Method for separating lead and antimony from lead antimony crude alloy

A crude alloy and lead separation technology is applied in the field of separation and extraction of lead-antimony alloys, which can solve the problems of inability to form industrialization, low lead-antimony direct yield, and difficulty in removing impurities, etc., so as to improve the quality of crude lead and improve furnace Bed capacity, effect of less smelting flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

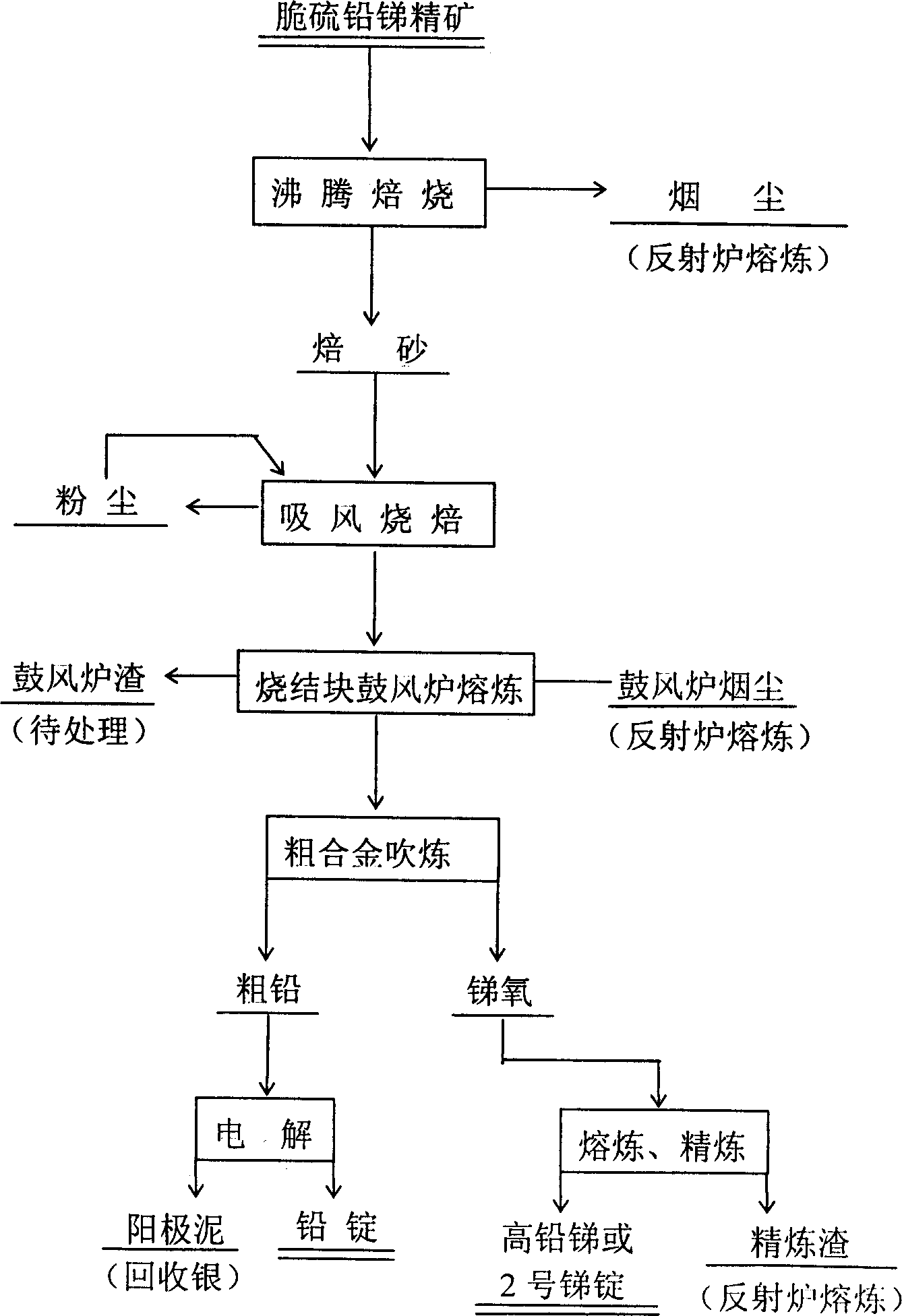

