Method for the continuous casting of a metal strand

A technology for casting metal and continuous casting slabs, which is applied in the field of continuous casting metal continuous casting slabs, can solve the problems of reducing the quality of metal continuous casting slabs, and achieve the effect of high accuracy and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

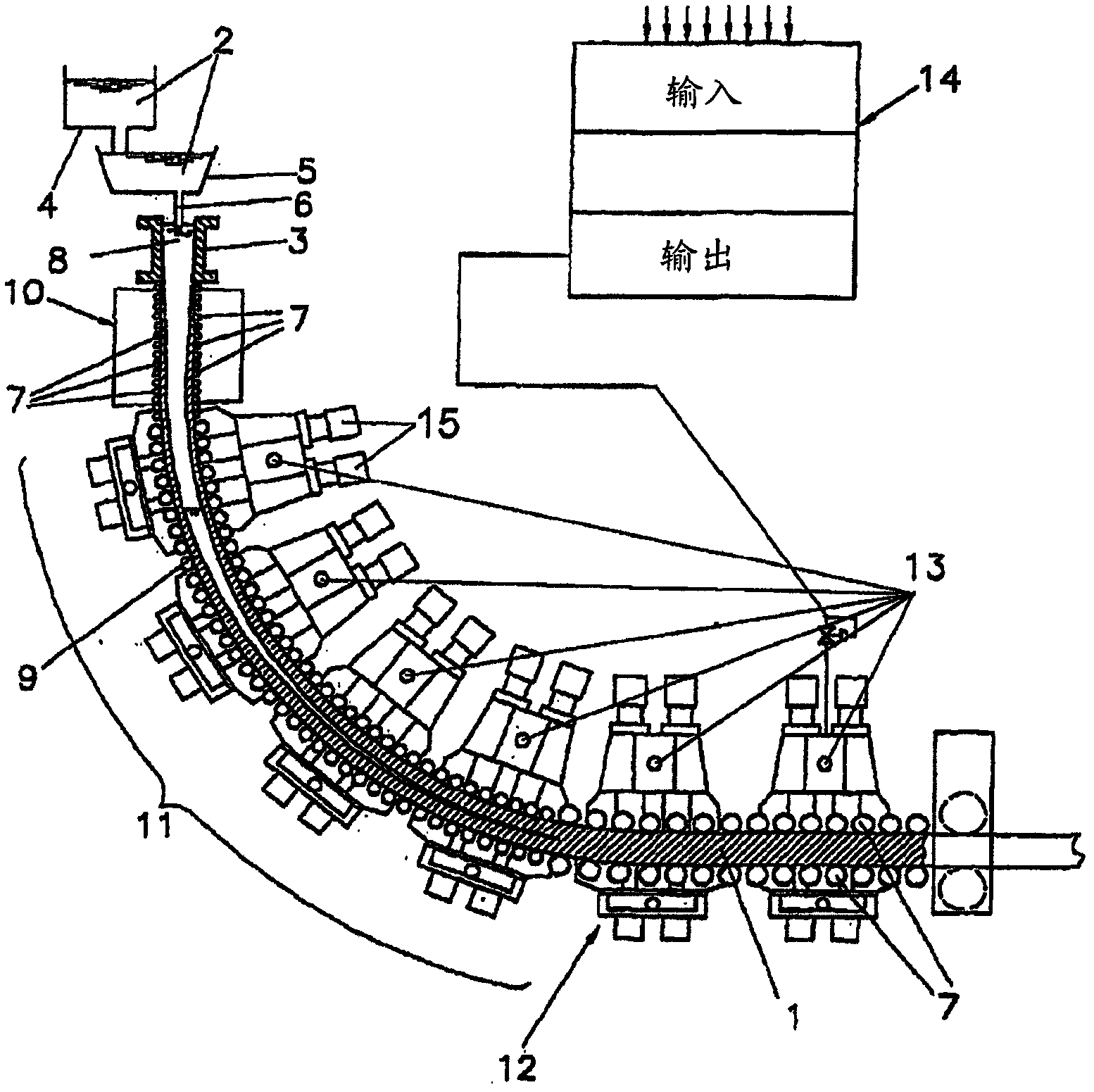

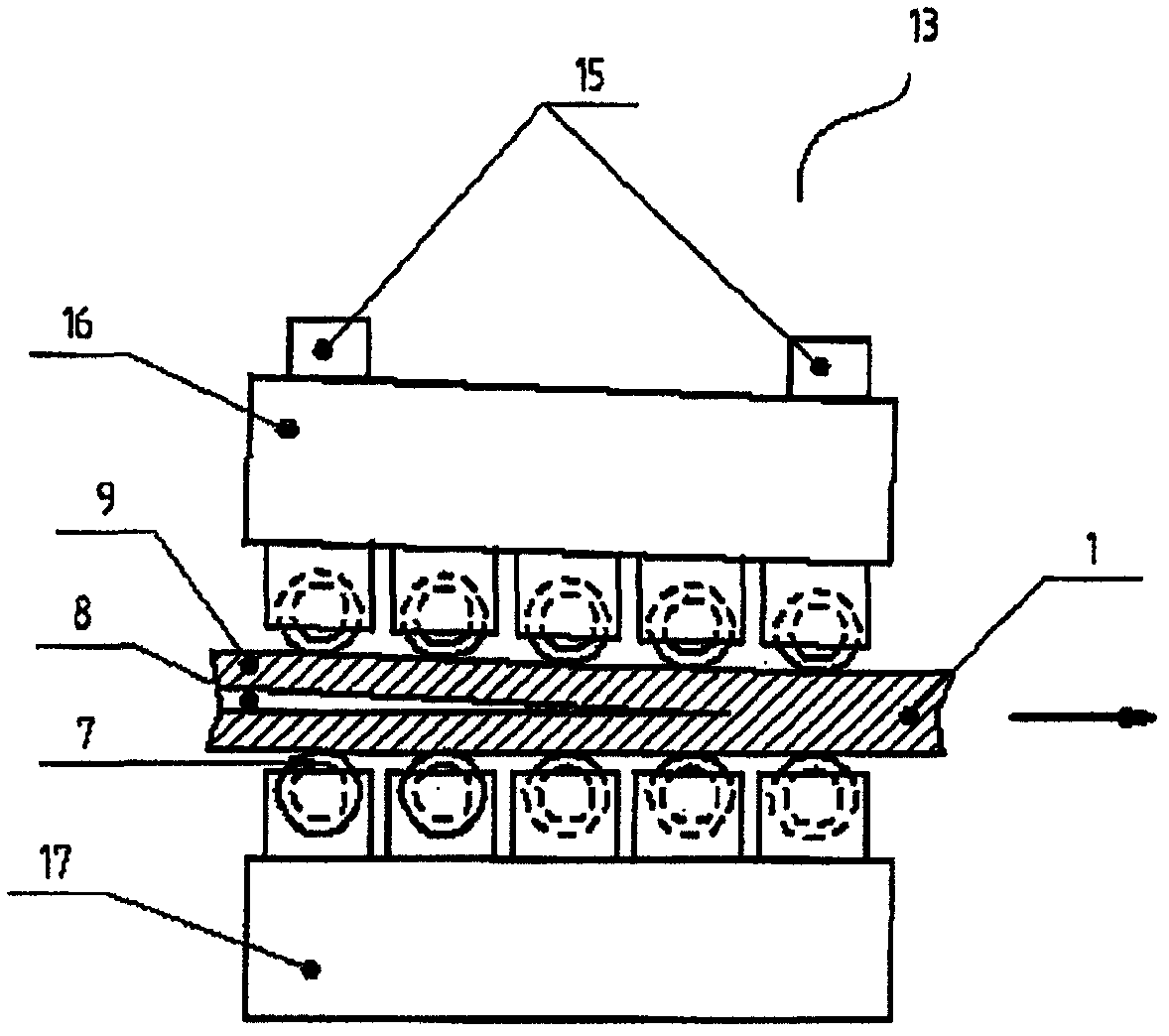

[0022] The continuously cast steel slab 1 is formed by casting molten steel 2 with a specific chemical composition in a cooled straight-through mold 3 . The molten steel 2 is injected into the straight-through mold 3 from a ladle 4 through an intermediate container 5 and a casting tube 6 extending from the intermediate container 5 below the level of the casting liquid formed in the straight-through mold 3 . The continuous casting slab guide roller 7 of the continuous casting slab support device is arranged below the straight-through mold 3, and is used to support the steel continuous casting slab 1. This steel continuous casting slab 1 has a core 8 that is still in a fluid state. It also has a very thin continuous cast slab shell 9. The steel continuous casting slab 1 coming out of the straight-through mold with a straight axis turns into the arc track 11 in the bending zone 10, and is supported by the continuous casting slab guide roller 7, and the continuous casting slab gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com