Composite additive for producing nickel-iron particles by using laterite, and application method thereof

A composite additive and laterite nickel ore technology, which is applied in the field of composite additives for the production of nickel-iron alloys by direct reduction of laterite nickel ore, can solve the problem that the blast furnace method has poor adaptability to laterite nickel ore, the hydrometallurgical process is not very mature, and the rotary kiln-electric furnace process Long process and other problems, to achieve the effect of high-quality nickel-iron products, reduced power consumption, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

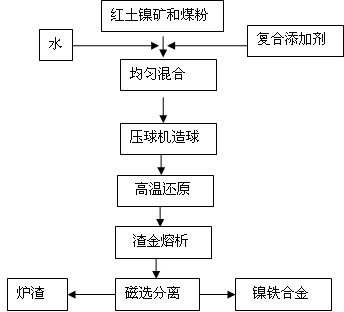

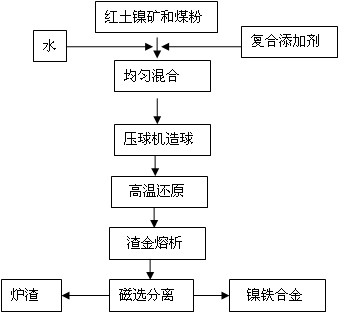

Method used

Image

Examples

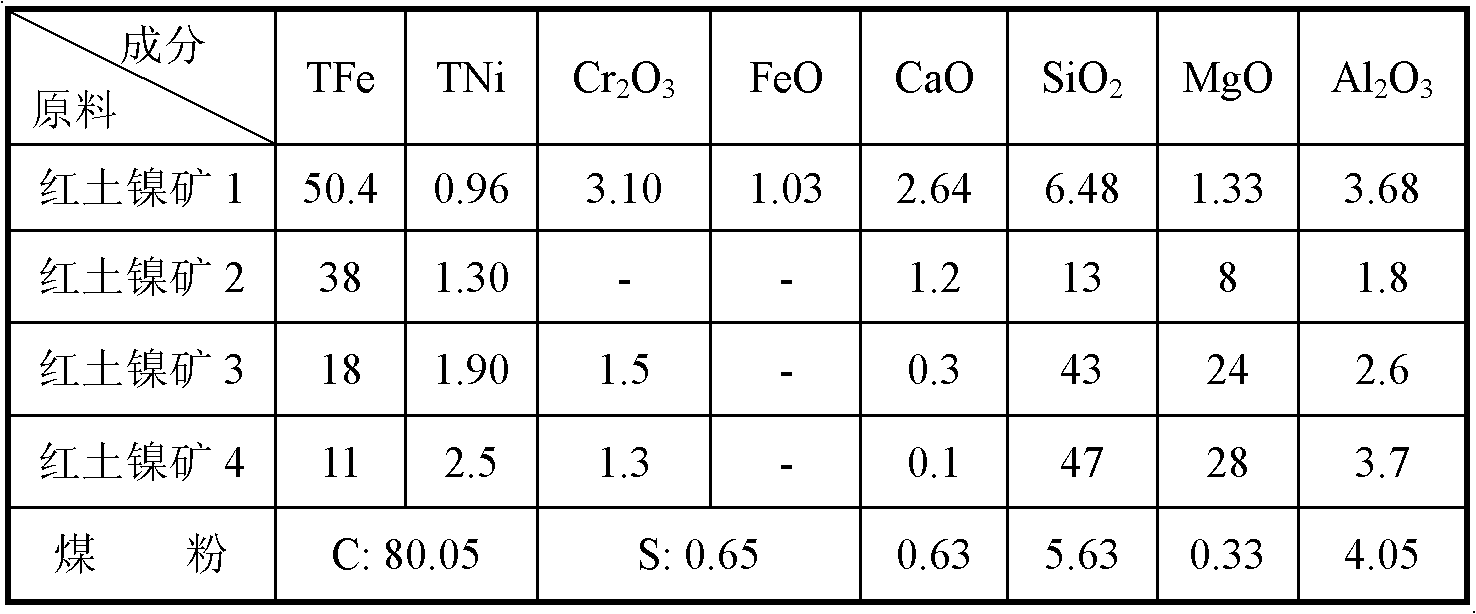

Embodiment 1

[0039] According to the composition of the laterite nickel ore 1, the ratio of raw materials for preparing the composite additive is 50% quicklime, 32% fluorite, 15% soda ash and 3% boric acid, and the composite additive powder with a particle size of less than 0.15mm is produced by a ball mill.

[0040] The composite additive is added to the laterite nickel ore powder according to the addition amount of 8wt% of the laterite nickel ore, the amount of coal powder added is 20% of the laterite nickel ore weight, mixed evenly, and after adding a little water, pressed into the laterite nickel ore carbon-containing ball The carbon-containing pellets of the laterite nickel ore were reduced for 8 hours at a temperature of 1200° C. (that is, kept at a constant temperature for 8 hours). After cooling, nickel-iron particles containing about 6 wt % of nickel were obtained by magnetic separation.

Embodiment 2

[0042] Change the addition of the composite additive to 5% of the laterite nickel ore weight, and other ingredients are the same as in Example 1, and the reduction temperature is increased to 1250°C. After 8 hours of reduction, the reduction of the laterite ore and the separation of slag and gold can be realized. Select the same nickel-iron particles containing about 6wt% nickel.

Embodiment 3

[0044] According to the composition of laterite nickel ore 2, the ratio of raw materials for the preparation of composite additives is 10% of quicklime, 70% of fluorite, 5% of soda ash, 10% of boric acid and 5% of cryolite, and the composite additive powder of less than 0.15mm is made by ball mill .

[0045]The composite additive is added to the laterite nickel ore powder according to the addition amount of 18wt% of laterite nickel ore, and the amount of coal powder added is 15% of the weight of laterite nickel ore, mixed evenly, and after adding a little water, pressed into laterite nickel ore carbon-containing balls Reduction at 1250°C for 7 hours can realize the reduction of laterite ore and the separation of slag and gold. After cooling, ferronickel particles containing about 12% nickel can be obtained by magnetic separation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com