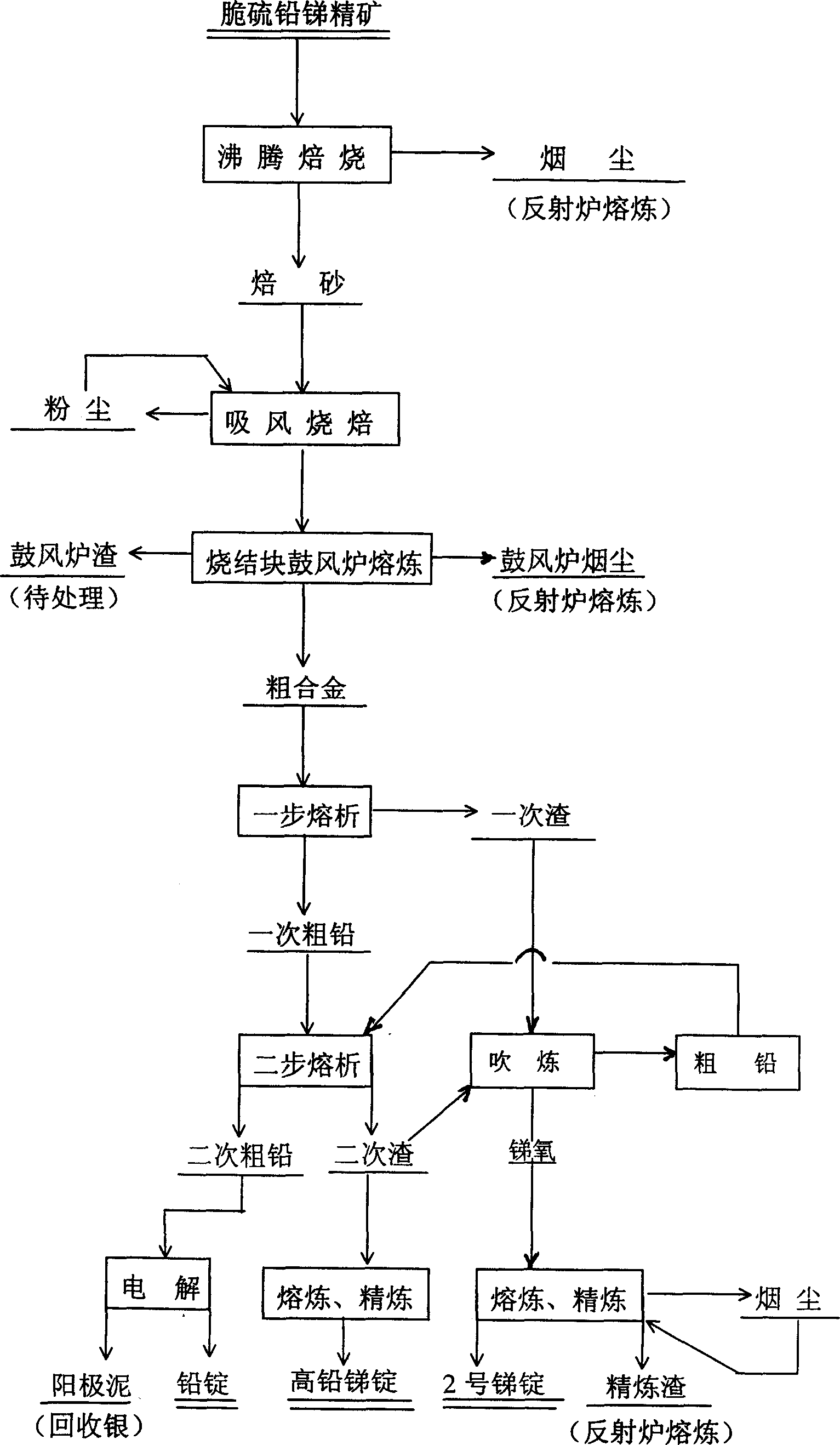

[0025] (1) Lead-antimony crude alloy undergoes one-step or two-step smelting to produce crude lead

[0026] The lead-antimony crude alloy is melted in one or two steps in a melting furnace to produce crude lead containing 78-84% lead suitable for electrolysis requirements and secondary melting slag that can be used to remove impurities and produce high-lead-antimony ingots and energy Combined with the secondary melting slag, blowing, smelting and refining produce the primary melting slag of No. 2 antimony ingot.

