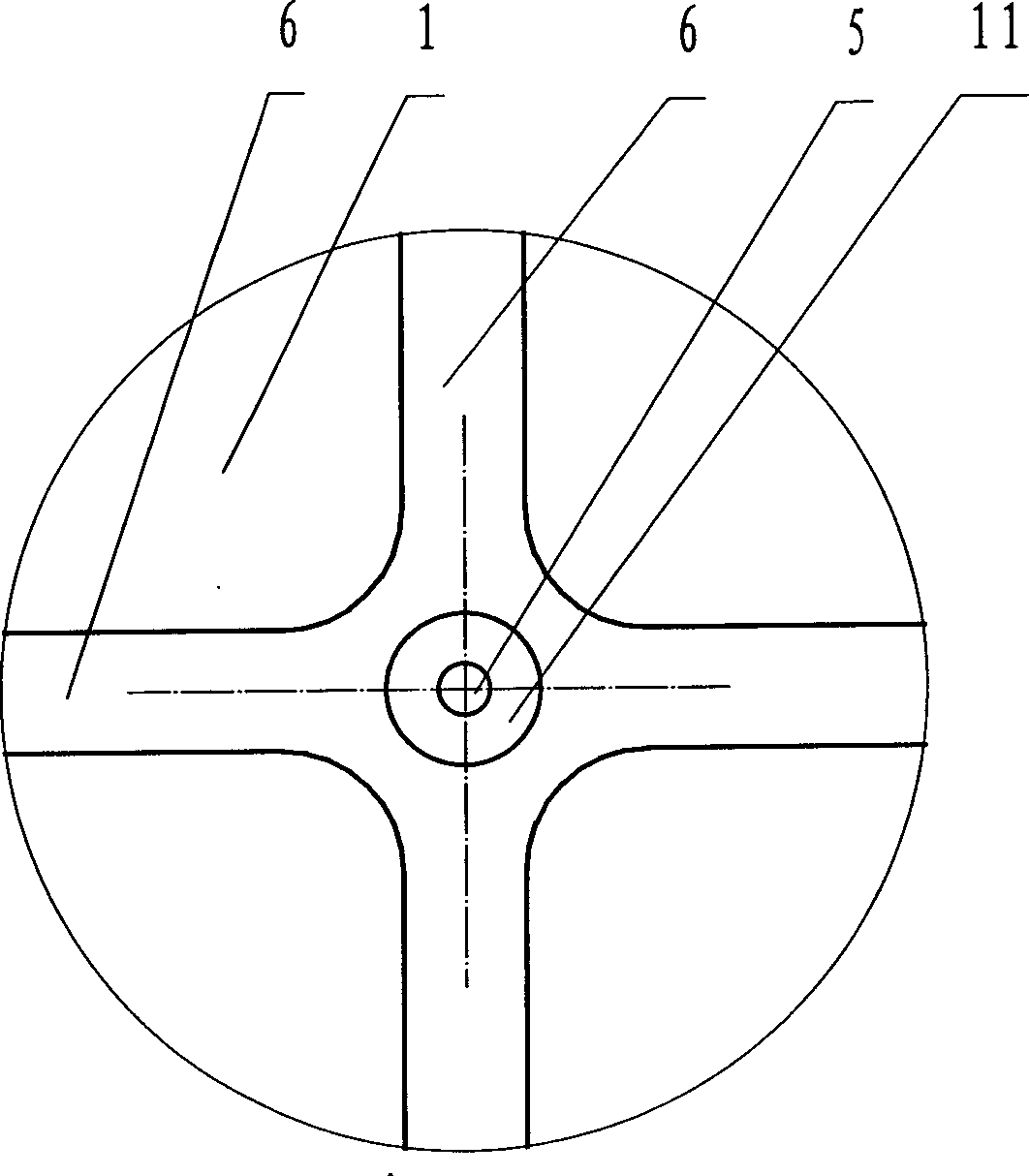

[0024] 1. Install a number of positioning lead rings 13 on the copper mesh 12 as the substrate. The number of positioning lead rings 13 is not limited and is determined according to the area of the copper mesh 12. If the area of the copper mesh 12 is small, it can be placed on the copper mesh 12. It is sufficient to install four positioning lead rings 13 around the circumference, such as Figure 5 with Figure 6 As shown, if the area of the copper mesh 12 is large, it is necessary to install a plurality of positioning lead rings 13 around and in the middle of the copper mesh 12. The thickness of the positioning lead rings 13 is the same as the thickness of the lead layer of the copper grid. The function of 13 is to position the copper mesh 12 when the copper mesh 12 is placed in the mold, and restrict the movement of the copper me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com