[0027] The specific implementation steps are as follows:

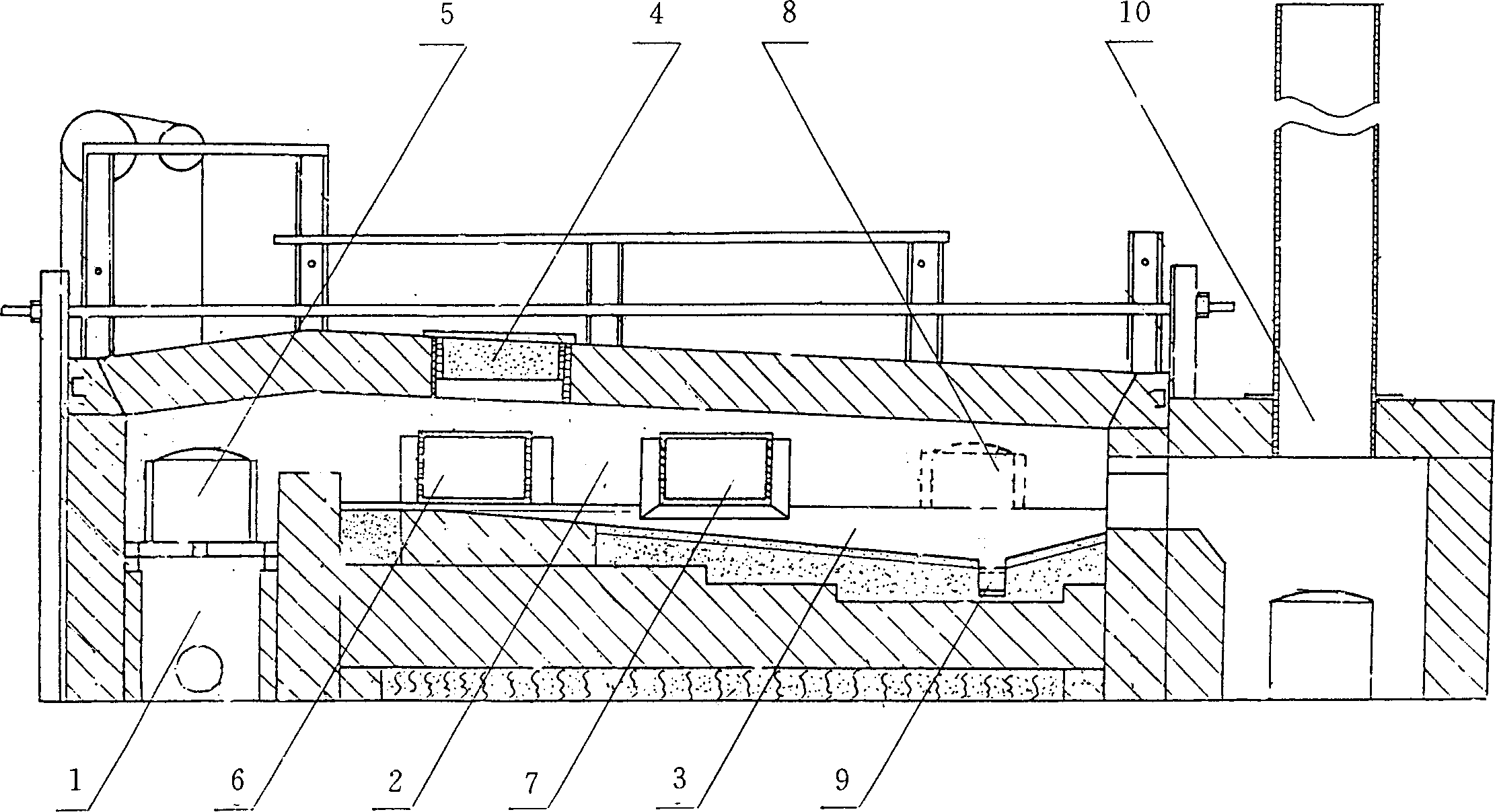

[0028] One-step smelting is to raise the temperature of the smelting furnace to 750°C in the high-temperature smelting zone, and then put the crude alloy containing Pb≥62% lead and antimony into the furnace from the feeding port (4). The melting zone is 350-440°C for 80-120 minutes per furnace, and the melting rate is 15-23 kg / min. After the material in the furnace is completely melted, most of the molten sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com